-

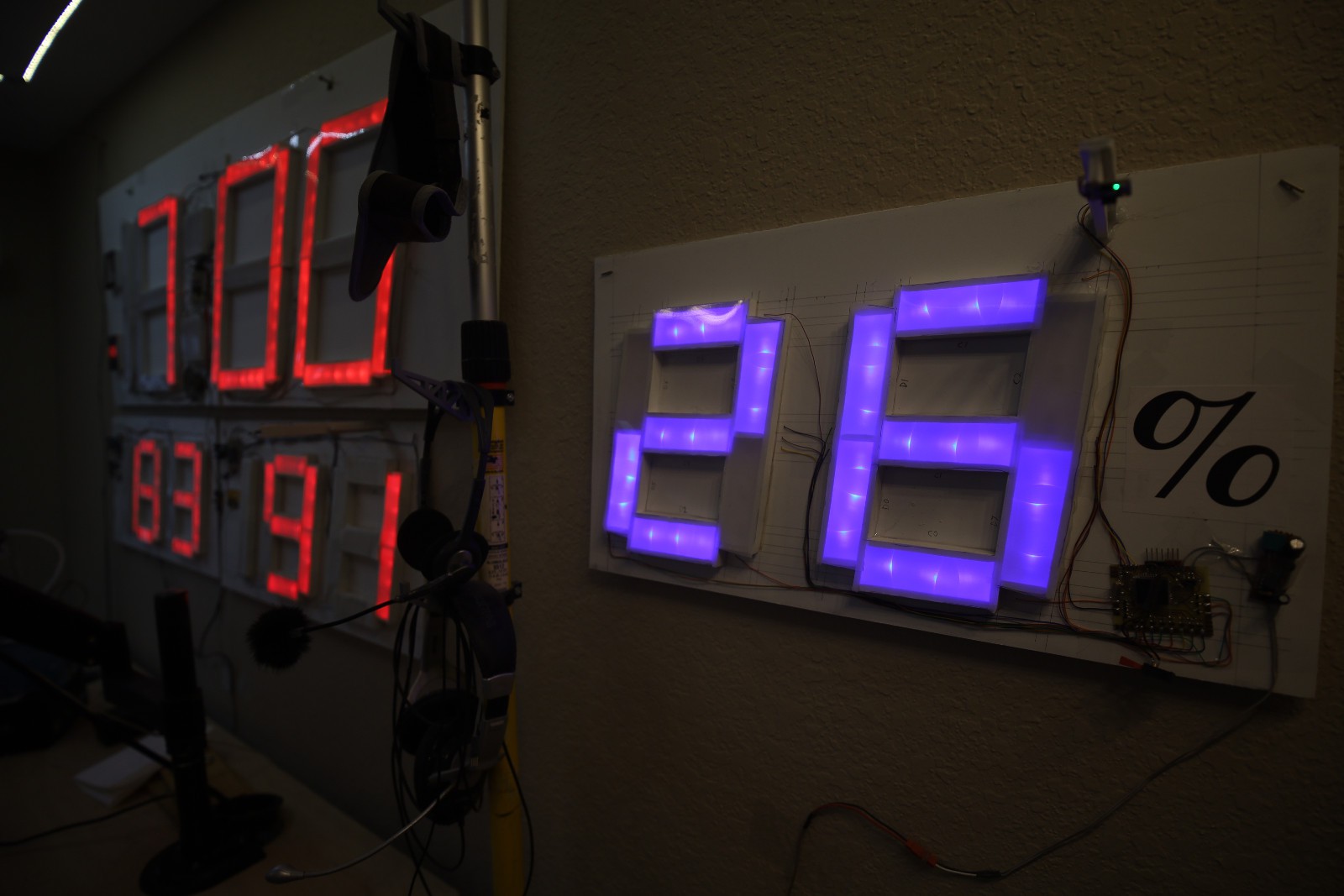

Dead 2nd board

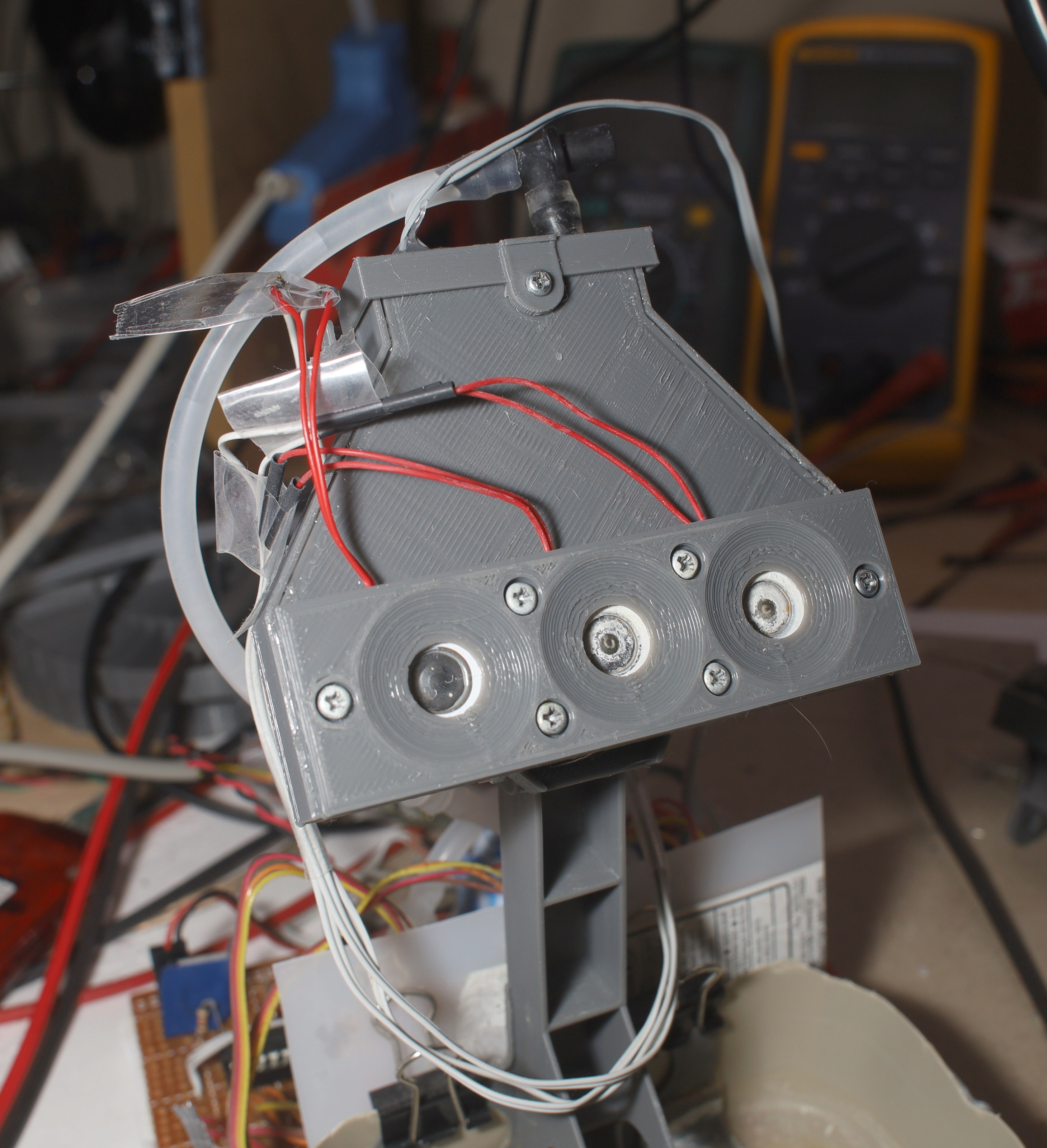

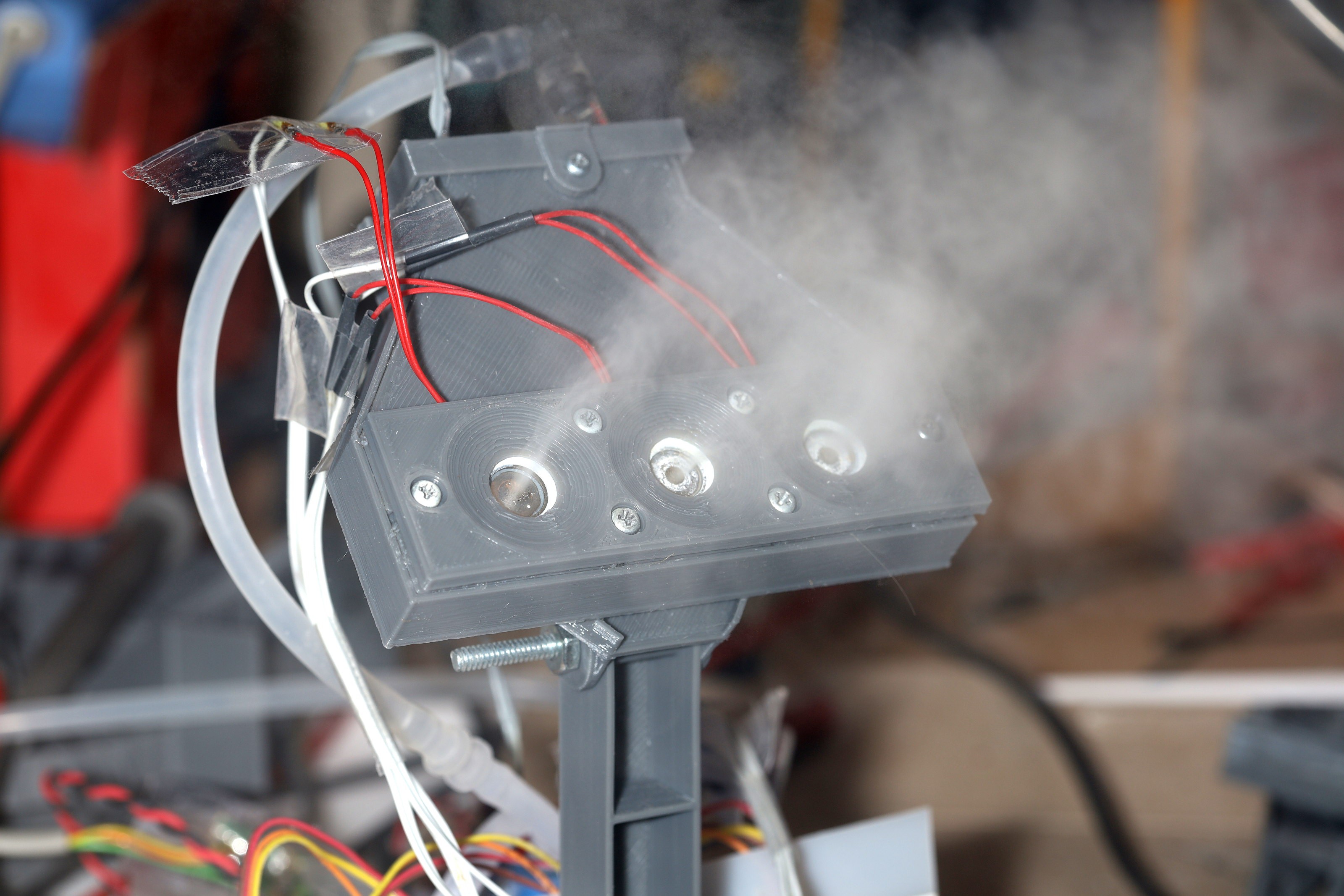

09/09/2024 at 07:22 • 0 commentsAfter many consecutive triple digit, low humidity days this summer, it became clear that the transducers had bigger problems that replacement didn't fix. They occasionally have to be cleaned of scale. The transducer which was replaced in june continued to be the problem child.

![]()

That one got a new transducer & board in June but it still tended to get into a state where it would die, the button would have no effect & no amount of whacking got it to start. It would start once per day & not again. Replaced its board with yet another board & got some promising results. These boards are so cheap, they're not worth troubleshooting. It subjectively looked like insufficient voltage. The spare board supply is now down to 2.

----------------------------------------------------------------------------------------------------------------------------------------------------------

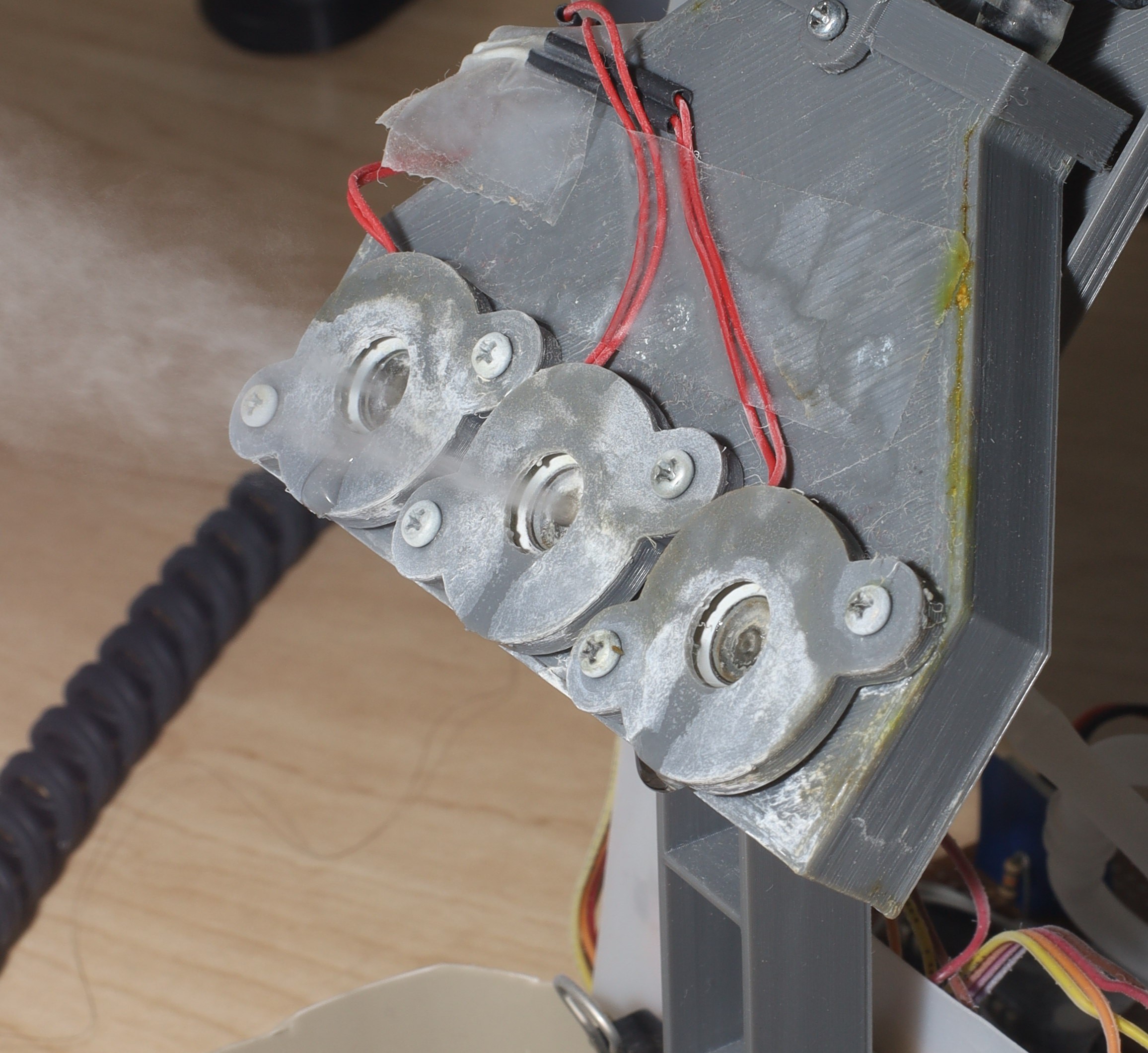

Pointing the transducers sideways more seemed to improve results. They were originally in a sideways mount so they probably have to be fixed that way instead of on a variable tilt. The spray would all go sideways or down to keep air bubbles from forming. The overflow would now run straight down & it would have to be in the center of the sump. It still needs a gutter to keep the wind from blowing it.

It's going to require a taller stand. The taller stand needs a counter weight, a way to farsten the water hose & power switch to the base.

![]()

The peak heatwave was intense enough to flatline the humidity even with the swamp cooler on.

-

Roasting lions

06/26/2024 at 02:04 • 0 comments![]()

After 3 mild & humid years, the weather once again turned back to many consecutive triple digit days with very low humidity. In these conditions, the swamp cooler has a notable effect right near the outlet. The overall room temperature only drops by 1F degree while the humidity rises 5%. The swamp cooler saw its most use in a long time, with expected failures quickly following.

![]()

The 1st thing to go was the pump. Another tube perished after a year. Instead of drawing air in, it was letting water out. It appeared as a small puddle & grew over the next day until the desk was a waterfall. Expensive stuff got soaked. Those are going to have to be preventatively replaced every year.

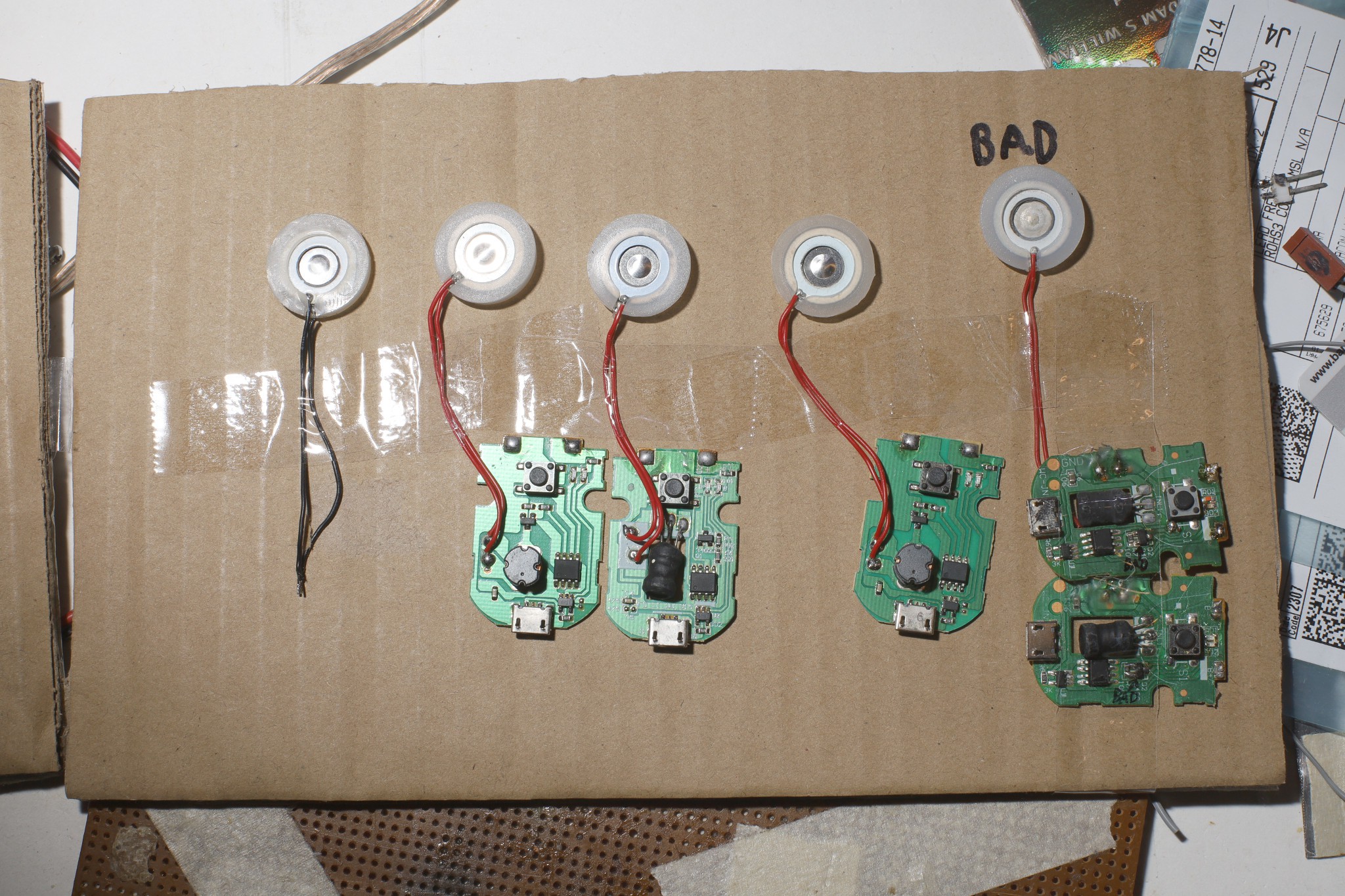

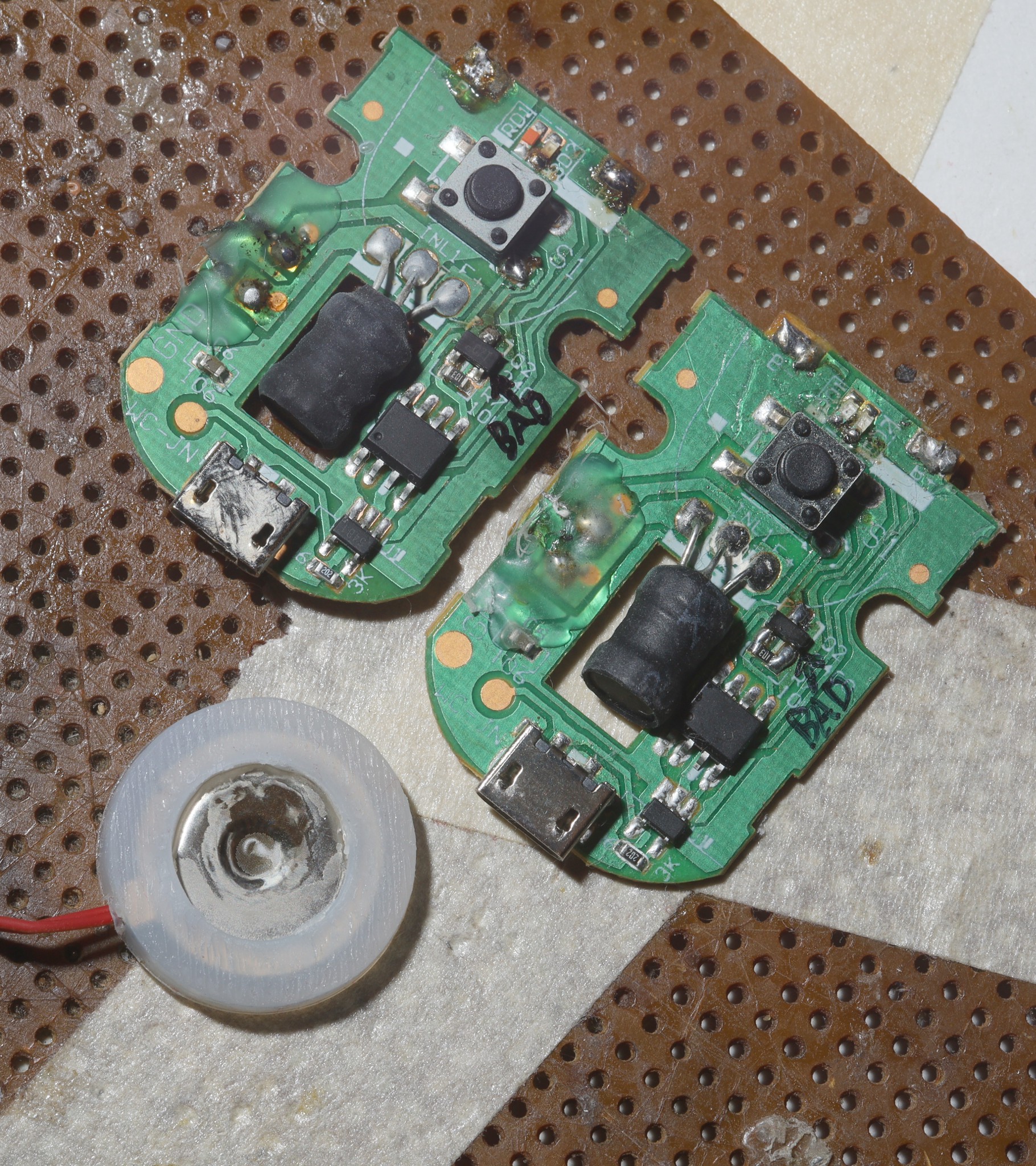

Then a transducer died. Tried to revive it by unplugging it but forgot this causes the flyback transistors to overload. The magic smoke came out & it was dead. It wasn't the 1st fried board.

![]()

![]()

There's an inventory of spare electronicals because they tend to die randomly. Got rid of the molex connectors so the transducers can't be unplugged. This transducer might have gotten silicone grease in its intake.

![]()

Upgraded the feed stock to 1 gallon of tap water. This lasts 12 hours.

The water level sensor managed to not have any issues so far. In the interest of preserving the water level sensor, it would be best not to put any fragrance in the water, especially oil based.

Noted the 1mm thick walls are not ideal. They should really be 2mm thick on the sides. It also needs a more permanent stand. It could be a shelf that keeps it on top of the expensive stuff it soaked when the pump died.

Measured it at 6W when not running the pump.

-

Distilled water fail

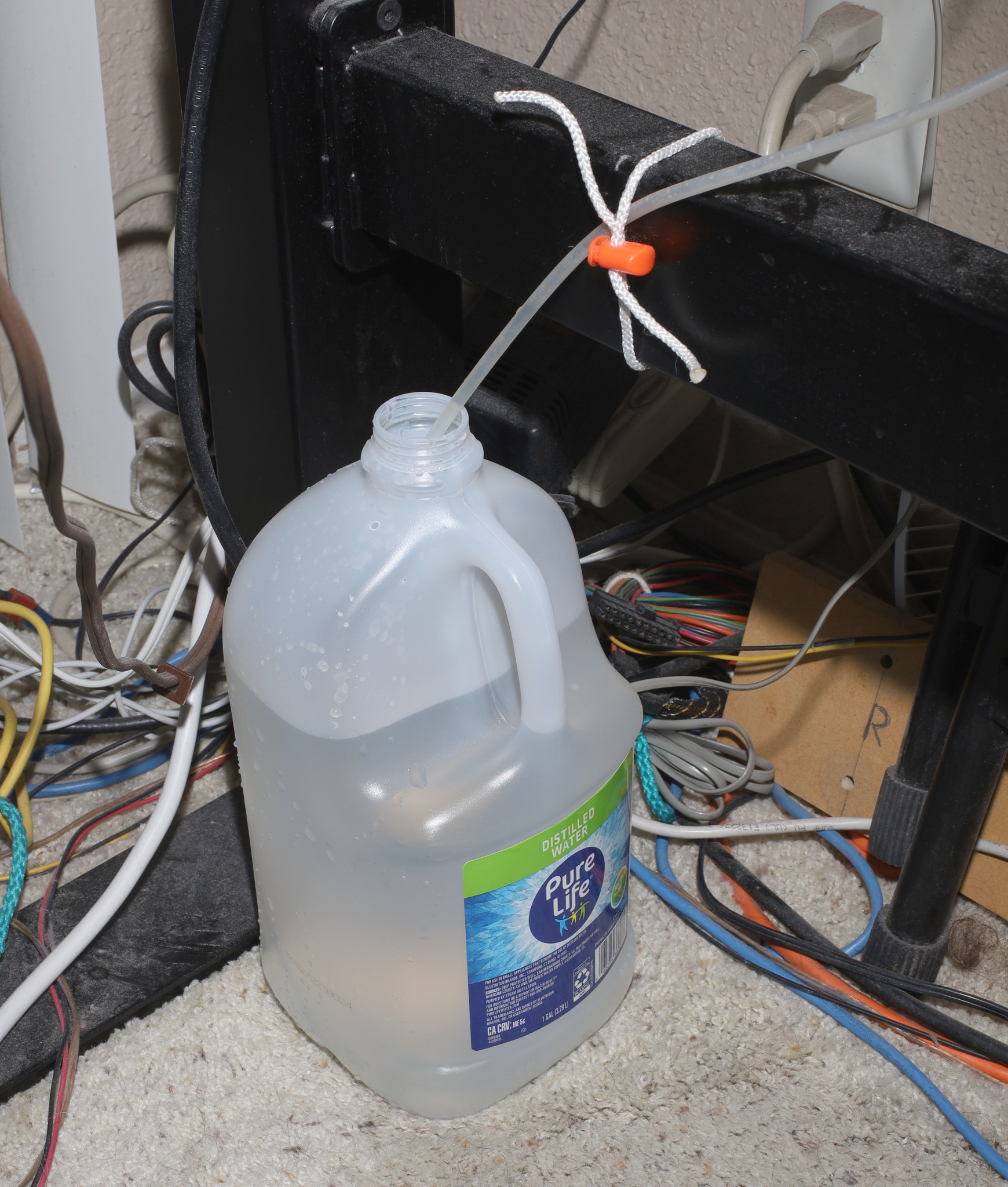

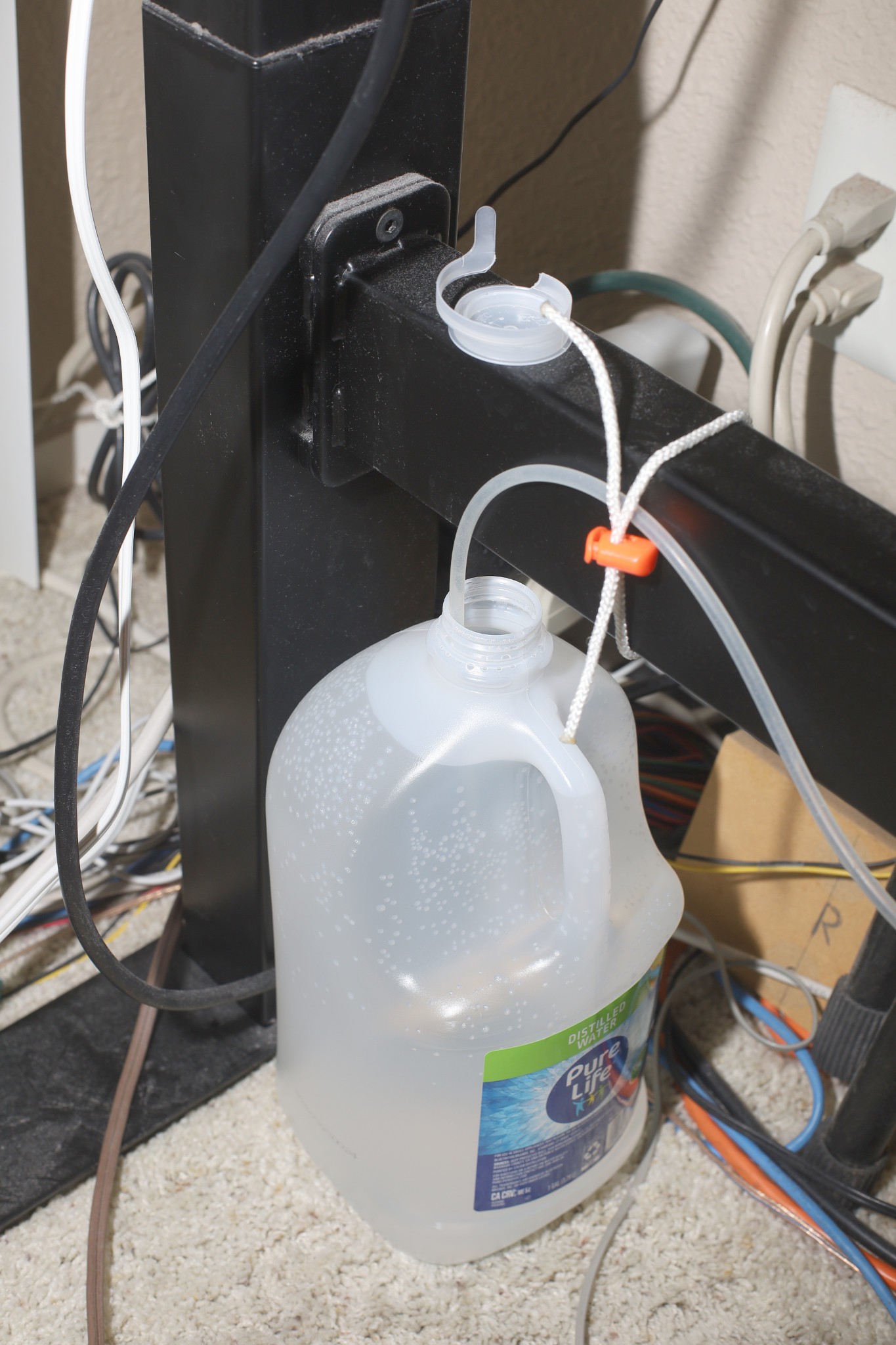

10/20/2023 at 05:16 • 0 comments![]()

![]()

An attempt to reduce the fogging of the windows, this was a fail. The obvious problem was the water level sensor couldn't detect it & failed negative. It doesn't conduct electricity.

The less obvious problem was the transducers leaking like crazy. Maybe electrostatic potential was required to aid the mechanical oscillation in accelerating water or maybe the electrostatic potential was keeping the water on 1 side. Something about the conductivity of tap water is required for the transducers to work efficiently.

So back went tap water & it worked perfectly again. There might be some additive which can create the required conductivity without fogging windows.

A bit surprising that the cleanest water in the world from the mokelumne river still has enough impurities to make a difference.

-

Water level sensor death

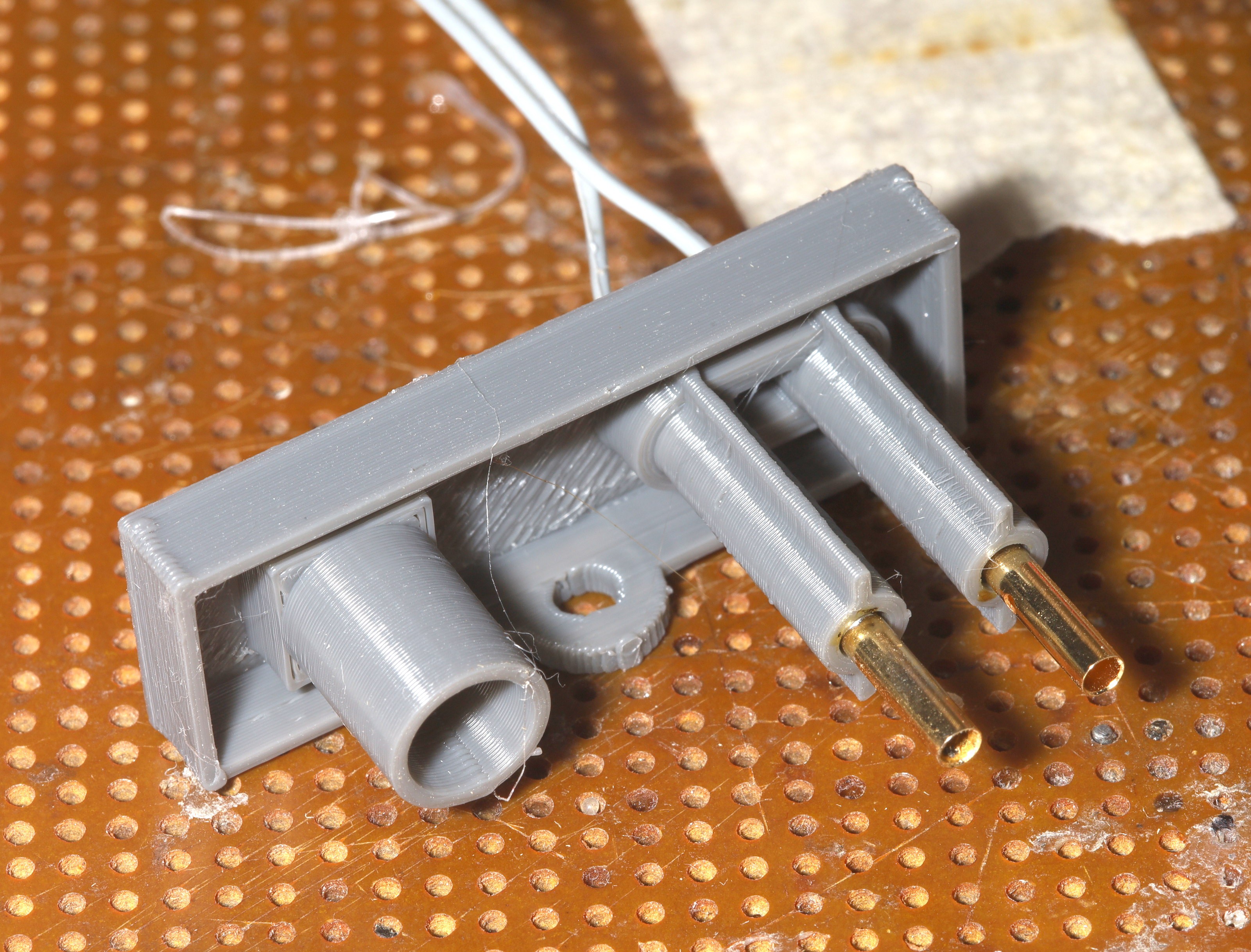

02/17/2023 at 00:46 • 0 commentsFired it up again after many months of winter to find the water level sensor failing low so it didn't stop pumping until timing out & shutting down. The electrodes were once again eroded & covered in goo.

The normal practice was to leave it on after the pump timed out, but it doesn't turn off the electrodes. When it was left on all winter, the electrodes continued electrolyzing & there might have been enough water to barely touch the electrodes, causing them to erode even though it wasn't pumping. It should turn off the electrodes when the pump times out.

The longer term solution might be a floating sensor.

-------------------------------------------------------------------------------------------------------------

35% proved to be the maximum humidity it was worth running at. Summer 2023 had no major heatwaves & no humidity low enough to run it all night. Humidity only got below 35% on a few days, then recovered to 40% every night. The pump needed another tube change. The sensor still got a coat of slime & algae.

![]()

-

The pump finally dies

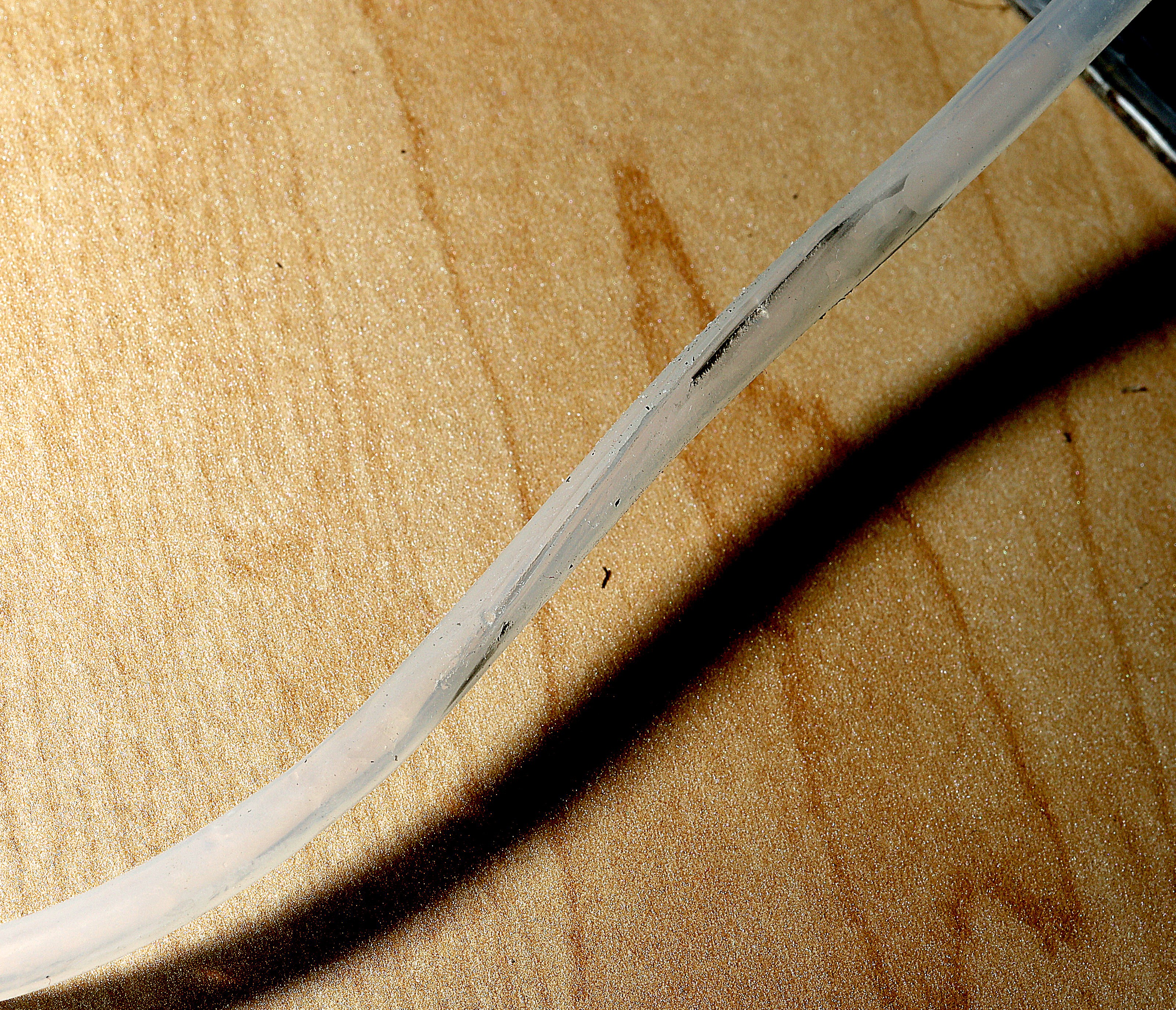

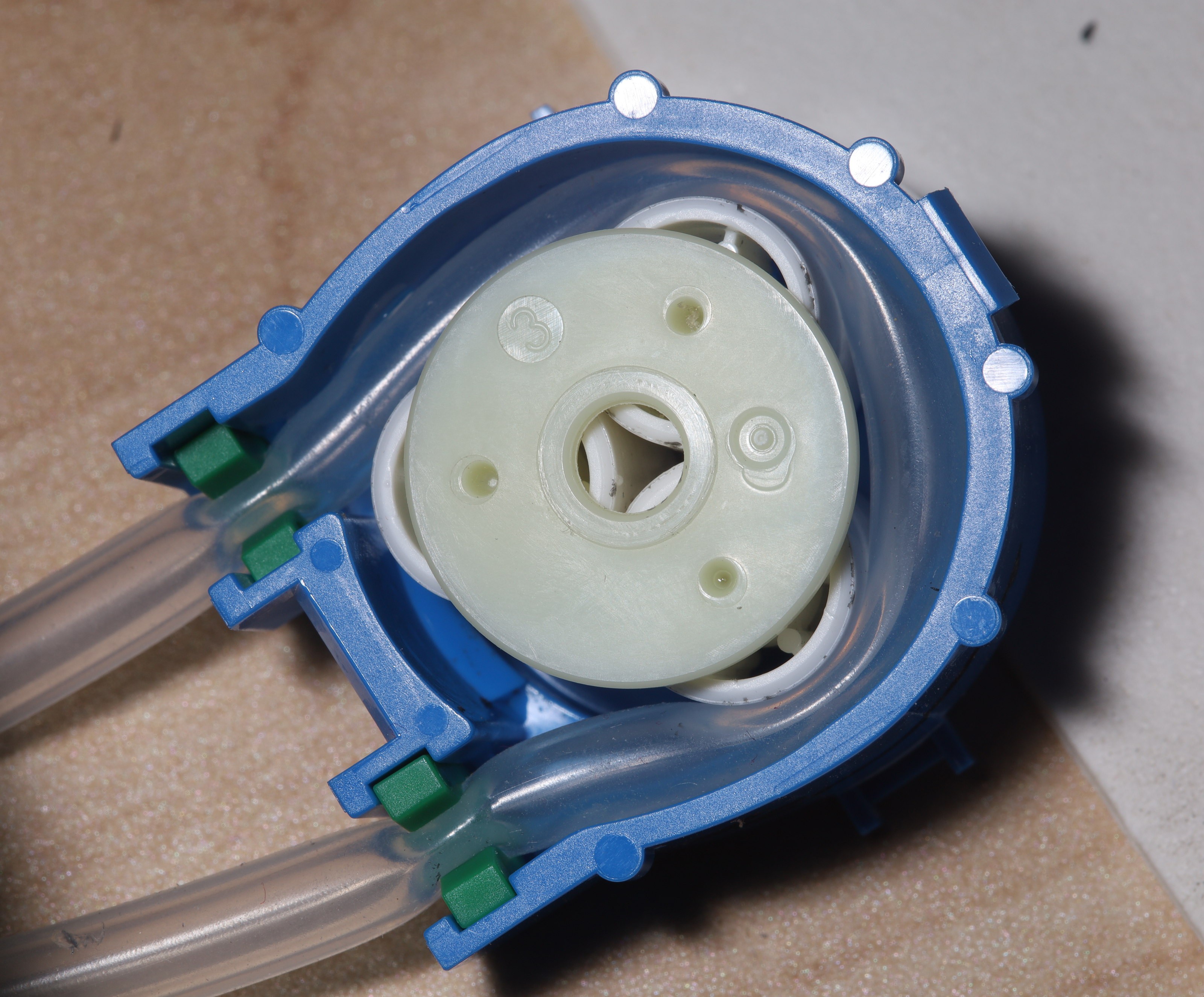

10/08/2022 at 23:26 • 0 commentsThe long awaited pump failure took only 9 months. Instead of a sudden pouring of water all over the floor, it manifested itself as the motor spinning without moving any water.

![]()

The 1st problem noted was the silicone tube being split down the middle & slowly dripping.

![]()

The stock motor has a segment of tube between 2 barrel connectors. To conserve material, don't cut off a segment of good tube to replace the entire segment between the barrel connectors. Just throw out the bad section & 1 barrel connector. Slide just enough good tube into where the former barrel connector was, every time it wears out.

Once new tube was inserted, the motor still didn't have any luck spinning the rollers. Either the tube needed some fidgeting to get it loose enough or the rollers are truly worn out. It eventually started working again.

Most likely, when the tube split it no longer pressed the rollers against the motor shaft enough to get good friction.

![]()

Important to note the direction of pumping when inserting the new tube.

The transducer replacement, pump repairs, water level sensor erosion, & tank leaks have made this quite a manetenance nightmare. Every gadget involving water has lived up to its reputation as a manetenance nightmare. There's still a desire to have it automatically manetain 40% humidity, but investing more time in such a manetenance intensive gadget isn't appealing.

Maybe a lion could make a more reliable pump out of a servo & imperial unit tubing. The tubing is going to wear out fast, no matter what. There are still anecdotes of common 3V brushed motors being waterproof.

-

New transducers

09/23/2022 at 01:08 • 0 comments![]()

Knowing the transducers are consumables, a bag of new transducers arrived. Despite runaway inflation, these are actually still trending towards $1.

https://www.amazon.com/dp/B08HK6Q95R

Knowing they have to be matched to the driver board, it's easier to get them as part of a nano mister. Then, take out the batteries before they puff. Those batteries are useful in remote controls since lions have no use for a nano mister.

Based on the shrinking component count, they'r going to have to change to a smaller board.

The next need is to turn off the transducers when the pump times out. Then, there will hopefully be something which can scent the room unattended.

A new batch of $1.25 perfumes arrived. #33 gets a thumbs up from lions.

#20 smells like a dentist so no.

![]()

The water level sensor in the newest enclosure had the opposite problem as the previous one. It constantly failed off, causing the water to overflow. Stepped down the voltage thresholds to try to overcome what seemed to be a change caused by the new enclosure.

-

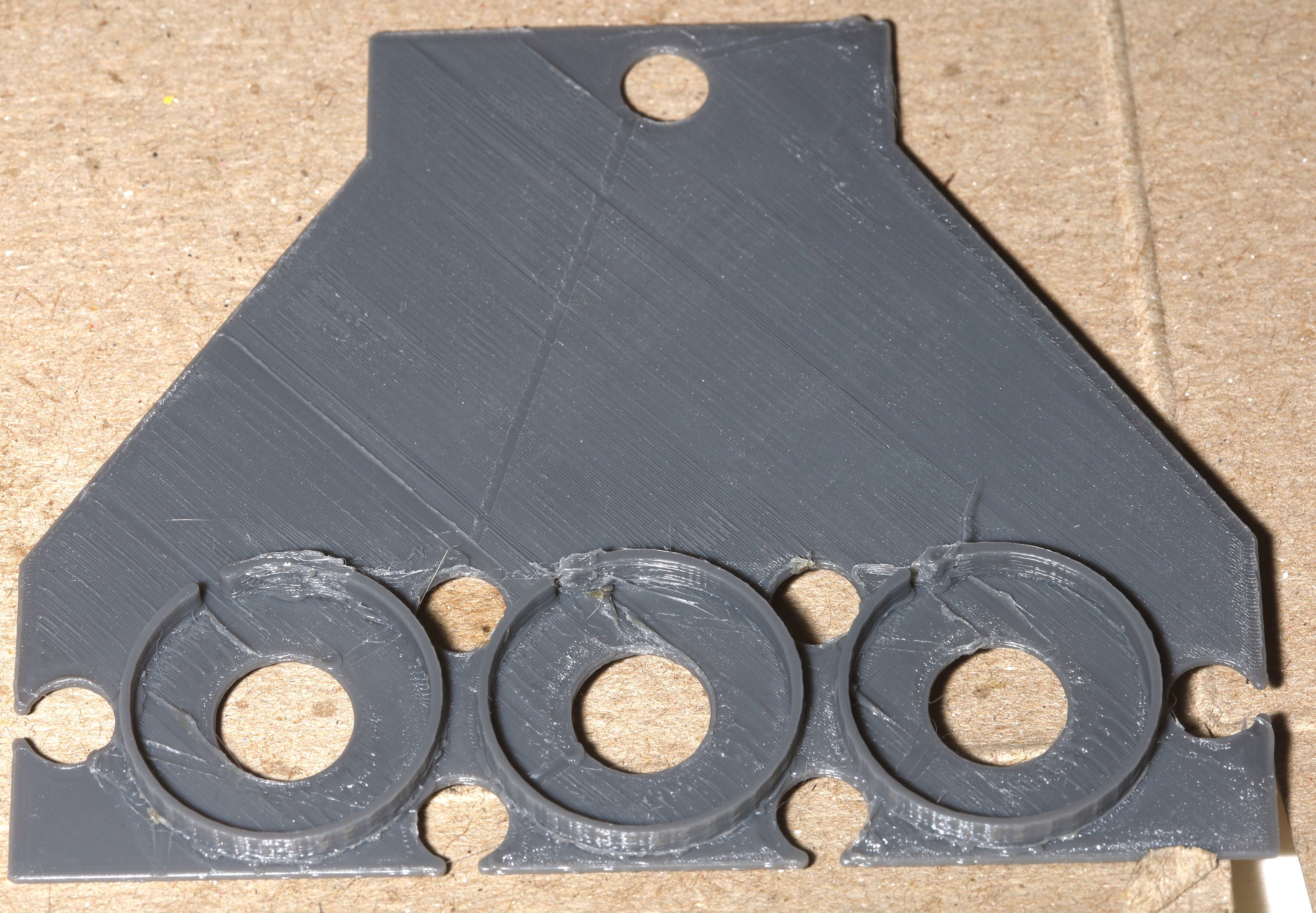

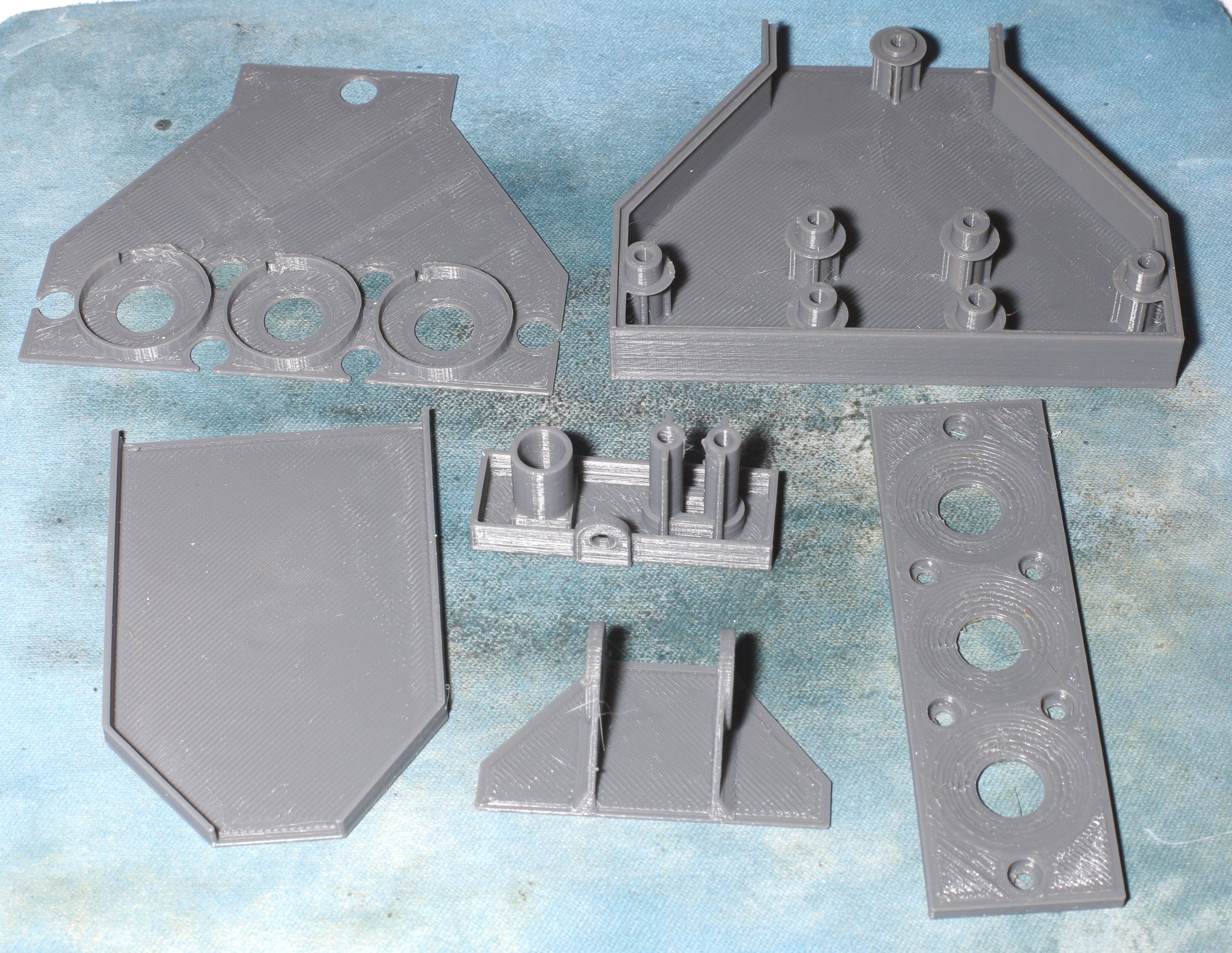

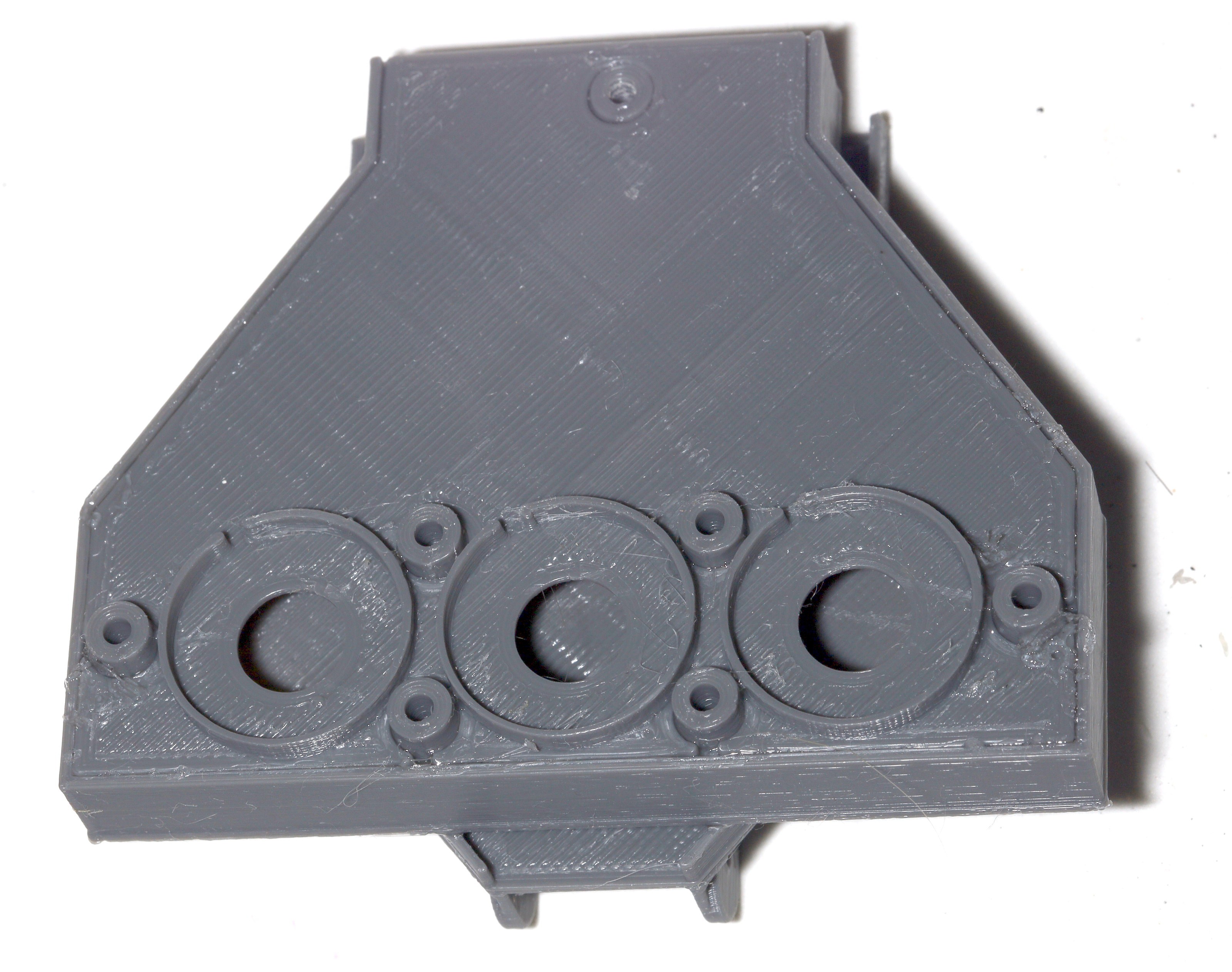

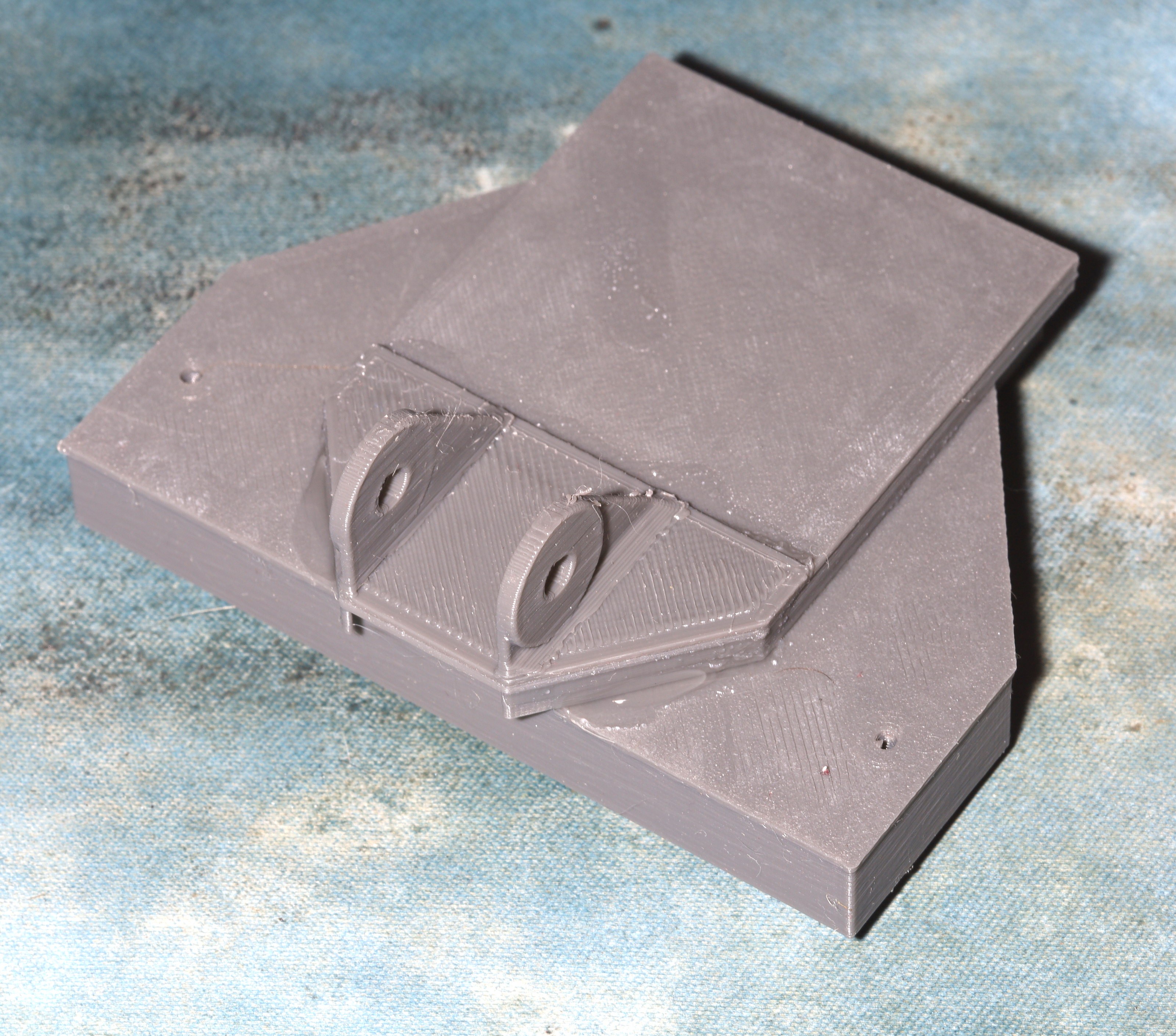

Enclosure #3

09/20/2022 at 23:03 • 0 commentsThe screw holes appeared to be leaking because they were cracked. The decision was made to scrap the year old enclosure.

![]()

1 discovery made was ironing does not make a smooth surface for the transducers to sit on. It leaves blobs. The best seal is still going to be plumber's grease or balloon rubber. There's a problem of plumber's grease clogging the transducers. There was an attempt to make the screw holes more water tight. The old screw holes were 2 pieces glued together. The new screw holes are a single piece.

![]()

![]()

Instead of clamps, it should have panels screwed in the existing screw holes with scraps of rubber pressing down.![]()

![]()

The drain & pivot are now glued on the enclosure. The drain needs a channel to glue into. It continues to be a source of dread. It needs to move water farther from the stand. It interferes with the screw holes. It's hard to model the channel. Printing temperature is now 230C instead of the 210C originally used. Getting a good seal with the overlapping areas continues to be problematic.

![]()

New panel was a lot easier to model but looked a lot better.

![]()

![]()

Initial results with a new transducer show the transducers are matched to the driver boards, but time will tell. The new drain doesn't work as well as the old one. It needs to be wider & extend more in front of the pivot point, but so far no drain has ever been needed.

-

Transducer blues

09/10/2022 at 21:39 • 0 comments![]()

A subtle detail was the failure of transducer #3.

![]()

A new one went in but still yielded a short period of low flow, then shut down & leaked lots of water. There might be a bad screw hole leaking water.

![]()

The original transducers have lots of scale but flow like they were new. Transducer #3 got a new driver board which didn't make any difference. The leading theories are a bad cable or the transducers having to be matched to the driver boards.

![]()

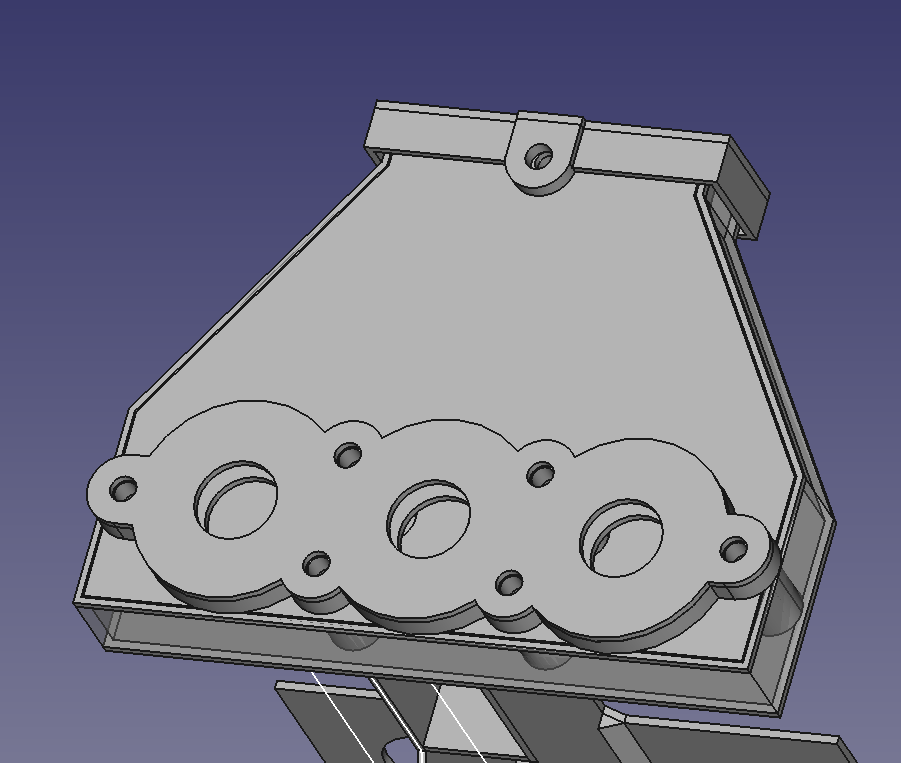

A new enclosure was already conceived to move the transducers closer together. To do this, they got a common cap which would have required removing 6 farsteners to access 1 transducer. Obviously, it's not practical in a world where transducers are consumable & must be replaced 1 at a time. The mane desires would now be thicker walls to try to reduce the water leaks, possibly more transducer spacing to keep water from landing back on the other transducers, possibly a 4th transducer.

-

Water sensor blues

09/08/2022 at 19:56 • 0 comments![]()

There was this idea of letting the vapor escape instead of condense, but it still failed on. It leaned towards splashing getting water on the standoffs.

![]()

Then this idea came along. This showed the spacing might be 2-3mm away from enough to overcome surface tension. It would require tweeking the ADC threshold. It is a fiddly value. There's mounting the electrodes sideways & opposing. The idea with vertical electrodes is the ADC value rises as the water level rises. Horizontal electrodes would give a single ADC value for all water levels.

![]()

Another sensor was made with 2mm wider spacing, but by then temperatures fell below what was causing the problems.

![]()

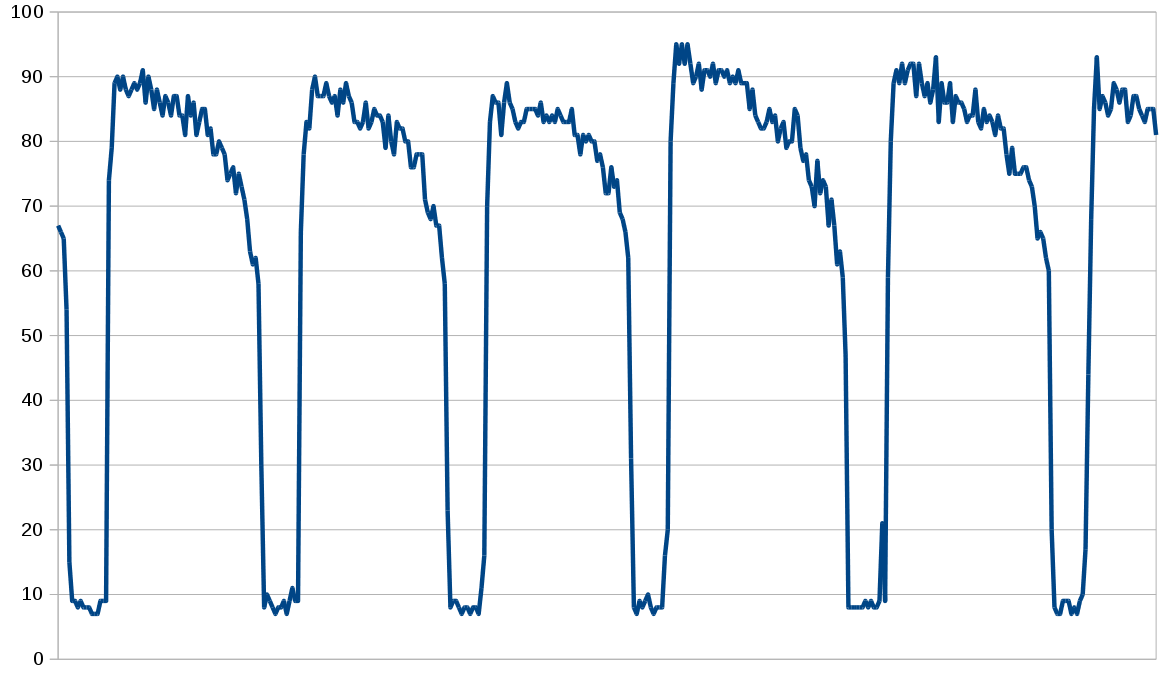

For future lion, we have the typical life of the sensor flipping high when the tank fills, slowly dropping as the tank empties, flipping low when the sensor dries out. The spacing didn't impact the readings.

![]()

It was noted that an electrode was eroding, so it was swapped out. Gold plating only buys time. This led to suspicions the sensor might fail off one day.

The decision was finally made to make the pump timeout after 90 seconds, to avoid emptying the 5 gallon tank on the floor. It typically takes 40 seconds to fill the tube & transducers.

![]()

The new sensor is a lower profile.

lion mclionhead

lion mclionhead