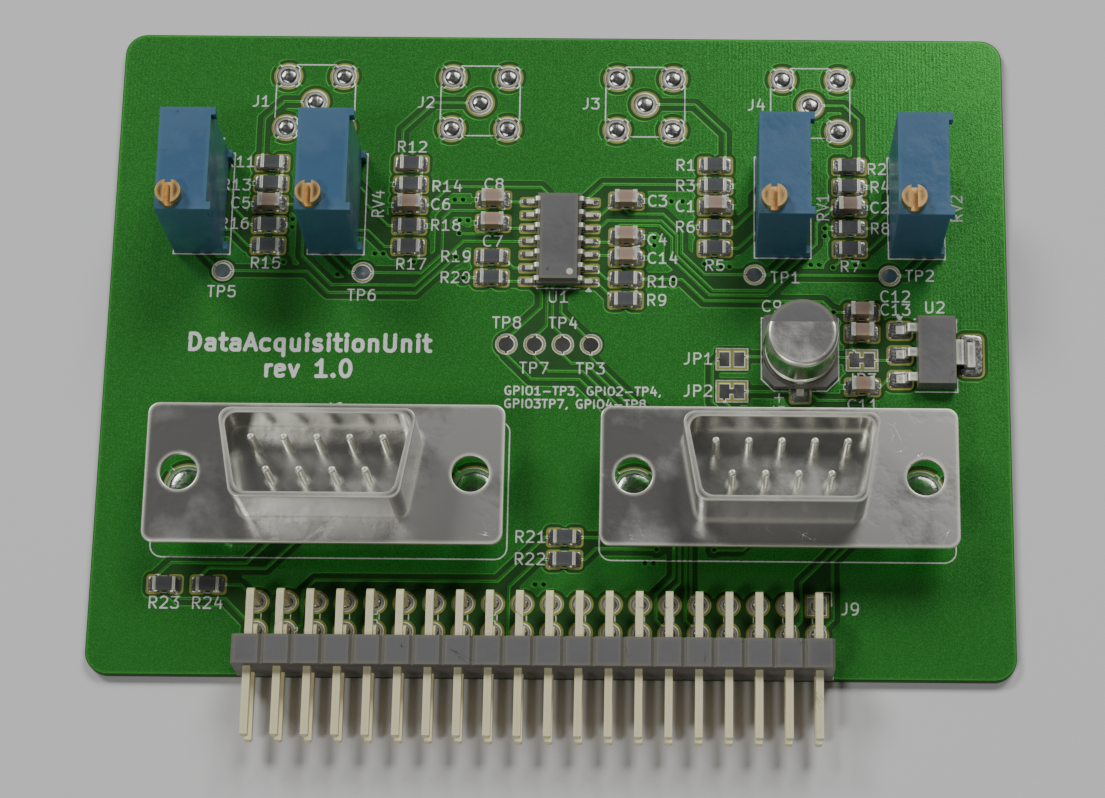

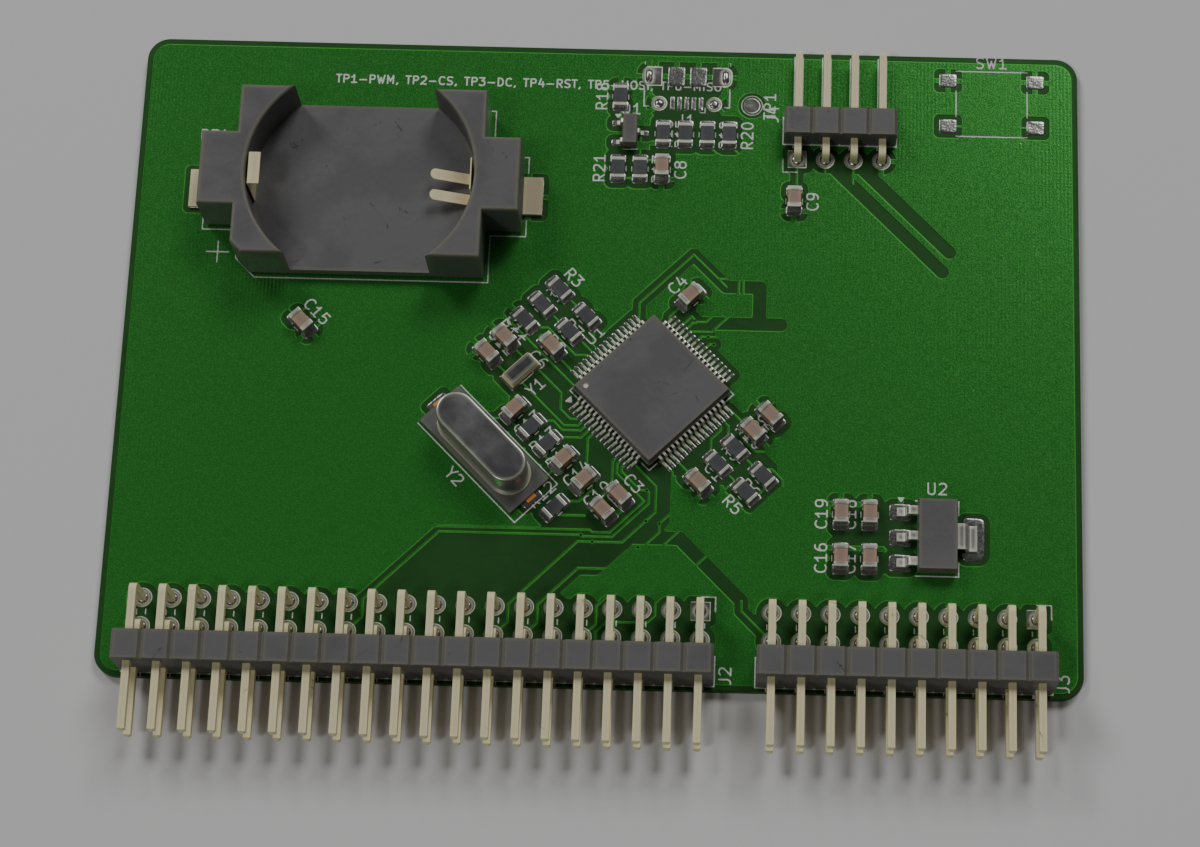

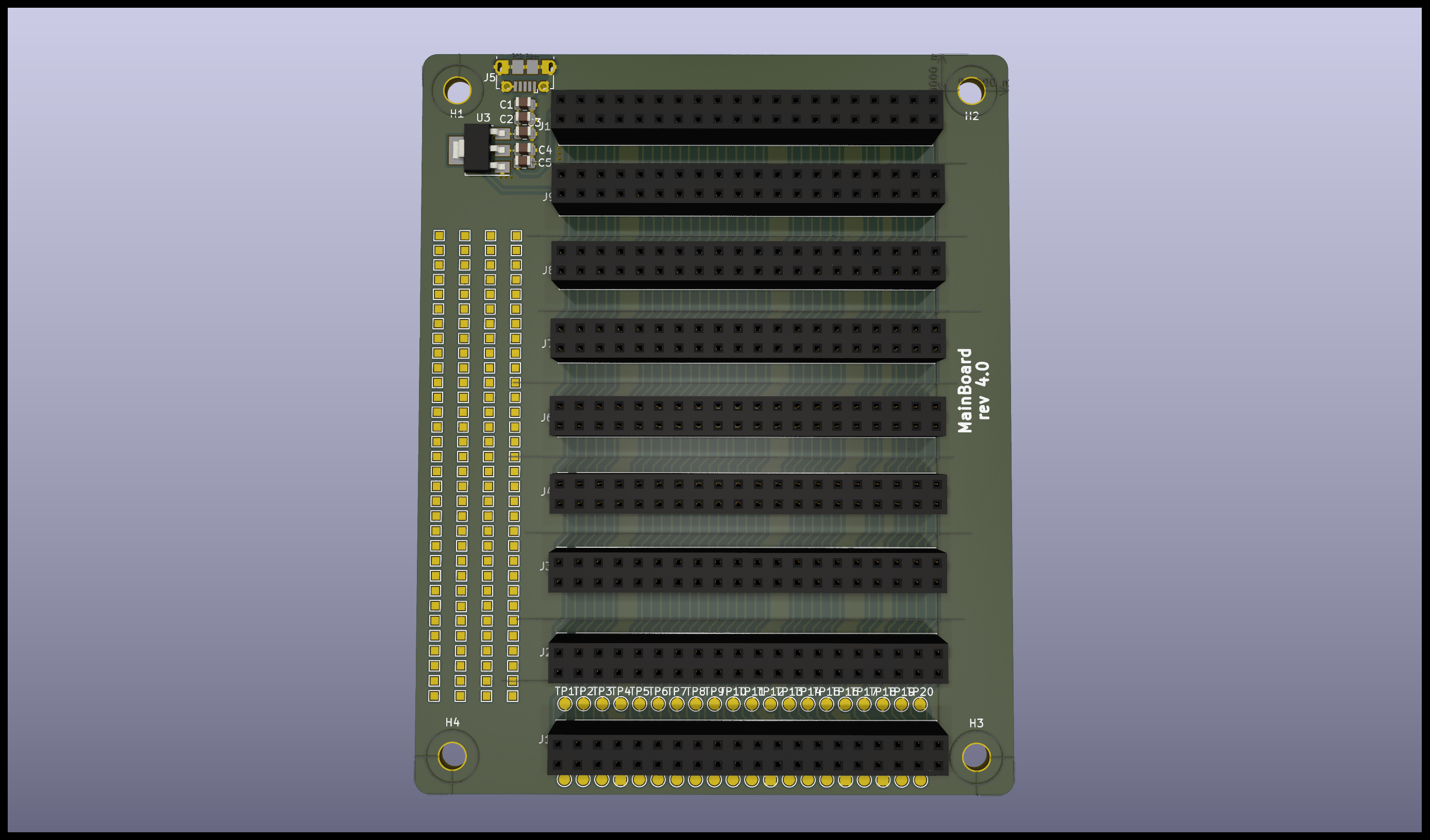

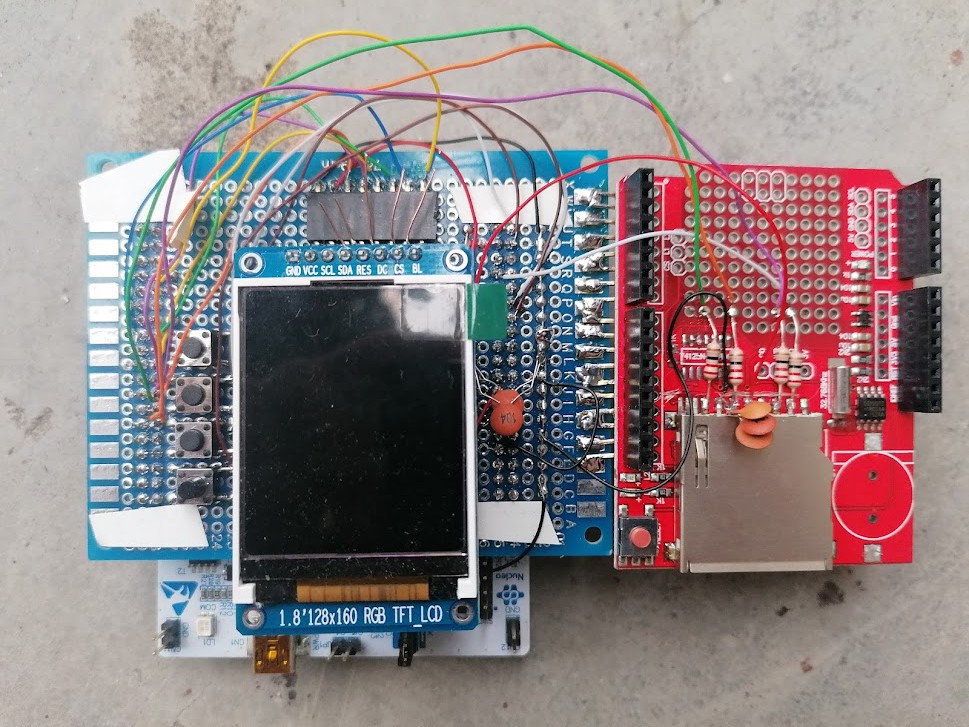

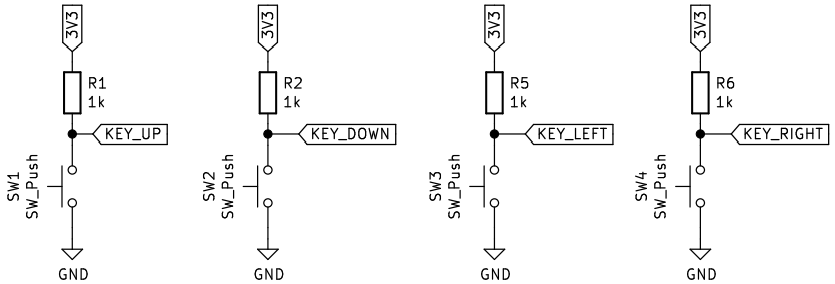

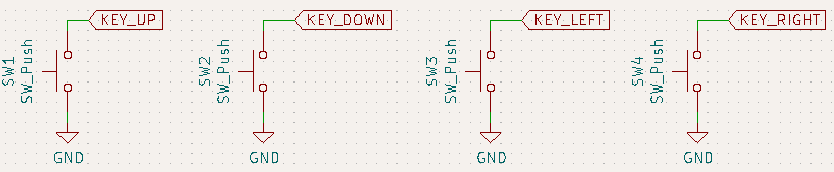

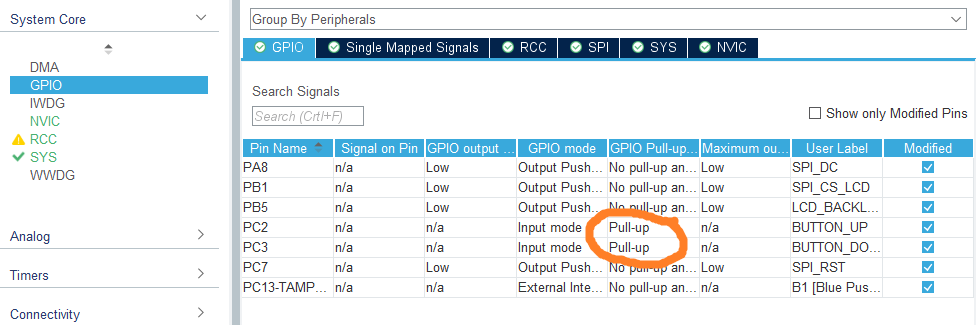

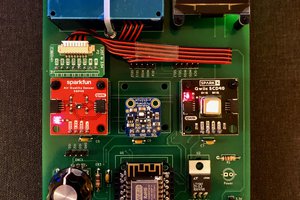

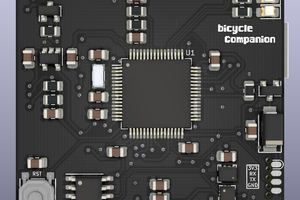

Hardware

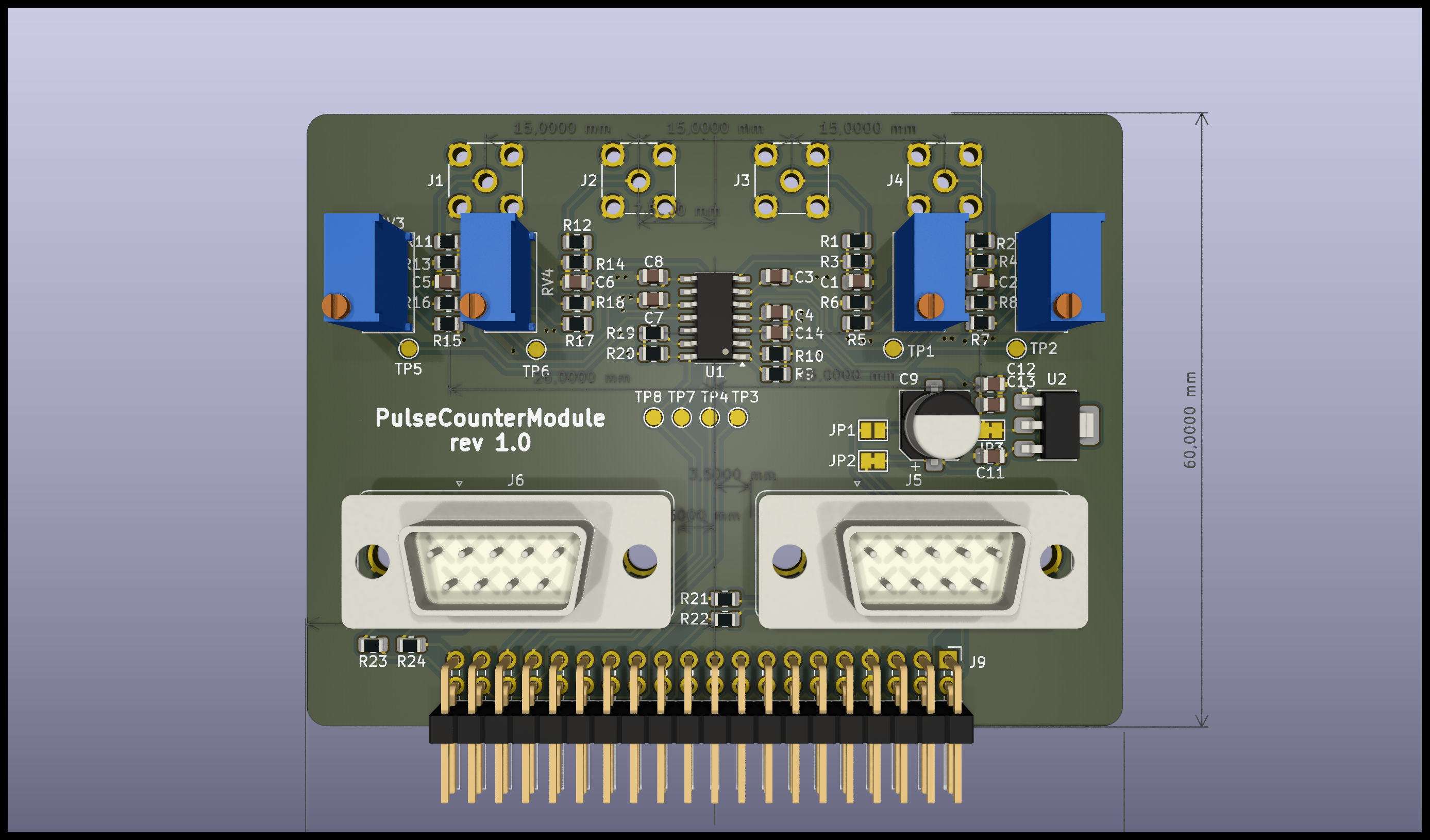

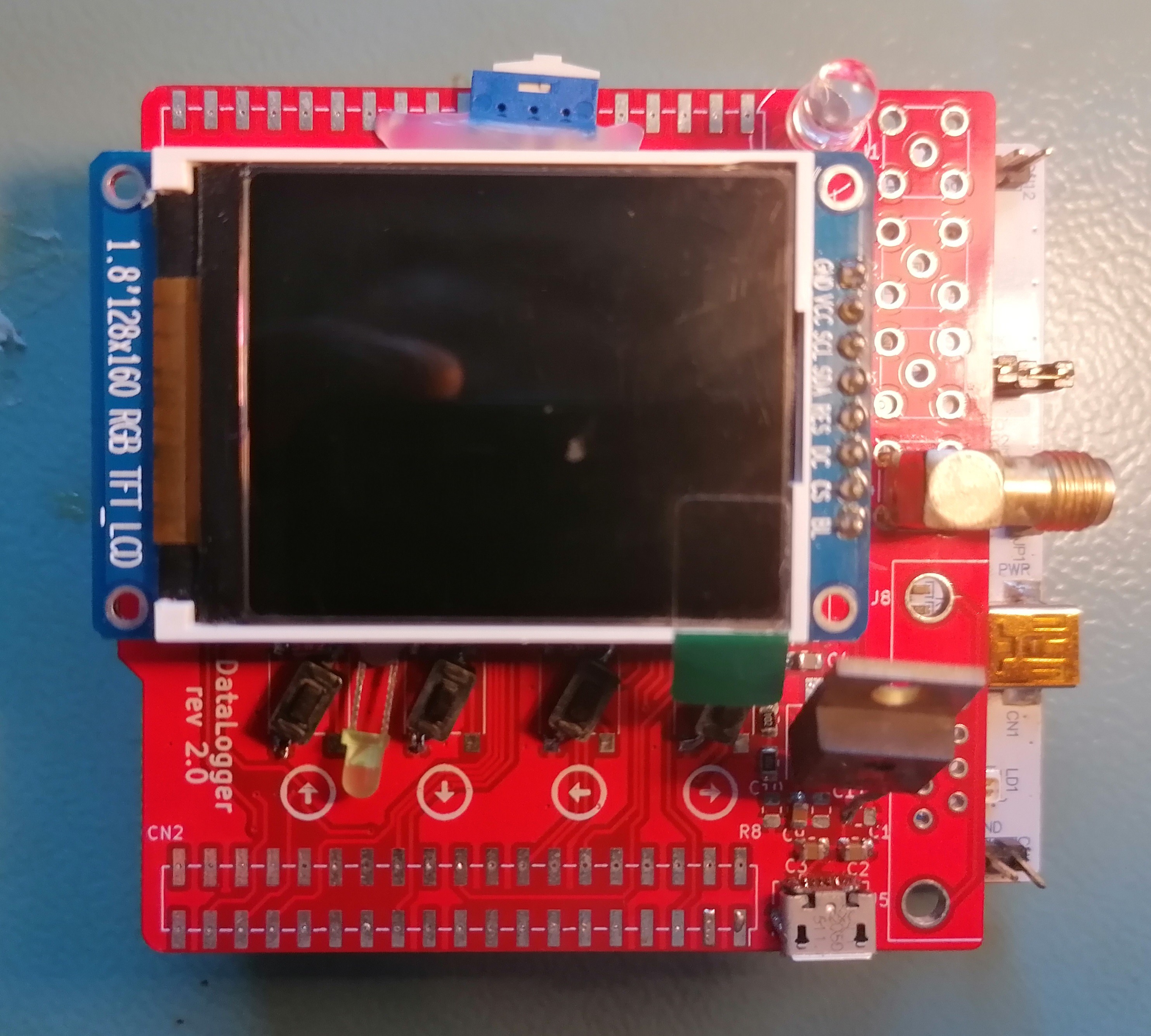

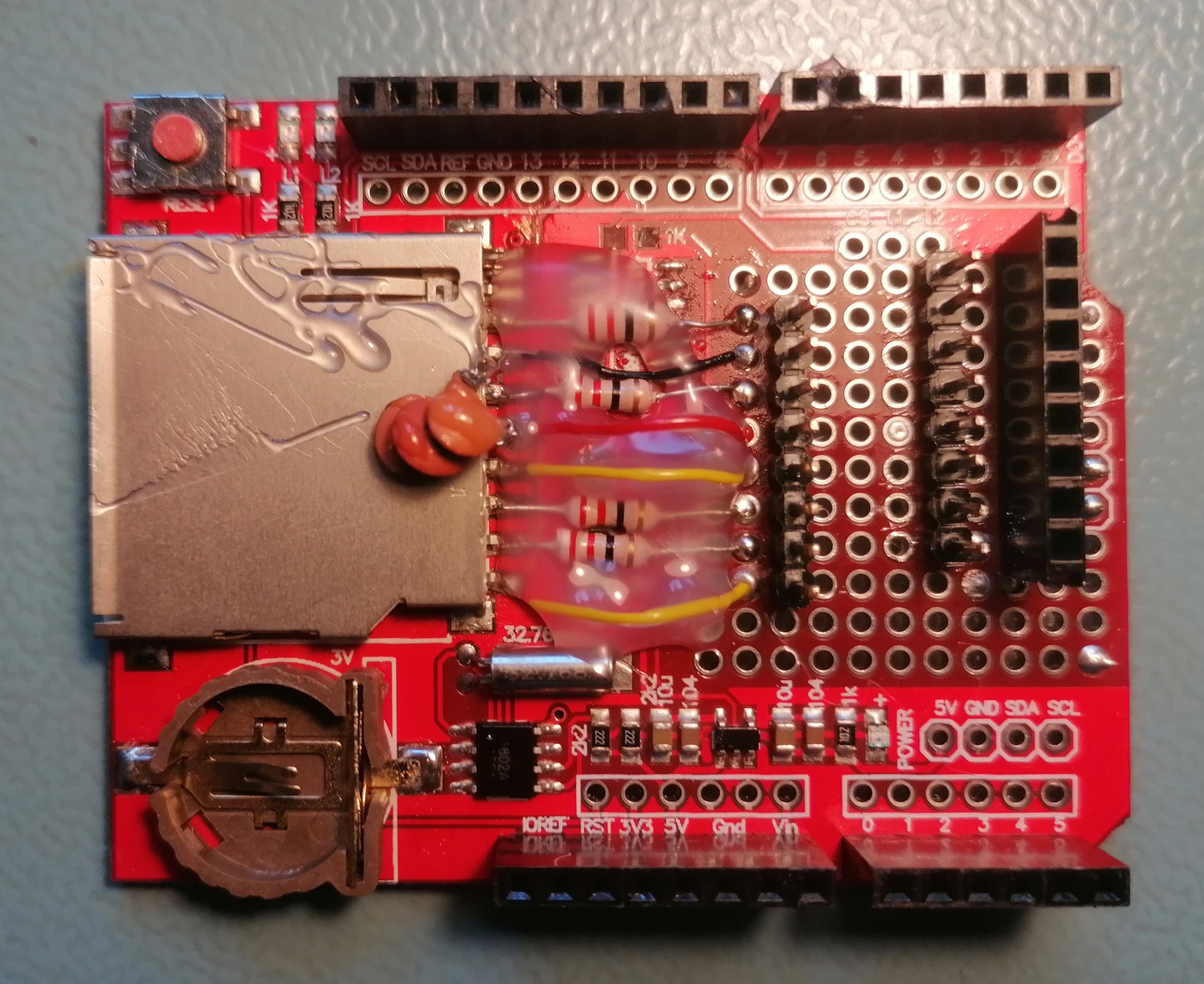

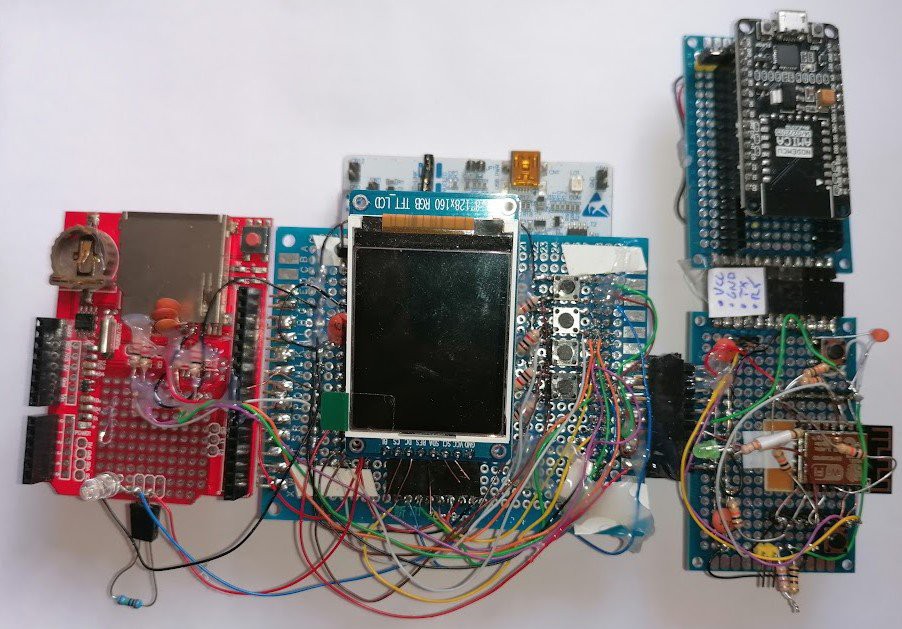

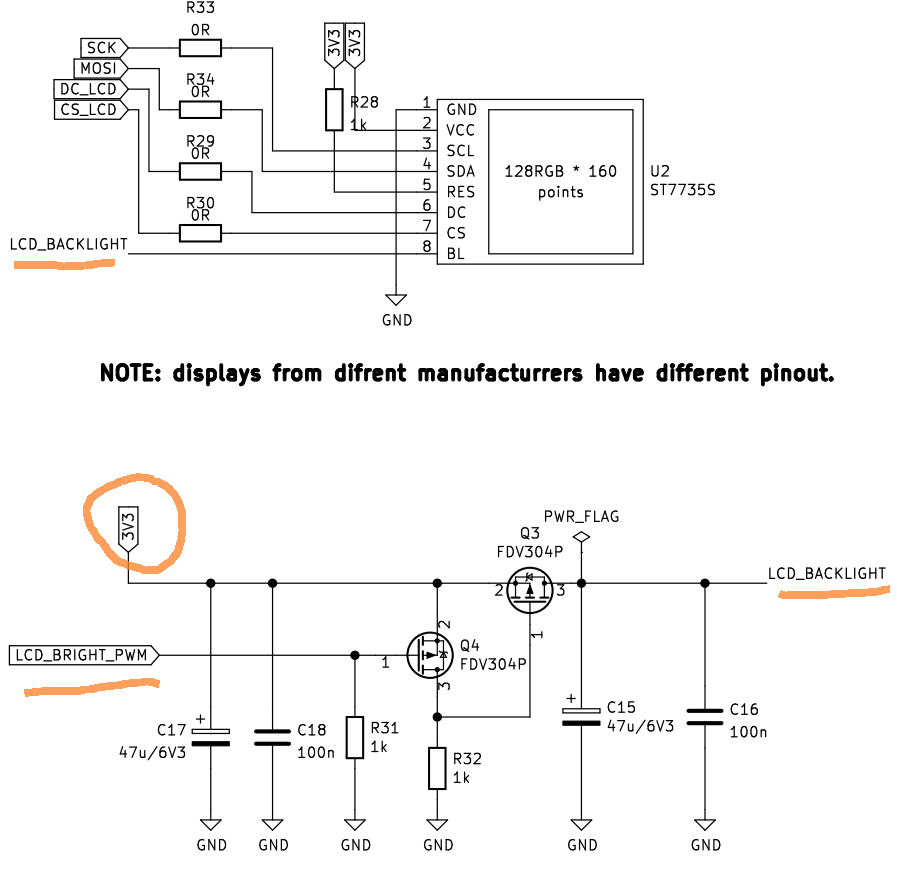

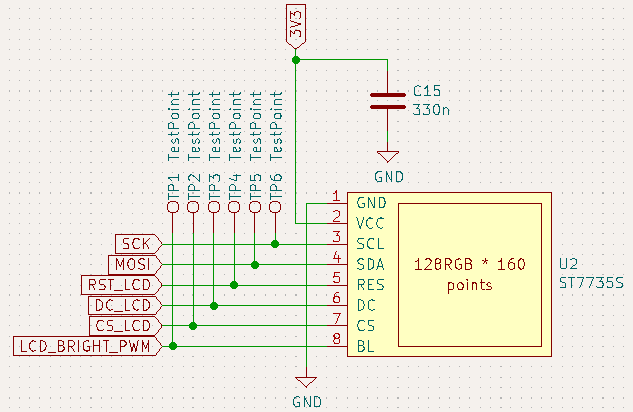

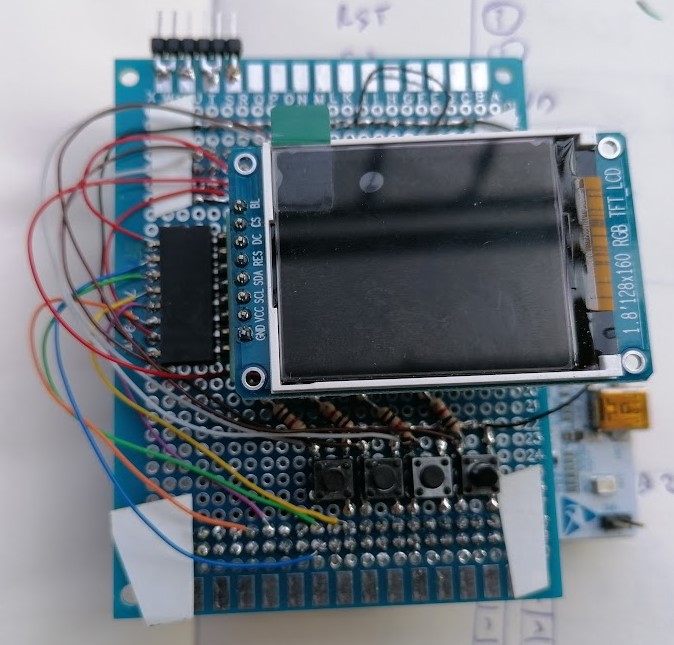

Due to the availability of low-cost, high-quality PCB manufacturing, home-etched PCBs have become largely obsolete. While the PCB design for this project may be difficult to etch at home, it is still possible. Subparts of the circuit can be assembled on a breadboard, making the process much easier, and the modular software design allows for easy reuse of these components.

- Circuit exported to .pdf is available here

- Toolchain: KiCad

- More info.

Software

NUCLEO-F103RB Board

The NUCLEO-F103RB serves as the main microcontroller, handling data acquisition, processing, storage, and user interaction. In future iterations, the NUCLEO-F103RB will be replaced by an STM32 chip directly integrated onto the PCB.

- Toolchain: C++17, C, STM32 VS Code Extension, CMake.

- More info.

ESP8266

The ESP8266 is currently used for data transfer via WiFi and will support FOTA (Firmware Over-The-Air) in the future.

- Toolchain: TBD, currently using Arduino IDE.

- More info.

DevOps

It's good to let the machine handle the tedious work of checking code quality, freeing up more time for the useful and interesting parts of software development.

- Toolchain: Unit tests (Google Test, Google Mock), code coverage (LCOV), static code analysis (Cppcheck), dynamic code analysis (Valgrind), Docker (for both local development and CI), GitHub Actions (CI).

Simulation

Embedded development is cool, but constantly flashing the target device for non-hardware-related logic, like the human-machine interface, can be time-consuming and frustrating. To streamline this, a simulation was developed that isolates the firmware not directly tied to hardware, adds stubs for drivers, and includes a GUI. This allows all high-level aspects, such as what’s displayed on the LCD, user interaction via buttons, and data parsing, to be tested without the need for hardware.

While this simulation handles the firmware, speed of execution isn't a concern since it focuses solely on high-level logic. For hardware or driver-related issues, traditional methods like using an oscilloscope or logic analyzer are still necessary, as the simulation cannot be used.

- Toolchain: pyqt6, cmake.

- More info.

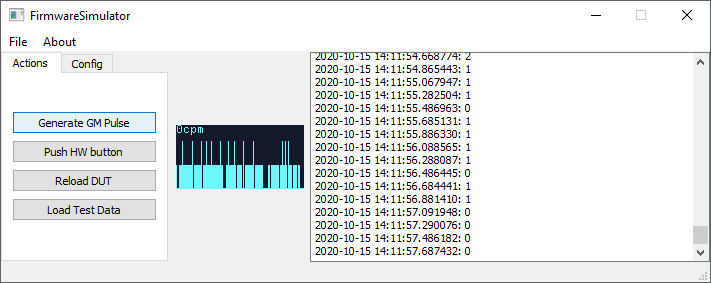

Below is a screenshot from the simulation. Note that this is from an earlier version when the device was designed to work exclusively with a Geiger counter. The current simulation doesn't work.

Documentation

UML diagrams will be added later using PlantUML.

Robert Gawron

Robert Gawron

tdw

tdw

Platinenmacher

Platinenmacher

Matias N.

Matias N.