-

Pre-school Work

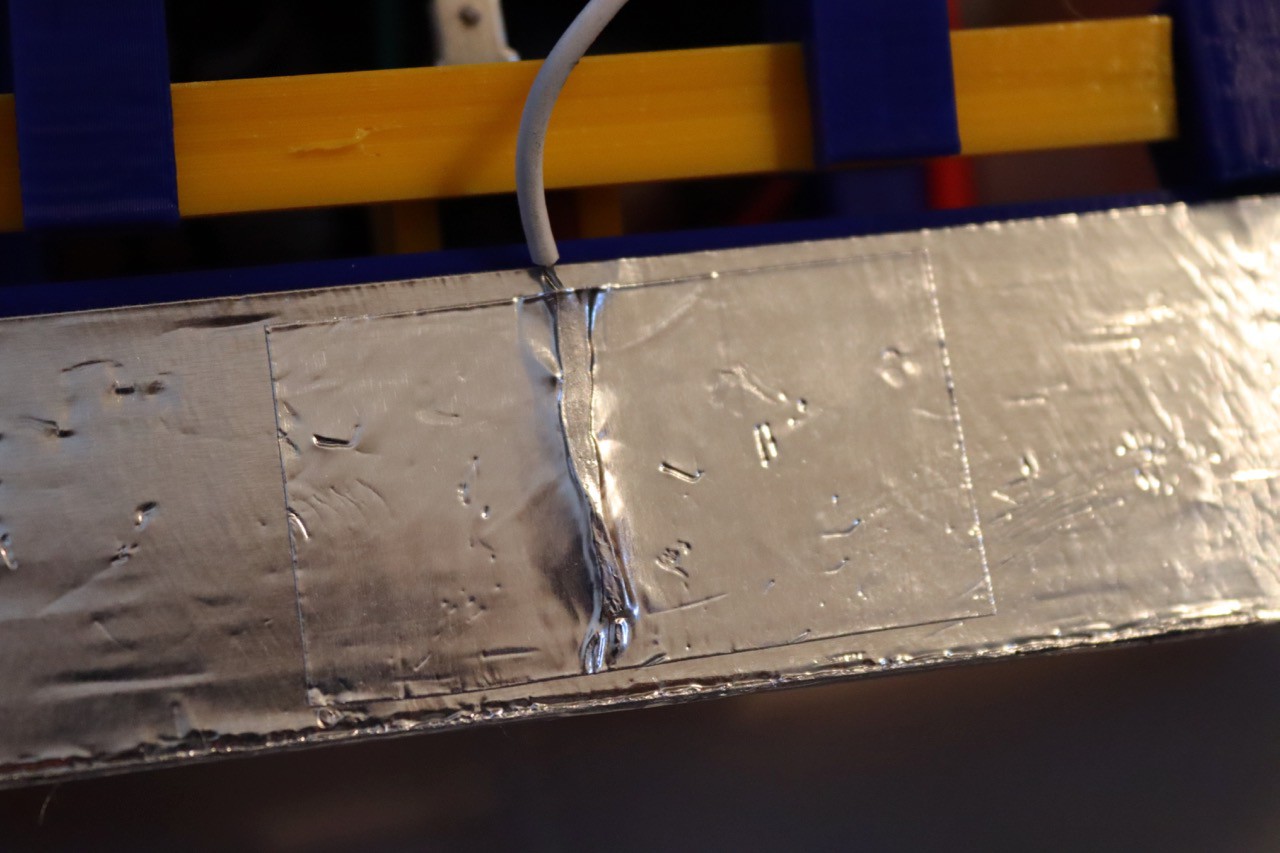

09/29/2021 at 21:24 • 0 commentsA section of the front bumper appeared "dead' to receiving charge. My bad. The sticky side of aluminum duct tape does not conduct, thus a good chunk of my front bumper "looked conductive," but wasn't. Note the area (in the photo below) where the wire is taped to the bumper. That big strip doesn't connect to the wire electrically.

![]()

I cut a piece of wire and (using my pre-school skills) cut a piece of tape.

![]()

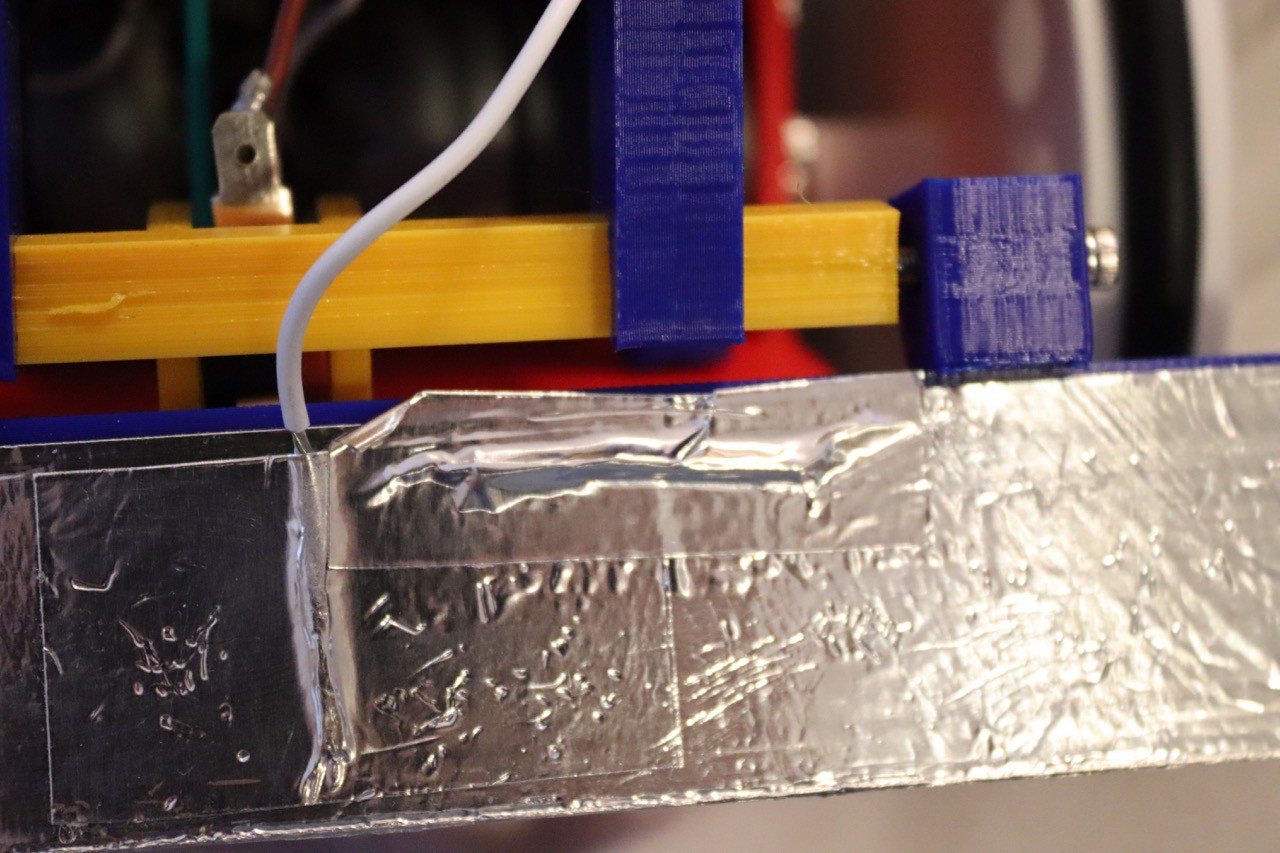

Taping the wire so that it bridges the "tape that taped the original wire" with main tape, the entire front bumper is now usable.

![]()

-

Solving Mobility Issues

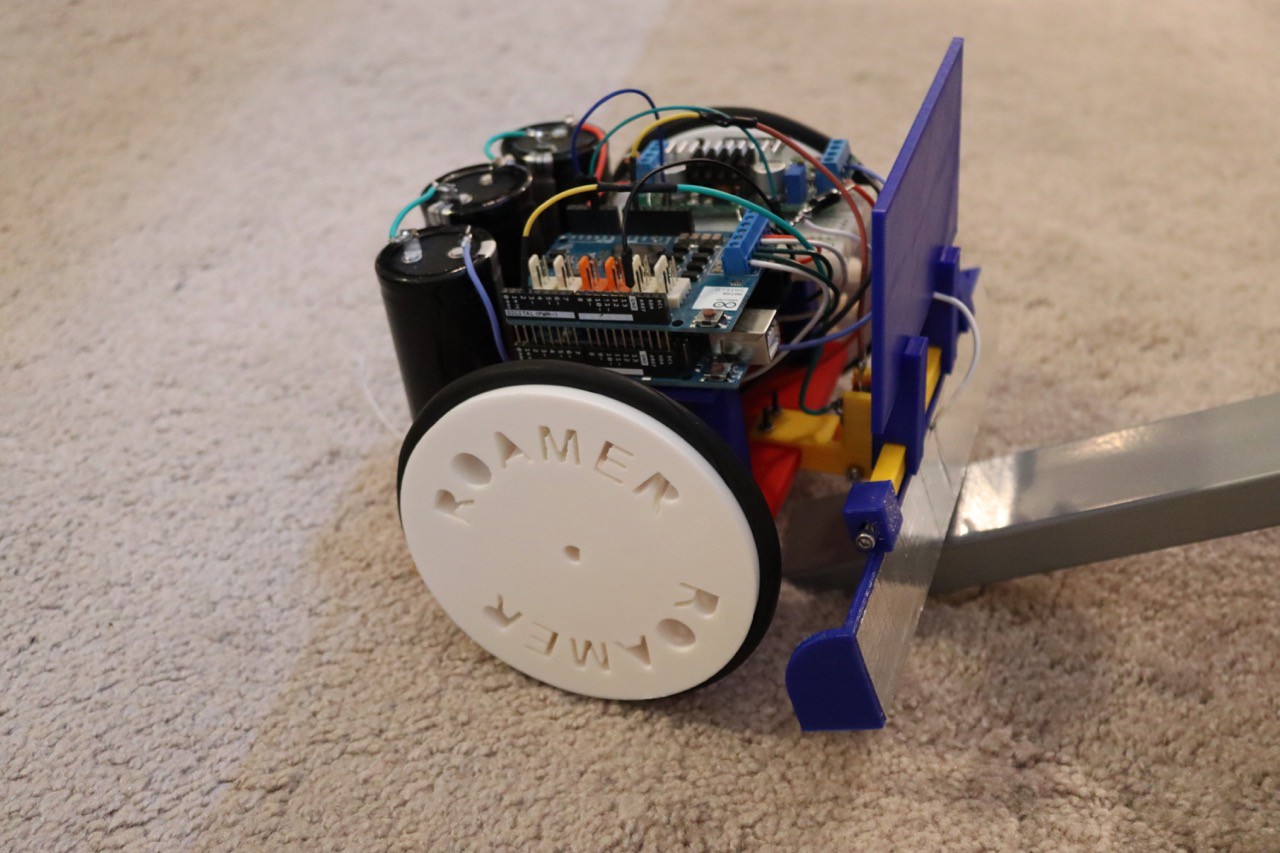

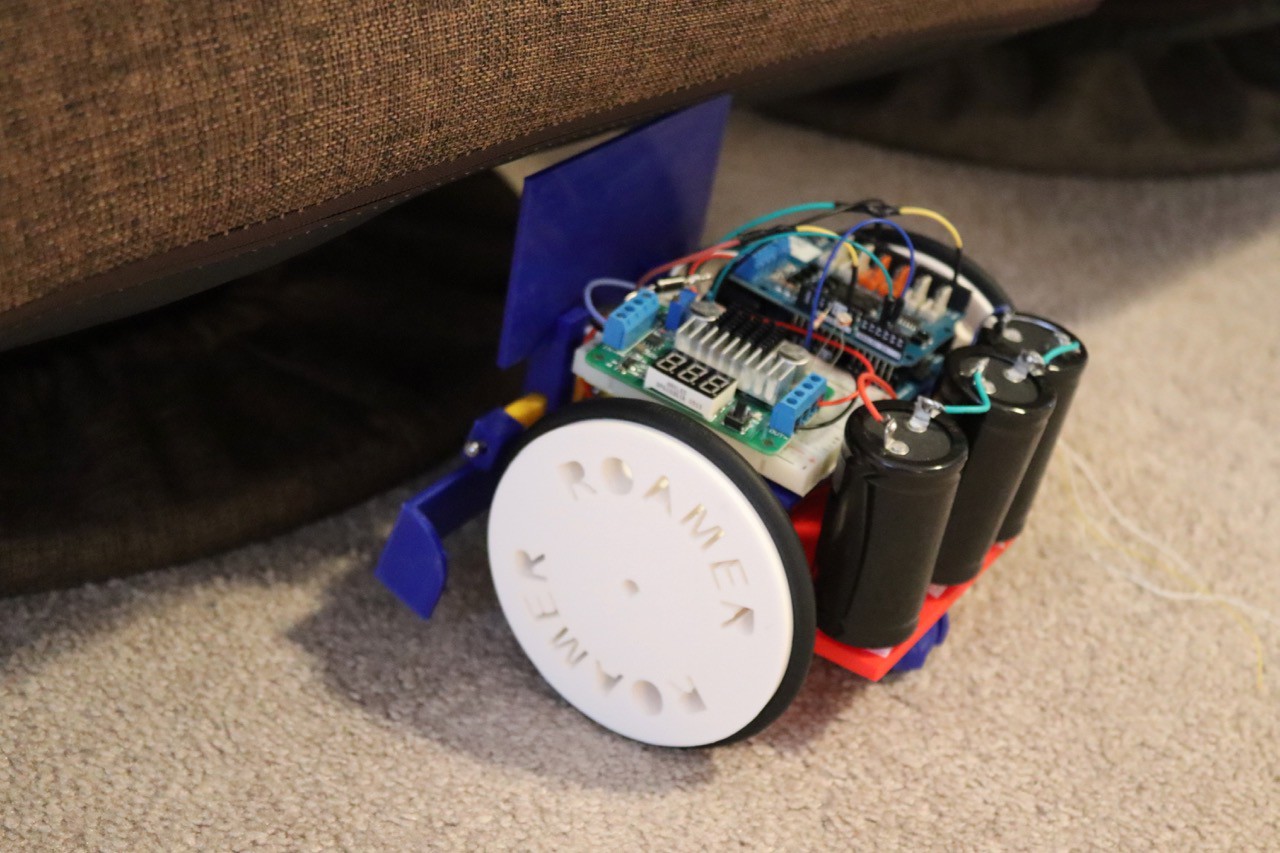

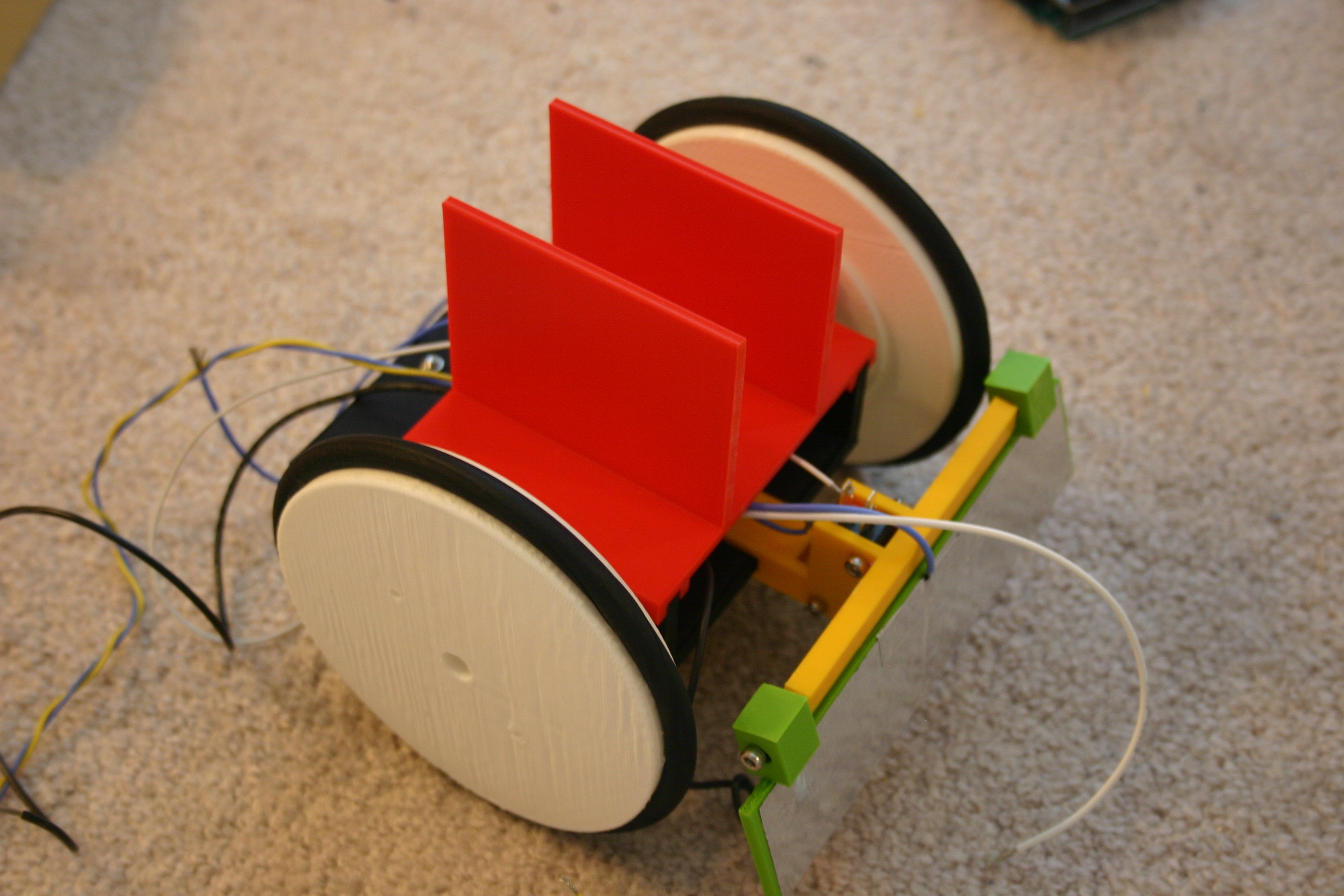

09/19/2021 at 20:25 • 0 commentsRoamer is now more quiet than the original version and has a run time of over 30 minutes on a charge, so I expanded her territory to the entire room (around 700 square feet) to let her find problems. She did. After solving her mobility problems, she pretty much handles anything and manages to return to the charge station before exhaustion

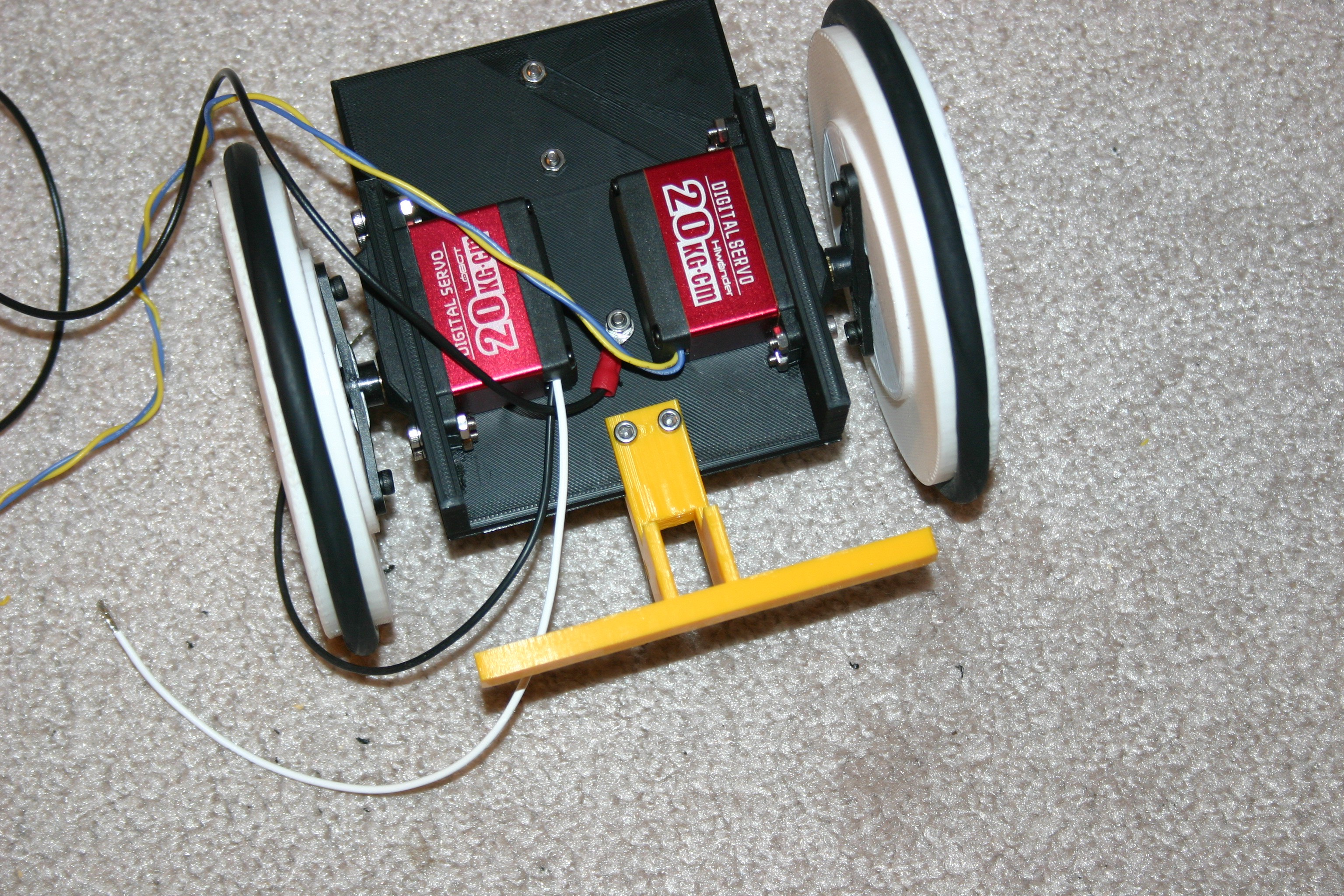

First, there are fancy sloped table legs that she liked to "climb and flip".

![]()

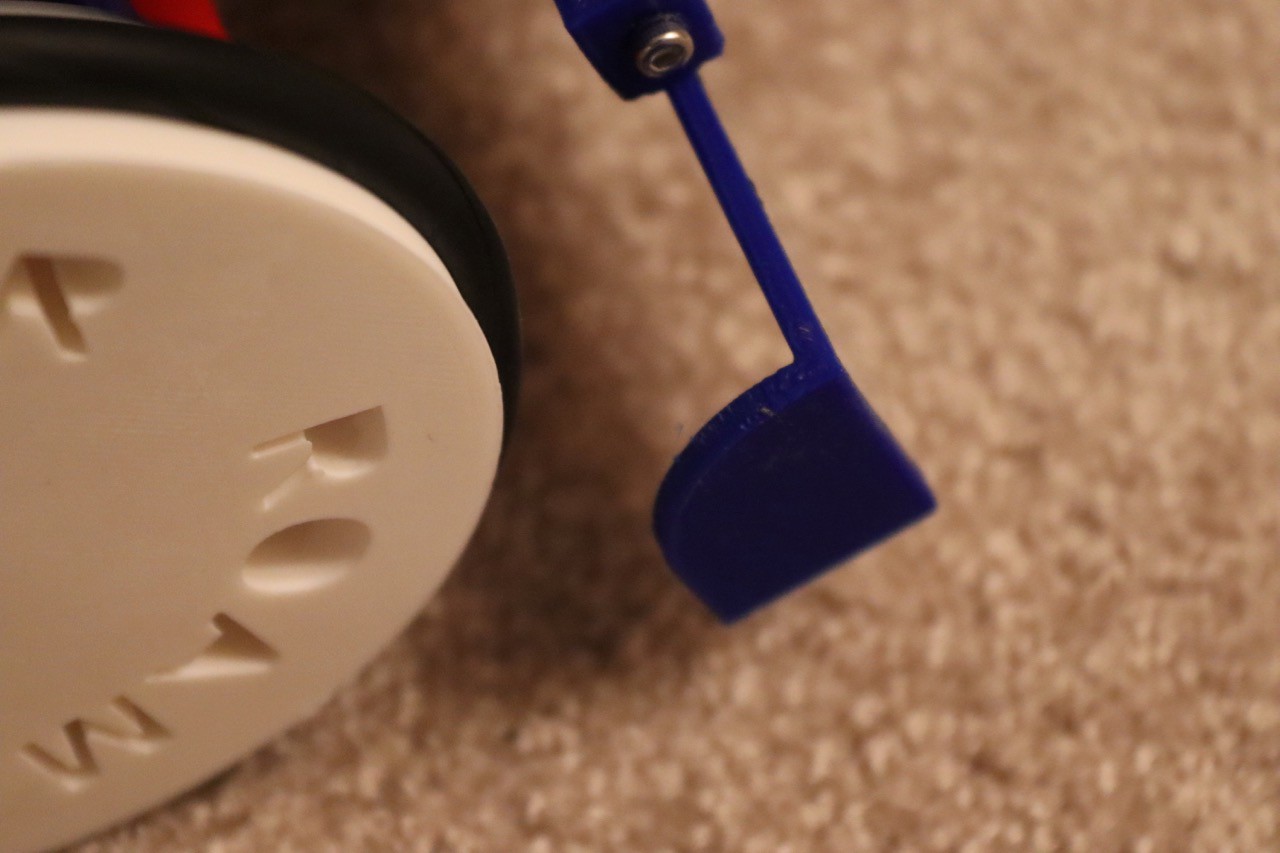

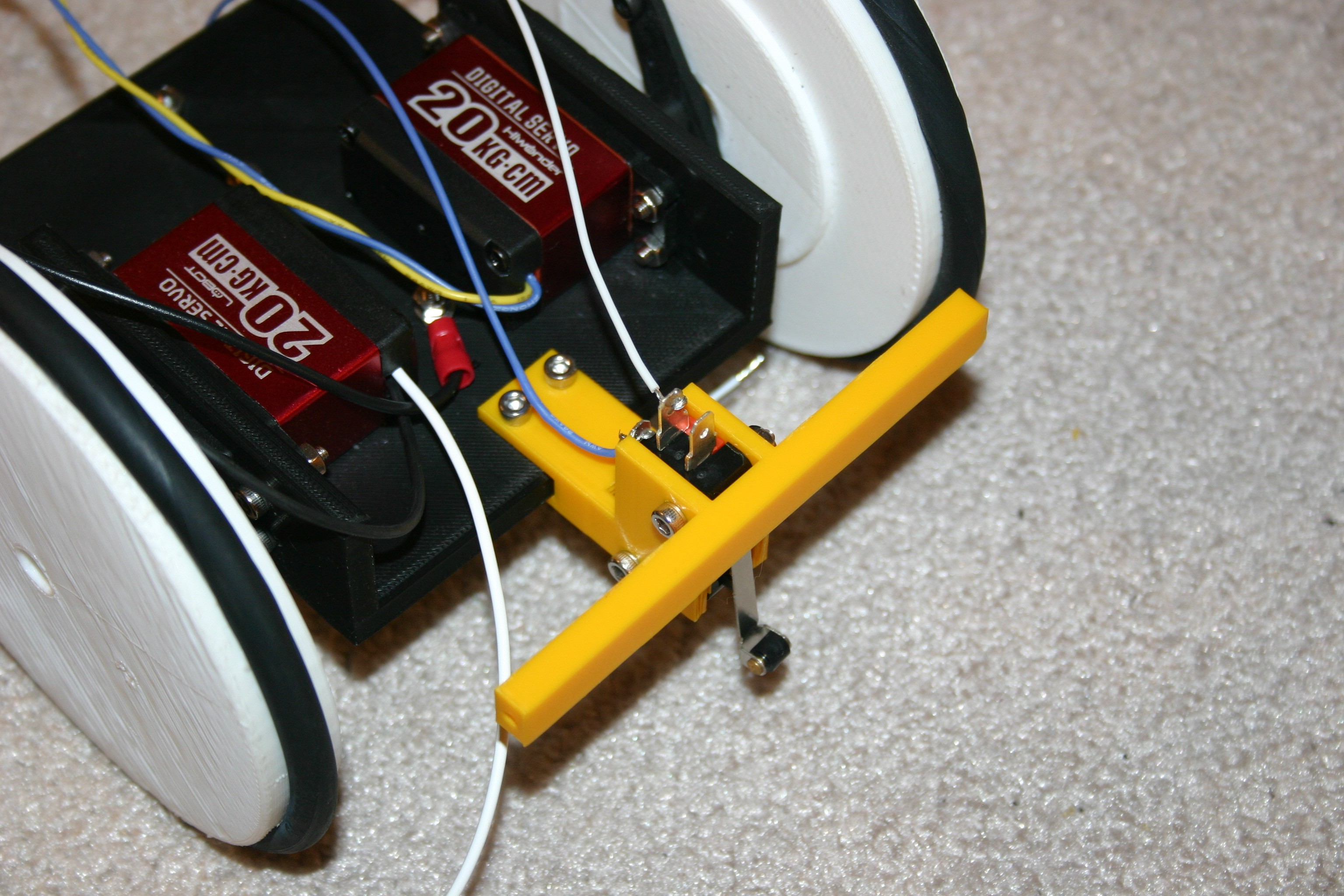

Adding a bit to the side of the bump bar seems to have stopped the wheel from slipping onto the leg (angle approach) and climbing for a flip.

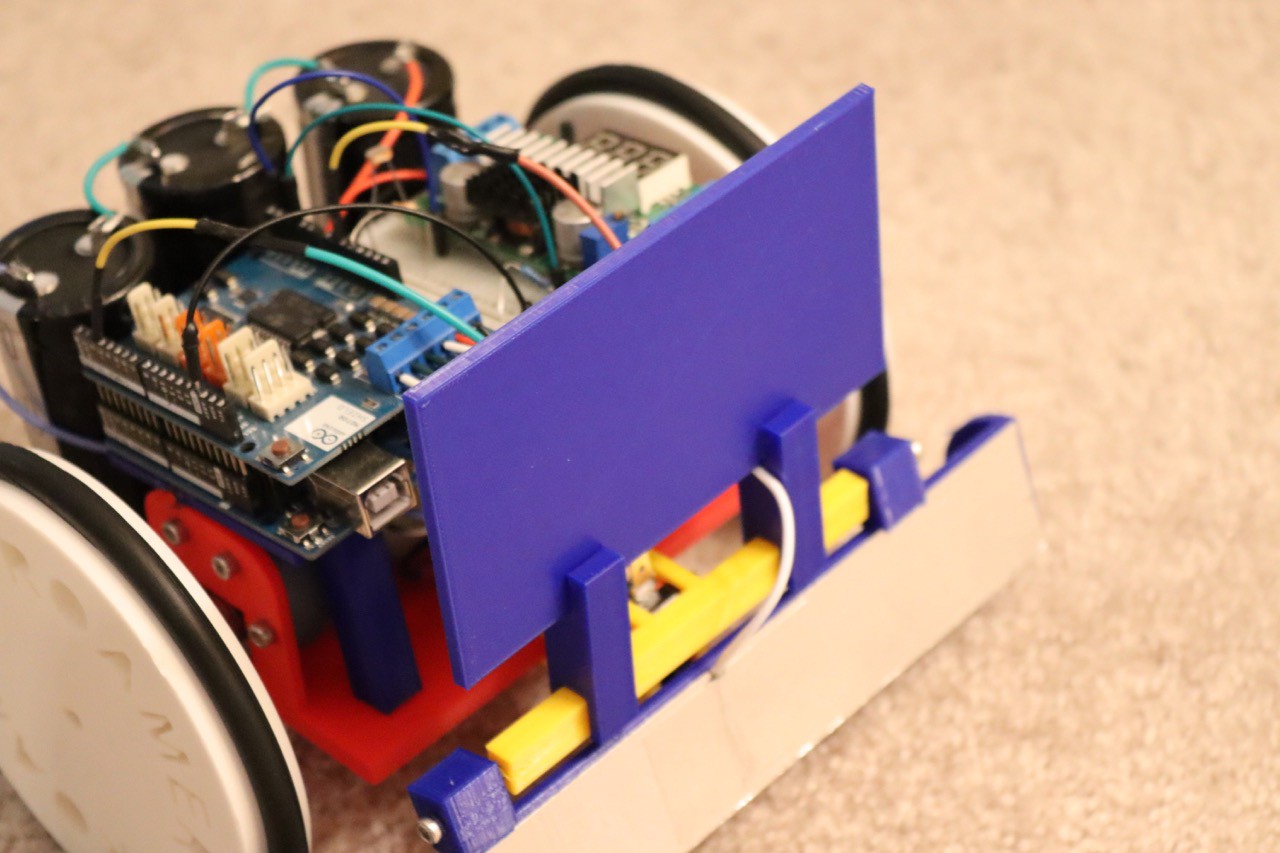

![]()

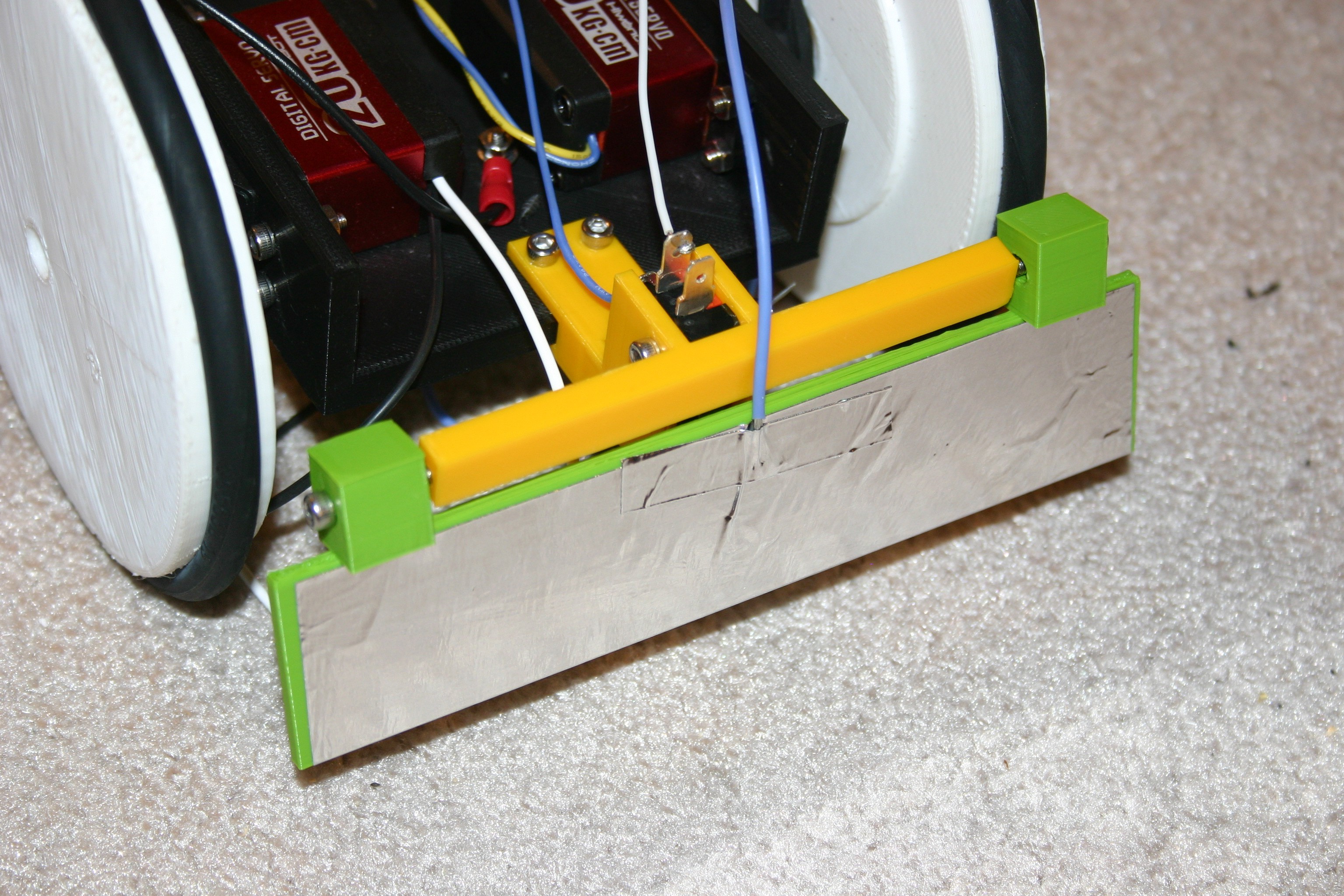

A second problem that emerged involved running under certain objects and snagging the (not well secured) wiring. A shield on the front bumper bar stopped that. Of course I could secure the wiring and add a cover--but that may come later.

![]()

![]()

Another situation occurs when she runs into an office chair or gaming chair.

![]()

![]()

Because this doesn't result in bumper switch operation, she sits there spinning wheels for up to thirty seconds (at which point a software "no switch bumped for thirty seconds" timeout results in a reverse/do something else maneuver.)

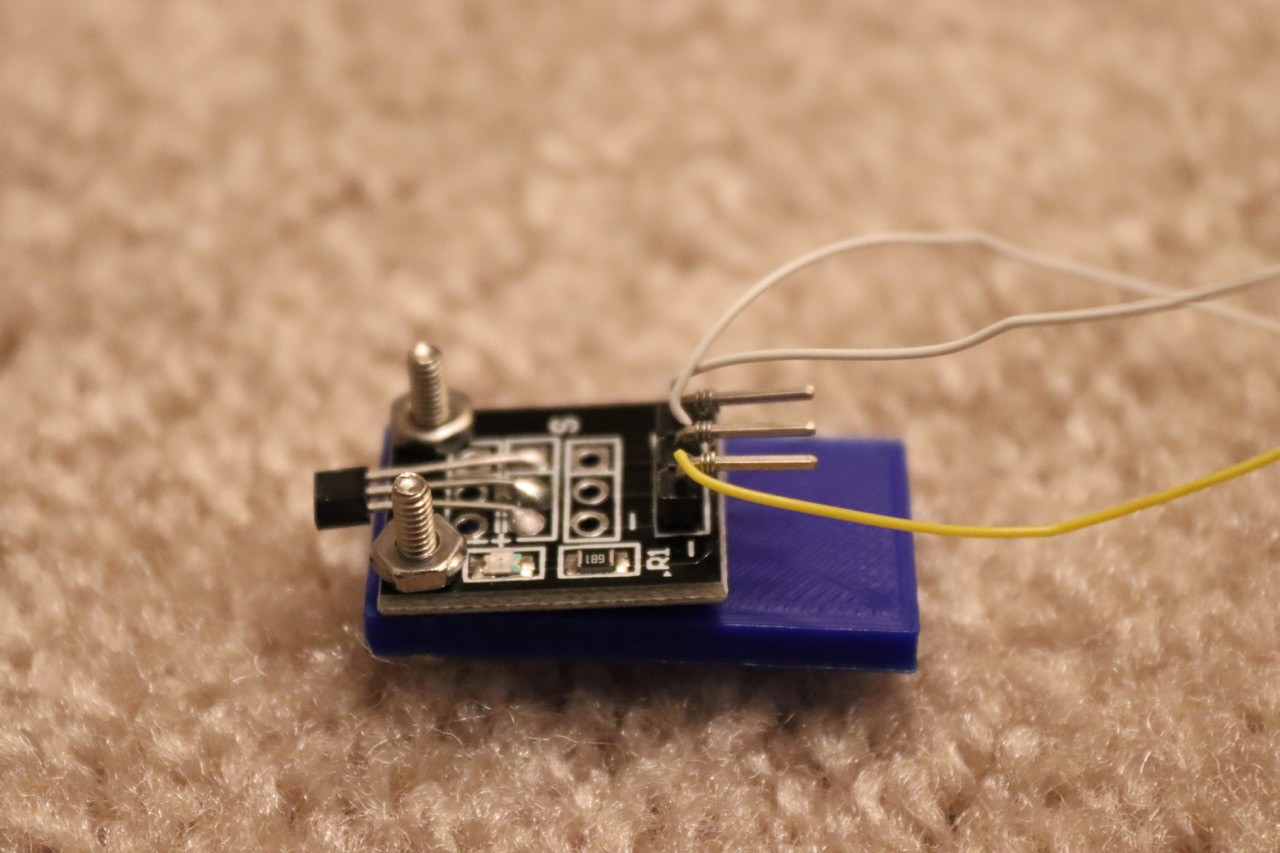

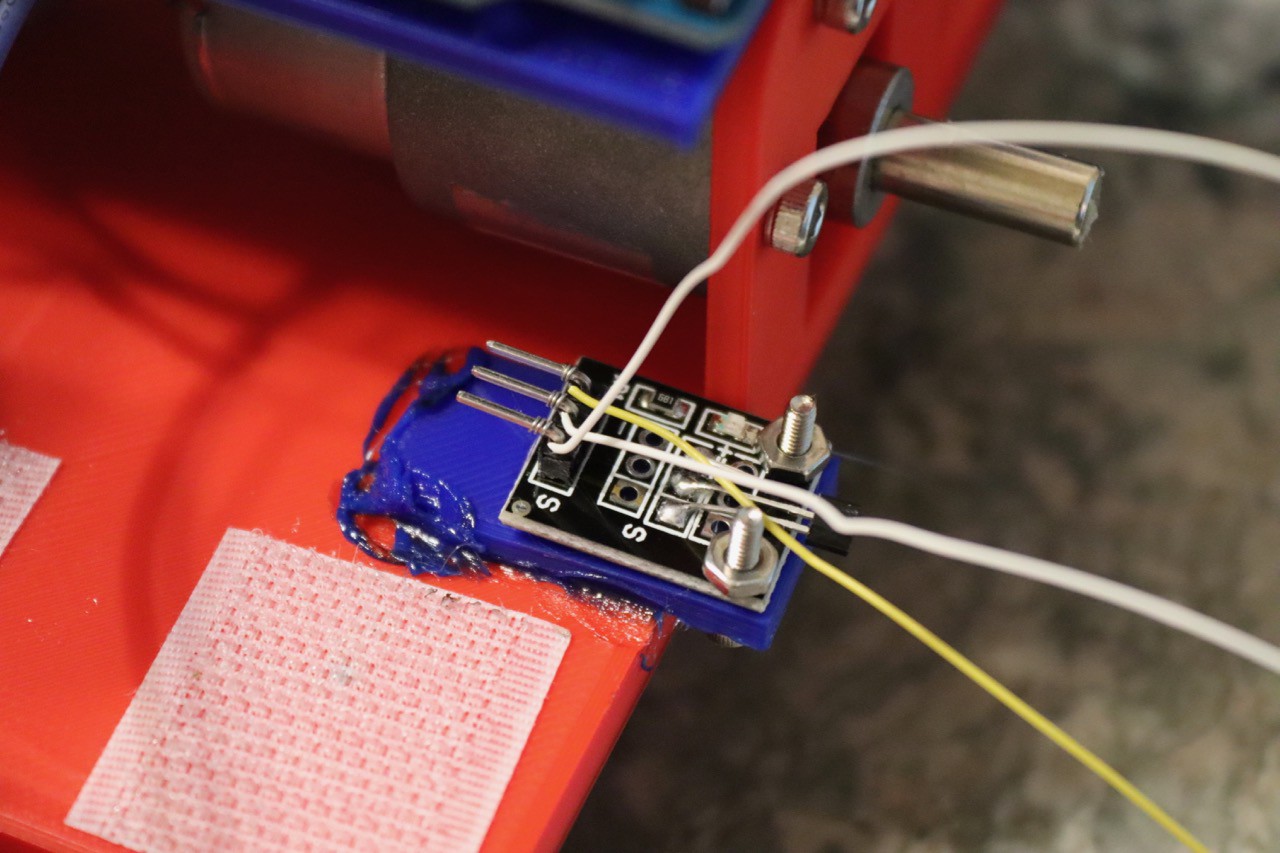

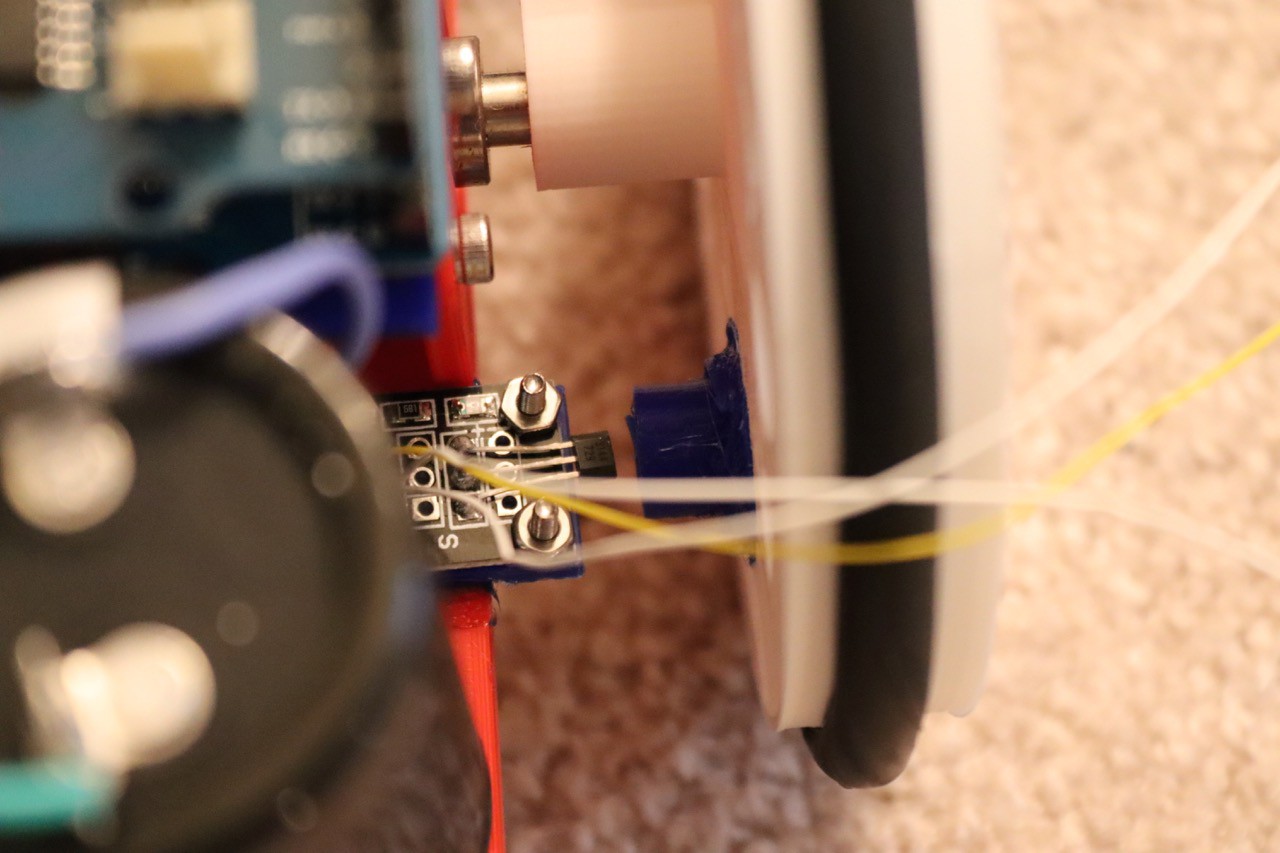

When stuck like this, her wheels turn more slowly. I added a magnet to one wheel.

![]()

![]()

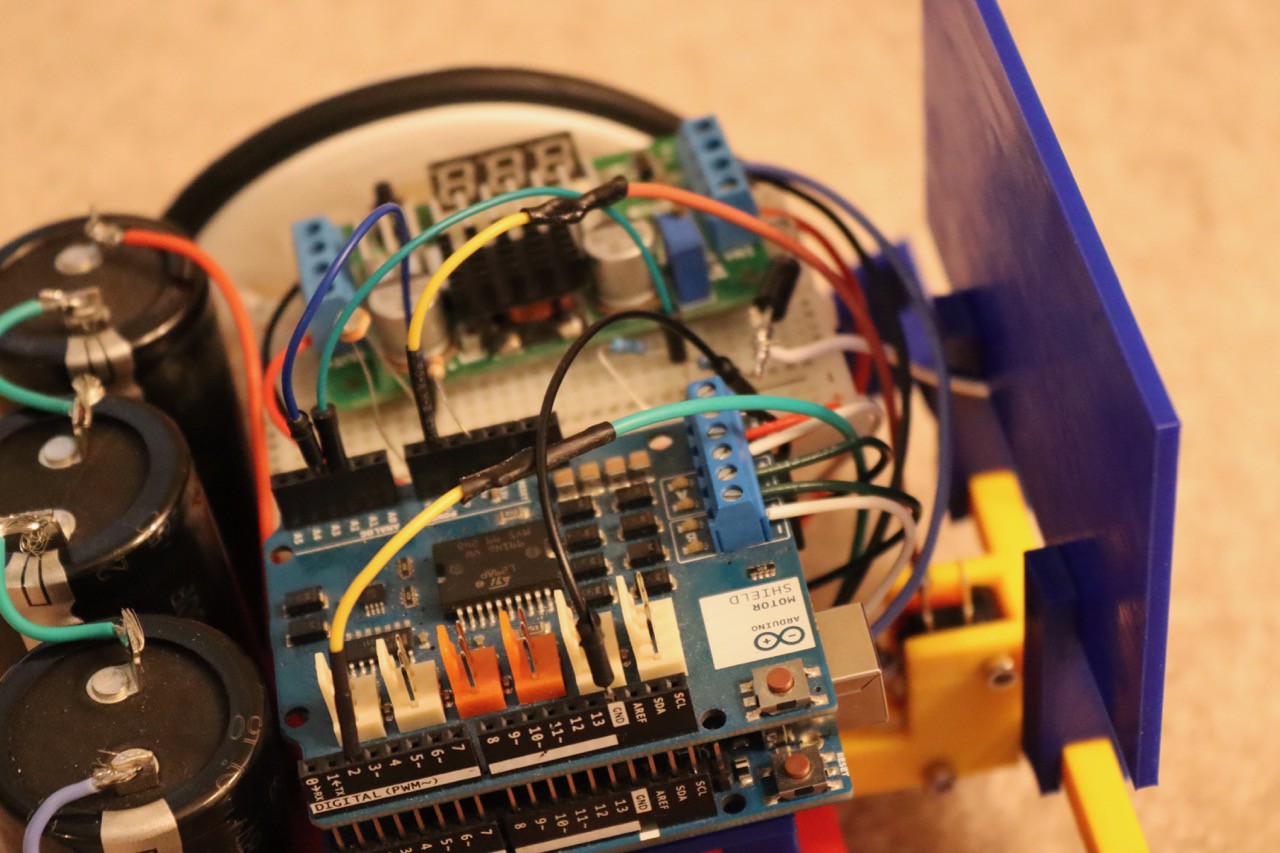

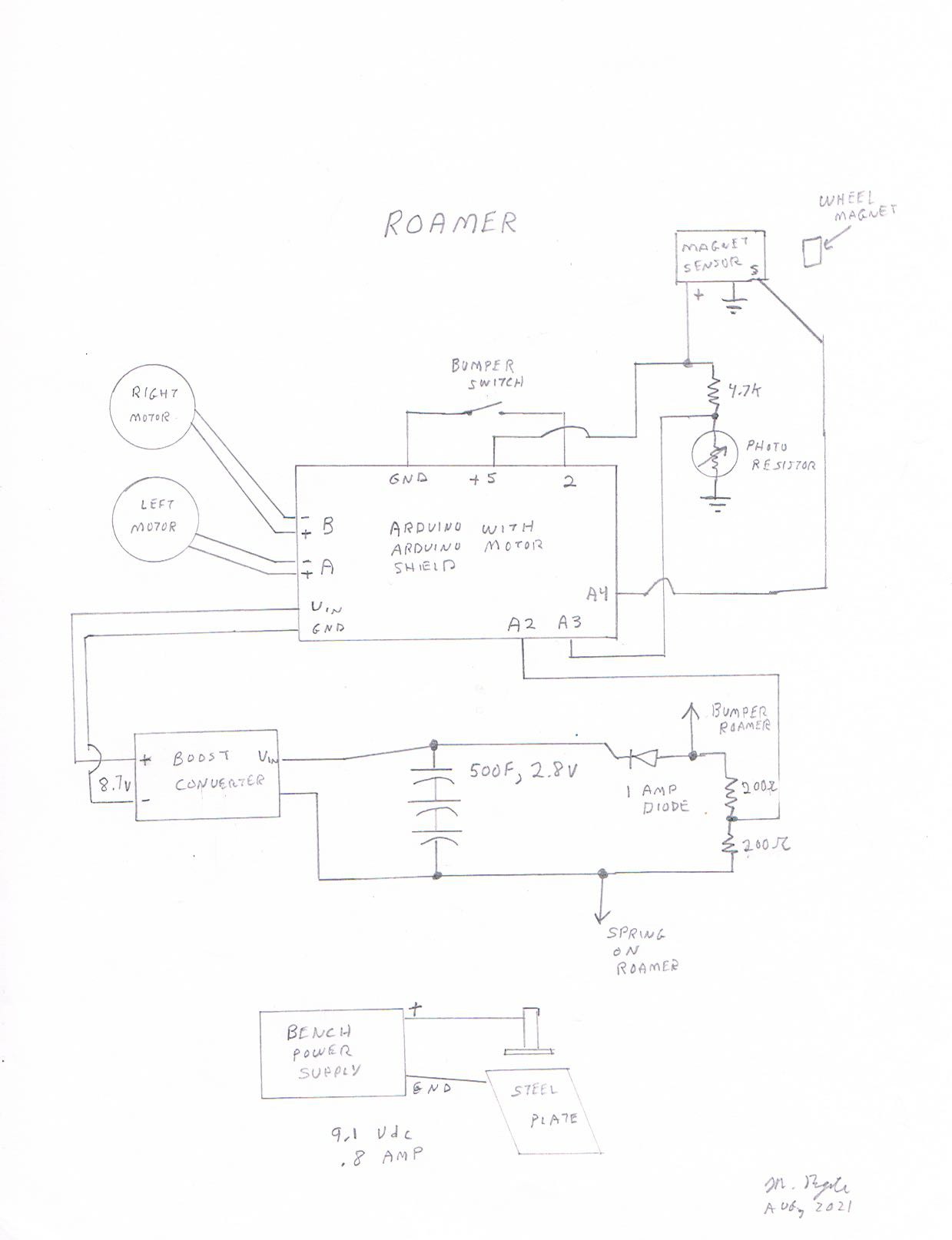

Coupled with a magnet sensor, I have a way to measure wheel speed.

![]()

![]()

![]()

This involved a change to the schematic and a change to the Arduino sketch.

![]()

No more waiting for "I'm stuck and can't move" situations--she now frees herself within a couple of seconds.

This is actually turning into a workable companion--sort of like a turtle that wanders about and feeds itself. She doesn't seek me out, whining for attention; and she isn't annoying or distracting like a tv--so, a pretty good workroom companion.

-

Motor Change

09/12/2021 at 19:03 • 0 commentsI changed dc motors to 70 rpm 12 volt gear motors. These motors are much more quiet and use less energy--hopefully will have a longer lifespan in this high use application. The maximum run time between charges is now 35 minutes (up from 20 minutes).

This required changes to the body, wheels and front bumper (to accomodate the new motors). The "Sept" files reflect those new parts.

-

Stepper Motor to Drive Wheels

08/28/2021 at 16:37 • 0 commentsNow I'm trying a thin Nema 17 stepper motor to replace the geared dc wheel driver motor--it works!

![]()

![]()

I'm driving the motor with an Arduino motor shield--motor pin 1 to B-; motor pin 4 to B+; motor pin 6 to A-; motor pin 3 to A+.

Code (stepper motor short) follows:

int delaylength=10;

int volt=220;void setup() {

pinMode(12,OUTPUT);

pinMode(13,OUTPUT);

pinMode(9,OUTPUT);

pinMode(8,OUTPUT);}

void loop() {

//round 1

digitalWrite(9,LOW);

digitalWrite(8,HIGH);digitalWrite(12,HIGH);

analogWrite(3,volt);delay(delaylength);

digitalWrite(9,HIGH);

digitalWrite(8,LOW);digitalWrite(13,LOW);

analogWrite(11,volt);delay(delaylength);

digitalWrite(9,LOW);

digitalWrite(8,HIGH);digitalWrite(12,LOW);

analogWrite(3,volt);delay(delaylength);

digitalWrite(9,HIGH);

digitalWrite(8,LOW);digitalWrite(13,HIGH);

analogWrite(11,volt);delay(delaylength);

//end round 1

}

I supplied 10 volts dc with one amp capacity to the motor shield power input.

-

Good News/Bad News

08/27/2021 at 23:20 • 0 commentsThe good news is that Roamer has run for quite a while, with never a failure to find the charging station. Like a turtle, Roamer has wound up with wheels off the ground a few times (I think I know how to solve that issue).

The bad news is that running for many hours takes a toll on little dc motors--shall we say failure?

![]()

There are no brushes in these little motors, merely little "fingers" that wear out rather quickly.

![]()

A dc motor with genuine brushes would probably last longer--but a robot that buzzes around twelve to fourteen hours a day is going to strain a brushed motor.

I'm testing a stepper motor to see if that might provide the reliability I want. A companion robot needs to run a long time without serious maintenance. I have more work to do.

-

Software

08/22/2021 at 19:32 • 0 commentsWhen Roamer's bumper is depressed, there are five possible "backup and turn" scenarios--the activation choice is random.

After 30 seconds of forward movement (stuck spinning wheels without depressing the bumper or long distance), she backs up and tries another direction.

unsigned long timestart;

unsigned long timeend;

unsigned long timetotal;int a=95;//speed for left? motor, increased from 80

int b=85;

int c=650;//value for photoresistor day/night higher = less light to keep going

int d=820;//upper voltage valueint t1=1;

int volt=A1;//bumper input pin

int val=0;//initial bumper value

int val1=100;//initial value for photocellint bumper=1;//setup bumper not pressed

long randNumber;

int x=1;//current read value to be determined in setup

int x1=0;//first of multiple reads

int x2=0;

int x3=0;

int x4=0;

int x5=0;int y=0;//counts for overcurrent rather than spike

int z=0;//storage area for temporary current readsconst int pwmA=3;

const int pwmB=11;

const int brakeA=9;

const int brakeB=8;

const int dirA=12;

const int dirB=13;void setup() {

pinMode (dirA,OUTPUT);

pinMode (brakeA,OUTPUT);

pinMode (dirB,OUTPUT);

pinMode (brakeB,OUTPUT);

pinMode (A1,INPUT);

pinMode (2,INPUT);

digitalWrite (2,HIGH);

randomSeed (analogRead(0));

digitalWrite(brakeA,LOW);

digitalWrite(brakeB,LOW);

digitalWrite(dirA,HIGH);

digitalWrite(dirB,HIGH);

analogWrite(pwmA,0);//changed to reflect no overcurrent mode

analogWrite(pwmB,0);

//delay(2000);//get motors started

//x1=analogRead(A0);//set normal motor value

//delay(10);

//x2=analogRead(A0);

//delay(10);

//x3=analogRead(A0);

//delay(10);

//x4=analogRead(A0);

//delay(10);

//x5=analogRead(A0);

//x=((x1+x2+x3+x4+x5)/5);

x=500;//arbitray number

timestart=millis();

}void loop() {

bumper=digitalRead(2);

if (bumper==0) {//bumper depressed

randNumber=random(1,5);//changed august 12 from 1,4

if(randNumber==1) {

analogWrite(pwmB,0);//check for power station

analogWrite(pwmA,0);

delay(500);//stop to read

val=analogRead(A2);

if (val>100) {

val1=analogRead(A3);

while ((val<d && val>100) || (val1>c)) {//was 815 instead of 600

val1=analogRead(A3);

val=analogRead(A2);

delay(100);

}}

digitalWrite(dirA,LOW);

digitalWrite(dirB,LOW);//reverse

analogWrite(pwmA,120);//was 150

analogWrite(pwmB,70);//reverse power

delay(500);

analogWrite(pwmB,0);

delay(750);

analogWrite(pwmA,0);//stop

digitalWrite(dirA,HIGH);

digitalWrite(dirB,HIGH);

analogWrite(pwmA,a);

analogWrite(pwmB,b);

delay(1000);

t1=0;

timestart=millis();

}

if (randNumber==2) {

analogWrite(pwmB,0);//check for power station

analogWrite(pwmA,0);

delay(500);//stop to read

val=analogRead(A2);

if (val>100) {

val1=analogRead(A3);

while ((val<d && val>100) ||(val1>c)) {

val1=analogRead(A3);

val=analogRead(A2);

delay(100);

}}

digitalWrite(dirA,LOW);

digitalWrite(dirB,LOW);//reverse

analogWrite(pwmA,70);//was 150

analogWrite(pwmB,120);//reverse power

delay(600);

analogWrite(pwmA,0);

delay(1000);

analogWrite(pwmB,0);//stop

digitalWrite(dirA,HIGH);

digitalWrite(dirB,HIGH);

analogWrite(pwmA,a);

analogWrite(pwmB,b);

delay(1000);

t1=0;

timestart=millis();

}

if (randNumber==3) {

analogWrite(pwmB,0);//check for power station

analogWrite(pwmA,0);

delay(500);//stop to read

val=analogRead(A2);

if (val>100) {

val1=analogRead(A3);

while ((val<d && val>100) || (val1>c)) {

val1=analogRead(A3);

val=analogRead(A2);

delay(100);

}}

digitalWrite(dirA,LOW);

digitalWrite(dirB,LOW);//reverse

analogWrite(pwmA,a);//was 150

analogWrite(pwmB,b);//reverse power

delay(600);

digitalWrite(dirB,HIGH);

analogWrite(pwmB,150);

delay(800);

analogWrite(pwmA,0);//stop

analogWrite(pwmB,0);

digitalWrite(dirA,HIGH);

digitalWrite(dirB,HIGH);

analogWrite(pwmA,a);

analogWrite(pwmB,b);

delay(1000);

t1=0;

timestart=millis();

}if(randNumber==4) {

analogWrite(pwmB,0);//check for power station

analogWrite(pwmA,0);

delay(500);//stop to read

val=analogRead(A2);

if (val>100) {

val1=analogRead(A3);

while ((val<d && val>100) || (val1>c)) {//was 815 instead of 600

val1=analogRead(A3);

val=analogRead(A2);

delay(100);

}}

digitalWrite(dirA,LOW);

digitalWrite(dirB,LOW);//reverse

analogWrite(pwmA,a);//was 150

analogWrite(pwmB,b);//reverse power

delay(500);

analogWrite(pwmB,0);

delay(1000);

analogWrite(pwmA,0);//stop

digitalWrite(dirA,HIGH);

digitalWrite(dirB,HIGH);

analogWrite(pwmA,a);

analogWrite(pwmB,b);

delay(1000);

t1=0;

timestart=millis();

}

if(randNumber==5) {

analogWrite(pwmB,0);//check for power station

analogWrite(pwmA,0);

delay(500);//stop to read

val=analogRead(A2);

if (val>100) {

val1=analogRead(A3);

while ((val<d && val>100) || (val1>c)) {//was 815 instead of 600

val1=analogRead(A3);

val=analogRead(A2);

delay(100);

}}

digitalWrite(dirA,LOW);

digitalWrite(dirB,LOW);//reverse

analogWrite(pwmA,a);//was 150

analogWrite(pwmB,b);//reverse power

delay(400);

analogWrite(pwmB,0);

delay(800);

analogWrite(pwmA,0);//stop

digitalWrite(dirA,HIGH);

digitalWrite(dirB,HIGH);

analogWrite(pwmA,a);

analogWrite(pwmB,b);

delay(1000);

t1=0;

timestart=millis();

}

}

//main body of action

if (t1=0) {

timestart = millis();

t1=1;

}

if (t1=1) {

timeend = millis();

timetotal= (timeend-timestart);

}

if (timetotal>30000) {

digitalWrite(dirA,LOW);

digitalWrite(dirB,LOW);//reverse

analogWrite(pwmA,a);//was 150

analogWrite(pwmB,b);//reverse power

delay(1000);

digitalWrite(dirB,HIGH);

analogWrite(pwmB,150);

delay(1000);

analogWrite(pwmA,0);//stop

analogWrite(pwmB,0);

digitalWrite(dirA,HIGH);

digitalWrite(dirB,HIGH);

analogWrite(pwmA,a);

analogWrite(pwmB,b);

delay(1000);

t1=0;

timestart=millis();

}

digitalWrite(dirA,HIGH);

digitalWrite(dirB,HIGH);

analogWrite(pwmA,a);

analogWrite(pwmB,b);

z=analogRead(A0);//read current

if (z>(x+210)) {//turn around and restart

digitalWrite(dirA,LOW);

digitalWrite(dirB,LOW);//reverse

analogWrite(pwmA,150);

analogWrite(pwmB,150);//reverse power

delay(1000);

digitalWrite(dirB,HIGH);

analogWrite(pwmB,150);

delay(600);

analogWrite(pwmA,0);//stop

analogWrite(pwmB,0);

digitalWrite(dirA,HIGH);//go forward one second

digitalWrite(dirB,HIGH);

analogWrite(pwmA,a);

analogWrite(pwmB,b);

delay(1000);

t1=0;

timestart=millis();

}

} -

Baseboard Charger

08/21/2021 at 13:12 • 0 commentsI set up a baseboard charging station--took about five minutes.

Start with an eighteen inch by six inch sheet of steel and an eighteen inch piece of 1 x 2 wood.

![]()

Drill holes (I drilled three) in the edge of the steel.

![]()

Screw the wood to the steel.

![]()

Add aluminum duct tape to the wood, making sure that the tape does not touch the base.

![]()

Set against a wall and attach the bench power supply--it's ready to go!

-

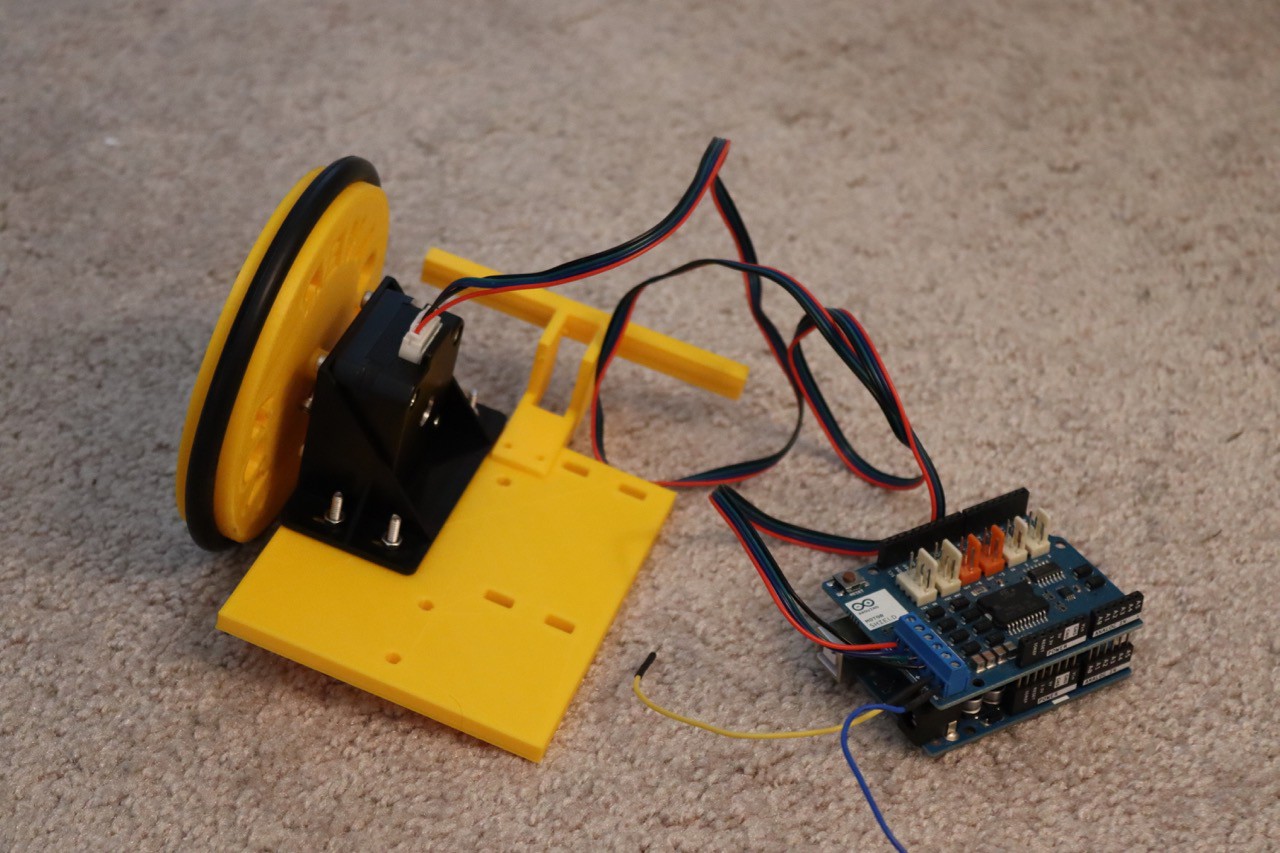

How Roamer was Assembled

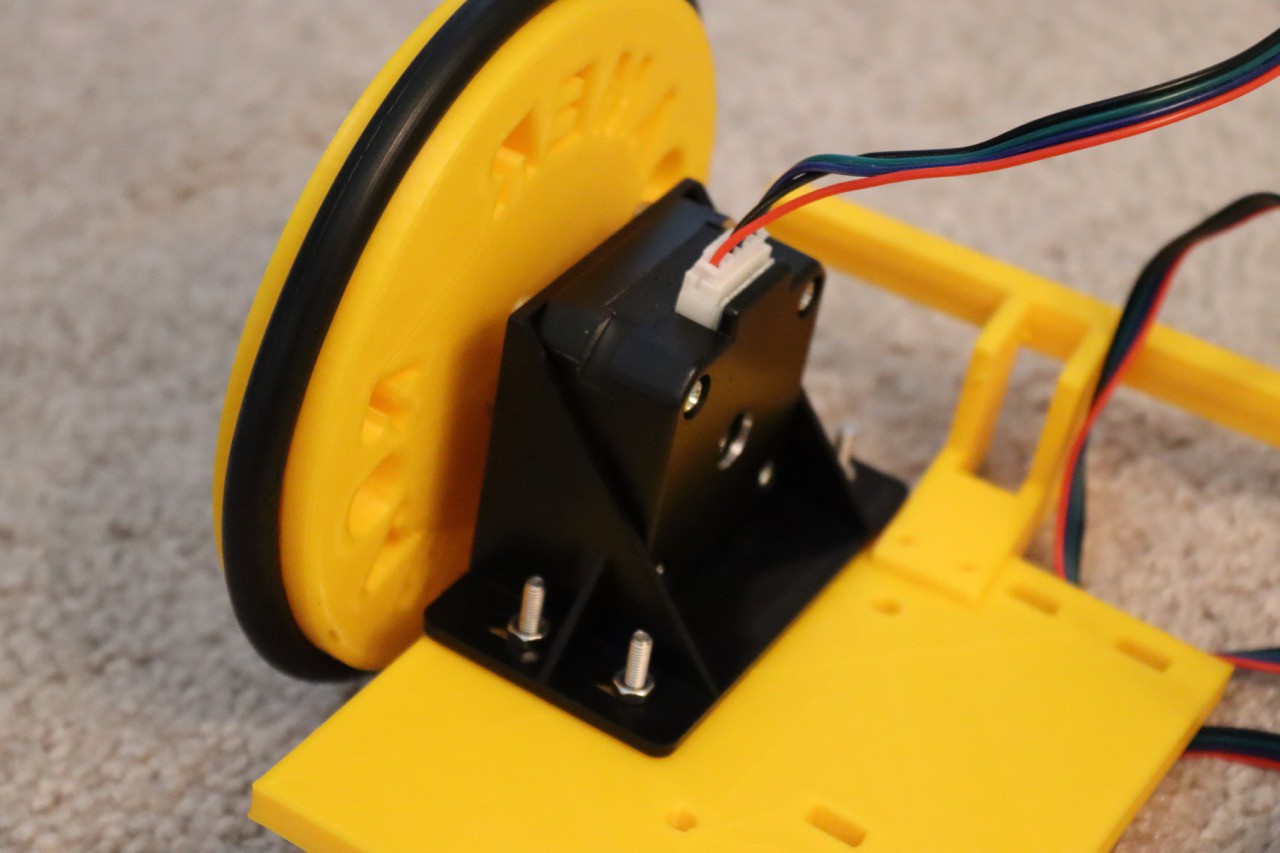

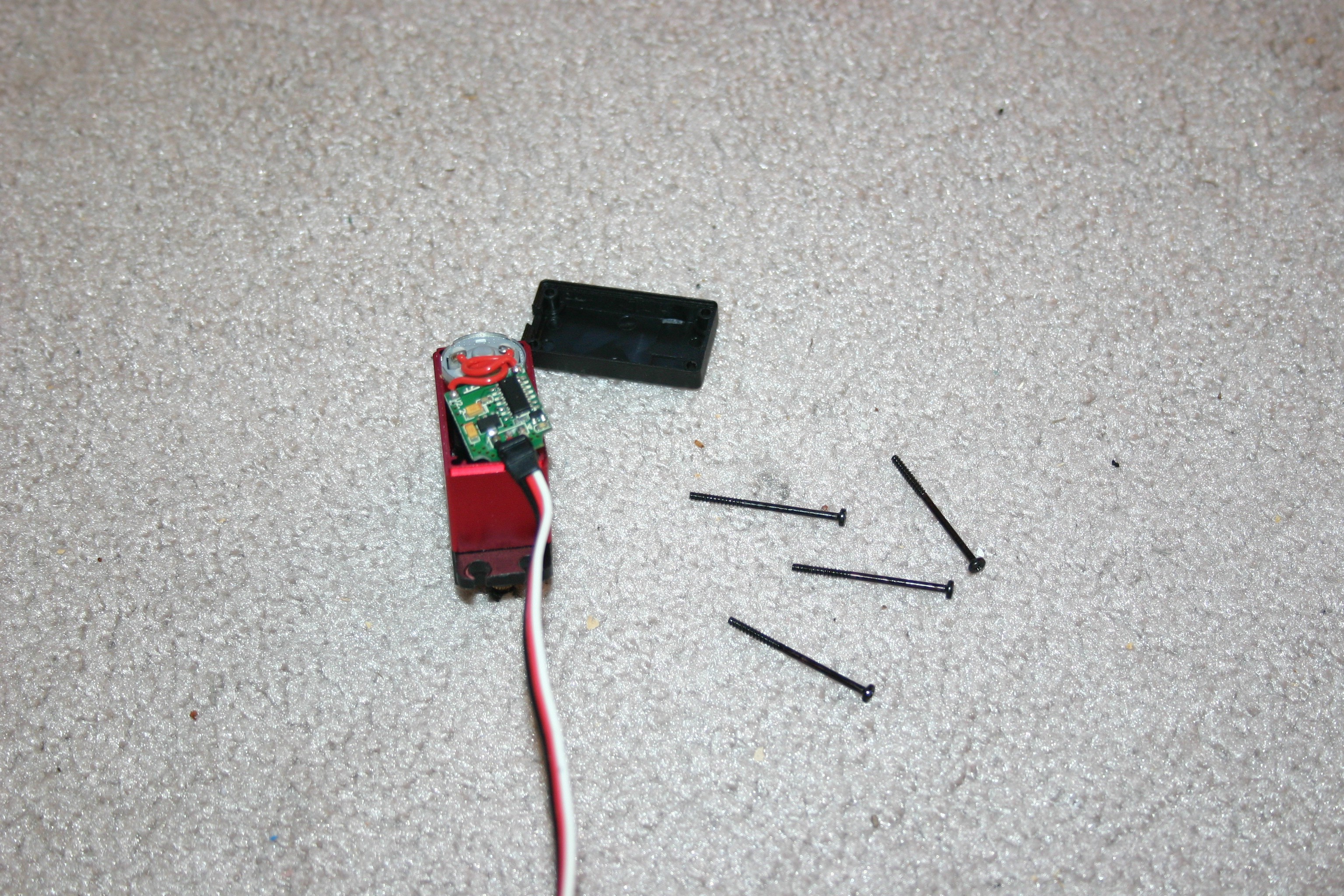

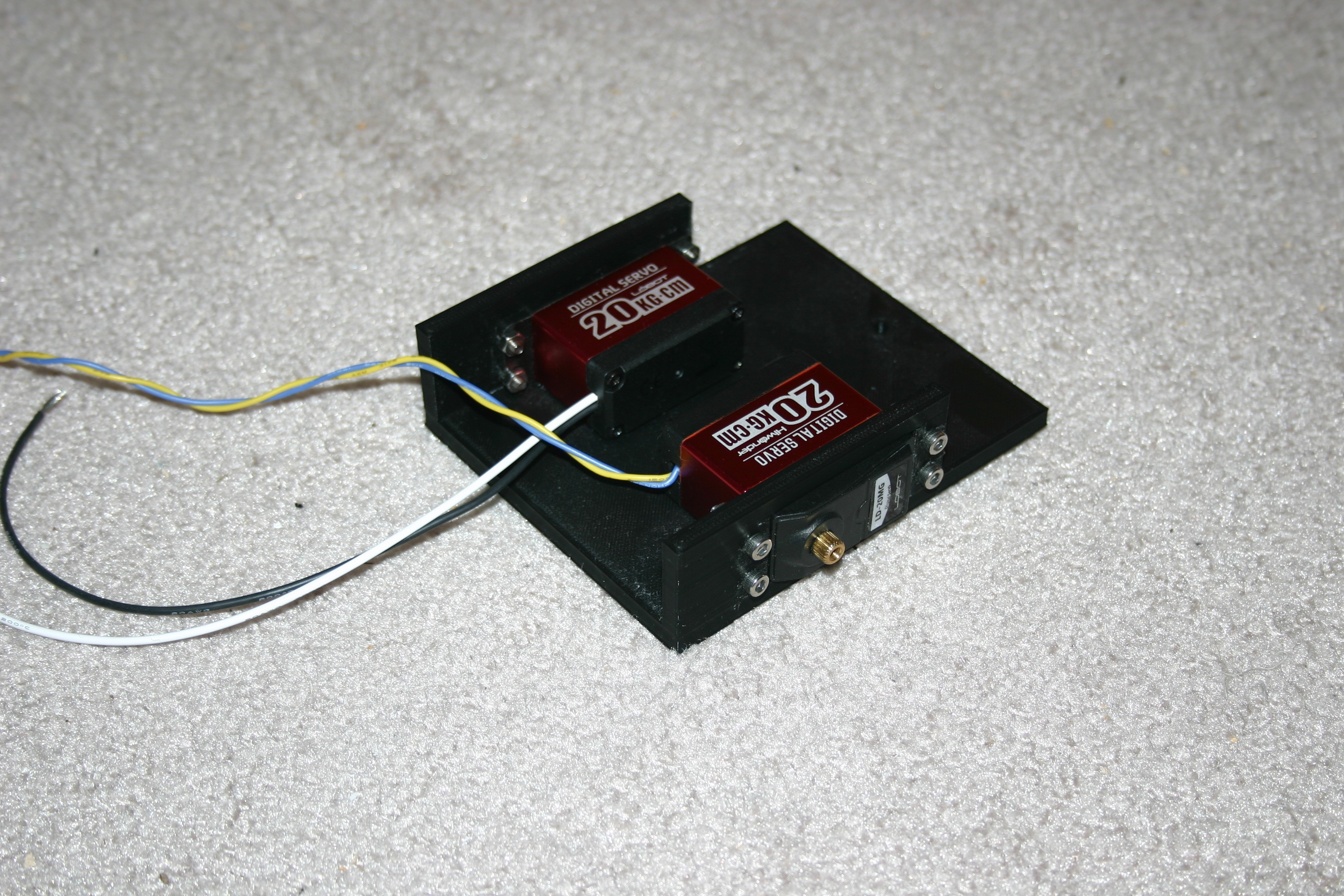

08/20/2021 at 19:08 • 0 commentsStart with the servo motors--I selected metal gear servos that do not have end stops.

![]()

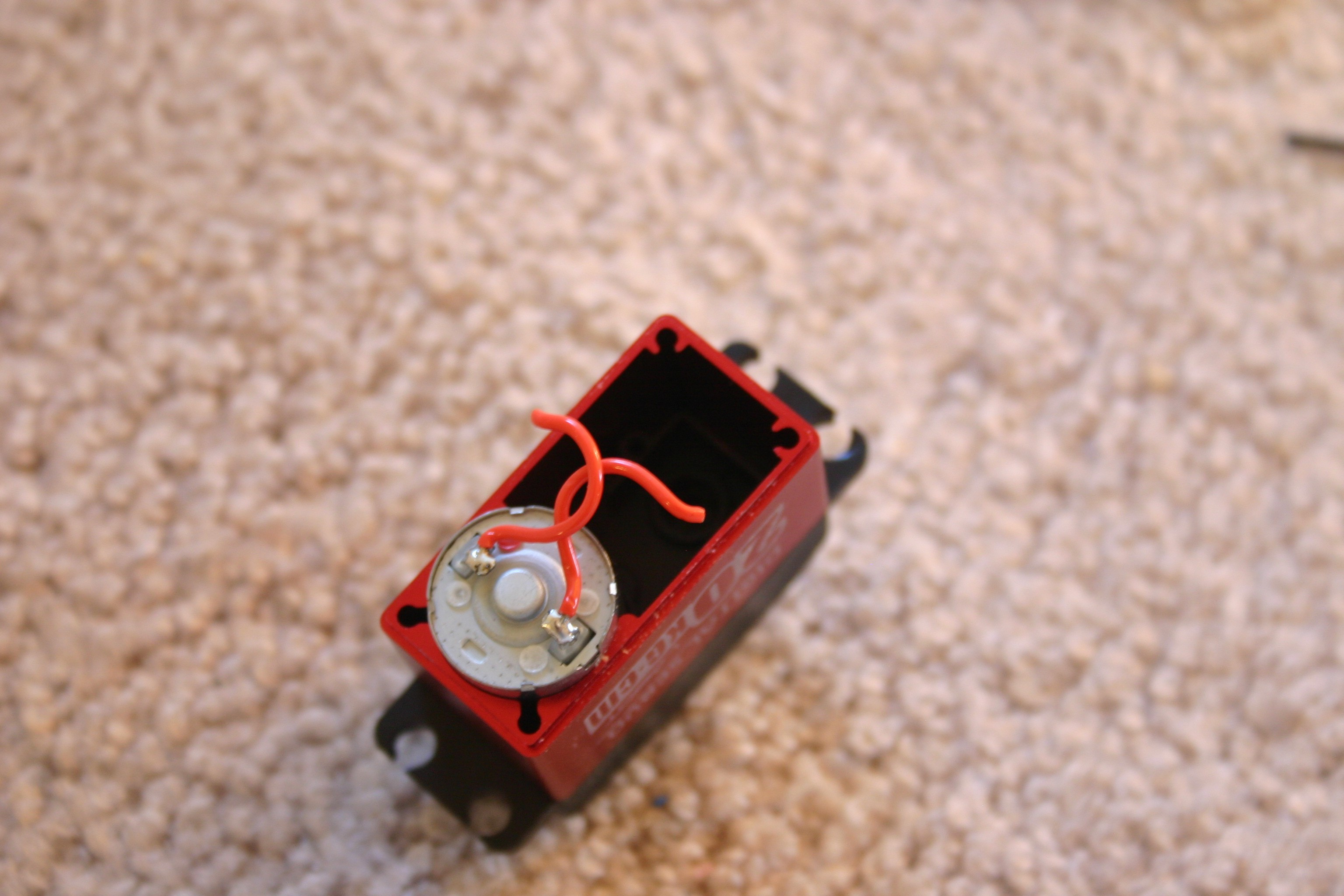

Remove the circuit board.

![]()

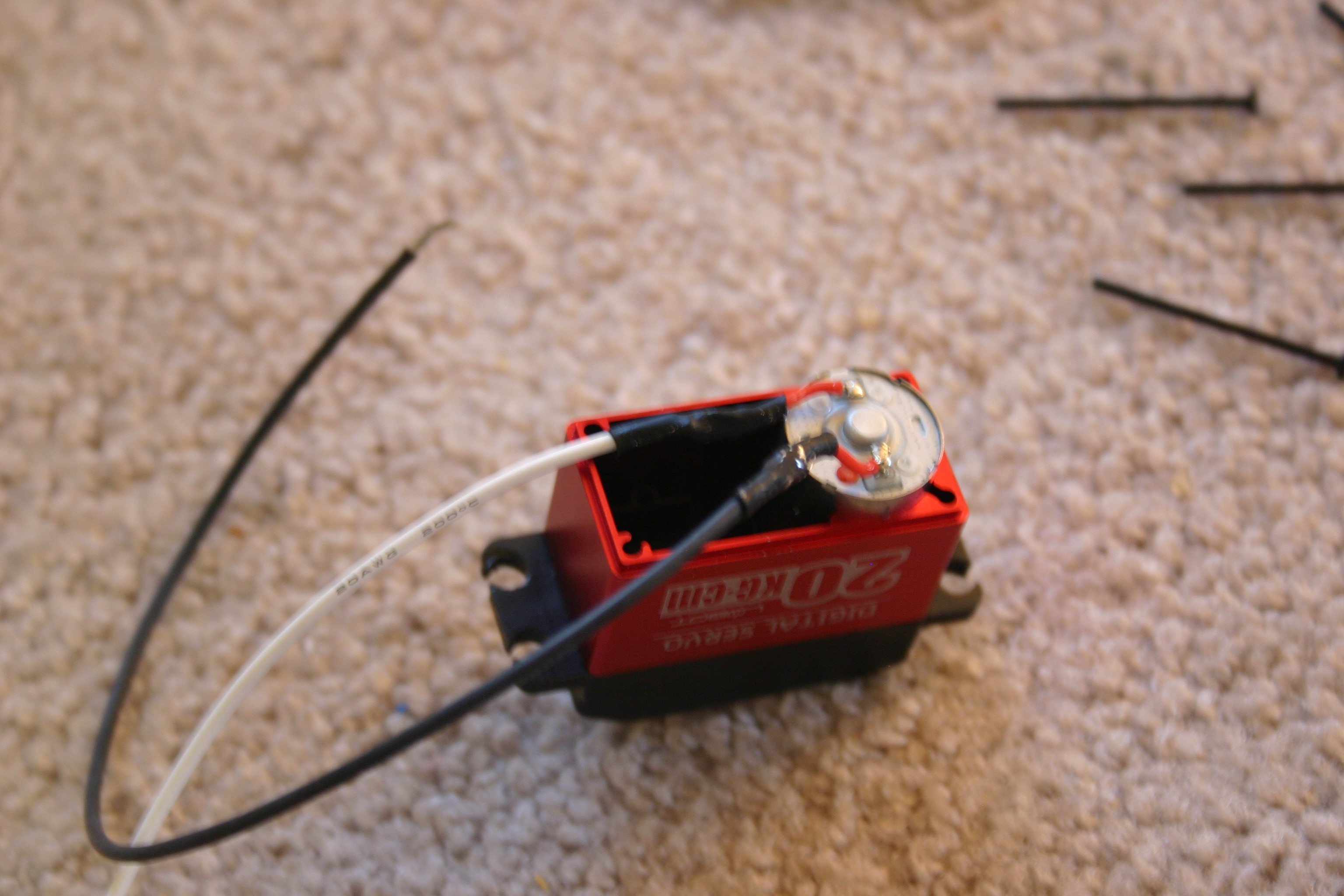

Solder wires to the motor connections.

![]()

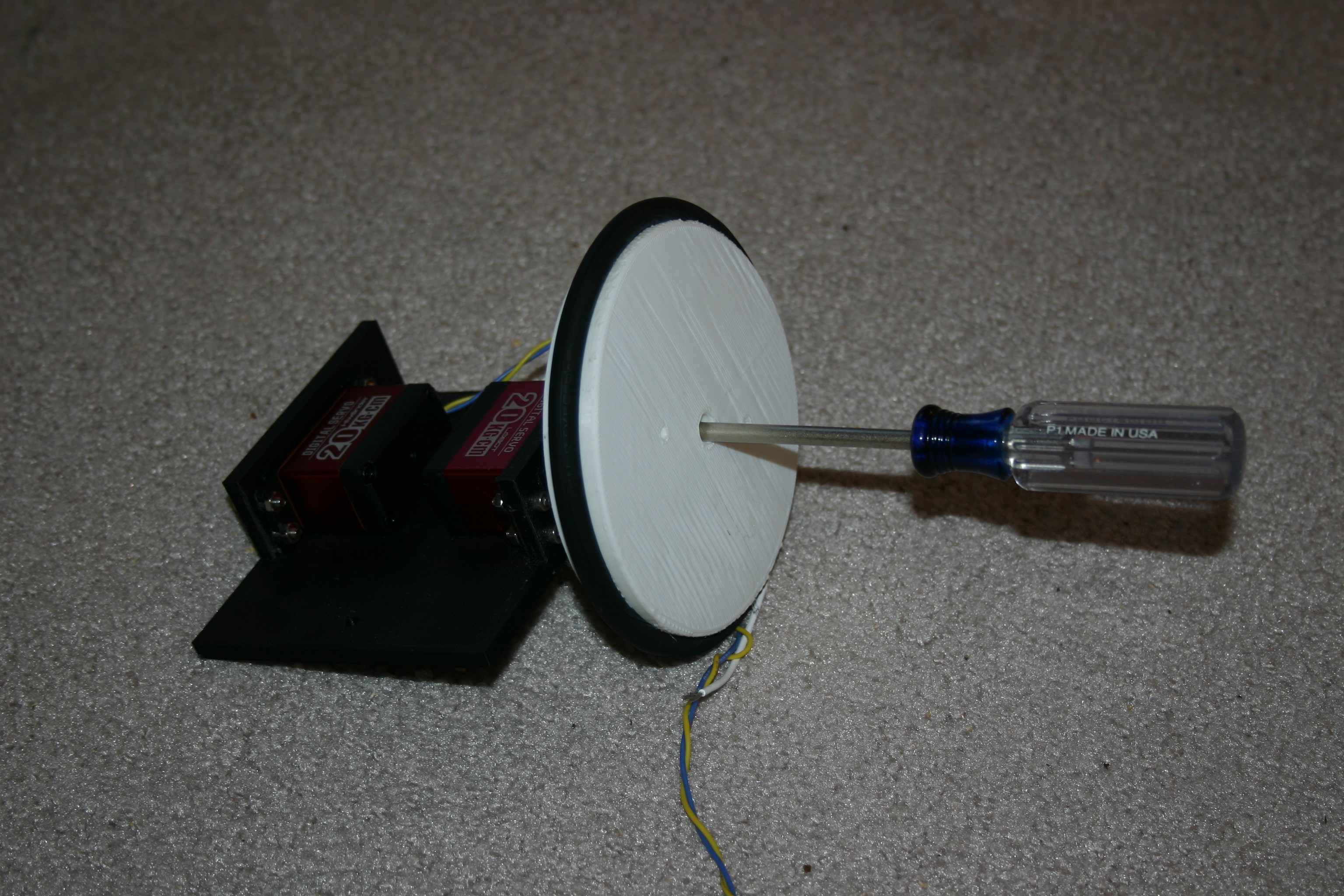

Put the motor back together. Place the vacuum belt (tire) on the wheel.

![]()

Attach the servo horn to the wheel using 3mm screws.

![]()

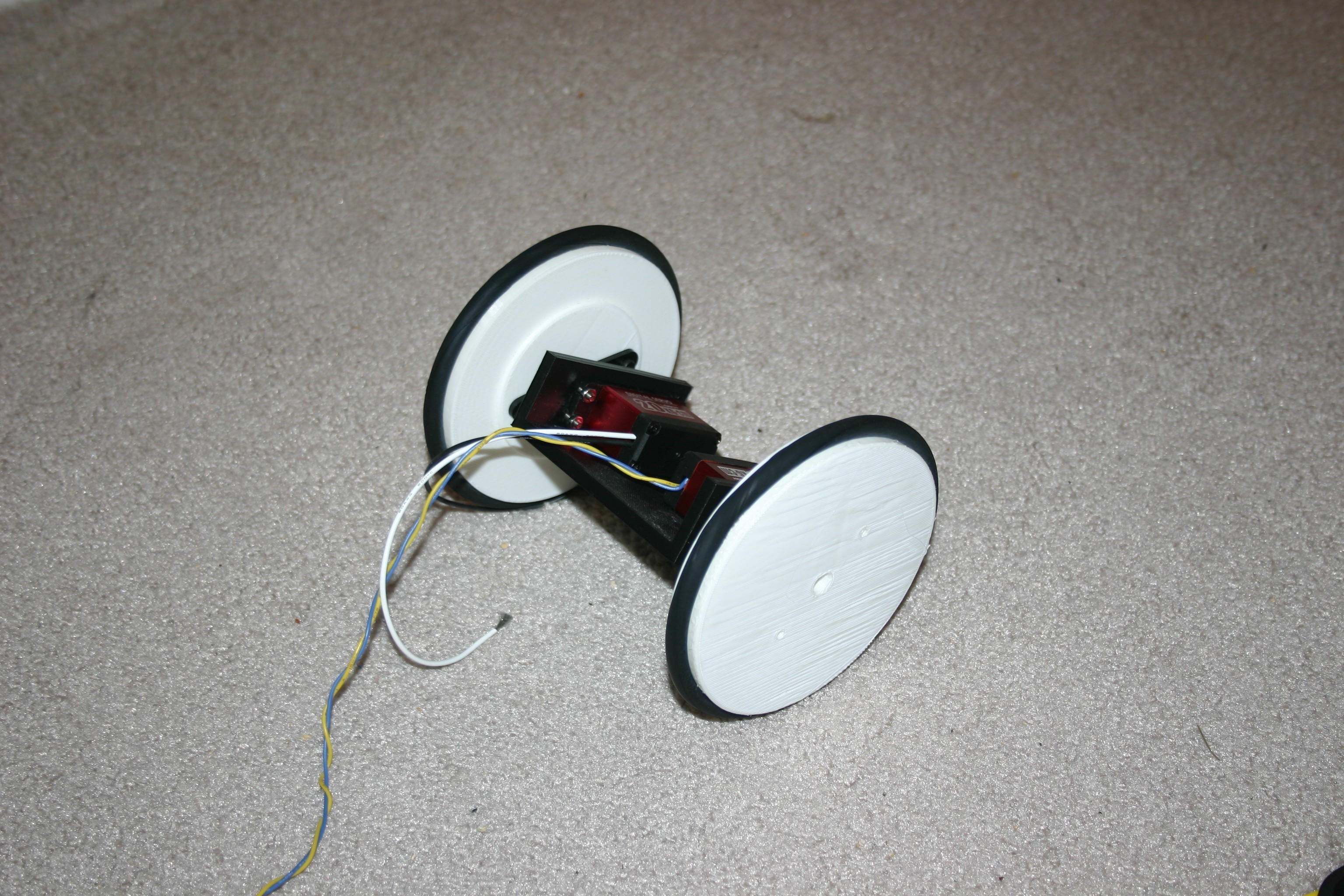

Install the servo motors.

![]()

Secure the wheels to the motor shaft.

![]()

Repeat.

![]()

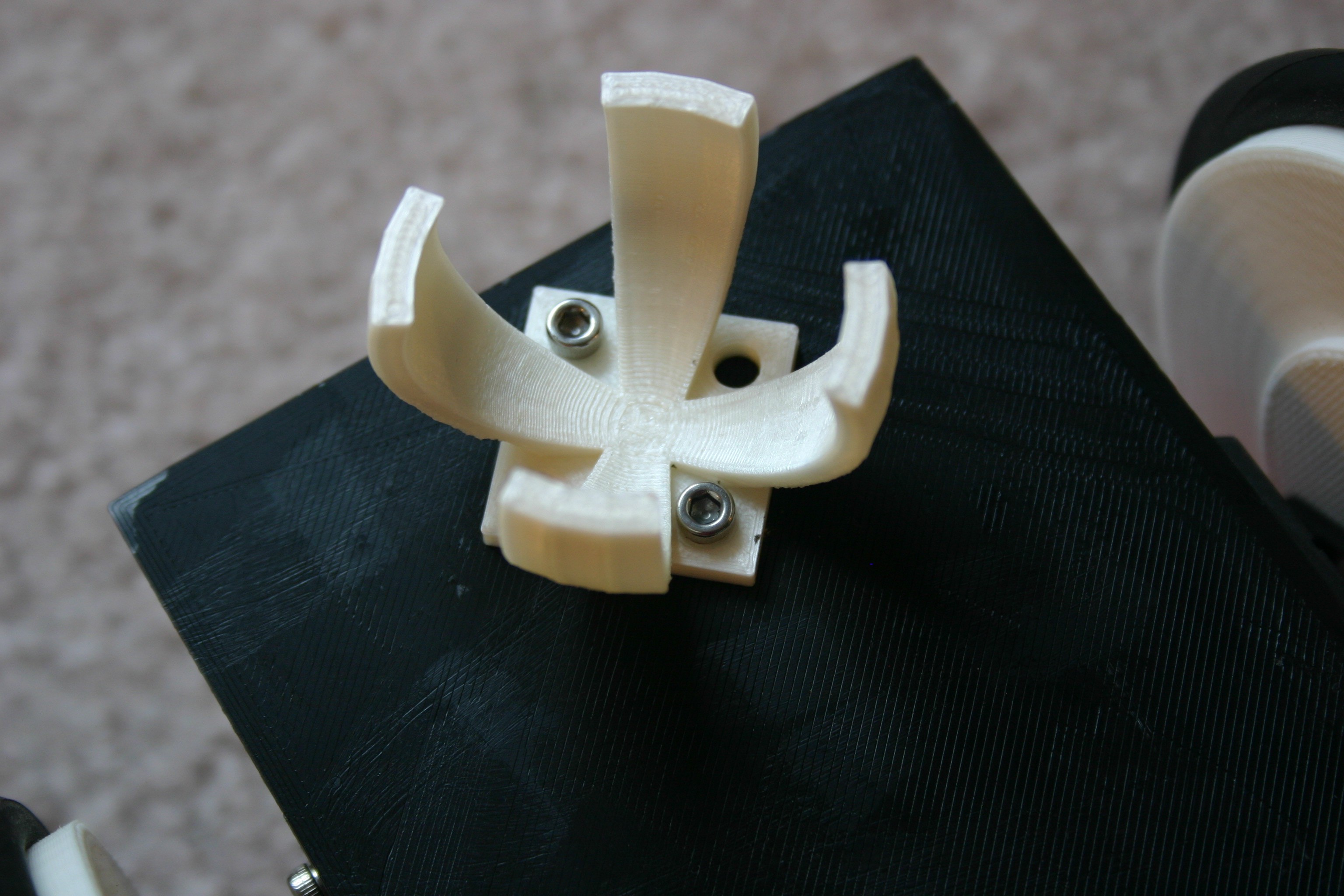

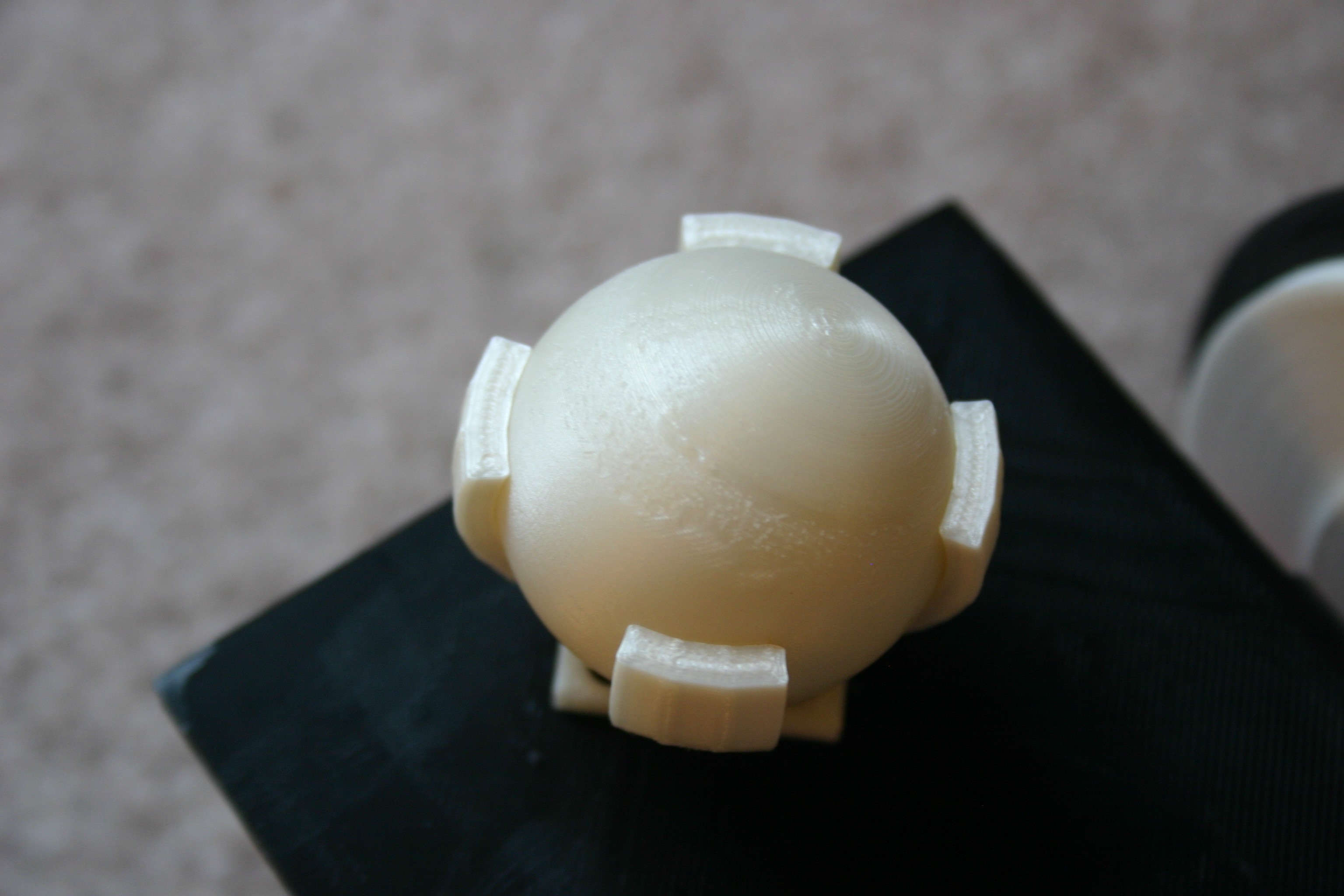

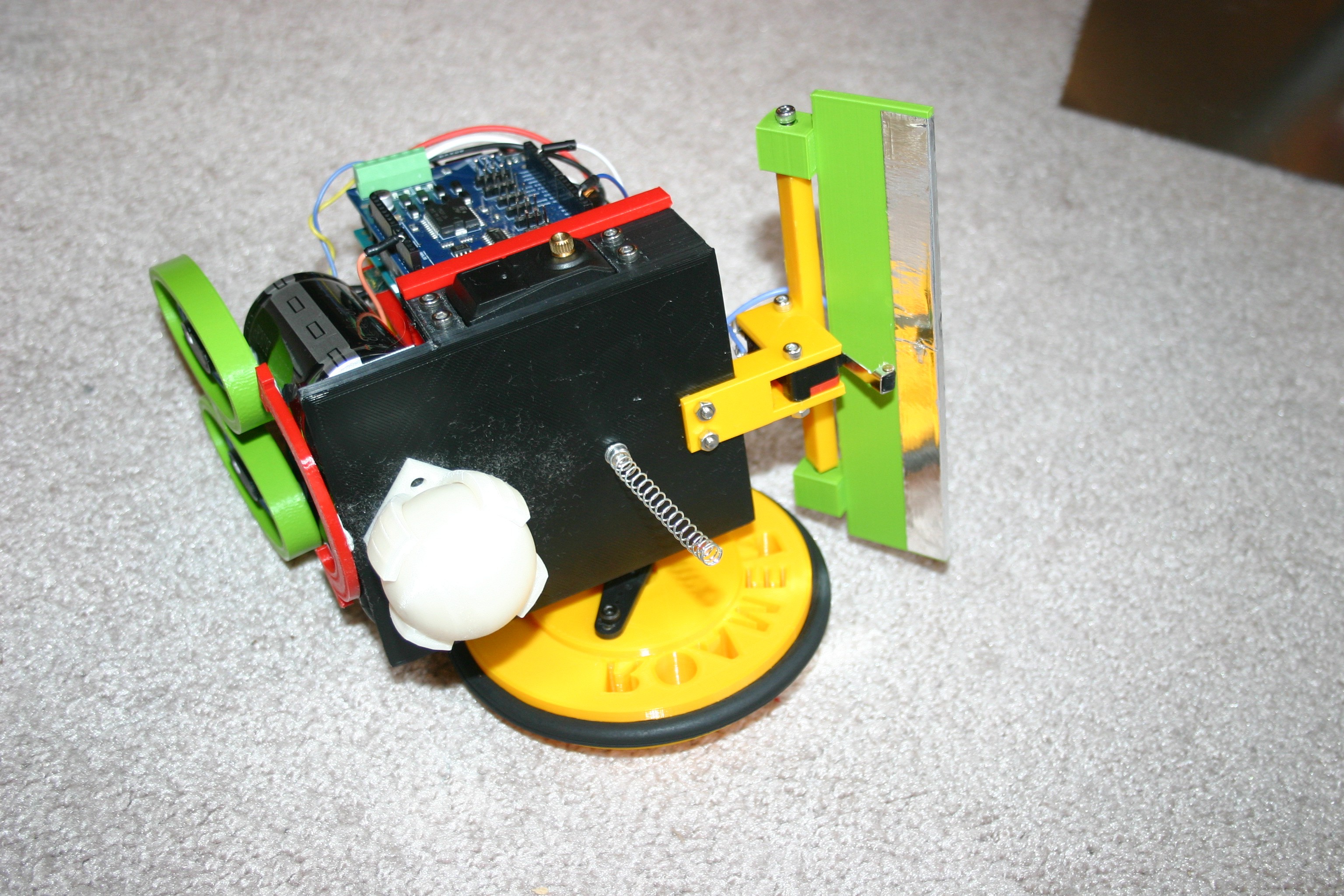

Install the holder for the rear caster ball.

![]()

Insert the caster ball.

![]()

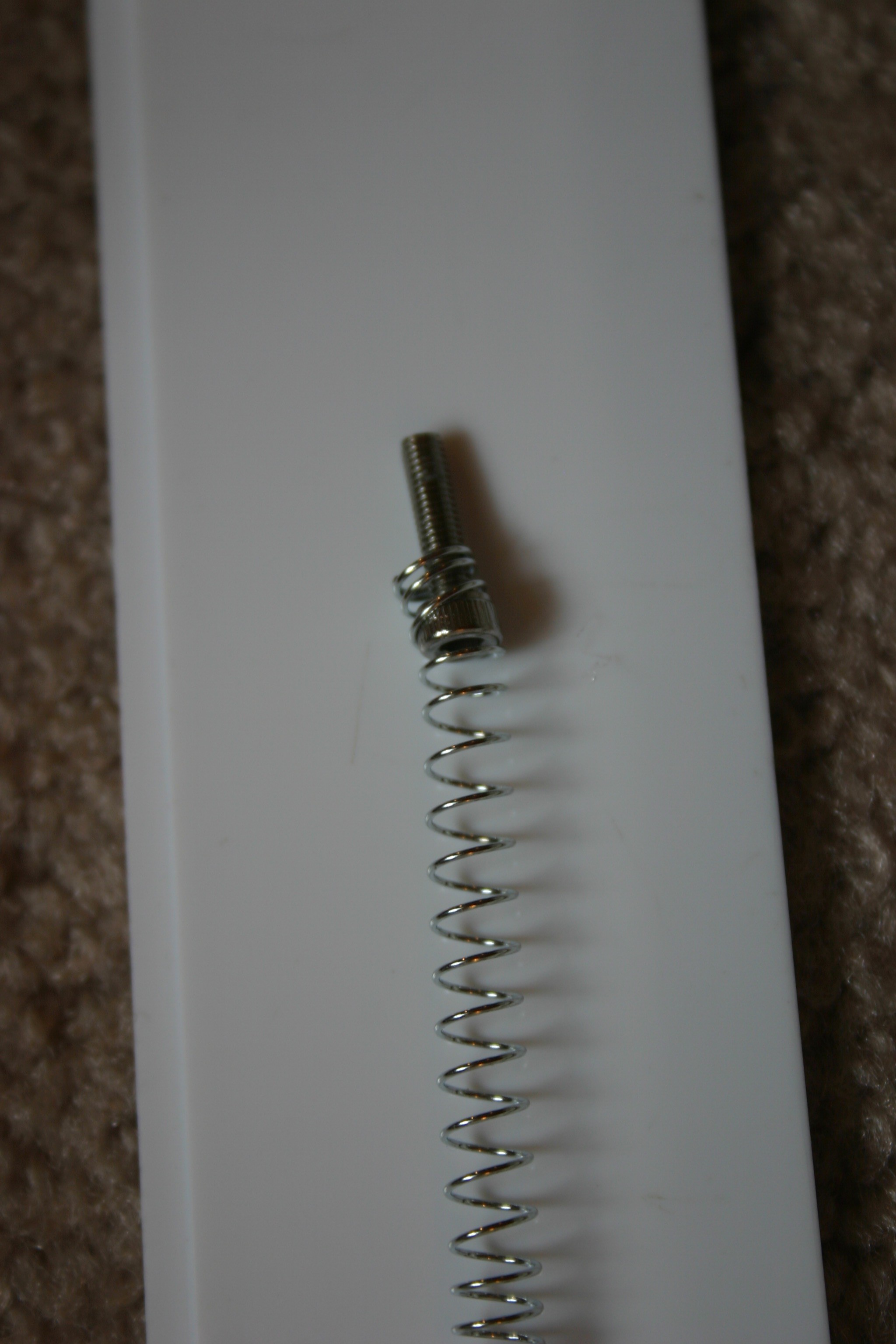

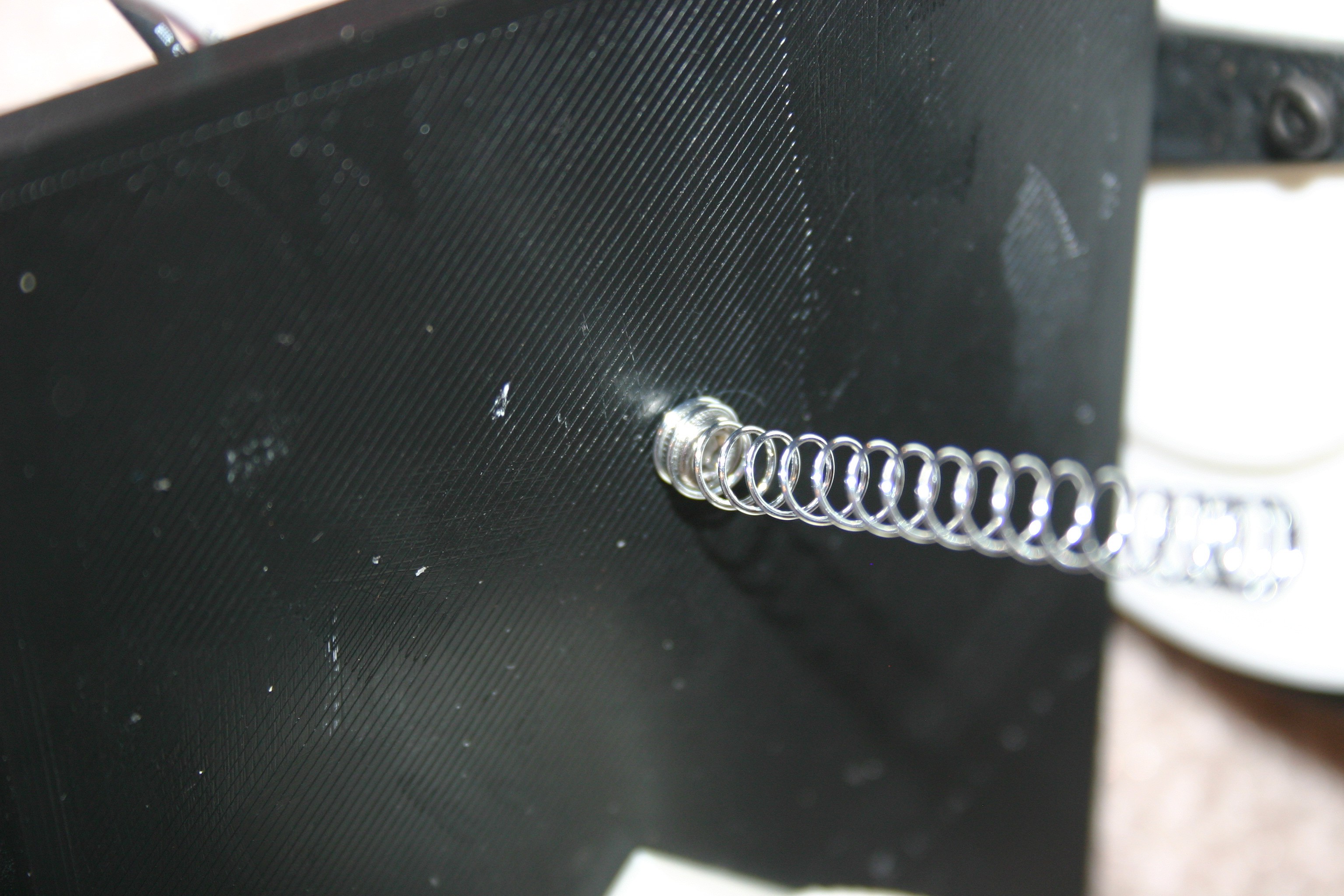

Insert a 3mm screw into one end of the spring.

![]()

Drill a hole in the base and put the screw through the hole.

![]()

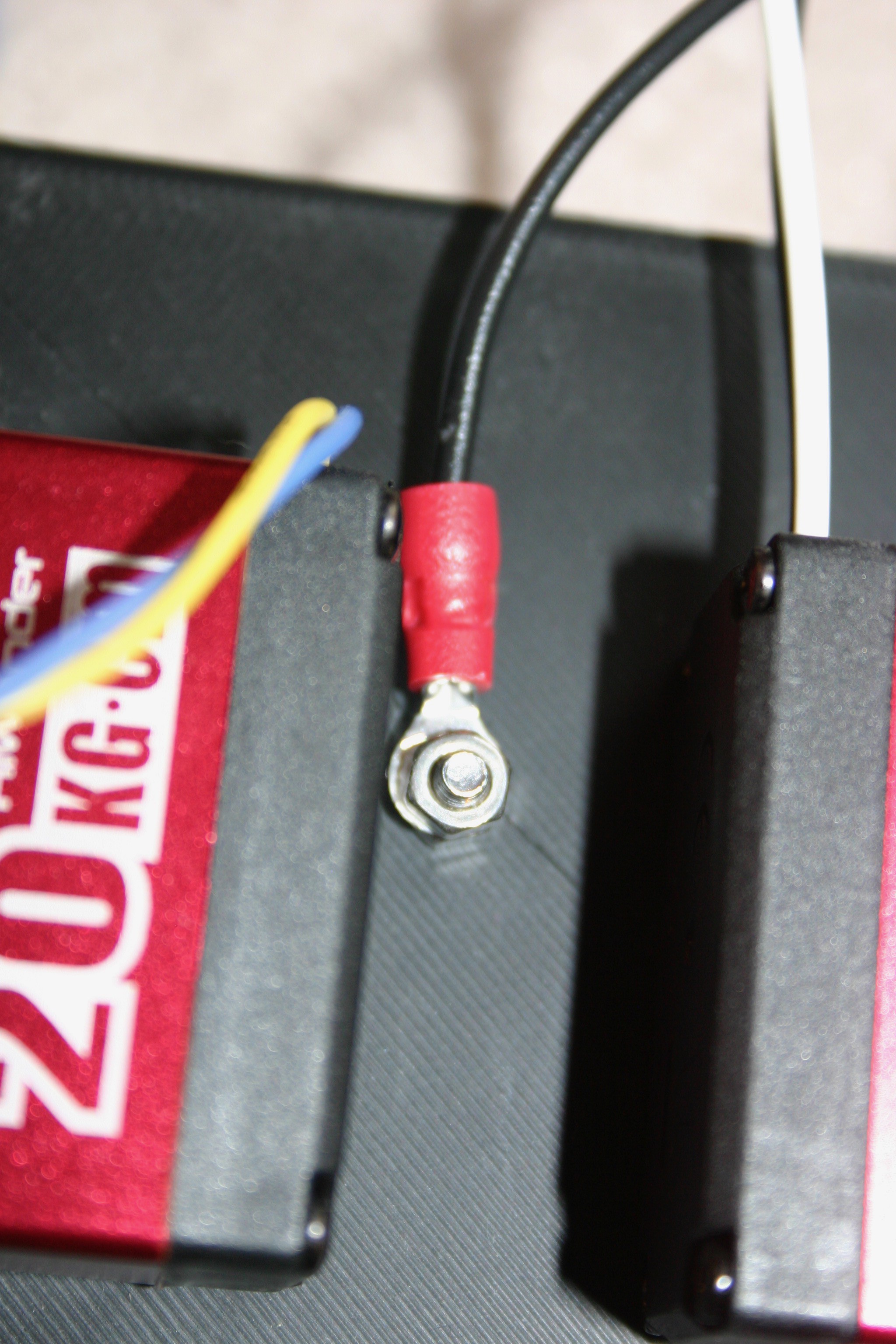

On the other side of the base attach the pickup wire.

![]()

Secure the switch holder to the front of the frame.

![]()

Attach aluminum duct tape to the front bumper. Tape a wire (so that it connects to the foil electrically) to the bumper.

![]()

Install a lever switch in the switch holder.

![]()

Attach the bumper to the switch holder using 3mm screws.

![]()

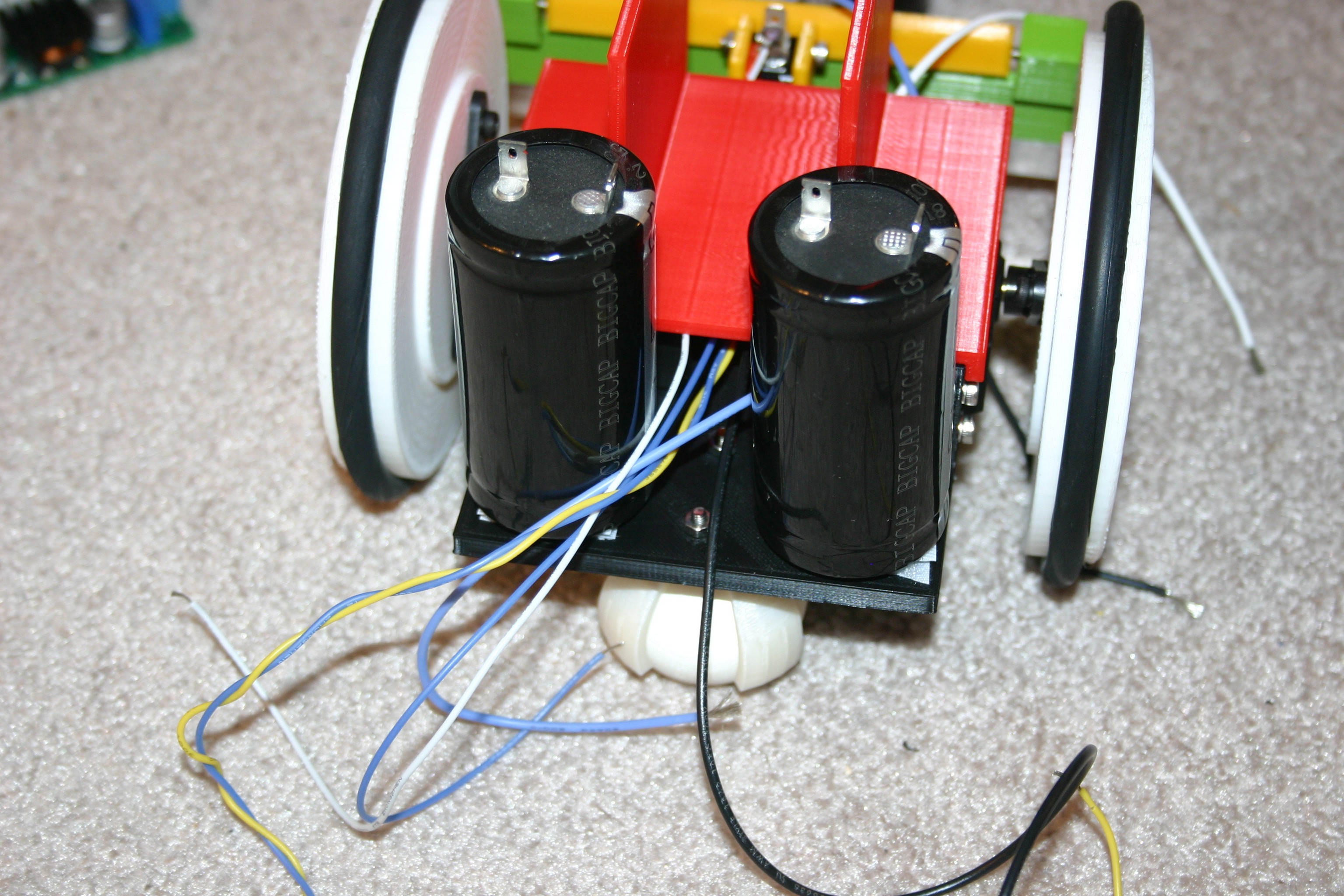

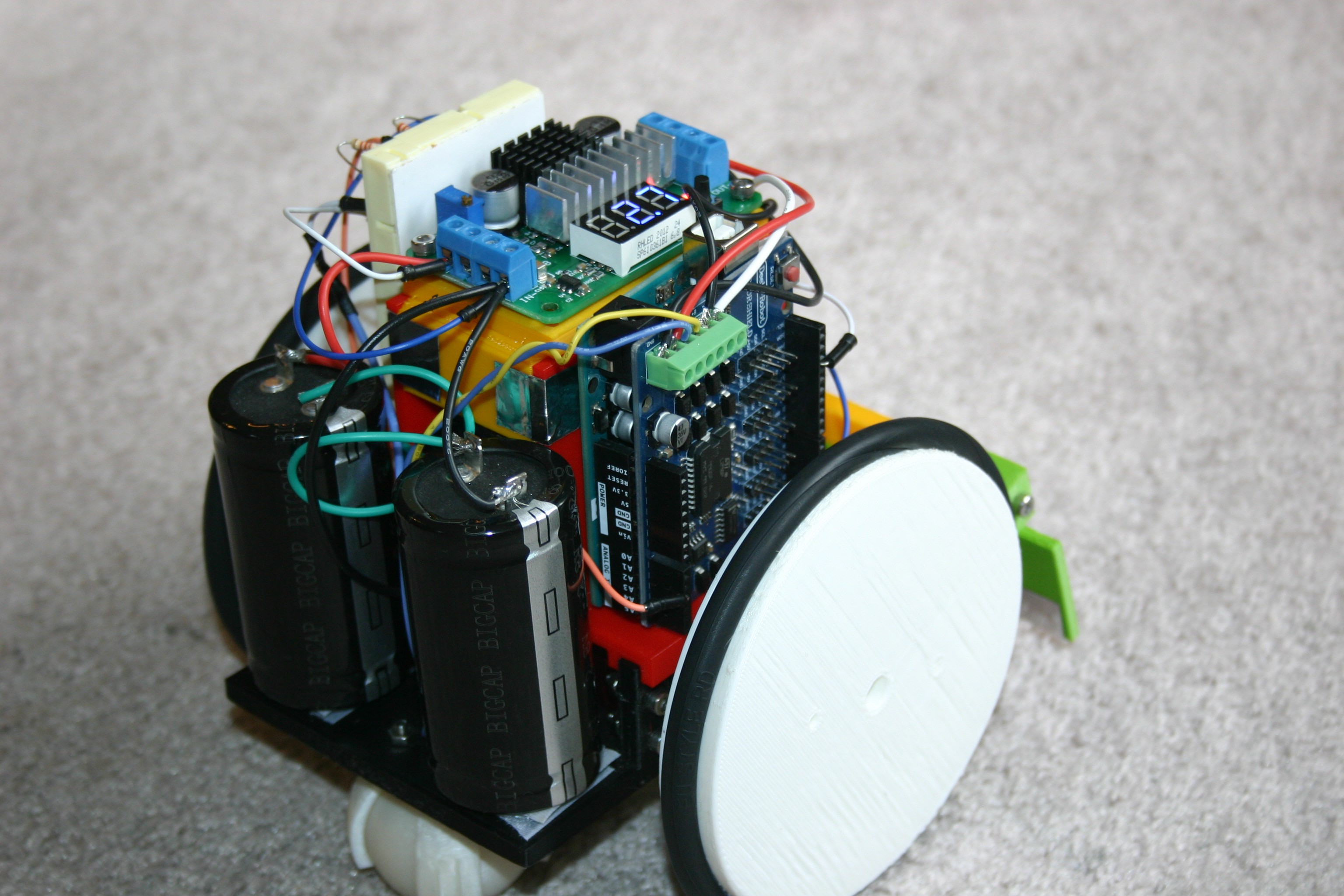

Place the board/capacitor holder onto the frame. Glue together (or lightly melt using a soldering iron).

![]()

Attach two capacitors to the rear part of the frame using Velcro strips.

![]()

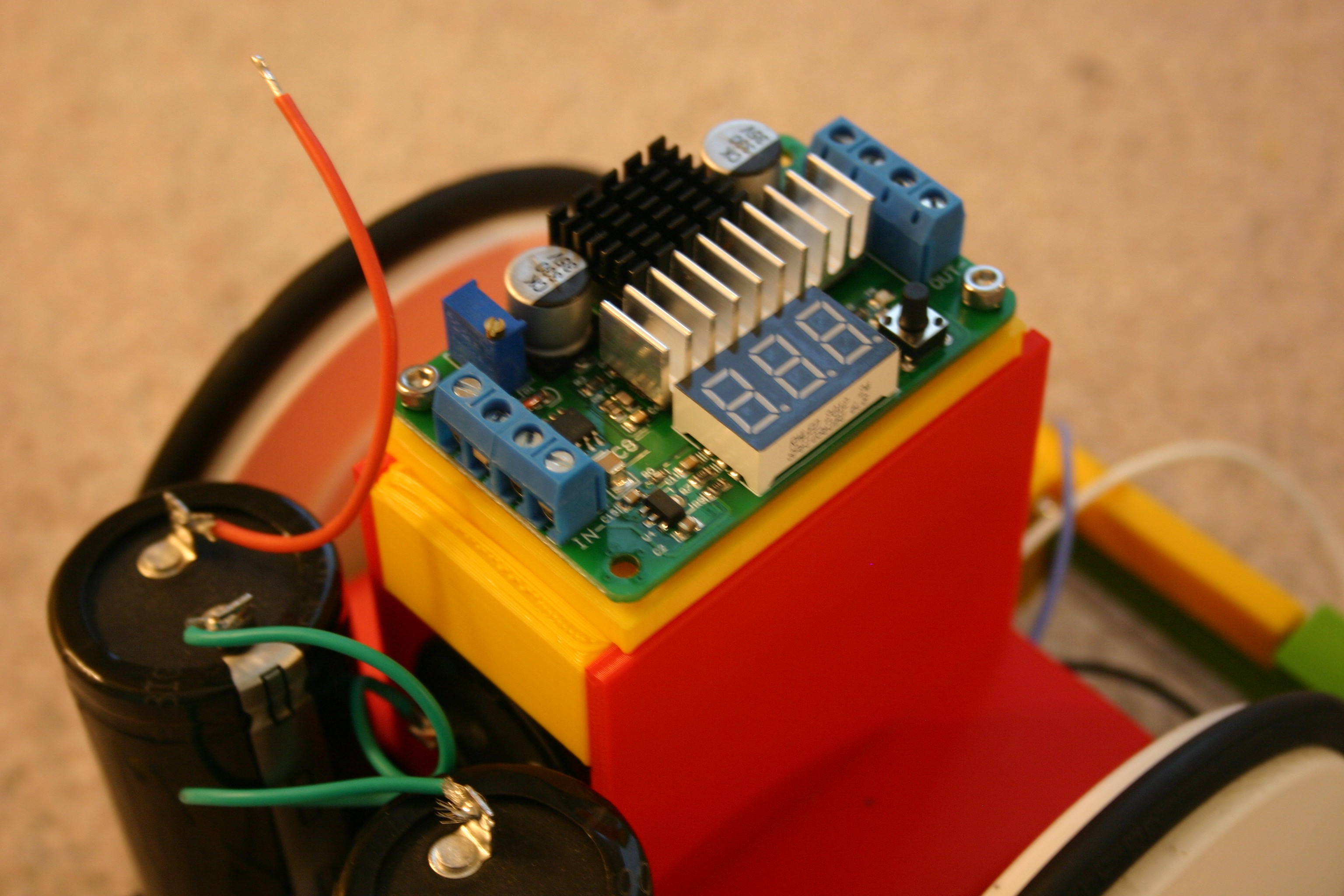

Place the boost converter on the electronics holder.

![]()

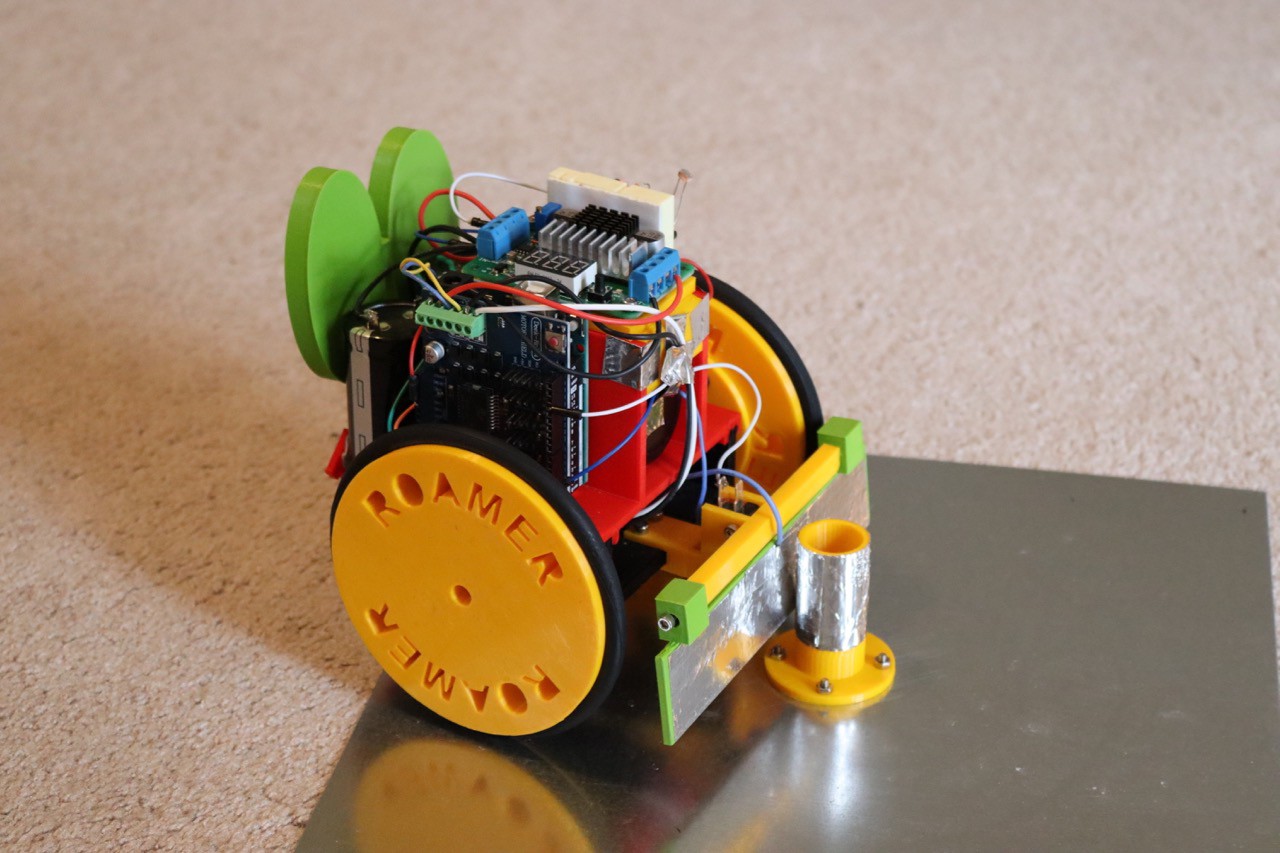

Secure the charge plate pole to the charge base using 3mm screws.

![]()

Place foil tape on the pole--not touching the base.

![]()

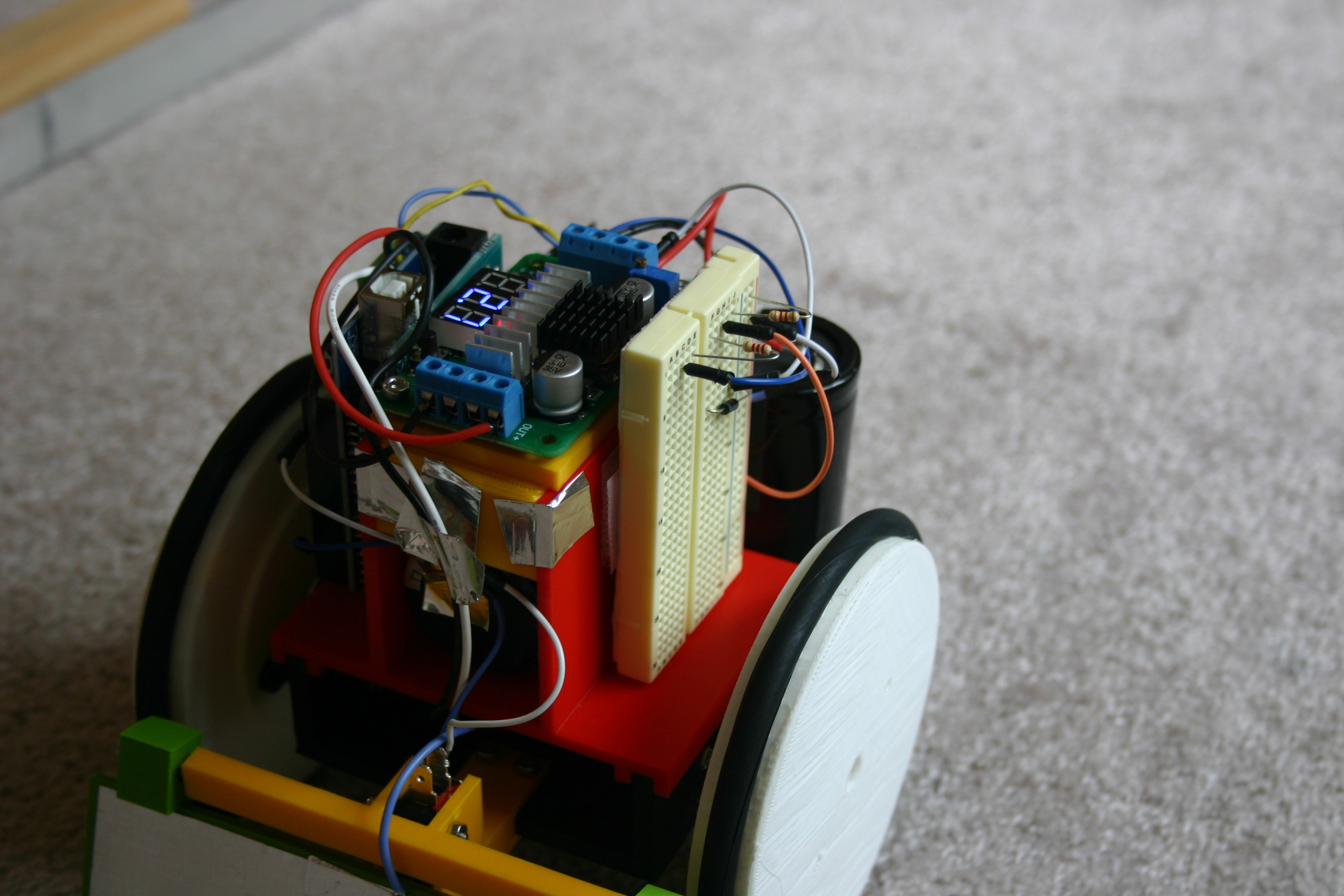

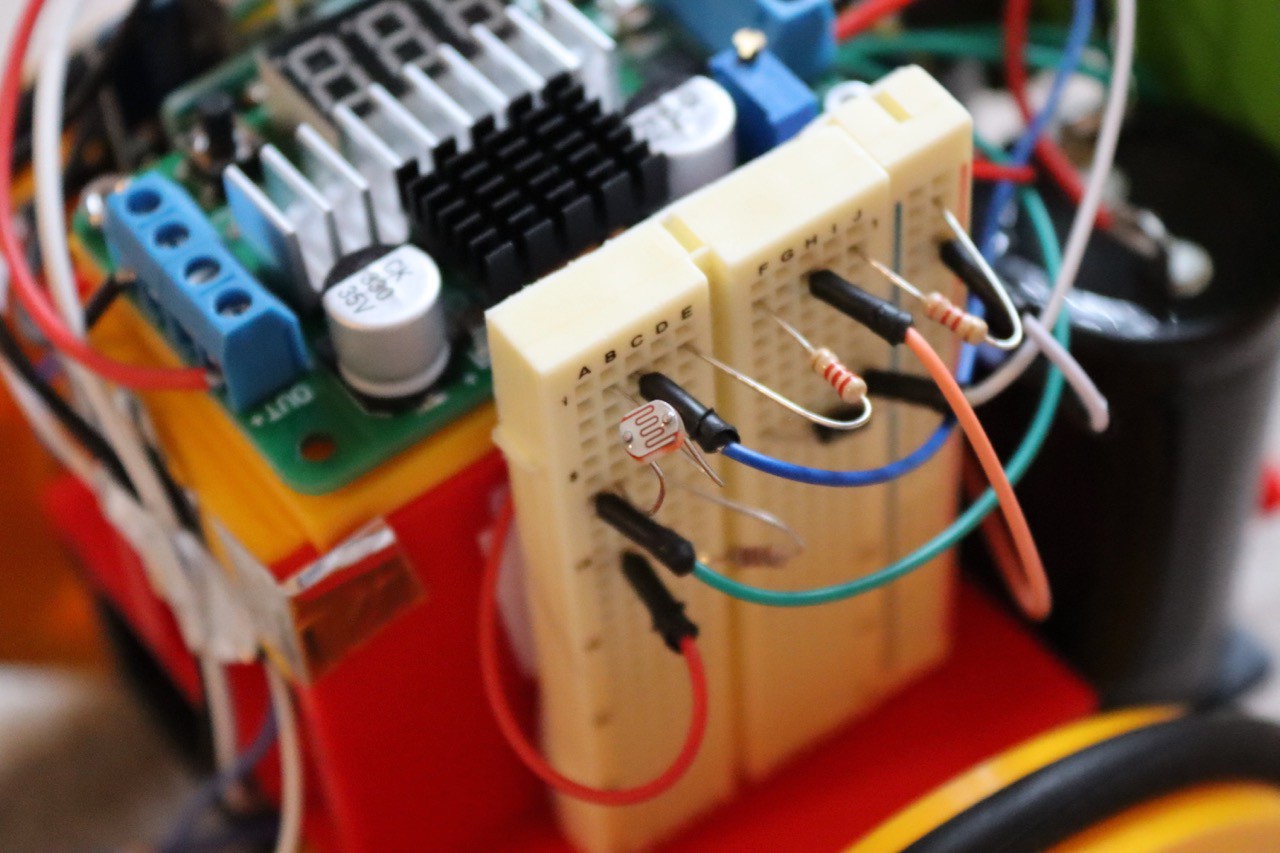

Add the breadboard and wire according to the schematic.

![]()

![]()

Add the Arduino and motor shield. Secure using Velcro.

![]()

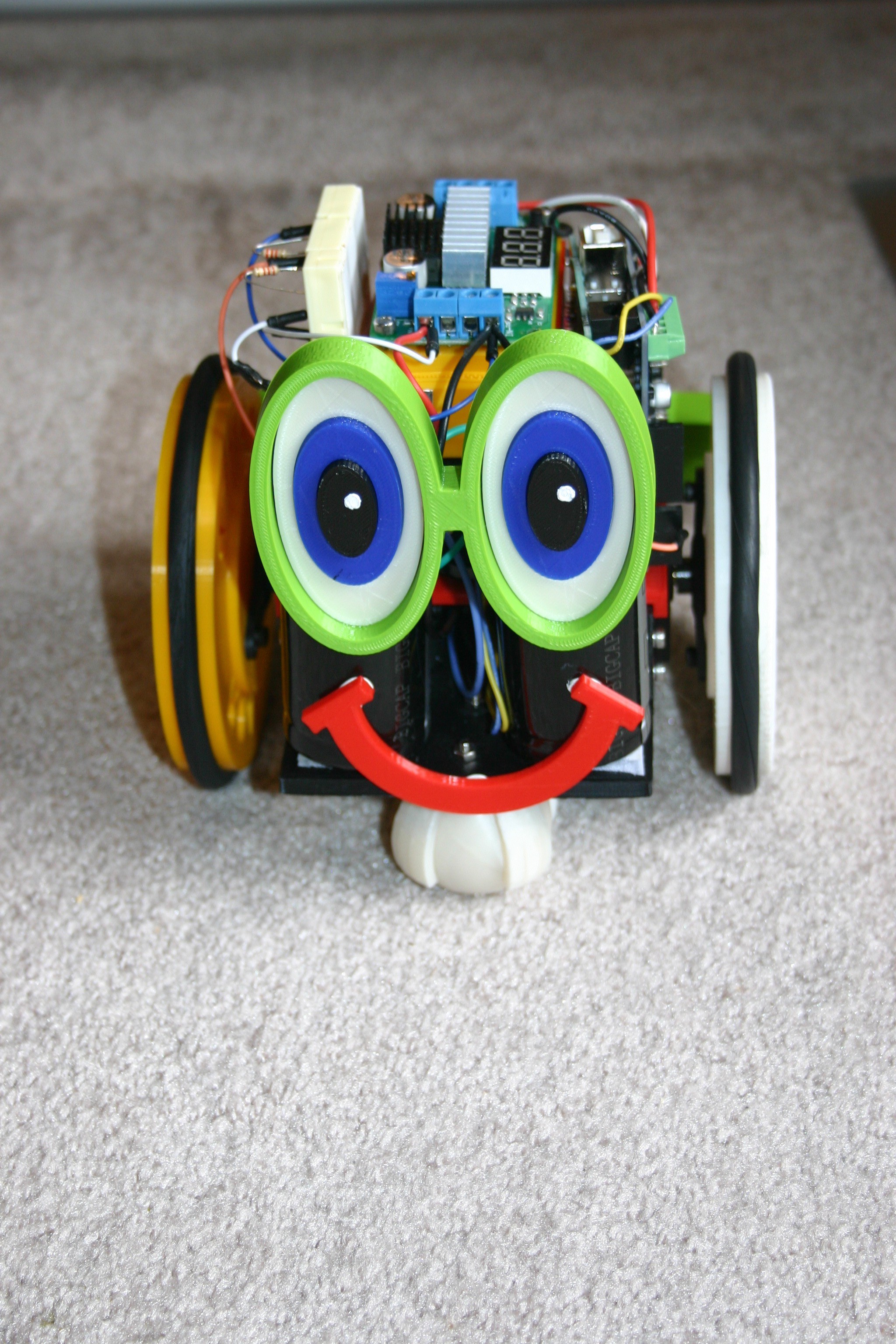

Add the eyes and smile to the back.

![]()

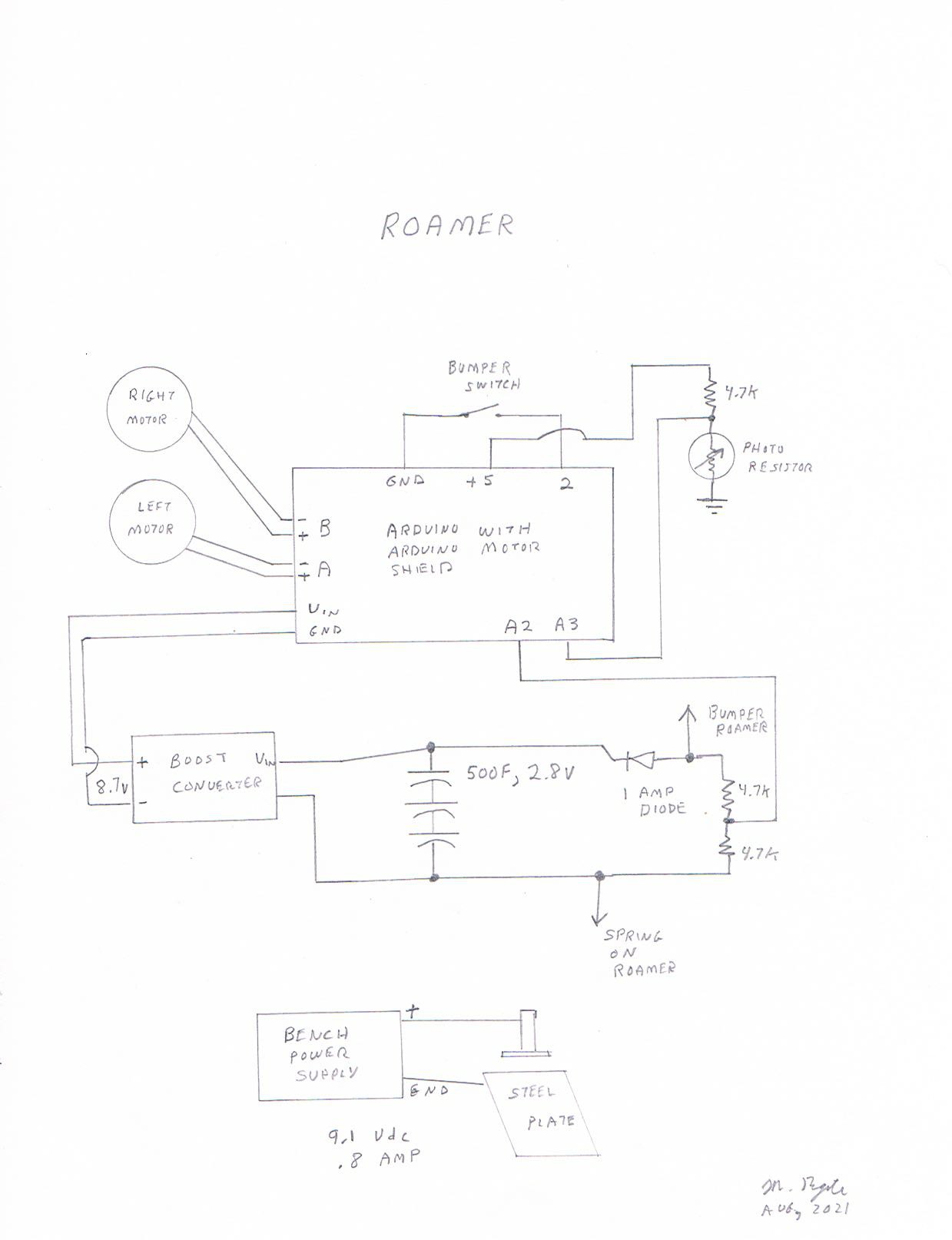

The spring and the bumper are the contact points for charging. The bumper should receive positive voltage from the power supply and the spring receives negative.

![]()

![]()

![]()

The photocell enables Roamer to "know" that it is dark--then remain on the charger until morning.

![]()

Roamer, the Self Charging Companion Robot

Roamer is a self-charging, switch free, capacitor powered, wandering robot companion.

Mike Rigsby

Mike Rigsby