-

[P - E1]

03/07/2022 at 20:26 • 2 commentsConstant force spring

It seems that I've been sent the wrong spring here. As you can see from the listing, I'm expecting the spring to be around 8-9cm in size and 0.8mm thick.

It seems that I've been sent the wrong spring here. As you can see from the listing, I'm expecting the spring to be around 8-9cm in size and 0.8mm thick.

[Edit 1 - 24 March 2022] - Wear gloves and eye protection when removing the metal band around it. 2 fingers just got slashed when the spring rapidly expanded:

Cheap 608 bearings

I bought the black ones on Amazon UK almost 2 years ago (April 2020) for £16.33, and while the colour wasn't seemingly in stock, the other 3 colours are at around the same price (£16.99), suprisingly.

I cleaned the black bearings as I assumed I'd have to do something when I got them; these bearings are drastically cheaper than even the second cheapest option I could find. To my suprise, 96 black bearings seemed to roll fine. These new green bearings also look fine. They're both no butter but I'm on a budget, but I feel like the oil(?) coating the greens are sticker than when I was cleaning the black ones. That's another 100 bearings I've got to clean up to see how many of them are good.

The design so far only calls for 144 bearings, so I should have plenty of spares on hand.

-

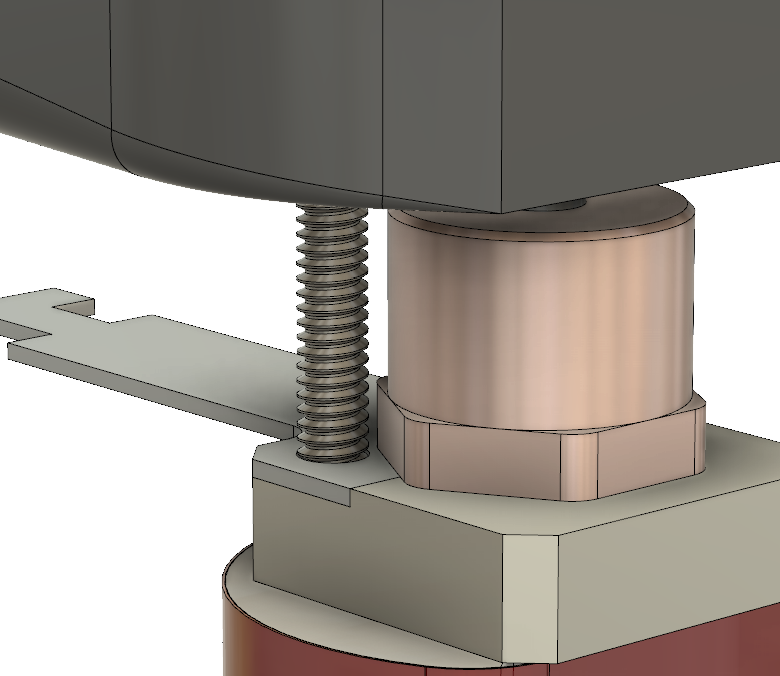

[M] Current Modelling Progress

03/06/2022 at 20:55 • 0 commentsThis is the current location I am with modelling (the [M] tag):

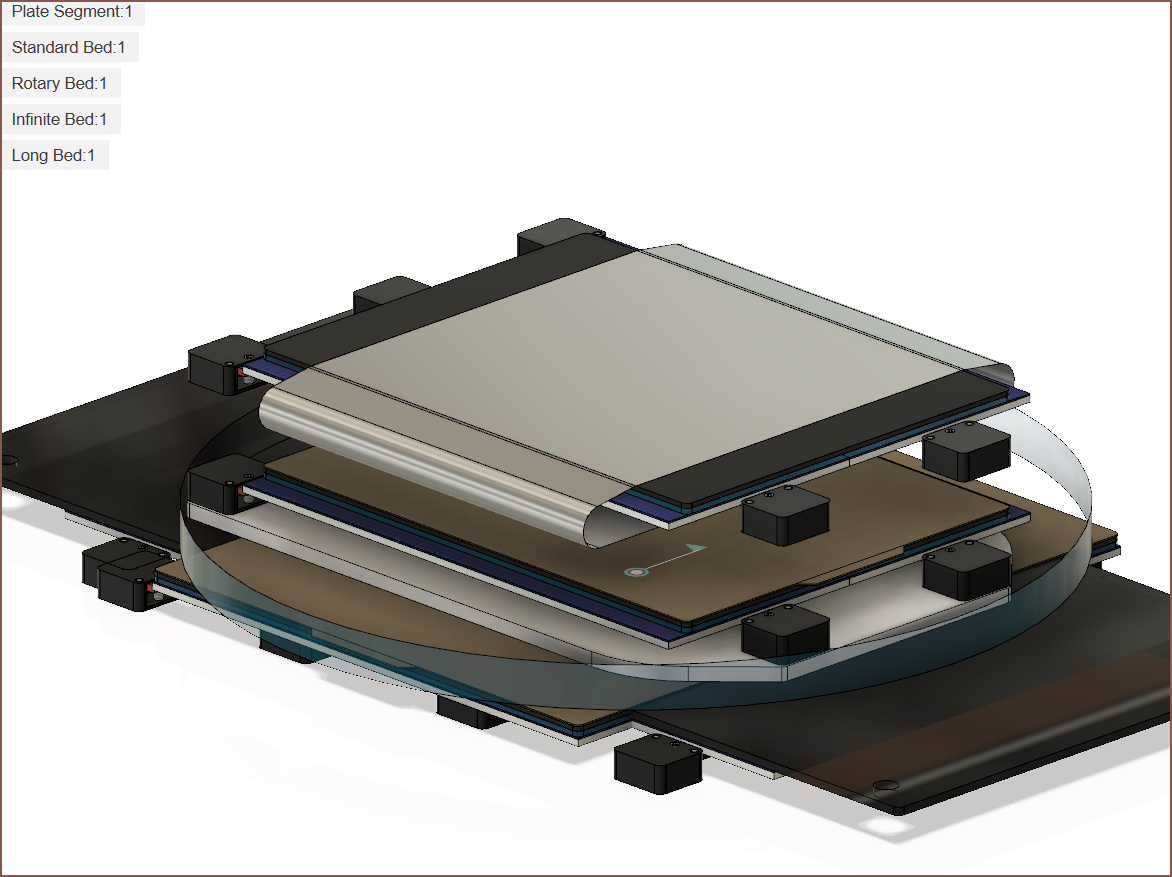

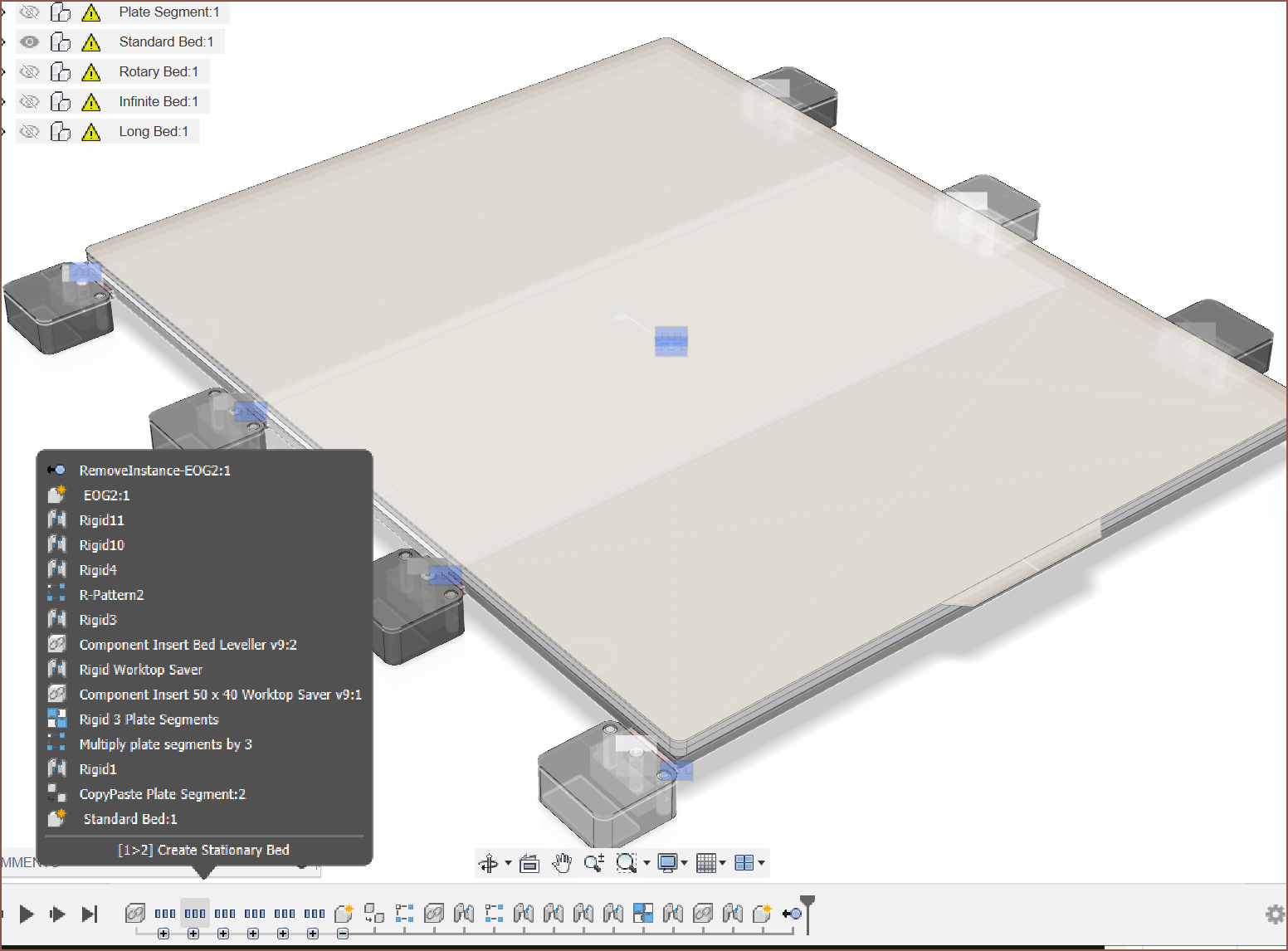

Beds

Each bed segment is 166x400 such that 2 of them make a 333 x 400 bed (used in the belt and rotary beds), the default of 3 makes a 500 x 400 bed, the same size as glass worktop savers, and 4 can be used for 667 x 400 of heated area. 900 x 400 glass was the cheapest stuff I could find. Technically, 5 for a 834 x 400 bed can be done so I'm going for 900mm instead of 700mm or 800mm glass to keep my options open.

In this file, I'm also trying out some new ways of keeping the Fusion 360 timeline ordered, such as [X>Y] for "multi-timeline" changes, and creating and subsequently removing an "End Of Group" component so that I don't have to keep recreating a group every time I want to add something onto the end.

I also want to get into the habit of naming features.

I also want to get into the habit of naming features.SecSavr Slime

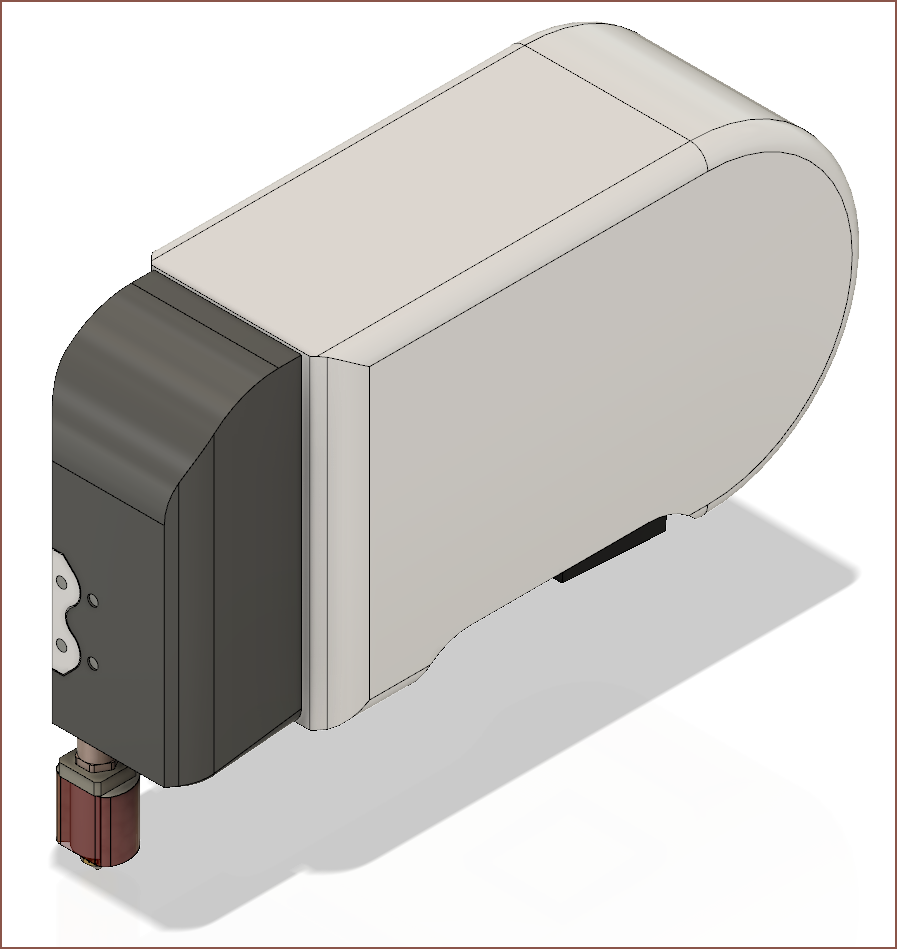

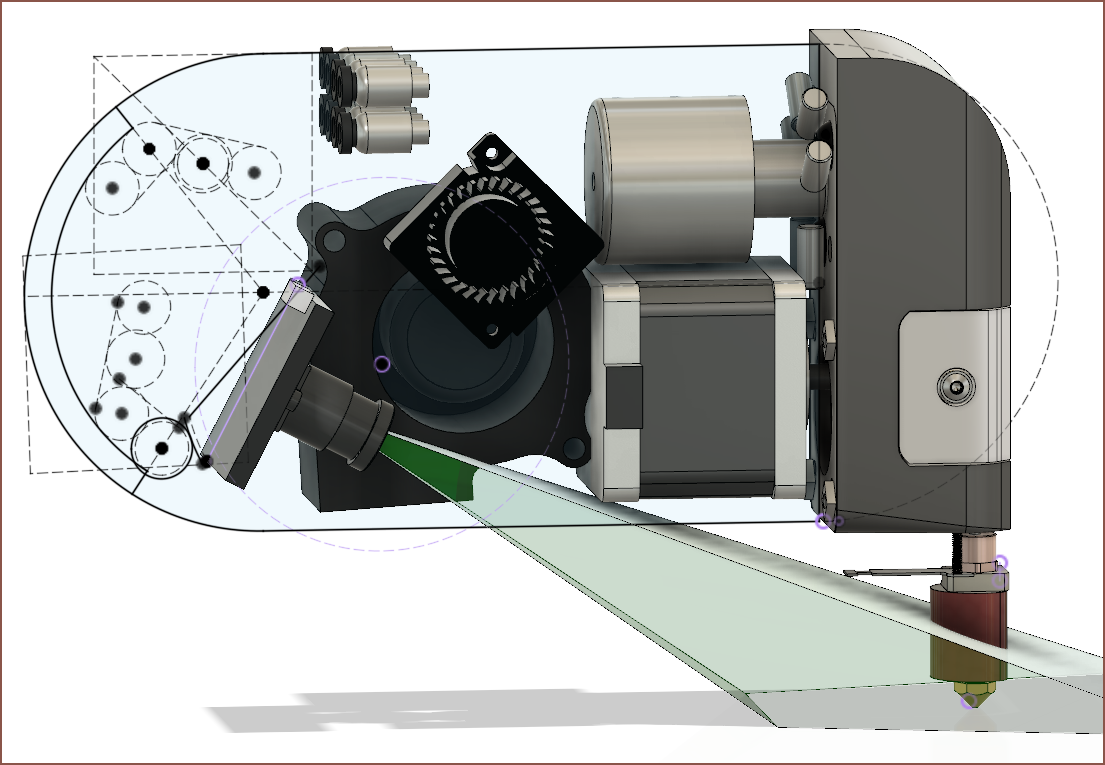

This is the end effector of the SecSavr, with the SecSavr Slight attatched. It uses a 20kg degaussing magnet to attract a 15x15 magnet when unpowered. The pull should be somewhere between 10kg (the 15x15 magnet pull strength) and 20kg (the degaussing magnet pull strength). Then there's a 6028 blower with the 330fps camera (and field of view in green) which is going to be on a motorized pivot so that different melt zone lengths can still be seen and cooled. Lastly, there's the 4010 blower for coldend cooling and the 8 PTFE couplers, for which I need to swap out the design for some cheaper ones I found. The V axis pivot is at the centre of the semicircle.

The Orange Pi was also in here before I decided on including a True IDEX feature, so that the amount of cables connecting the Slime to the main electronics enclosure was reduced. The Slime is designed not to have any outter air vents as I want to try pumping cool air to components that need it if they are to be subject to a heated chamber of 60C.

-

[R] Enclosure design considerations

03/06/2022 at 20:40 • 0 commentsSo it does seem that large amounts of trapped air is how soundproofing is done, looking at this and other videos:

I'll see what other things I can find, as I'd rather have a more expensive enclosure than a SecSavr I can't use because it's too loud.

-

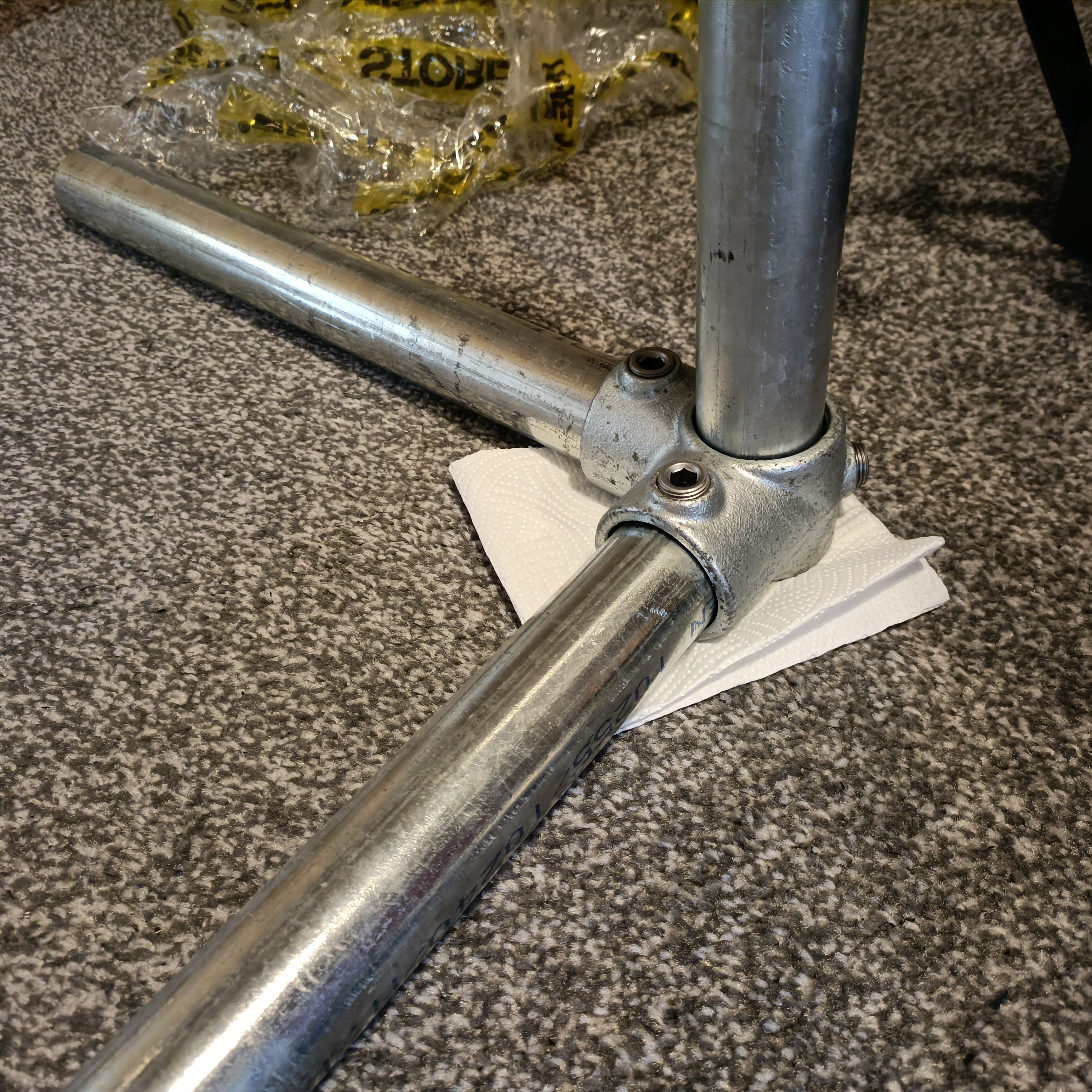

[R] Information for galvanised pipe + key clamps

03/06/2022 at 18:50 • 0 commentshttps://keesafety.co.uk/images/uploads/uk/documents/Kee_Klamp_Tech_Spec.pdf

This is a PDF outlining safe maximum limits for key clamps, which I'll be using with 42.4mm galvanised pipe.

-

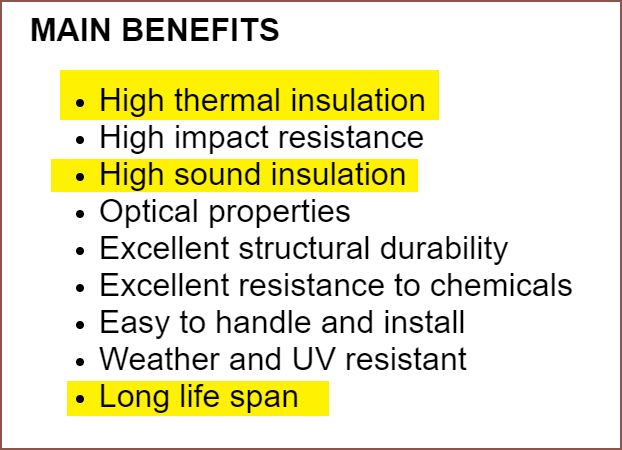

[R] Enclosure Material

03/06/2022 at 14:53 • 1 commentContinuing on my research, I've discovered corrugated plastic due to this.

Coming in white and black variants, it seems that I can get panels large enough for the SecSavr for just a little extra than the acrylic panels for my Hexadecibel enclosure for the Anycubic Linear Plus. As there will be nozzle cameras installed and I'm both looking for ways to isolate sounds (milling is very loud and I don't think there are transparent soundproofing solutions) and easy cleaning, I'm more than fine with opaque solutions.

[Update]

I did a bit more looking around just because 4mm may be a tad thin for the size I want to cover, and I found polycarb sheets which look pretty nice:

and the description sounds even better:

The polycarbonate sheets can be had in either 10 or 16mm, but there are no opaque options other than the somewhat cheap looking Opal. The panels are also more expensive, but I might save in terms of sound and thermal insulation costs.

-

[R] Finding other projects

03/05/2022 at 13:12 • 0 comments[R] = research log

- I've just found a hackaday project that I could learn from to implement my "Auto Paintshop" feature, which I hope can be used to paint full colour prints.

- Here are projects that could help me implement PCB creation:

- https://hackaday.io/project/183939

- https://hackaday.io/project/165491

- https://hackaday.io/project/182467-solderocket

- this is for inserting solder paste

- https://www.youtube.com/watch?v=cU9yRKr6NlM

- solder paste

- This one for CNC:

- https://hackaday.io/project/170164

- Using laser cut wood as the linear slide is an unexpected idea.

- Quite a few for Pick and Place:

-

[P] = Parts received

02/28/2022 at 20:02 • 0 comments[28 Feb 2022]

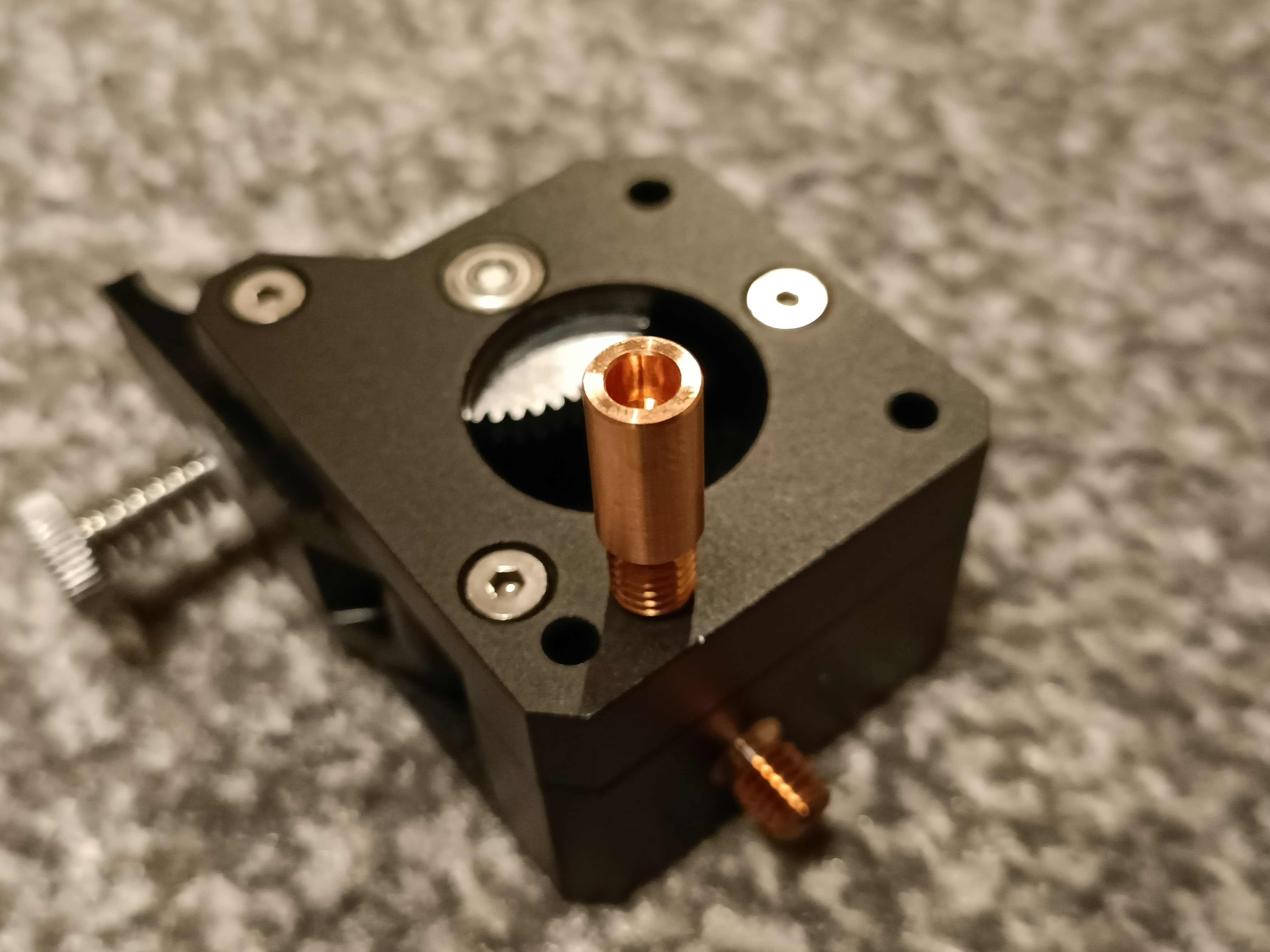

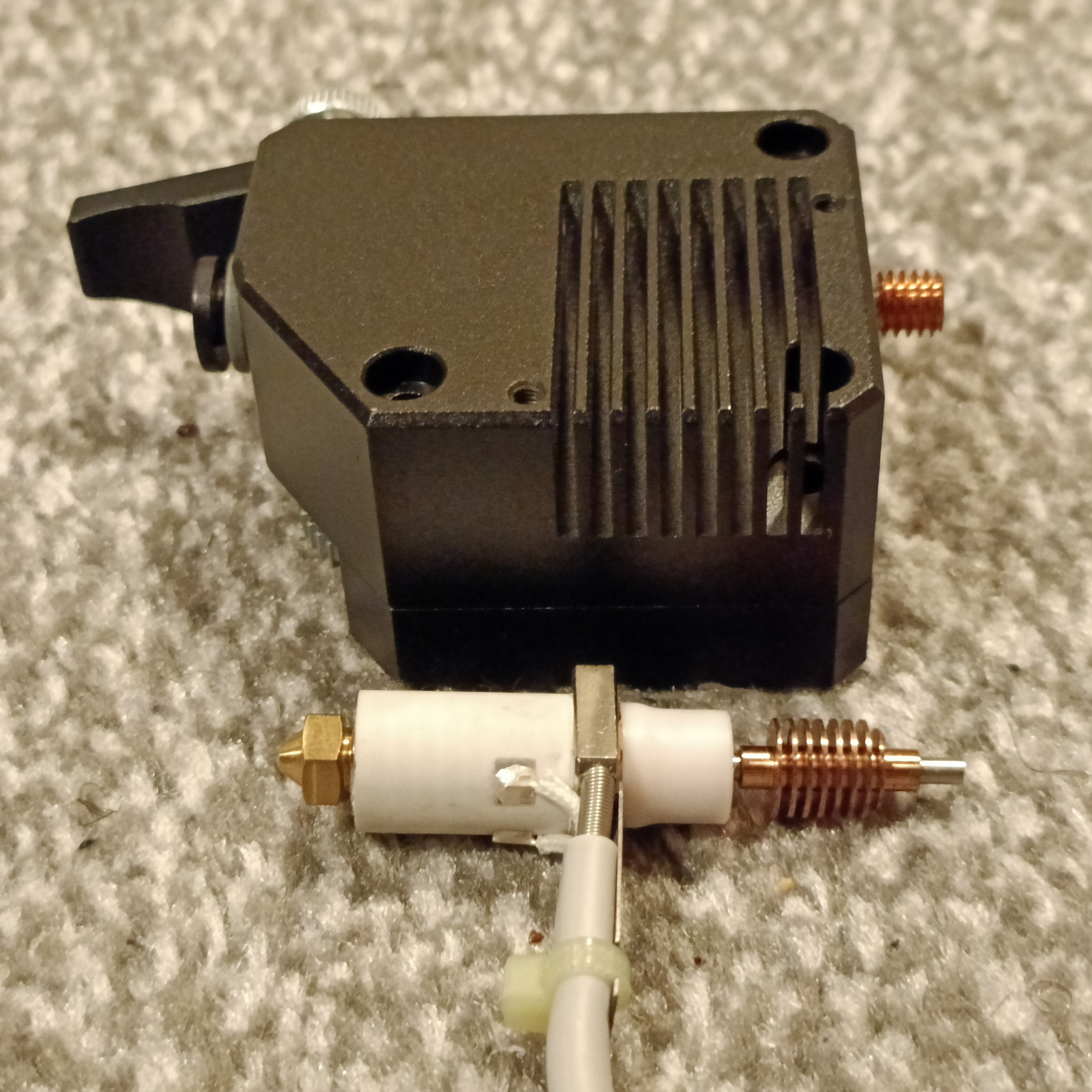

CHC Pro and heatbreak for the SecSavr Slight [gd0089]

The SecondSavr Slight is the name of the custom extruder that I'm designing instead of the originally planned metal BMG from TwoTrees, as £19 incl tax per extruder is a lot. Along with 2 spares, I'm planning the stock gd0036 setup to consist of 2 * (2 0.8mm nozzles + 2 0.2mm nozzles) (4 nozzles per SecSavr Slime [gd0088]). This means that, with 2 printer "cores"/"bays", 18 extruders are needed. The only reason I needed the metal BMG's was for the integrated heatsink, but on searching for something else, I found £3 "High Flow" bimetal heatbreaks with integrated copper cooling fins.

Now for some reason, I've never really liked the idea of using these £19 BMGs, and after the 5th time searching to see if any hip new extruder hit the AliExpress market, I remembered back to those heatbreaks and thought about just designing a custom extruder. I had also just recently seen this extruder, which reminded me of this extruder I saw way back in maybe 2017 - I considered it the fanciest looking hotend but the price was (and still would be) too much. Ever since then, I've always wanted a double drive extruder, and now was the opportunity to get it.

The design of the heatbreak allows me to go straight from the extruder gear into the stainless steel tube, which should be an even more constrained path than a metal BMG and normal bimetal heatbreak as there is a larger hole that is chamfered to the steel tube.

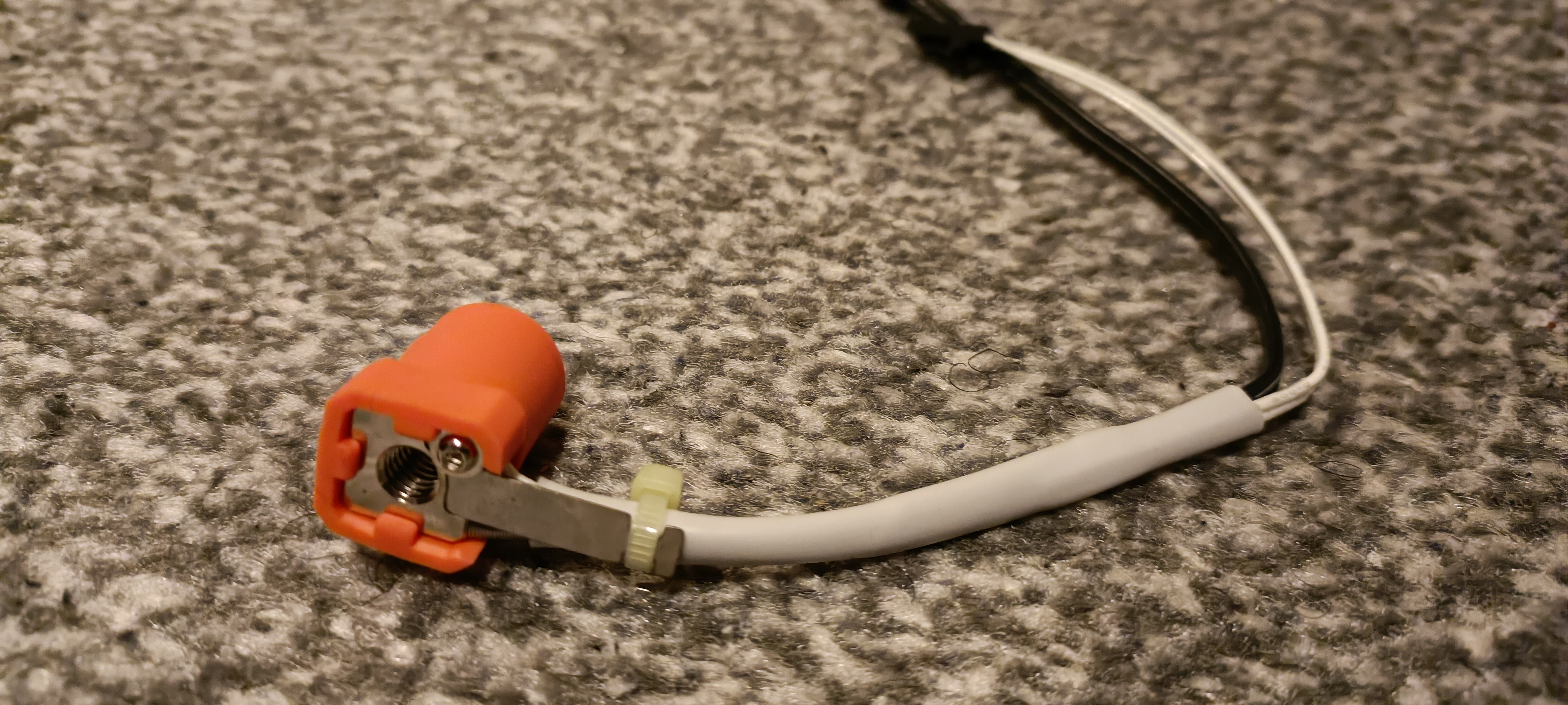

It also seemed that, if I took off the blue silicone seen in the product listing, I'd also be able to replace the bolt holding the metal wire strain relief with a titanium bolt to possibly have a single handed nozzle change -- a feature seen in todays latest hotends.

Due to the aluminium spacers as a melt zone extender (idea from the Rapido hotend), and the desire to print up to the maximum 300C allowed by the CHC Pro's stock thermistor, I'm using good old fashioned ceramic wool + kapton tape to insulate the hotend instead of the nice looking included silicone sock (which is an upgrade to the E3D-SuperVolcano-like insulation its predecessor included).

If you're not aware, the new CHC Pro is a 60 - 115W ceramic heater around a plated copper block. It consumes more watts when cooler to speed up heating times. It feels like the included power wire is a silicone wire instead of the typical fiber sleeved wires on heater cartridges.

Anyway, to my suprise, the blue silicone sleeve surrounding the high flow heat break aiirved in white, and it's rigid. It's not silicone at all.

I'm going to need to ask the seller if it's able to handle 300C, and figure out how to take it off if the answer is no. Conveniently, the screw hole is still accessible even if it's left on:

I've gone with the High Flow variant as the regular version is the same height, the high flow has a higher heat sink that will be encompassed by gd0089 and high flow = more flow, presumably.

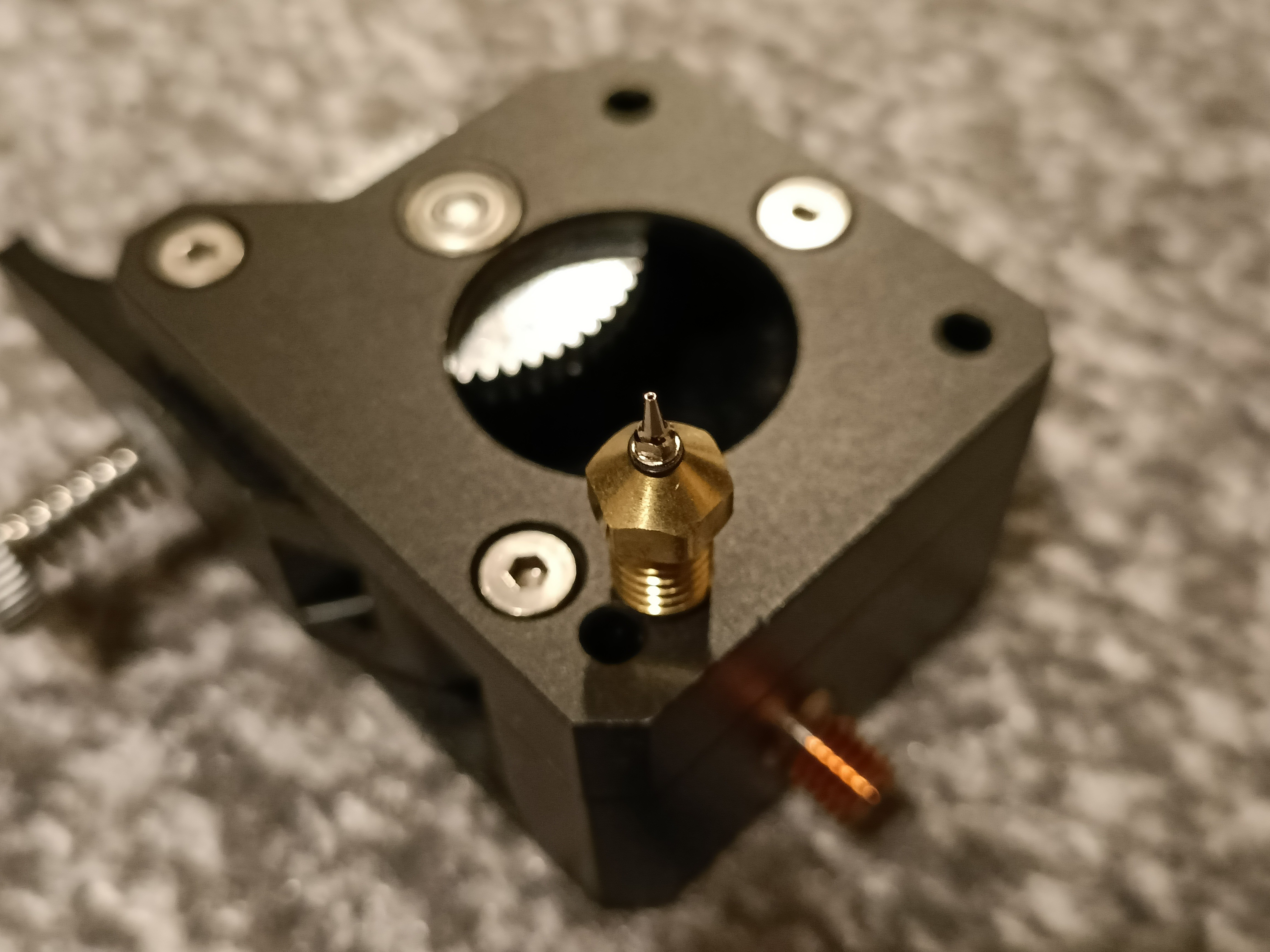

Here's all the components together, with the metal BMG for scale:

Truly compact stuff.

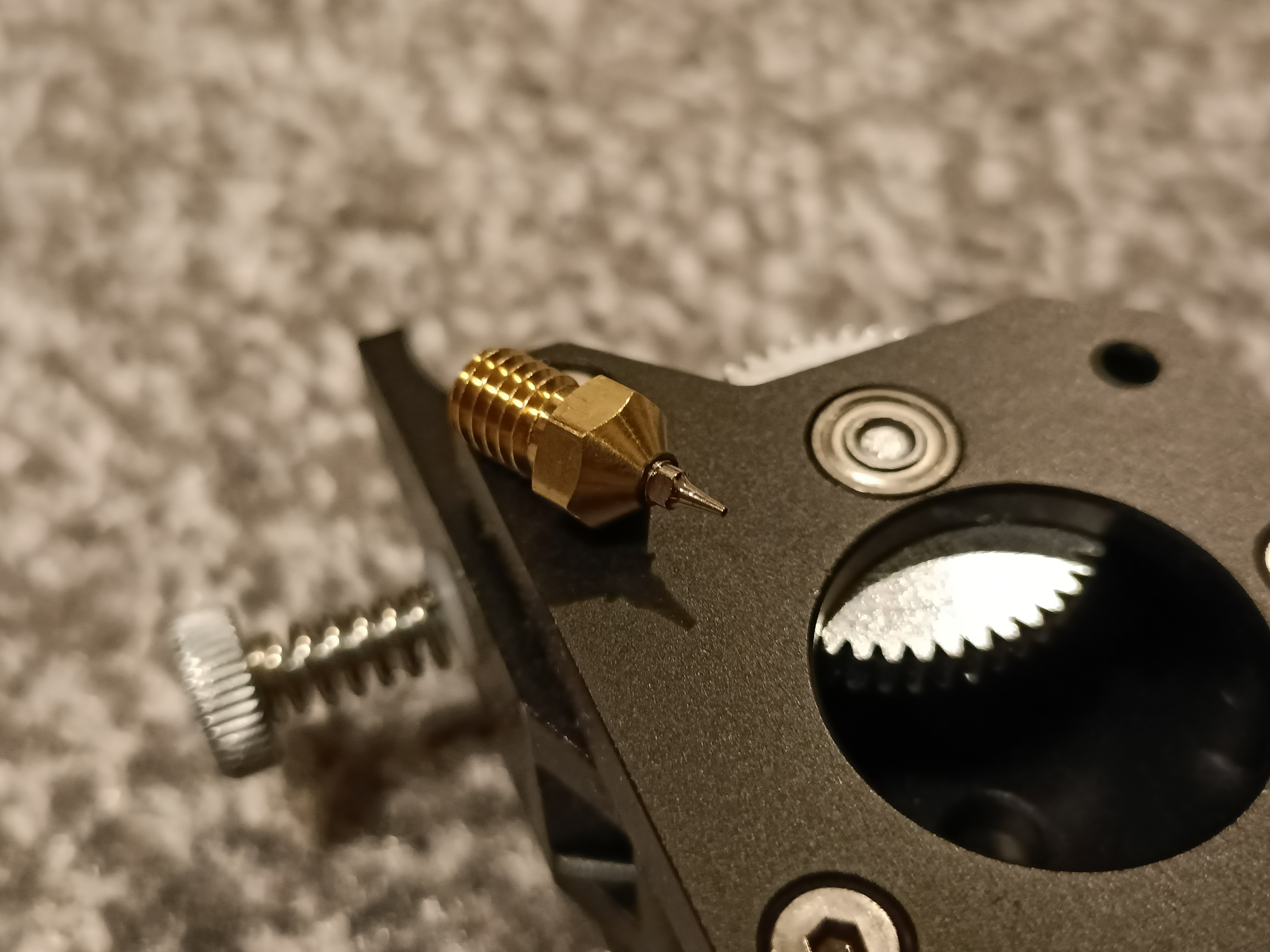

Airbrush nozzles

I know they were going to be small from the product listing image, but the airbrush part is truly tiny. The thread for it is very small too. I wonder if it's possible to actually get any volcano hotend with a sufficiently large orifice and tap out the thread.

I just hope that the black sealing ring is something like silicone or another material that can safely handle printing temps. Anyhow, these nozzles are intended to be used with this volcano block adapter as the proper nozzles from Mellow cost way more. I just got 5 of each for testing purposes.

I usually use 0.6mm nozzles, and any time I want to print in 0.4, I usually want something of even finer detail. There's almost no online experiences with airbrush nozzles, so I never got around to getting one to try until now. Ideally, I'd like UV resin prints without the UV resin drawbacks of single colour printing and, more importantly, the cleanup and health concerns (gd0036 is likely going to be over my bed). 200 microns might not be as crisp as the Form2's 140 micron minimum dot size, but I should be able to get some crisp-for-FDM prints.

Tubes

So on the 26th, I received a new set of ordered 400mm tubes because the first set was out of tolerance. The quality sure increased. They're shinier.

-

Project progress before hackaday page

02/28/2022 at 18:58 • 0 comments[28/02/2022]

- Planned to use HGR20 for X and Y, then I thought that I could save money by using the same tube motion system as Z.

- Ordered and received 42.4mm galvanised tube from The Metal Store UK. The 608 bearings seem to roll without feeling bumps that could make their way into the print.

- Now I'm thinking that the X axis could also use 2 26.7mm tubes, which should be stiffer than the original unsuported HGR or lighter than HGR + 1 tube

- Name

- Thought of "Soap", "Steelium", "Scientific" and "Sevenly" but I didn't like them.

- After much research into camera modules, I decided to go with an off the shelf OV4659 that captures up to 330fps at 360p I believe.

- Planned to use HGR20 for X and Y, then I thought that I could save money by using the same tube motion system as Z.

-

If I made an ad, this would be the background music:

02/27/2022 at 19:32 • 0 comments

SecSavr Sublime [gd0036]

An FFF 3D printer that I described as "The FULL Coverage, Extended X, Pro Max, Ultramatrix Solution"

kelvinA

kelvinA