-

[E1][T] 160x160mm Bevelled HUB75 and Glue On Board coating

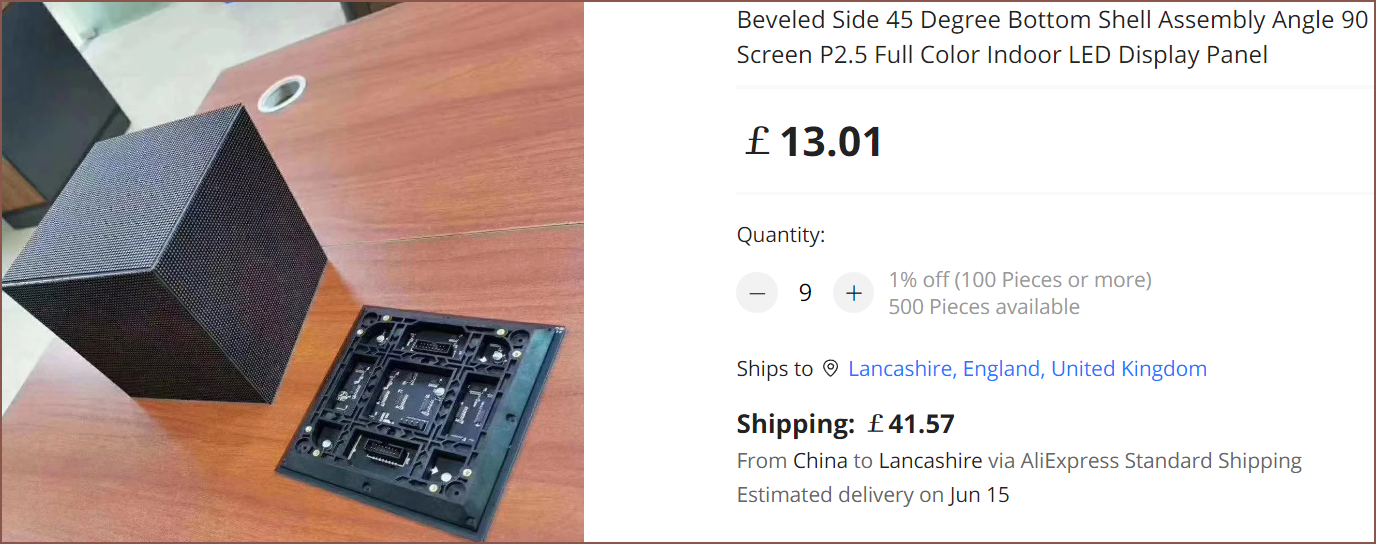

05/24/2023 at 12:41 • 0 commentsSo, while I was on my DIY Miini-LED backlight research, I came across this relatively unique panel:

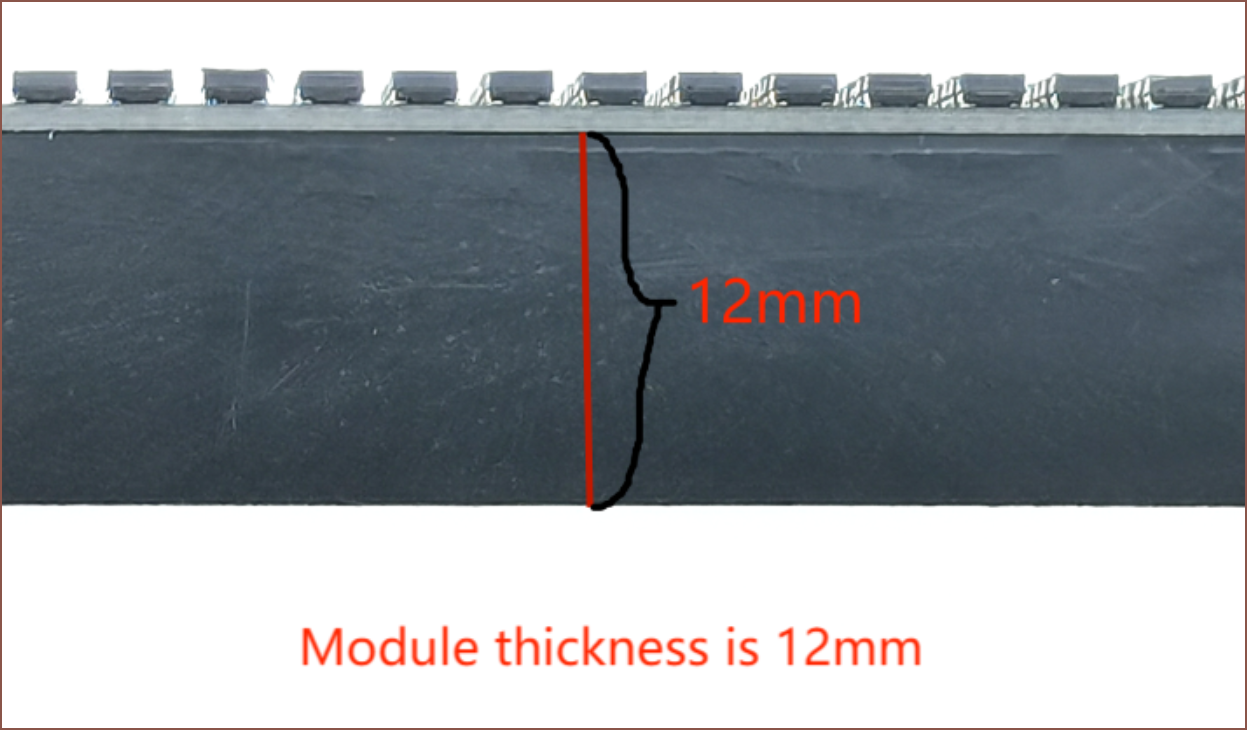

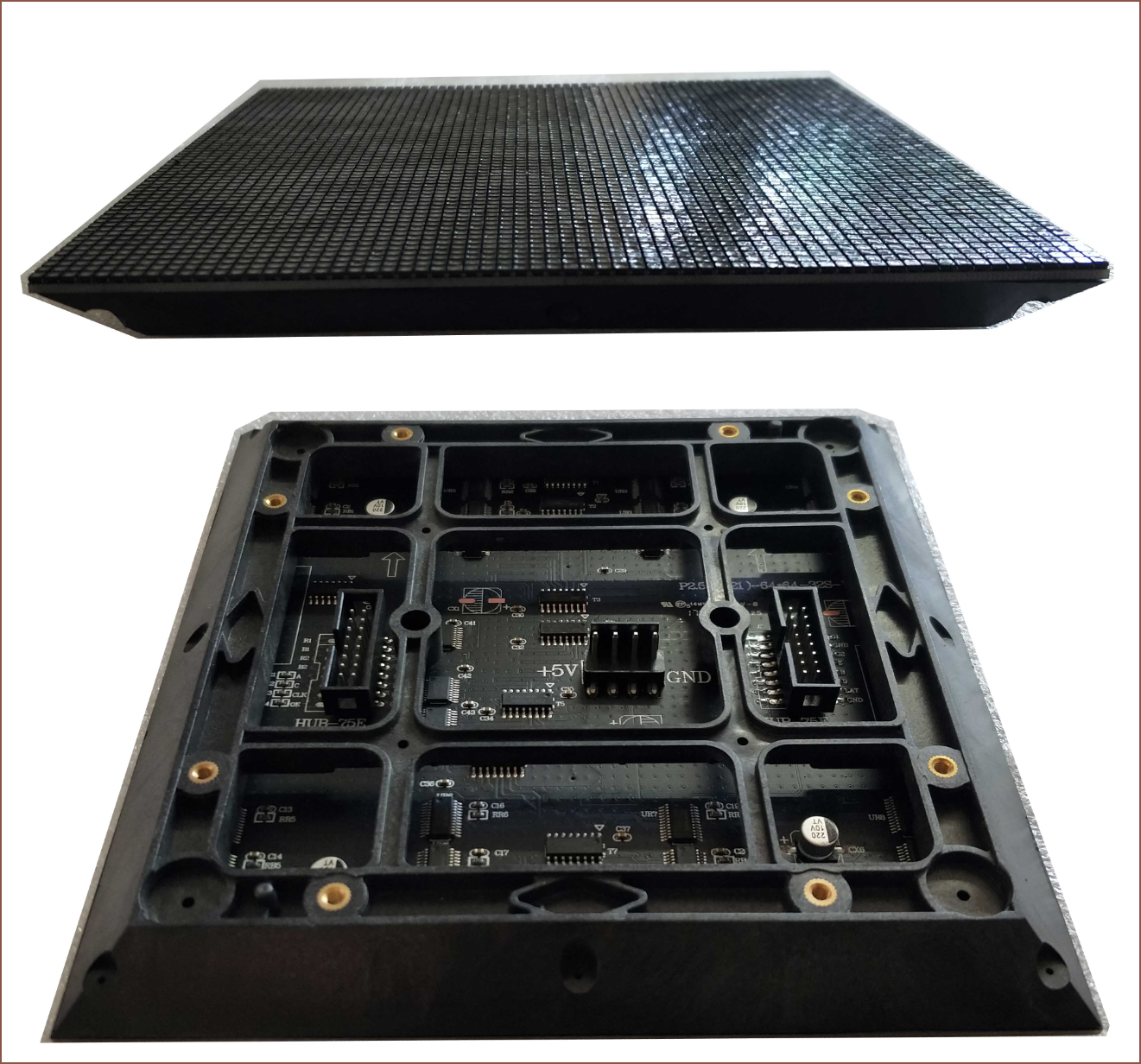

Traditionally, the panels have a rather chunky injection moulded frame:

On the contraty, these ones are thin in the corners, where it matters for this application:

I've also been worried that 256mm square panels are still a tad too large for being able to integrate the Tiles into a domestic setting. These 160mm panels mean that the Tiles will cover less area per each, but it also means that they need less space to operate and look sharper, since the same 64x64px display is compressed into a smaller area.

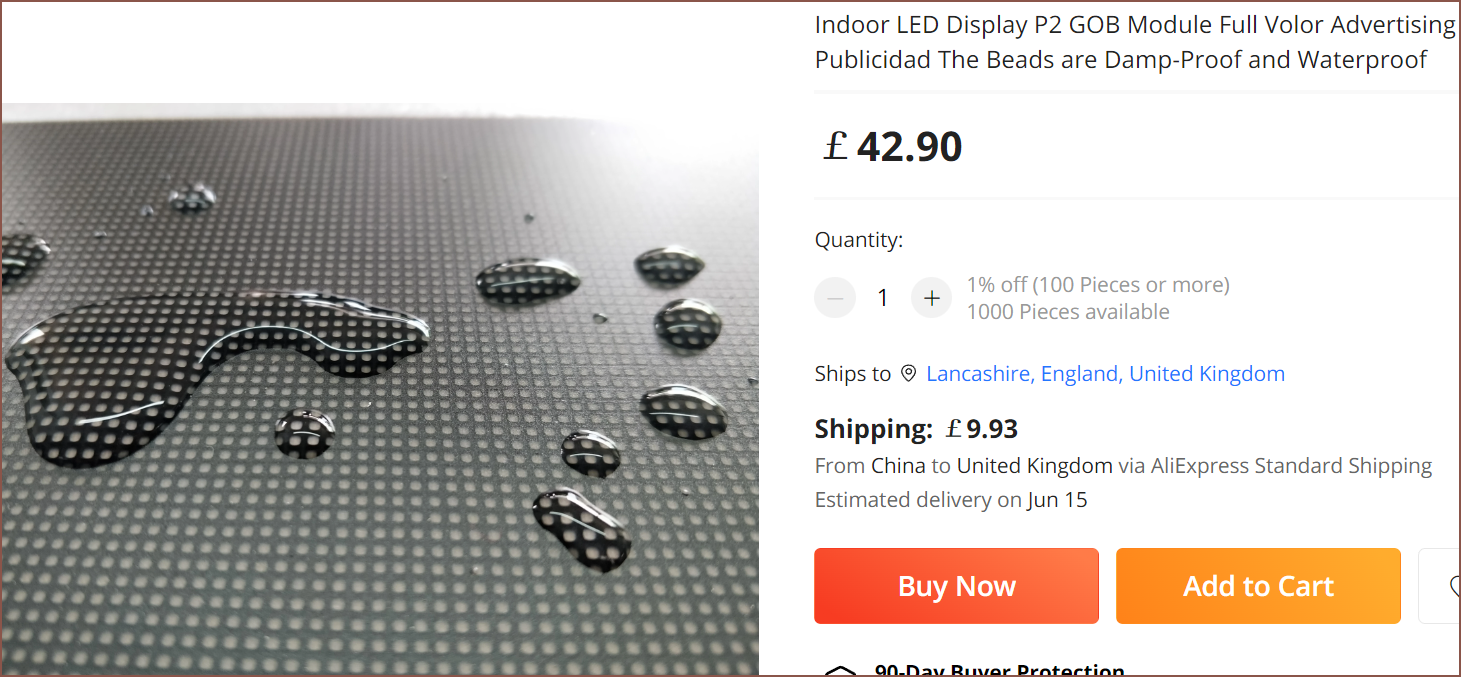

What would've made this even better is if the panel had the GOB (Glue On Board) coating found in another one of the seller's listings, which would prevent splashes and light knocks from damaging the panels:

Way back in 2020, I was wondering if it was possible to coat the panels with epoxy to obtain a flat top surface, because I wanted the T^2 Tiles to be able to actually hold light shelvable objects (and because thousands of tiny SMD components exposed to the elements of the home sounded damage-prone). Now I know it indeed is, though I'm still not sure if I'd have the skill to do it myself. There is this repair video I found (see below), so it's possible to touch it up on a small scale, but I wonder how hard it is to get uniform thickness and flush edges for doing the whole board.:

[26 May: Edit 1] Good news. I asked if I could get 10pcs of the bevelled LED modules with GOB applied, and the HONGHUI LED Display Store seller said it could be done if an additional 14 days processing time was acceptable. Obviously, that's fine and LED modules that move around could really use the additional durability. The height of the module would be 18mm. Now I just need to know about cost...

I'm also wondering how many Tiles is a low amount but still high enough to consider this project a success. I'm thinking 9 Tiles for a 3 x 3 installation (or 1 x 9 floor-to-ceiling strip). It's also the same amount you get in Nanoleaf "starter kits". Coincidentally, the "Canvas" tiles they make are 150x150mm large, so it further looks like a 160mm square T^2 Tile that can arbitrarily connect to other tiles is recommendable.

-

[T] Installation location and material issues

07/11/2022 at 00:28 • 0 commentsI'm thinking of going with a 2 wide by 7 high installation in a corner of my room.

I'd like to be able to power all tiles with a single 3kW socket, and I think I should be able to get 14 to fit in that power envelope. the space in the corner will allow the installation to be more like a pillar and not something that has to be attached to the wall in some way.

I'd like to be able to power all tiles with a single 3kW socket, and I think I should be able to get 14 to fit in that power envelope. the space in the corner will allow the installation to be more like a pillar and not something that has to be attached to the wall in some way.In other news, it doesn't look like the material situation is looking that good, so I'll have to factor in the price of standard rate filament. Maybe silver won't look so bad.

-

Project status

03/08/2022 at 21:48 • 0 comments

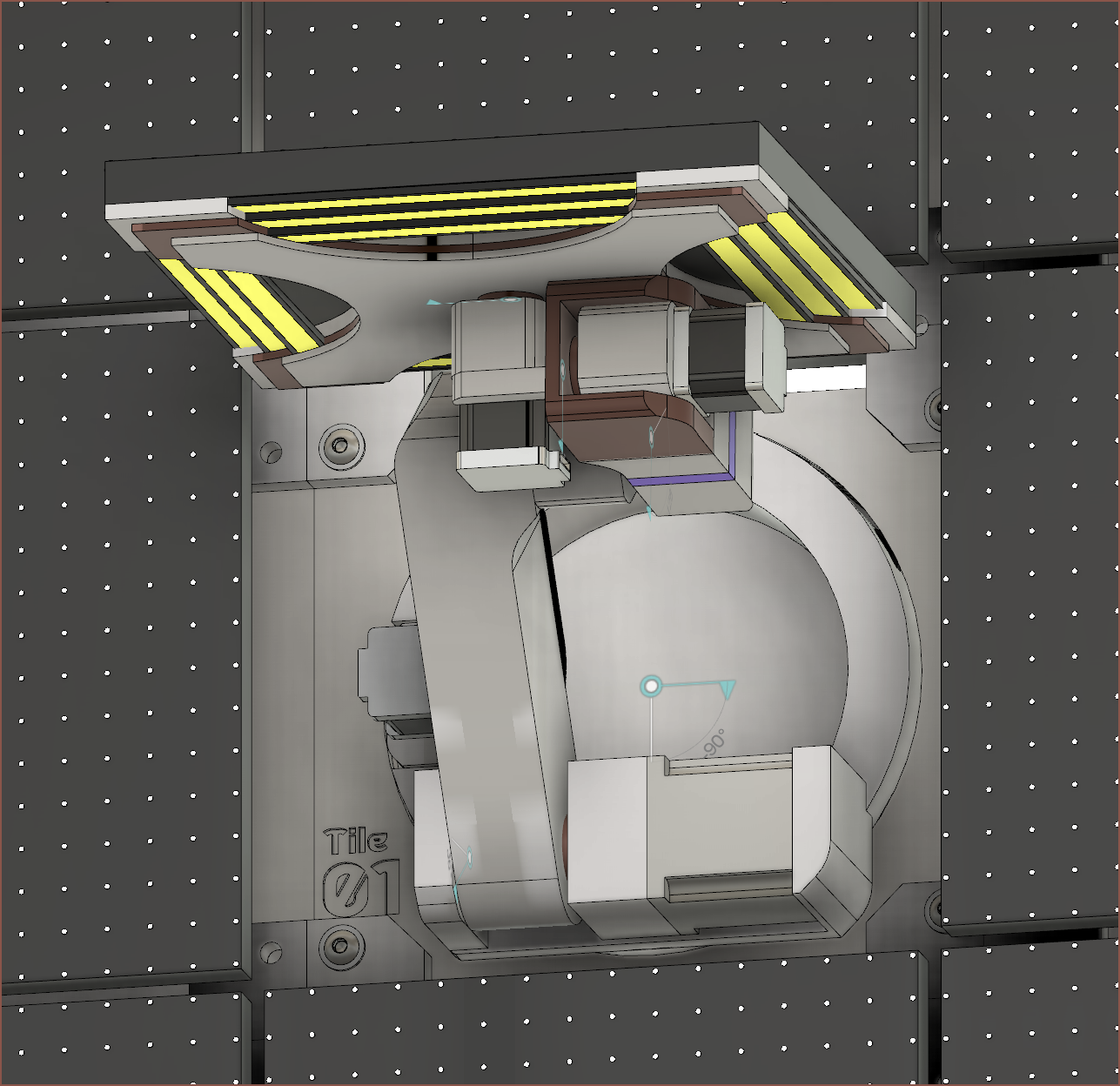

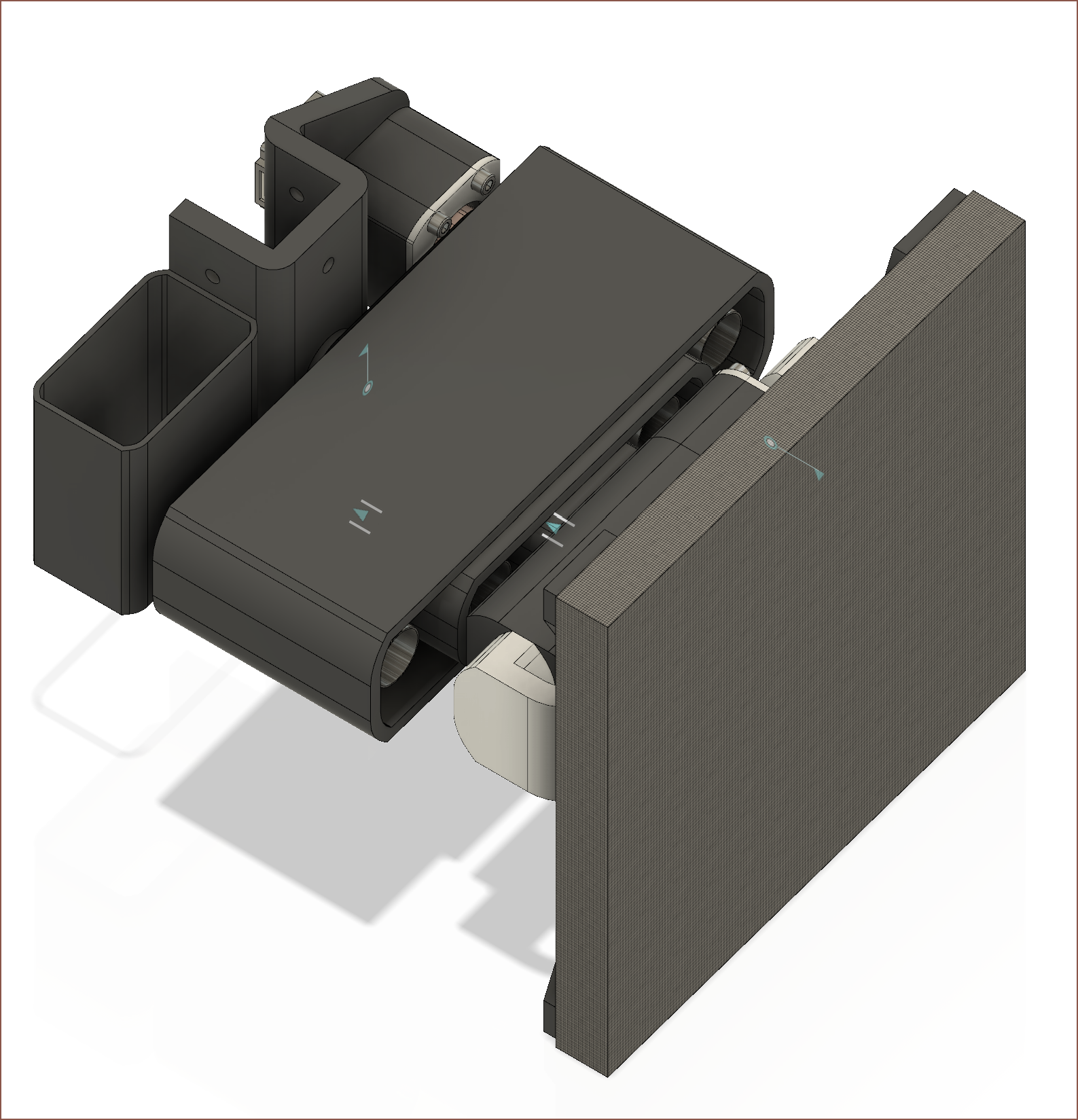

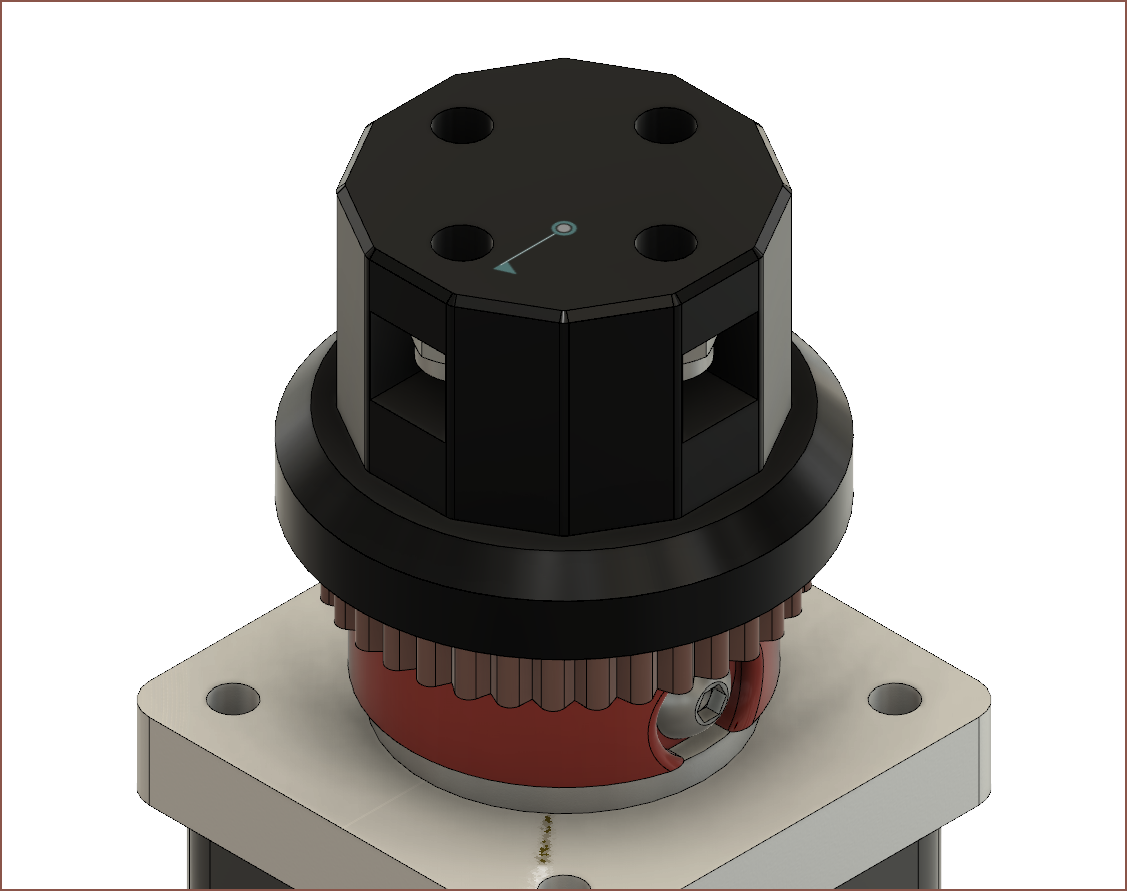

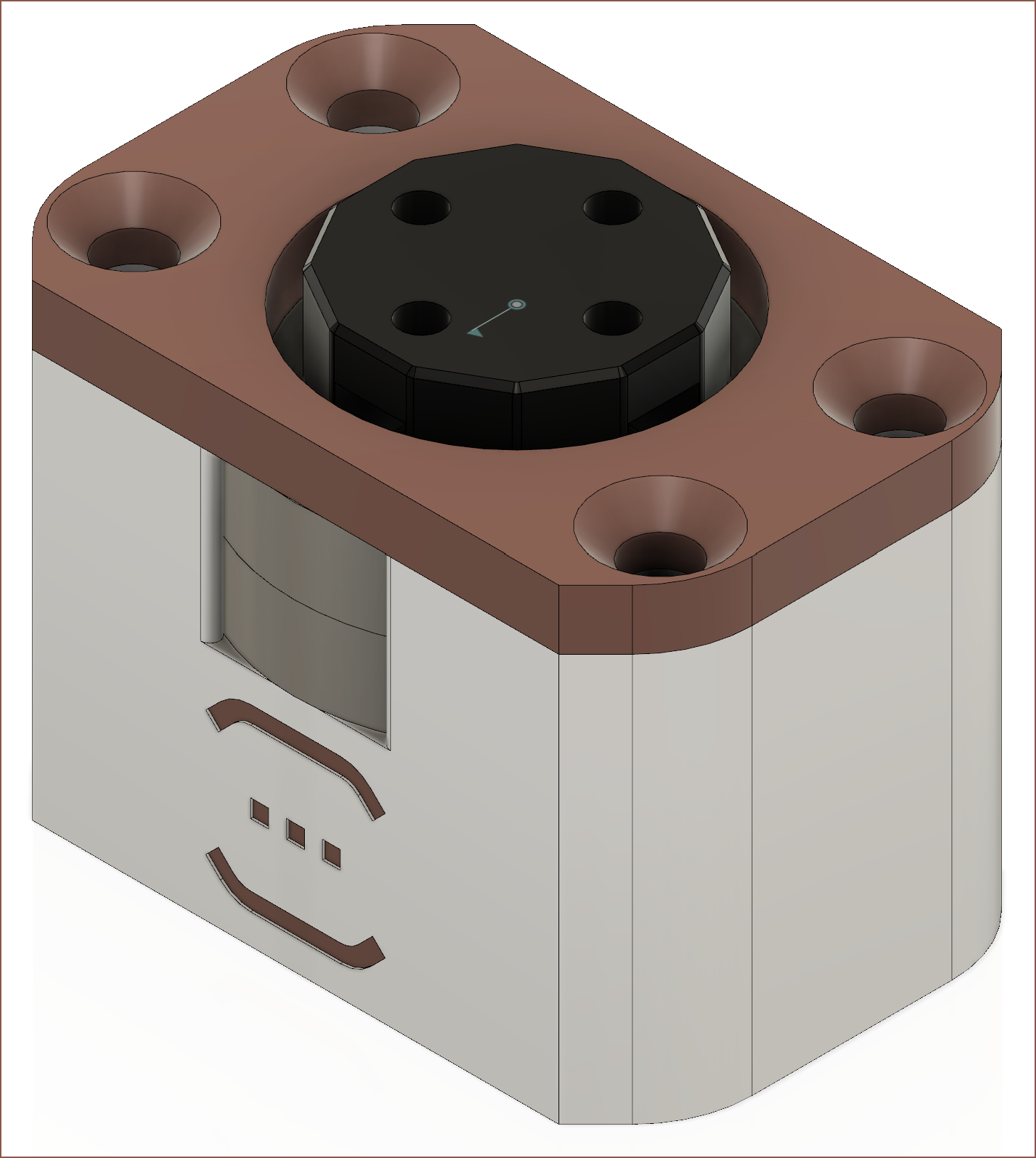

This is the concept model of one of the tiles. The frame is 4040 alu extru and the motors are all Nema 14 except for the N23. The front tile is a 256x256mm LED matrix and the back is an array of COB leds for backlighting effects.

One of the main positions I wanted was for the tile to be planar with the ground, so something like Fluidum wasn't going to work. I also want these tiles to be quiet as I intend to have them running in the background, so hobbyist servos were also not an option. I've already bought 200 Nema 14 motors.

3 Axis

Originally, I only wanted to go with a 3 axis tile, but the concept turned out to be too large and likely too wobly to work (not like an arm configuration is any stiffer)

Perhaps I could revisit this idea, as less motors means less motor drivers and less power consumption, meaning more tiles for a given power socket. It also makes animations faster to make. The 7x7 wall installation would theoretically take up more power than the 3kW from the socket, so I started looking into battery storage solutions so that there was a store of energy in times when the tiles took up more than what was available from the mains. I also wanted to cover the tile in a fabric like material so that it just looked like a nice looking wall when it wasn't doing anything.

Perhaps I could revisit this idea, as less motors means less motor drivers and less power consumption, meaning more tiles for a given power socket. It also makes animations faster to make. The 7x7 wall installation would theoretically take up more power than the 3kW from the socket, so I started looking into battery storage solutions so that there was a store of energy in times when the tiles took up more than what was available from the mains. I also wanted to cover the tile in a fabric like material so that it just looked like a nice looking wall when it wasn't doing anything.Reducers

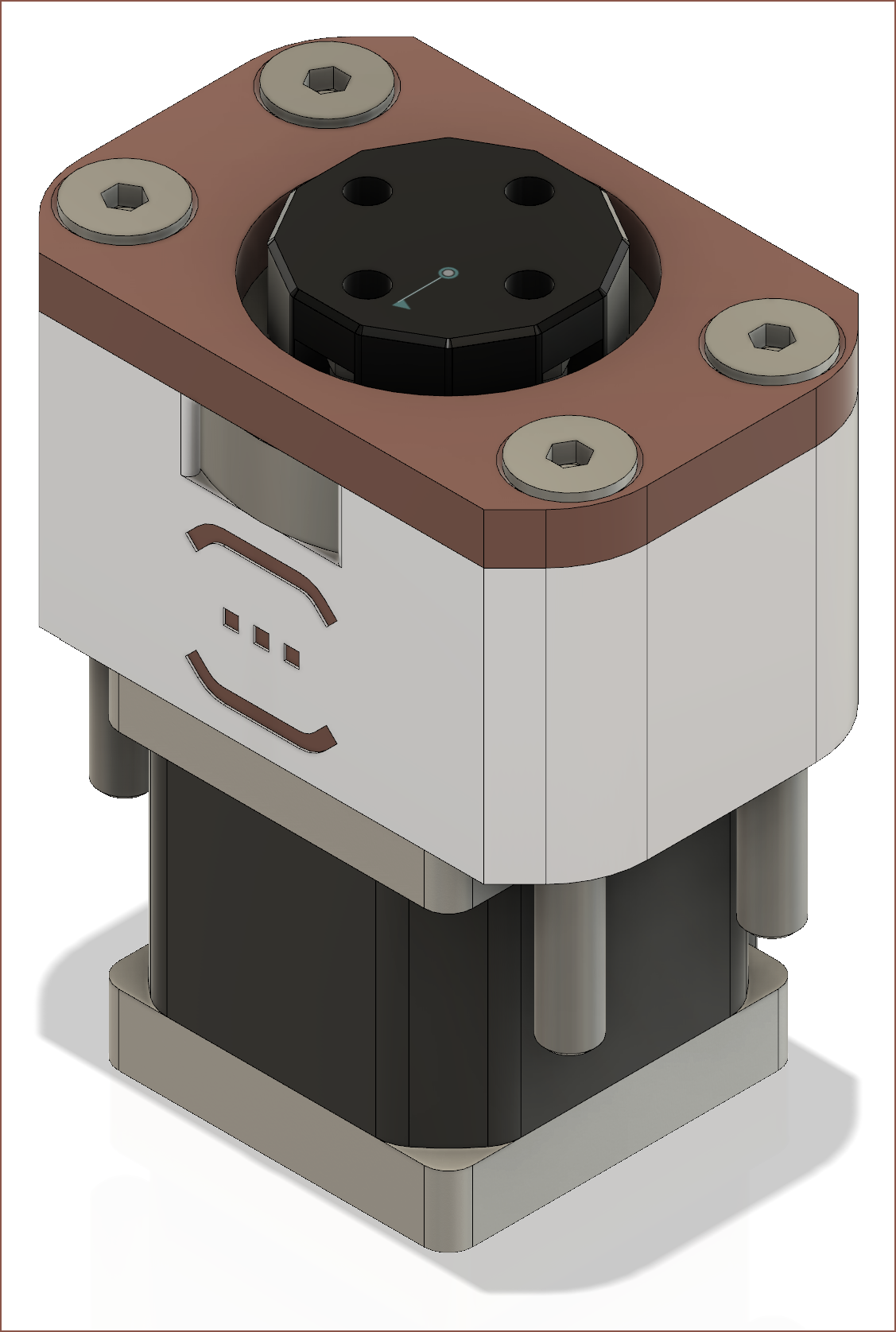

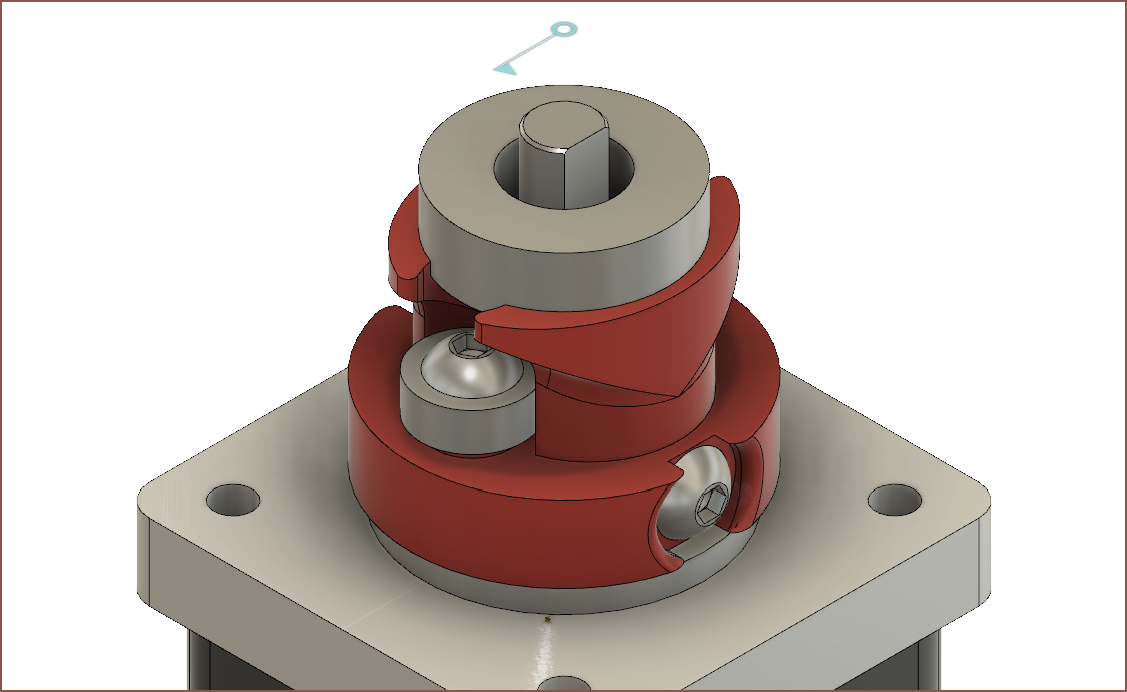

For the motors, I've opted for a harmonic drive that I currently haven't tested. It's currently a 17:1.

It uses a TPU belt-like print for the gearing.

It uses a TPU belt-like print for the gearing.

Looking at results from other peoples designs, I'm thinking of going from a dual bearing to a triple bearing to increase the amount of teeth engaged.

The top bearing is a thrust bearing. There is also a double bearing version: This reducer is for axes that have the space for it, so that the overal arm is stiffer.

This reducer is for axes that have the space for it, so that the overal arm is stiffer. -

[E1] Project inspired by...

03/05/2022 at 15:34 • 0 comments

T^2 Tiles [gd0095]

If a competing company produced a home-use version of Aperture Laboratories Panels.

kelvinA

kelvinA