-

Quick orientation overview

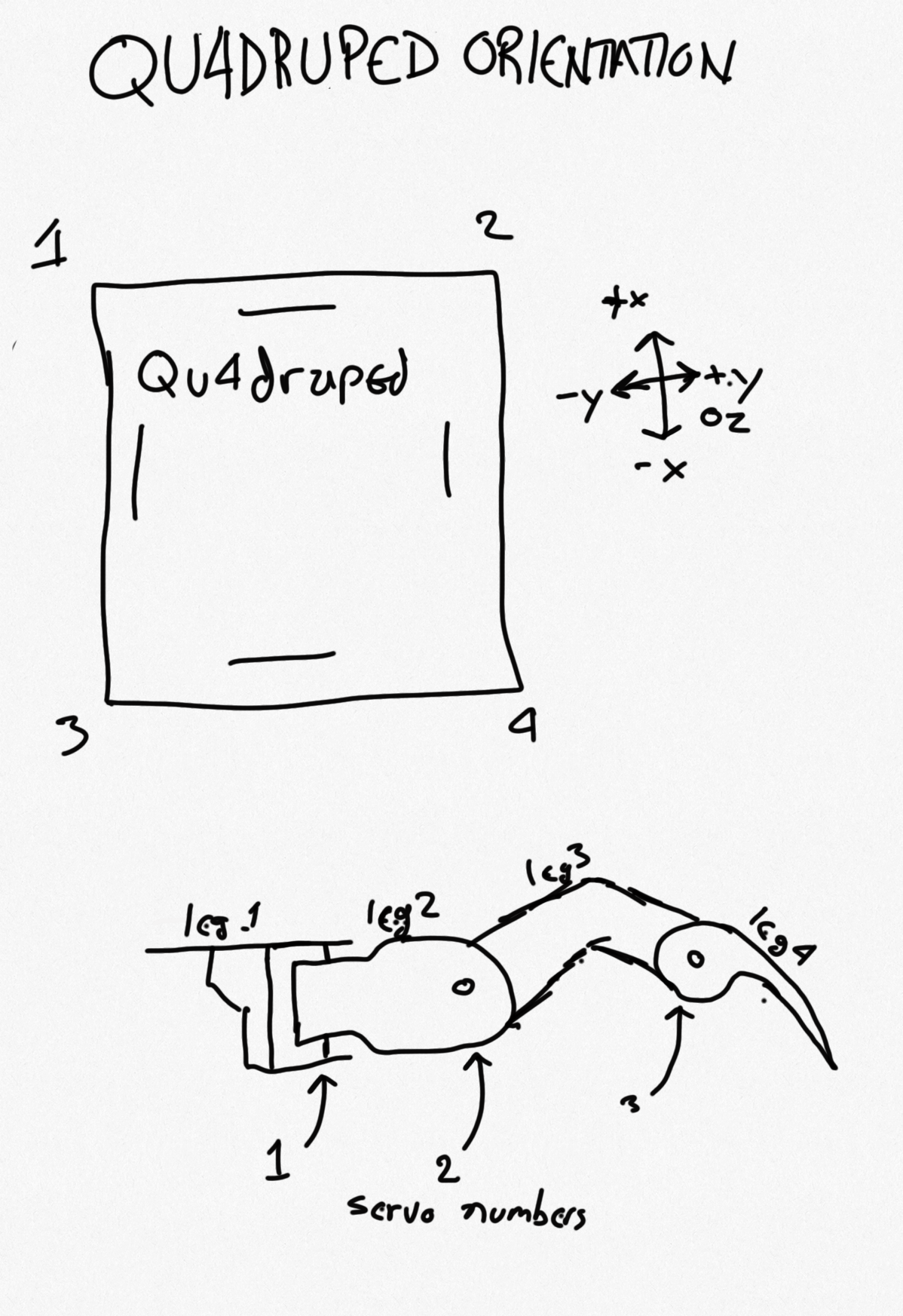

03/30/2022 at 02:57 • 0 commentsI drew up a quick overview of the qu4druped's orientation. This numbers each leg, as well as the segments and servos in each leg.

![]()

-

Basic progress

03/29/2022 at 07:36 • 0 commentsI have an OpenSCAD model done up for the base plate; I'm new at 3D CAD so this is mostly a matter of trial and error. I targeted a basic plate with M3 mounting screws (matching the Qu4druped model base plate) and a pair of mounting holes for an 18650 battery pack. The first print shows my screw holes are a little small.

![]()

I have one leg (a mirrored leg) printed and assembled correctly. I've had a lot of trouble printing parts for this, which I'll talk about in a future log.

The picture also shows the control system that I'm using to experiment: a Sparkfun Blackboard and a Sensor Shield 5.0 that I got in some kit at some point. It works, but I've got a Teensy 4.0-baesd control board that just left for the fab tonight. The first experiments were... a little twitchy.

My plan is to use this to develop a serial-based gait test platform. Basically, it will receive lines over the serial console in the form3 15 15 145

That's the leg number (number three is the back right leg), the servo angle (0-180º, with 90º as the "neutral" position) for the first (innermost) to third (outermost) servo. I'm building out a chart of general servo settings to help develop the gaits, and I'll probably use a Python program on my laptop to test out gaits - that will help me figure out gaits for walking, turning, obstacle navigation, etc.

Eventually, I might go to a Raspberry Pi/ROS-based system with maybe a TFLite model for motion planning. This will go hand-in-hand with a general pan/tilt sensor system that I'm designing. I have some drawings, but my CAD skills are not up to par yet.

I still need to print another mirrored leg, and I have segments 1-3 of the non-mirrored legs. I'm debating printing out section 4 (the black leg tip) in PETG because I've had a lot of problems with cracked parts, even right out of the printer. I think PETG might be helpful because it's more flexible but I need to install the high-temperature nozzle in order to do that.

Kyle Isom

Kyle Isom