-

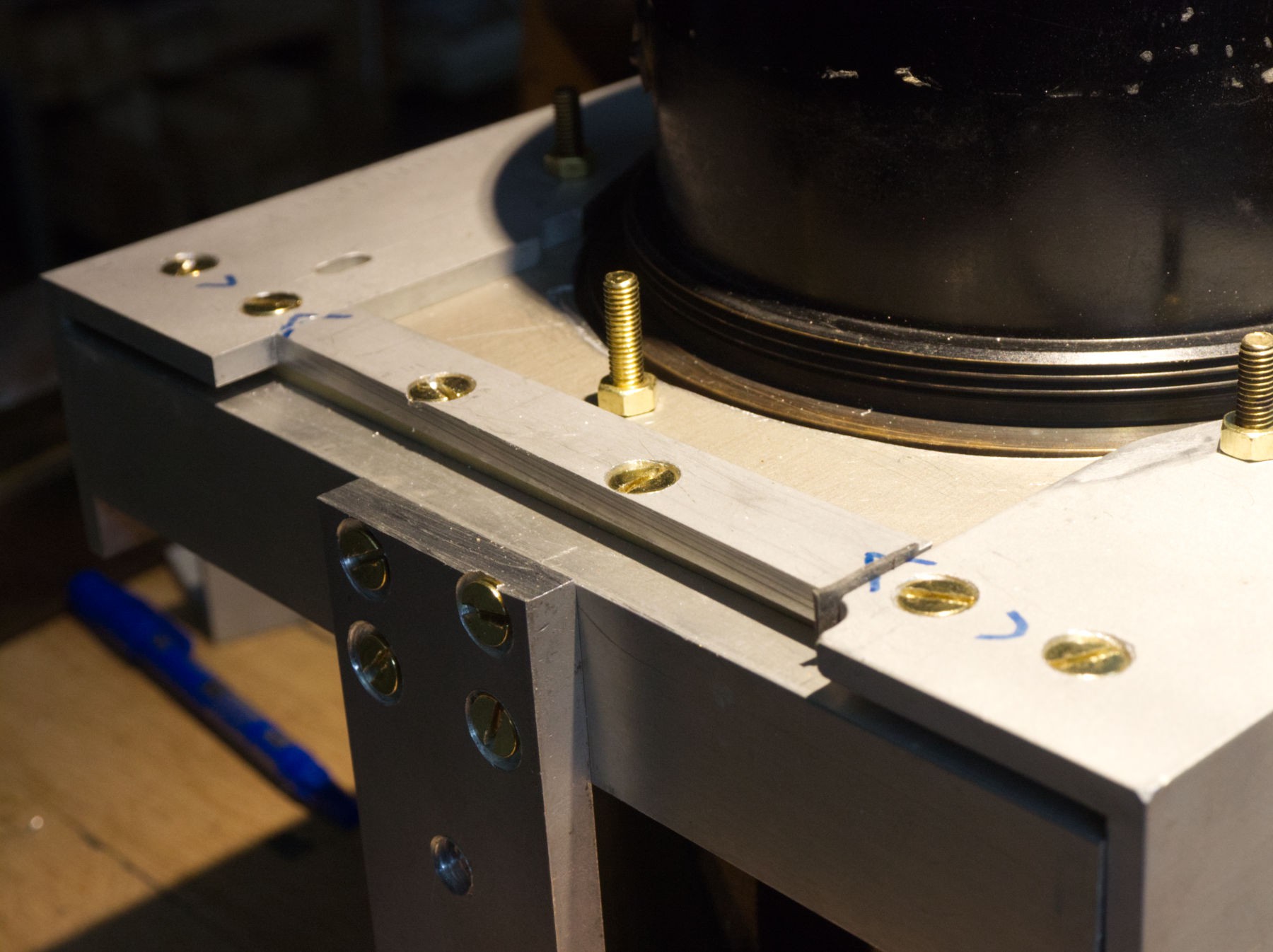

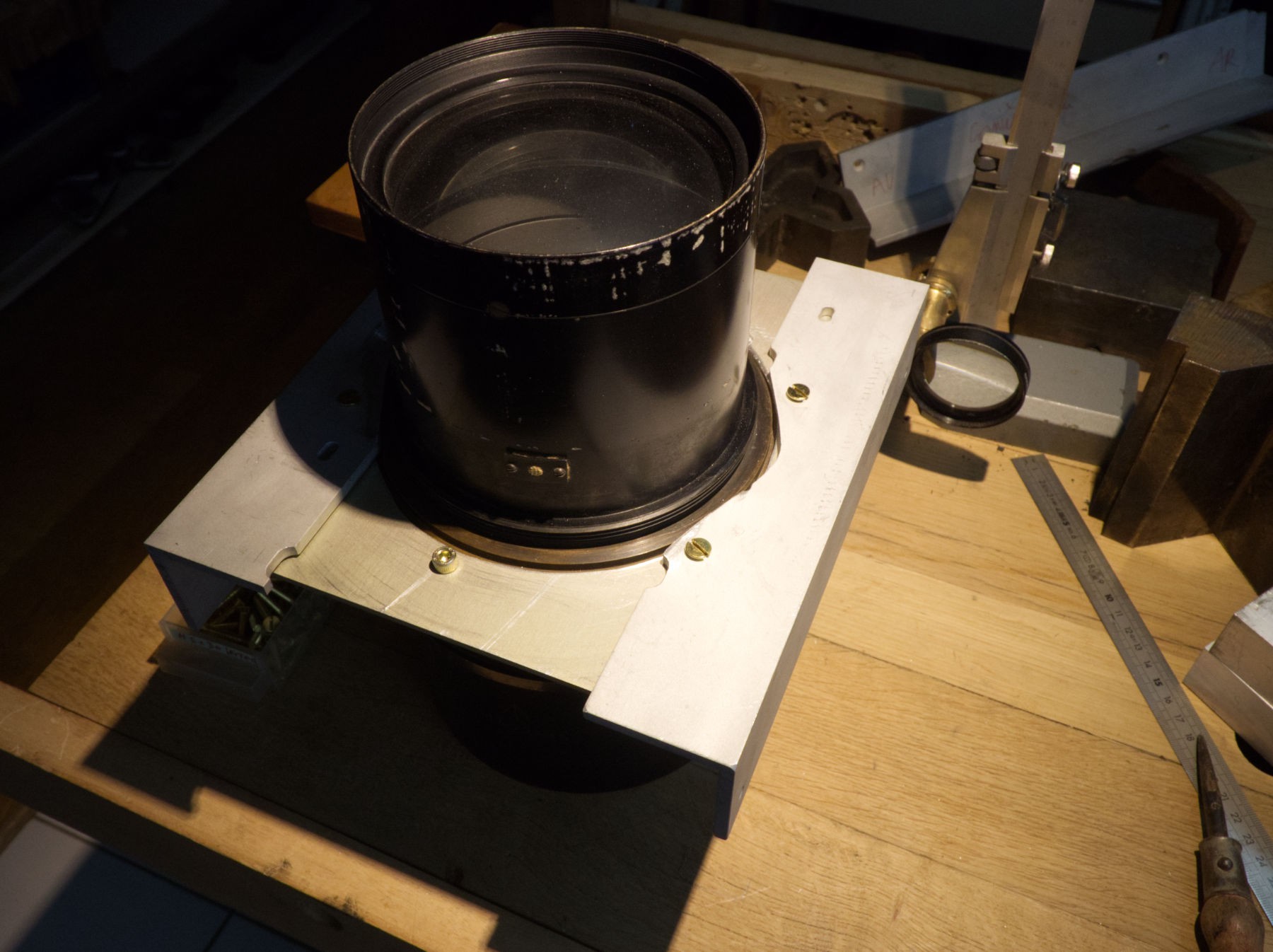

adjusting the rear of the board

04/27/2022 at 14:39 • 0 comments![]()

Now it will be lightproof, with the help of a small piece of bicycle tire inner tube to realize a perfect fit (under the left blue arrow).

-

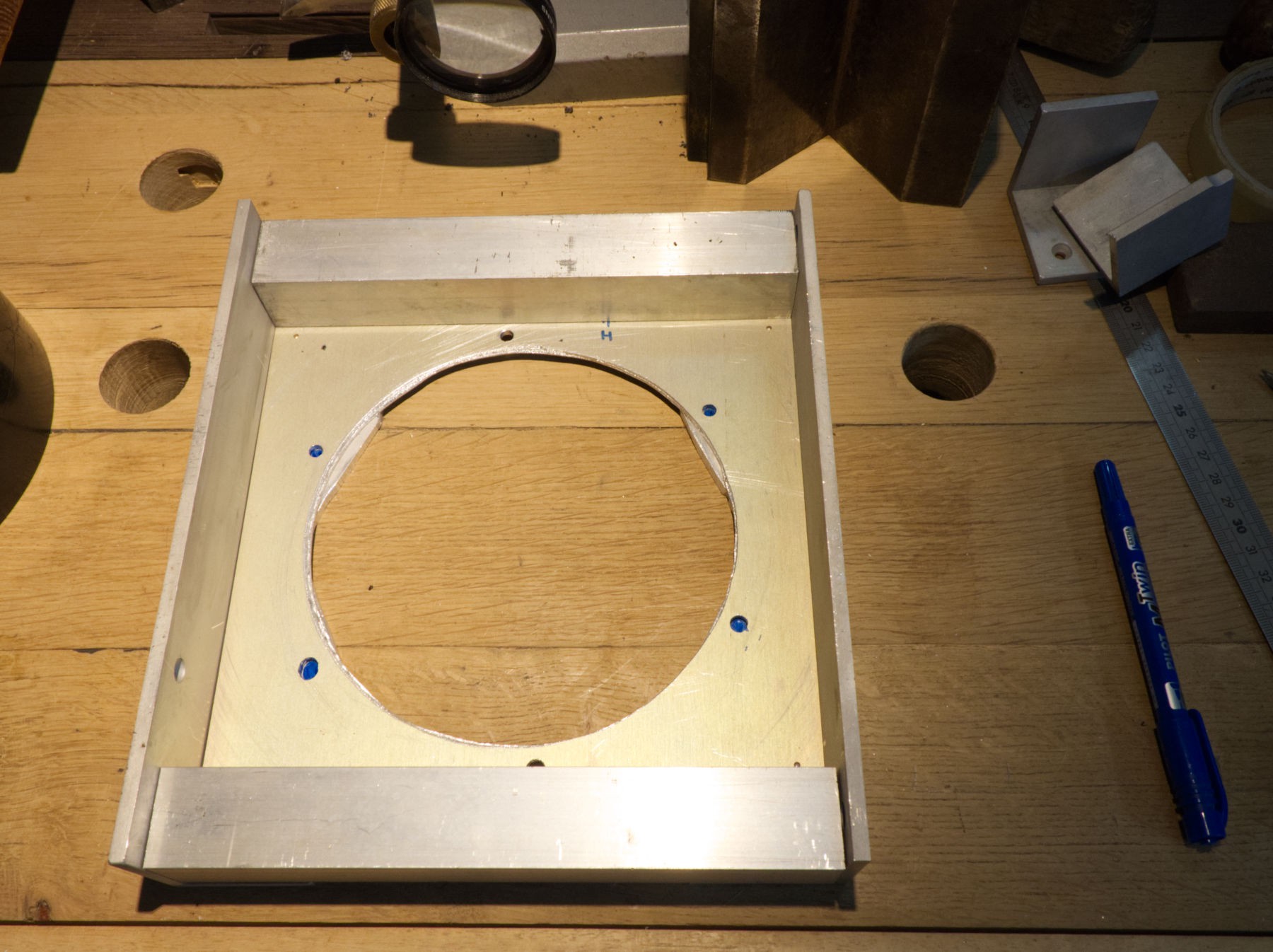

taping the rear of the board

04/27/2022 at 14:26 • 0 comments![]()

Two 5 mm thick aluminium bars are needed on the back, to give more strength on both sides and to close the rear from light, to have the same thickness as the L profiles.

-

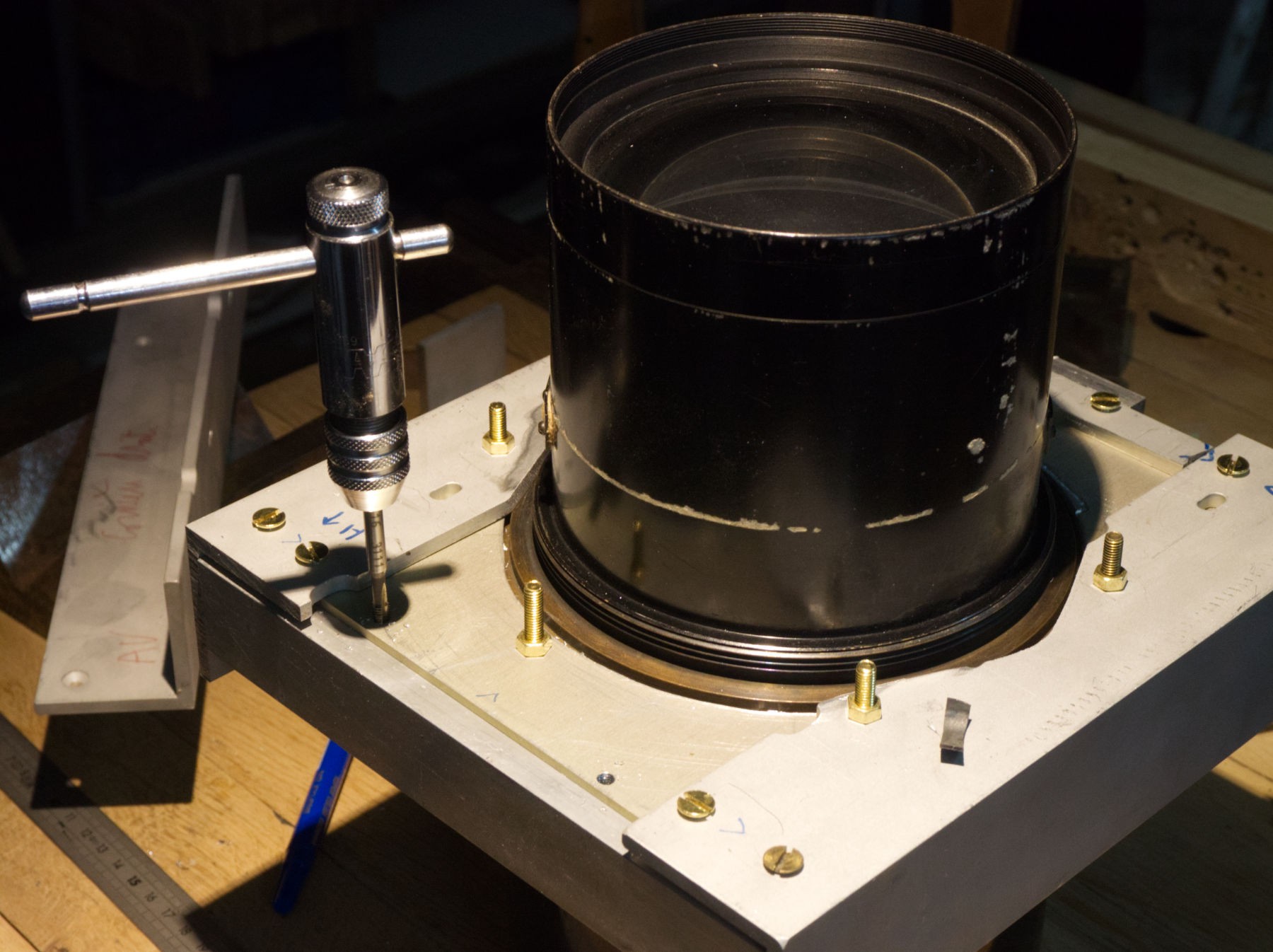

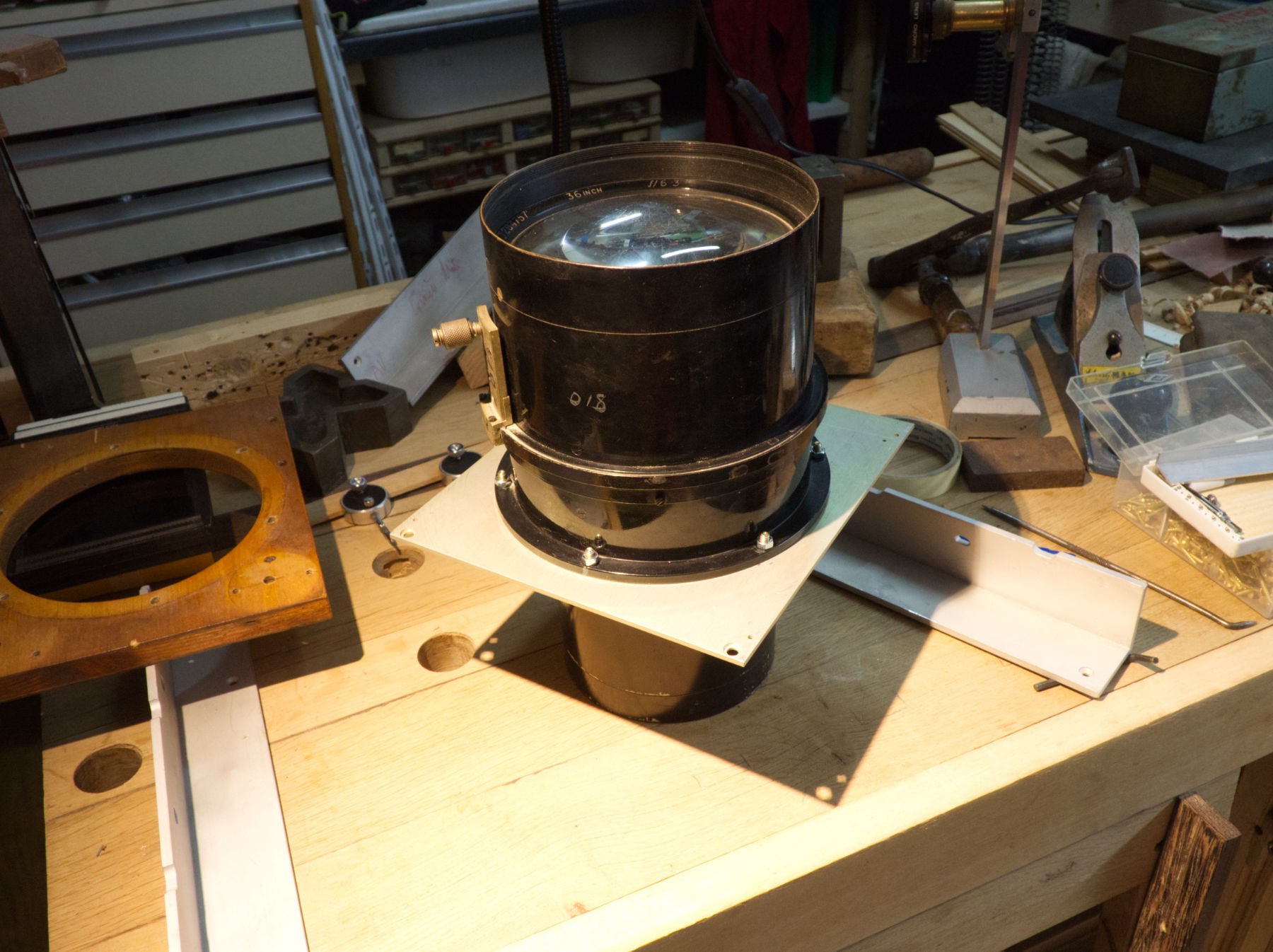

First try on a tripod

04/27/2022 at 10:41 • 0 comments![]()

The 3/8" threaded hole has been drilled around the center of balance of the lens, it's a little bit in front of the diaphragma as the front element glasses are bigger than the rear ones, as a telephoto lens, it isn't a symmetrical formula.

The piece of bicycle inner tube (left down the lens) is absolutely not necessary : there's no contact between the lens and the aluminium profile, and it does not move at all, but for the first try...

-

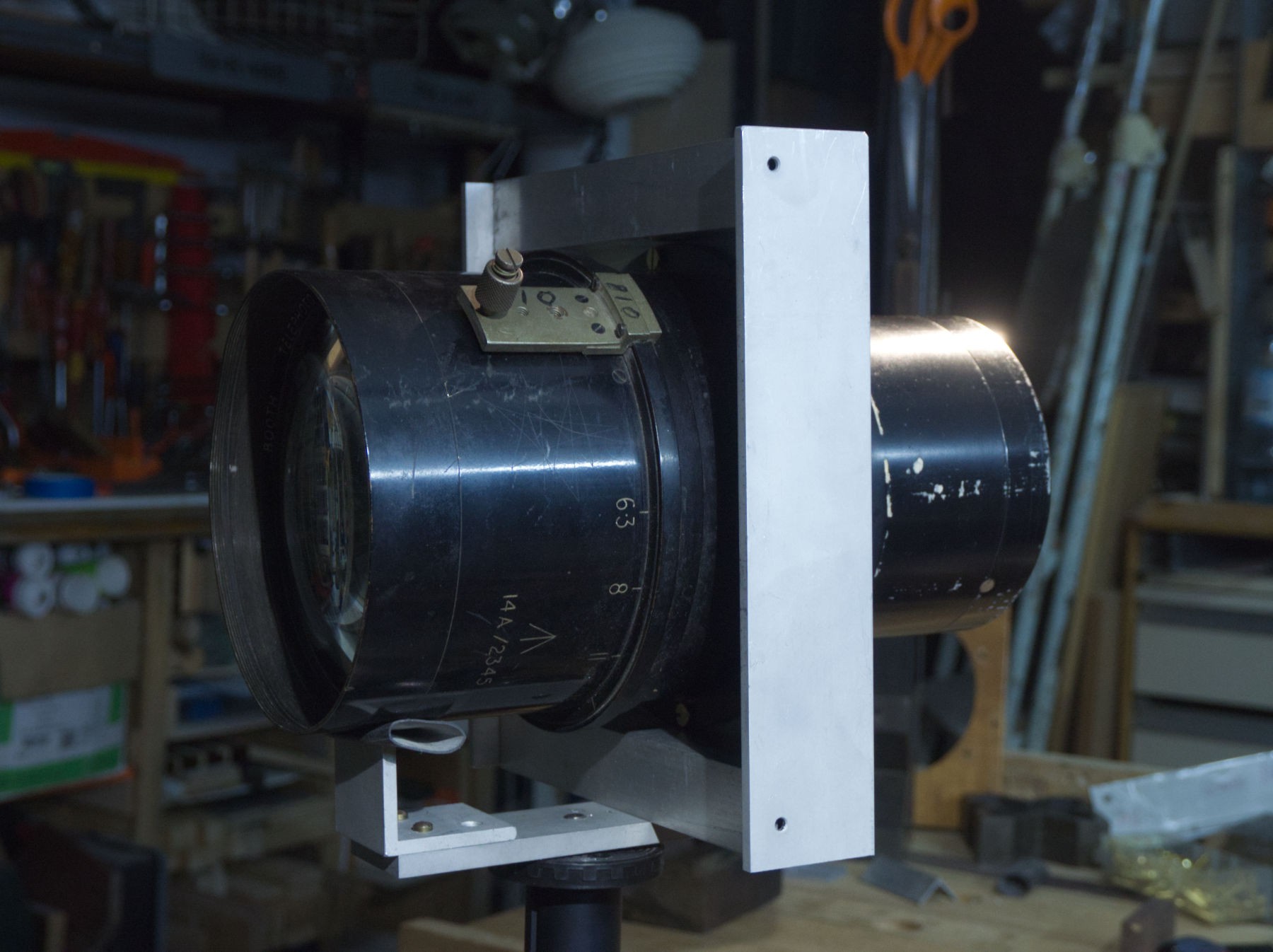

baseplate

04/27/2022 at 10:28 • 0 comments![]()

The baseplate has been cut from 8 mm thick aluminium. This thing must have been used in a lab to adjust a LASER beam.

-

Drilling holes to hold the square tubes.

04/27/2022 at 10:22 • 0 comments![]()

Drilling holes to hold the square tubes. I love when I can use those metallic 2 screws clamps to hold things.

-

First mont

04/27/2022 at 10:17 • 0 comments![]()

The holes have been drilled at the right place, it fits.

-

Carefully marking the holes.

04/27/2022 at 10:13 • 0 comments![]()

Carefully marking the holes. The board color has little yellowish tint du to an anodization process, so chic.

-

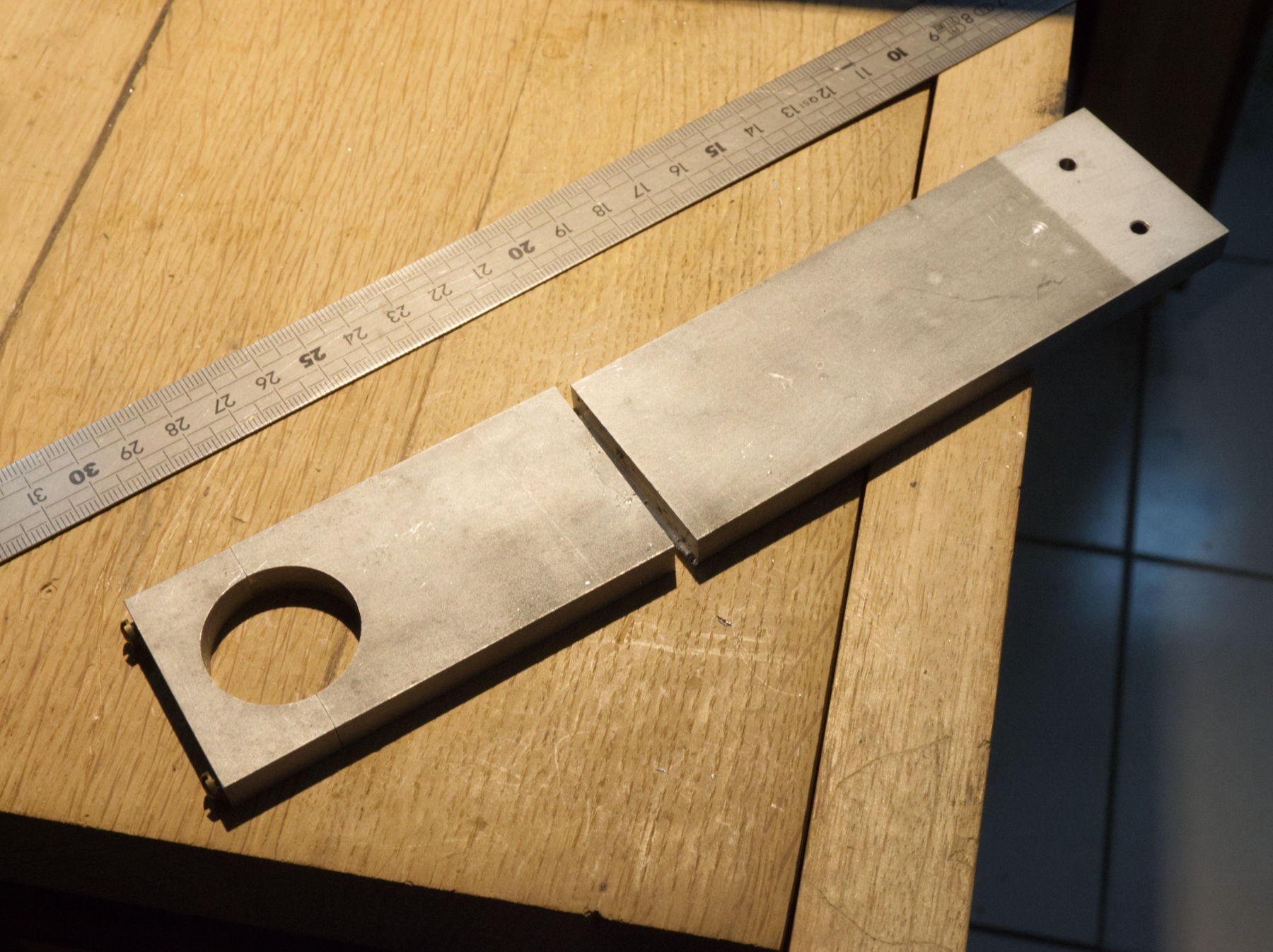

The board material list

04/27/2022 at 10:05 • 0 comments![]()

The 5 mm thick L profiles have been roughly cut to fit the circular shape, they already had exactly the good length.

2 holes that hold the lens are going to pass thru the 3 mm board and the 5 mm L profile on each side, 8 mm thickness should be good enough to hold the beast in place.

The 2 mm thick 3 cm square tube was bought on a garage sale, it's not as good quality as the other aluminium (the sidewalk high quality), but it will harden the assembly and will be convenient for the design of the hole thing.

-

fits perfectly

04/27/2022 at 09:01 • 0 comments![]()

After drilling the 6 necessary holes.

-

last pass

04/27/2022 at 08:55 • 0 comments![]()

Finally I can see the end !

It's been very long to drill that hole, hours... but could have been much faster : I didn't think of changing the drill speed and it was at around 500 RPM only !

How to use an aerial 36 inches lens

the different steps involved to shoot with an aerial photographic (enormous) lens when you don't have the airplane to hold it

[zit] Olivier Gade

[zit] Olivier Gade