Hybrid additive manufacturing of 3D electronic systems: https://iopscience.iop.org/article/10.1088/0960-1317/26/10/105005

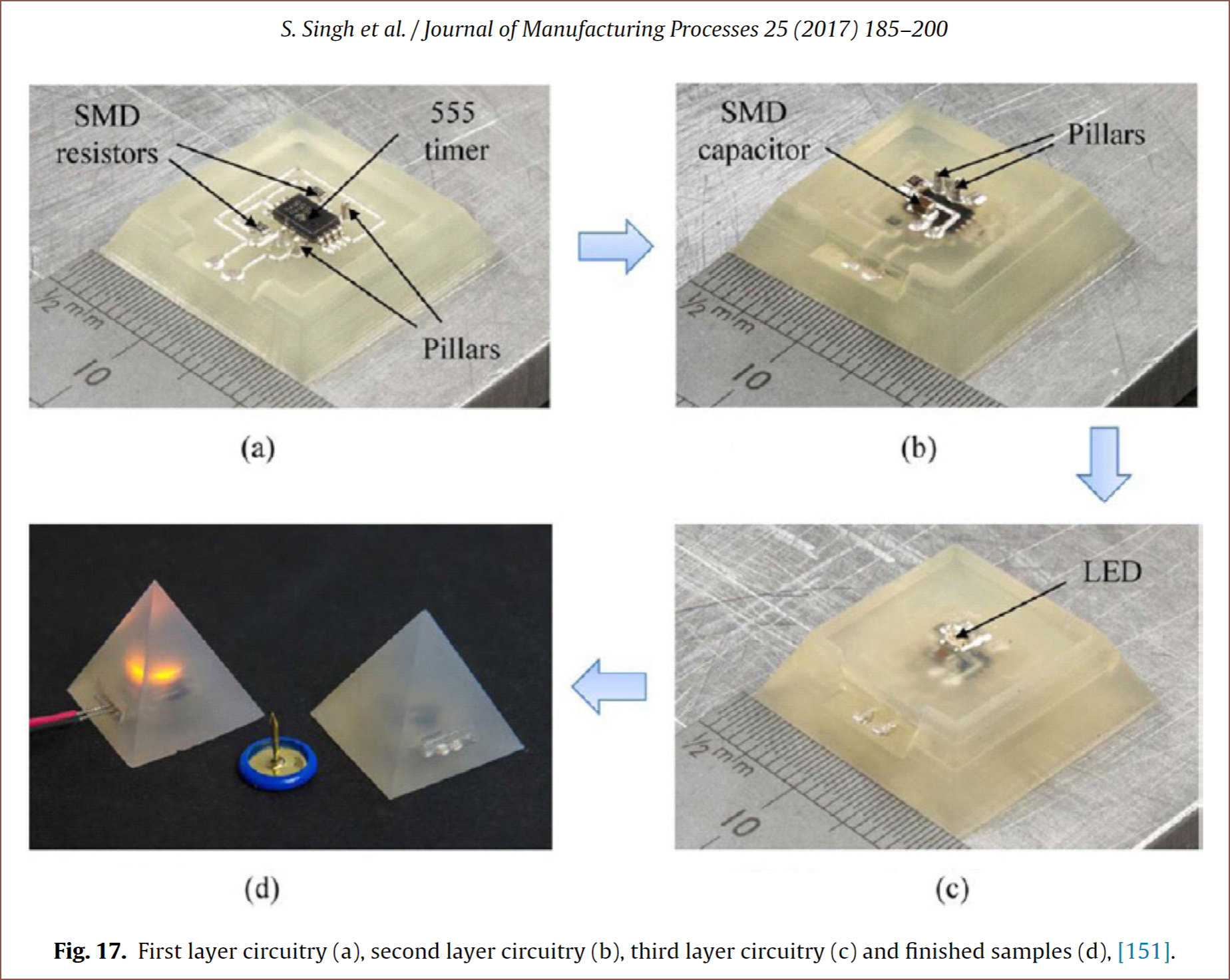

I've got no idea why so much (additive manufacturing) research is behind an access wall that only university students or those willing to pay ££ per paper, but I was reading Material issues in additive manufacturing: A review and the last set of images looked very intriguing:

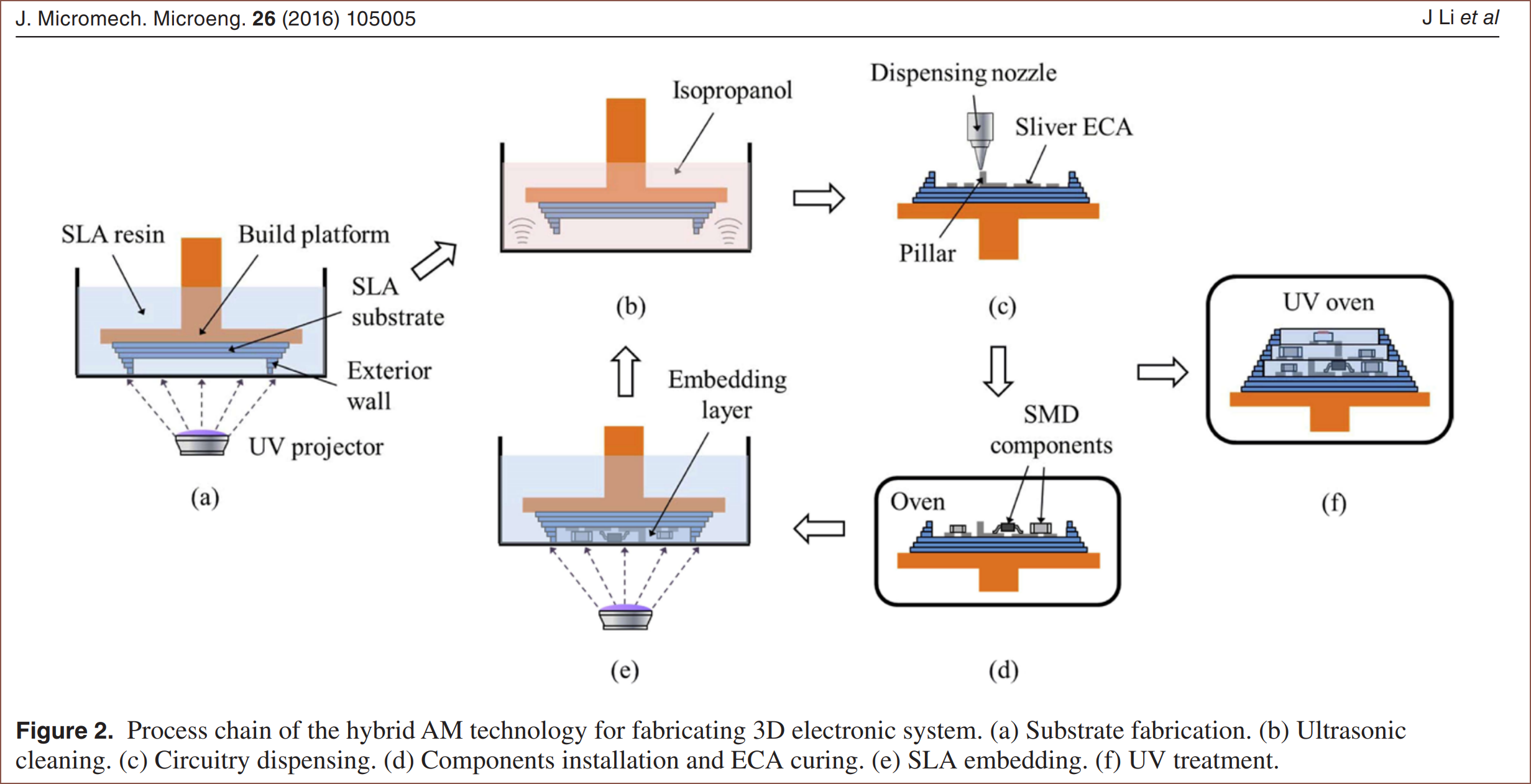

So I looked into this paper and the method they used, which is seen below:

So I looked into this paper and the method they used, which is seen below: I had a feeling that some kind of dispensing paste was more likely to happen than a decently conductive UV curable resin. If the cleaning roller works as intended, I'd likely be able to have a more streamlined process to what these researchers acheived in 2016. I doubt I'd have to use the oven until the part is finished since they won't be upside down or pushed around by resin in a vat. They use a clear resin with a Tg of 100C.

I had a feeling that some kind of dispensing paste was more likely to happen than a decently conductive UV curable resin. If the cleaning roller works as intended, I'd likely be able to have a more streamlined process to what these researchers acheived in 2016. I doubt I'd have to use the oven until the part is finished since they won't be upside down or pushed around by resin in a vat. They use a clear resin with a Tg of 100C. Resistivity

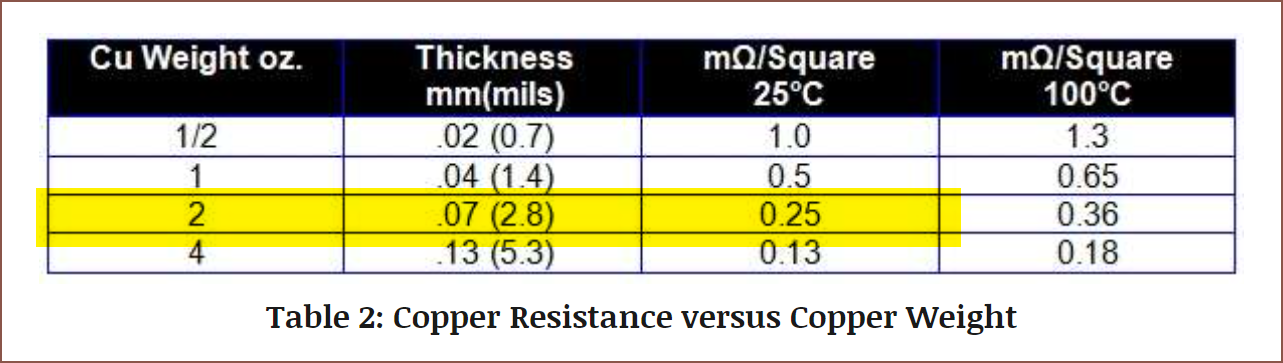

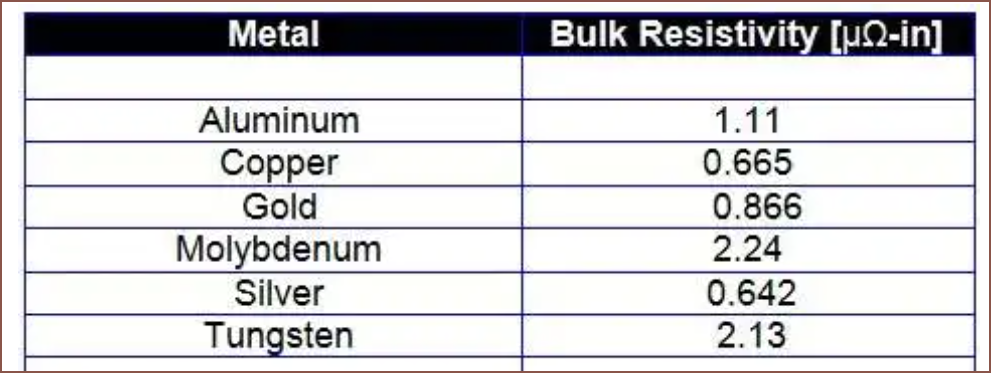

For a reference, this is the milliohms/sq for copper.

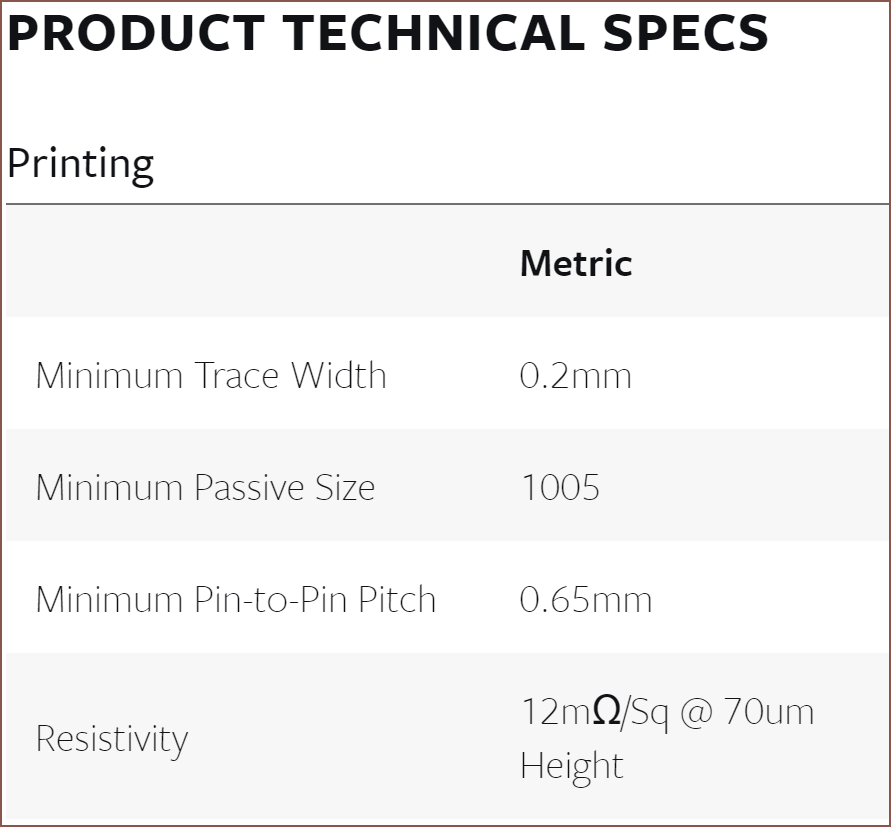

I've highlighted 70um because that is the same thickness stated from Voltera, who sell a PCB that prints in gels.

I've highlighted 70um because that is the same thickness stated from Voltera, who sell a PCB that prints in gels.

As you can see, the gels are pretty distant from copper (and the other metals, seen below).

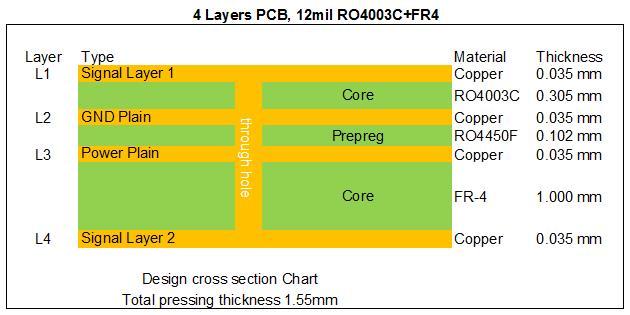

For a 1.6mm, 4 layer PCB, there does seem to be enough room to make any 1oz traces (35um) into thicker ones like 80um or 160um, which should help with resistance issues.

For a 1.6mm, 4 layer PCB, there does seem to be enough room to make any 1oz traces (35um) into thicker ones like 80um or 160um, which should help with resistance issues.

.16+.28+.16+.12+.16+.28+.16 = 1.32mm .16+.32+.16+.12+.16+.32+.16 = 1.40mm

That would leave enough for a 120um thick soldermask each side to acheive a 1.64mm PCB.

Anyway, it seems they're using "silver electrically conductive adhesive" and I was able to dig around and find something:

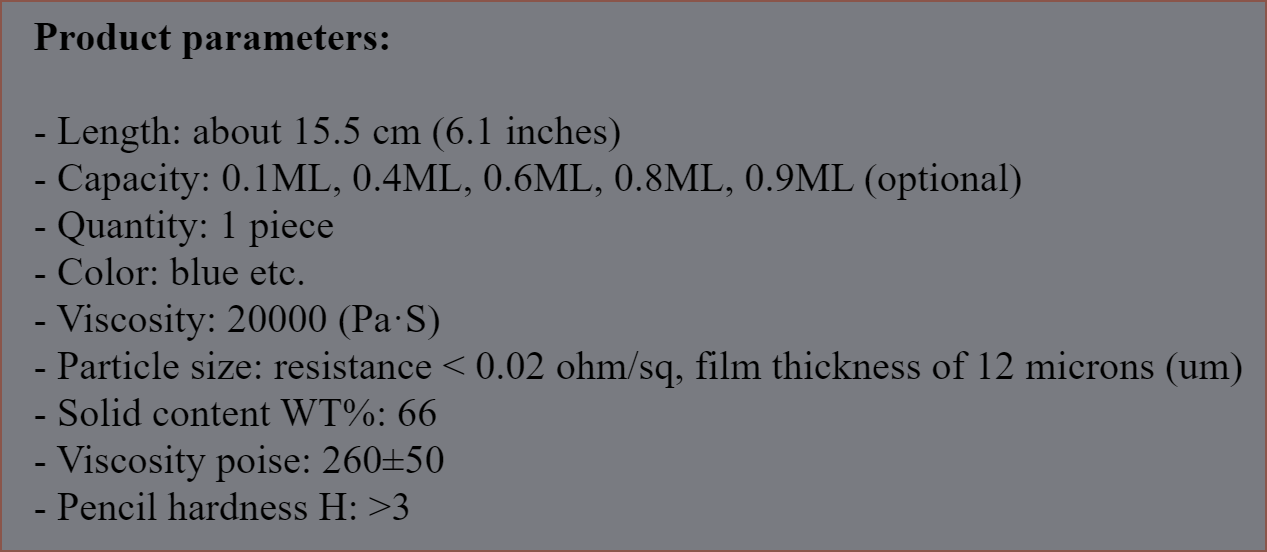

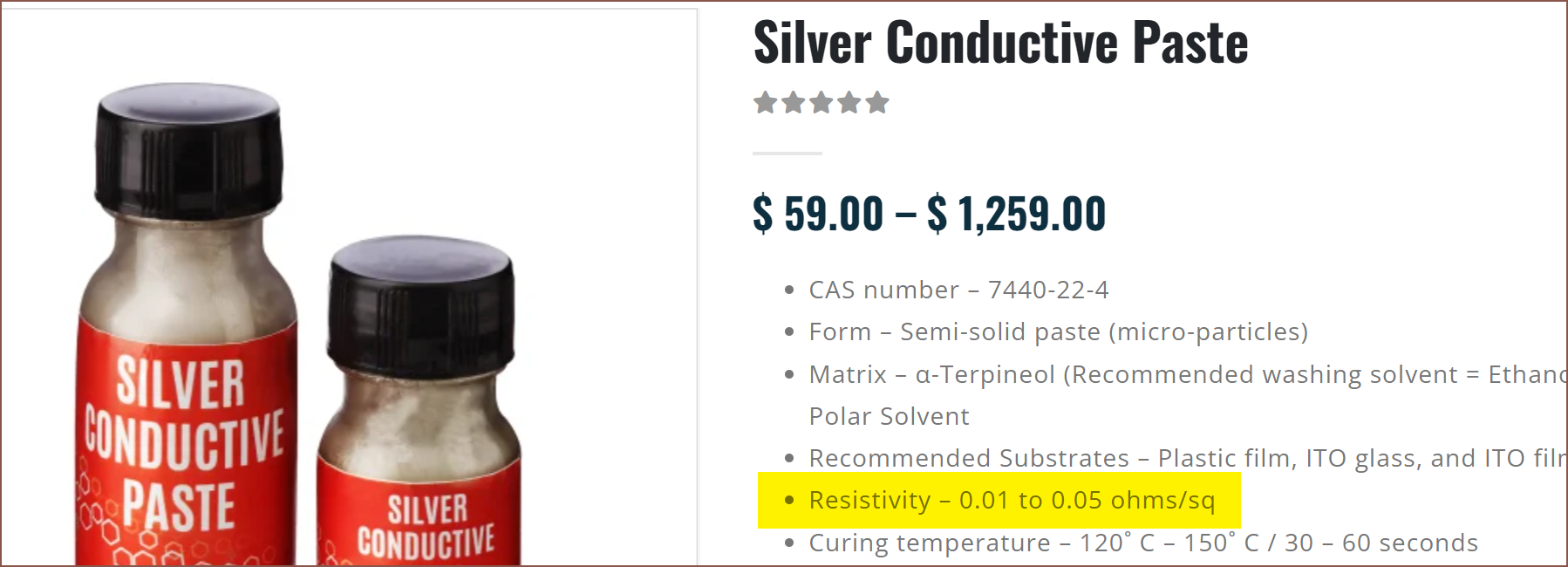

While technically expensive (£7,866/L), it sounds like the stuff in the paper by the description:

While technically expensive (£7,866/L), it sounds like the stuff in the paper by the description:

Is it me, or is that resistance really low? Perhaps there's an extra 0?

Is it me, or is that resistance really low? Perhaps there's an extra 0? Nope.

Nope.Why is the resistivity 1/6 of copper? I don't recall silver being that much better than copper in the electrical resistivity table I found a day or two ago.

[26th Aug] It's because I didn't notice that the pastes are in ohms/sq not milliohms/sq. The first paste is 20mOhm/sq and the second is 10-50.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Little known secret of research papers:

Most universities have an agreement with publications that encourage students to publish papers for credit. Those publications have contracts with anyone submitting a paper that restrict them from doing certain things with the papers. That includes openly publishing it for free or pay.

But there's been a loophole in as long as this has been a thing: they are allowed to share their paper one-on-one for free. The vast majority of people who have published papers will gladly email you a copy if you ask. They see ZERO money from anyone buying their paper through the publication and do not give two craps about the papers profits.

Yes, it's a hassle to have to email the authors, but I bet you could get any paper you wanted.

Are you sure? yes | no

At least now I know.

Are you sure? yes | no

As I started to suspect, it's been done with FDM: https://hackaday.com/2018/04/13/hybrid-3d-printer-creates-complete-circuits-case-and-all/

Is this like the 5 axis printer made by a uni student where it never got picked up by anyone else in the community and was slowly forgotten? Or perhaps it was because the feature sizes were still too large -- a 0.2mm nozzle would only be able to make 0.4mm lines before Cura 5.0.

Are you sure? yes | no