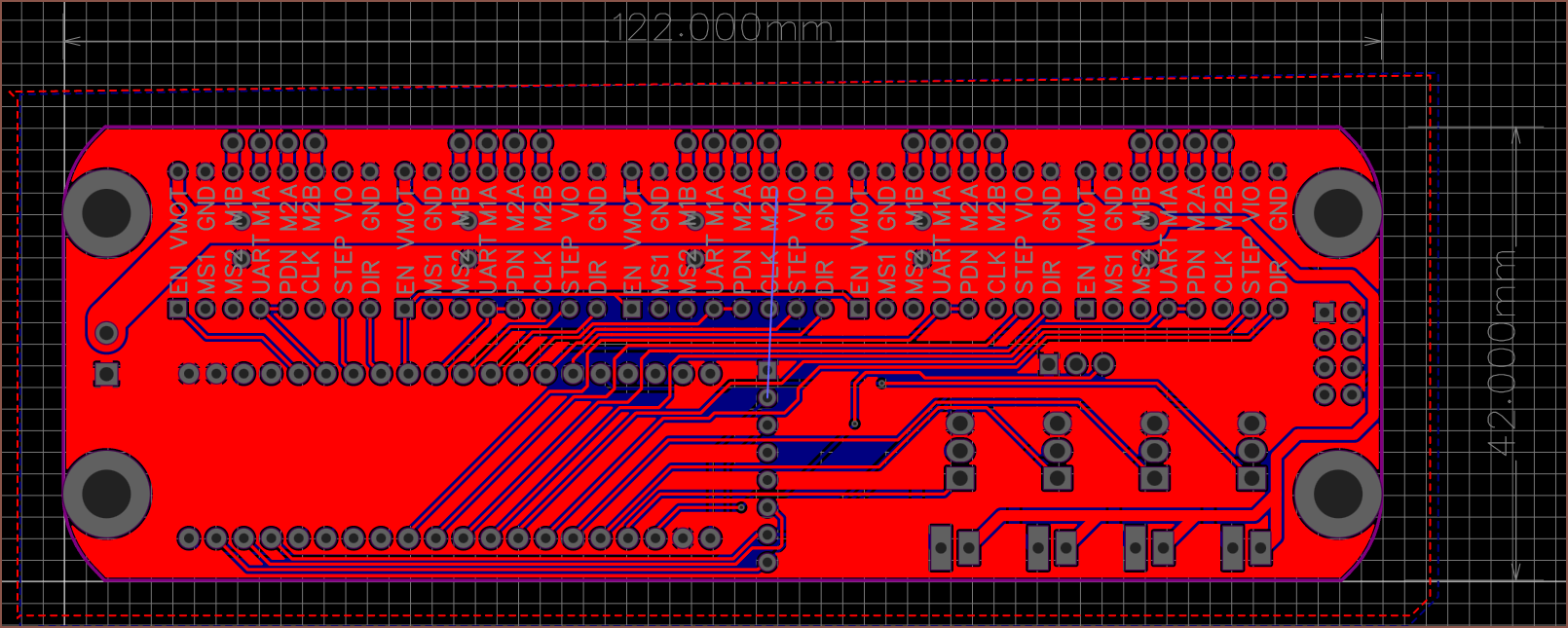

I've been meaning to find out how much conductive silver paste is actually needed for a PCB. I used an old gerber file for a #T^2 Tiles [gd0095] board I never got made. Long story short, Fusion 360 kept crashing when using the svg (converted to dxf), so I just went with a simplified dxf.

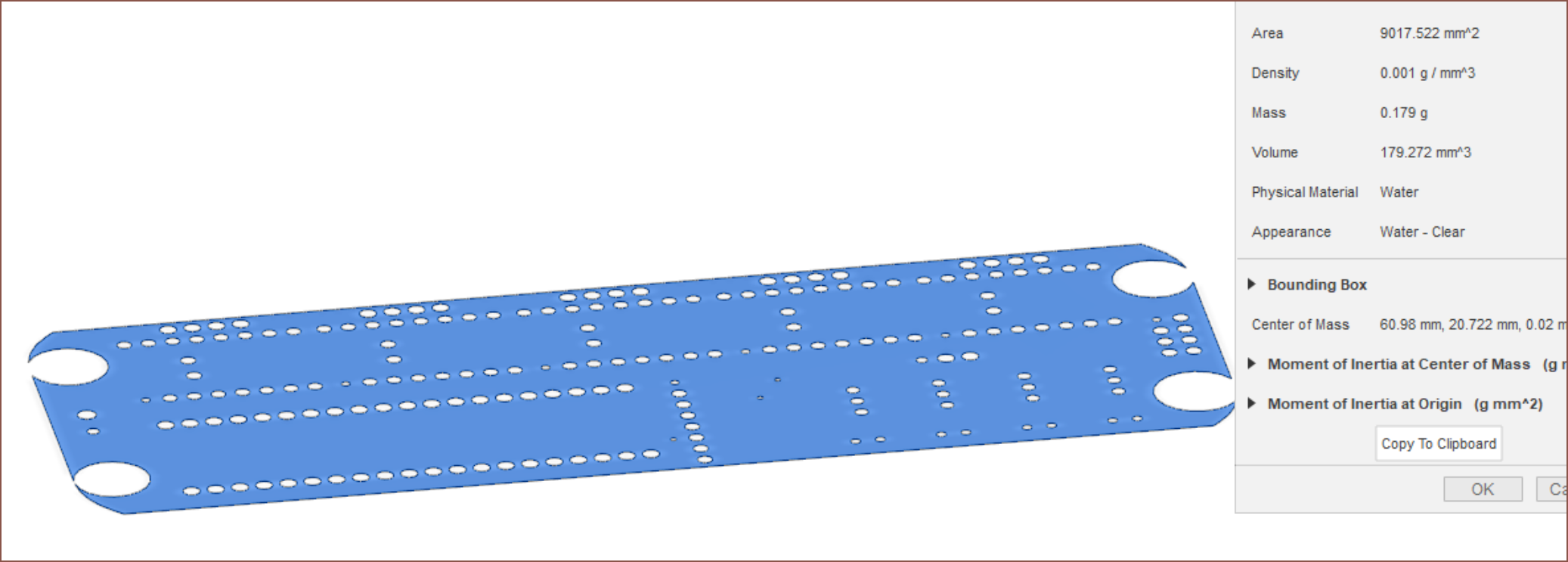

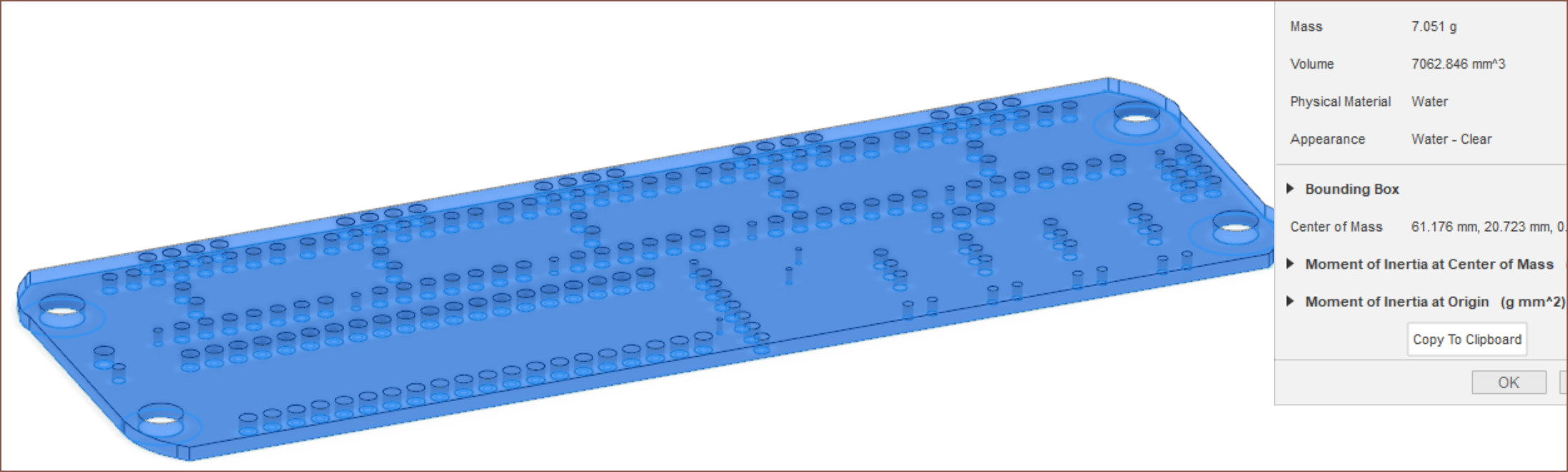

I've used water to get the volume, which would be 0.18ml. Multiply this by 2, and it's 0.36ml for a 2 layer board with conductive planes. For the resin minus the 80 microns for the conductive layers, the volume is 7.05ml.

I've used water to get the volume, which would be 0.18ml. Multiply this by 2, and it's 0.36ml for a 2 layer board with conductive planes. For the resin minus the 80 microns for the conductive layers, the volume is 7.05ml.

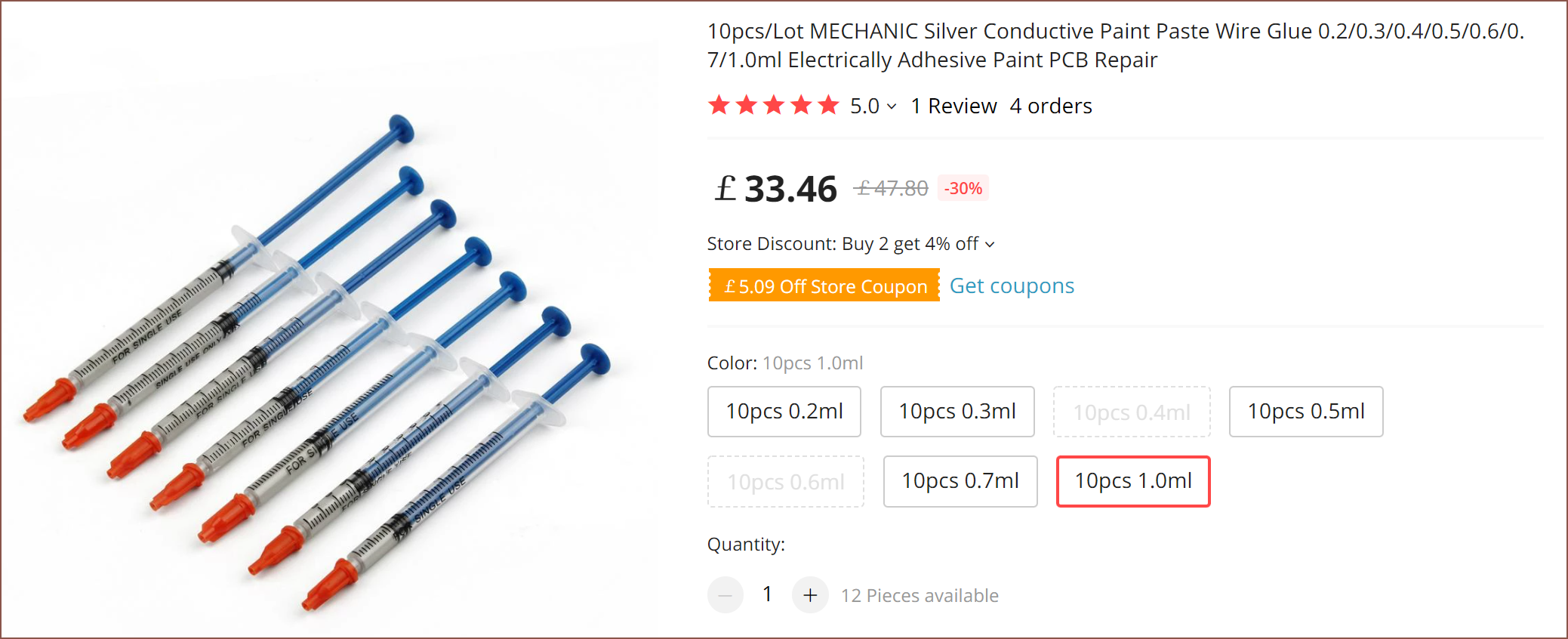

Looking across the internet, it seems that the going rate is £4/ml and up (incl 20% tax).

Then, even with this first-seen-in-industry, as-non-toxic-as-PLA-in-liquid-form resin I found out about yesterday that costs £78 after tax for 500ml, I'm only looking at £1.0998 in material. I'd like to believe that some high temp resin or "digital soldermask" resin would cost less than this.

Assuming the conductive paste is £4.50/ml, the final price is £1.10 + £1.62 = £2.72 for a 122x42mm (5124mm^2) board, which is actually in my league budget. The square area is 51% the size of the 100x100mm boards for $2 at JLCPCB. I had a second revision, 3993mm^2 board fabricated (which was 110mm on the long side so couldn't get the offer), and the minimum order quantity (MOQ) of 5 cost £8.70 with ultraslow shipping, coming in at £1.74/pcb. Extrapolating the above, a print of this size would cost £2.12 and should arrive wayyyyyy faster than 4 weeks. Likely even faster than next day delivery.

These conductive paste's required quanities and prices per ml mean that it's also not favourable to use the L^3 method. I imaginee that the lowest end minimum fill level for even a silicone-tube-only (no tank, but collector pump straight to application pump) cartridge would be >15ml.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.