So, 3 years after the start of this project, I've finally simplified the project description:

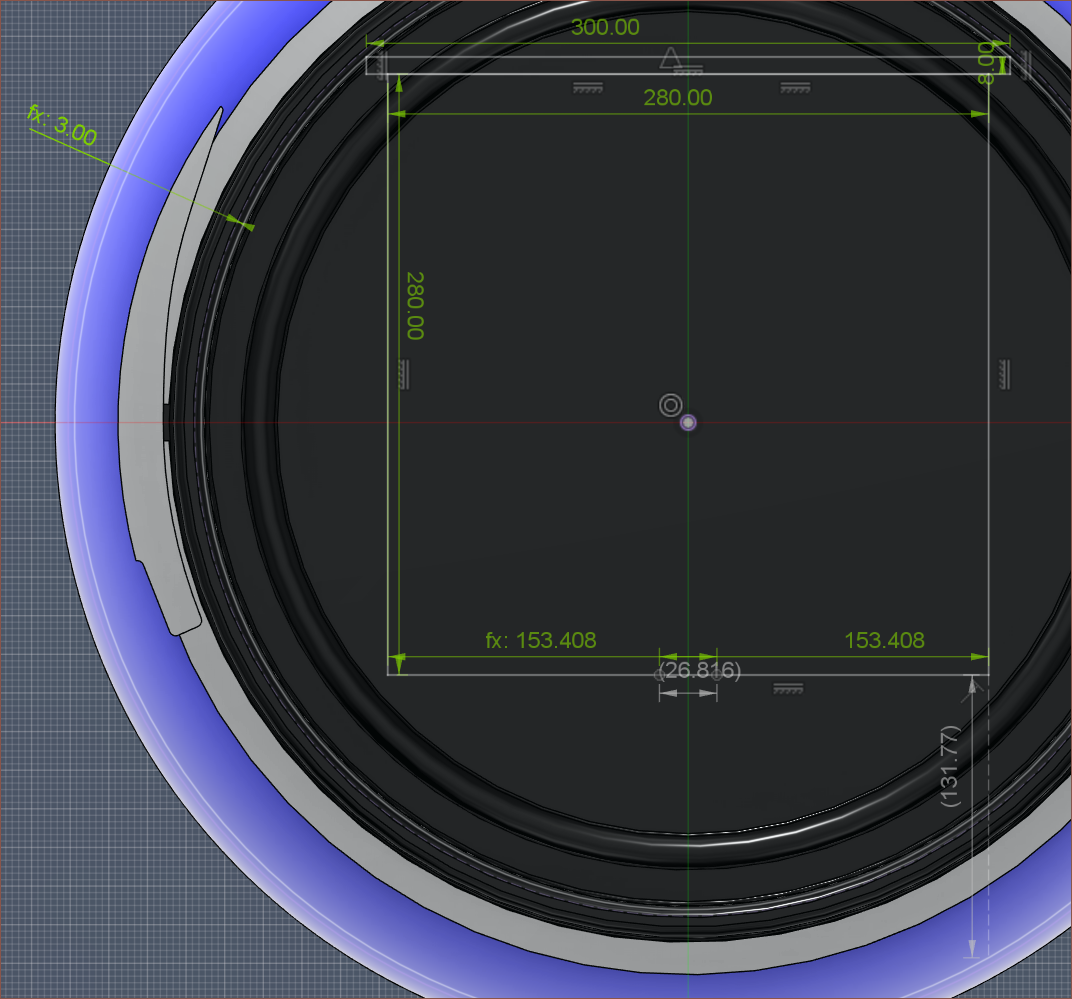

One of the points is the build volume. I've been sketching some rough measurements and I believe that 28 * 48 * 28cm (XYZ) is a reasonable goal to aim for.

This build volume is similar to a CR-10 (and its clones), but the Z axis isn't the longest. If anything, the Z axis will be the shortest if additional space is needed for internal components. Part of the reason is due to the shape of the barrel, but it's mainly so that the slowest axis isn't also the longest axis, which is usually the case in the MSLA industry.

The X axis is limited by the fact that PET cake collars max out at 30cm wide. It sounded reasonable to use a 30 * 50cm build plate and have the XY build area be a 1cm margin within, hence 28 * 48cm. Due to BambuLab, it's also wise that the X is at least 25.6cm so that Makerworld models fit. To allow for the printing of vases and other large, cylindrical objects, it would be ideal if the Z axis matched the X, hence a height goal of 28cm.

I expect the laser-accessible Y length will be around 10cm shorter. An area of 28 * 38cm is still plenty for PCBs, especially if they're printed such that the thin side is against the plate like standing dominoes.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.