Intro & Project Goals

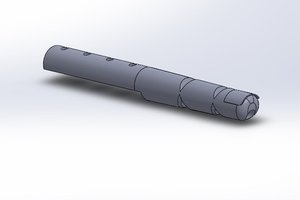

I have a wee sized shop measuring a measly 12' long 8' wide and 9' tall. So, I need a small dust collection system. I also wanted the system to be more efficient than just having a shopvac alone. Also, since my shopvac is so tiny (only 2.5 gal w/ 1.25" pressure fit hose) and I dislike having to buy filter bags, I decided adding an inline vortex particle separator and a 5-gal bucket would be just the ticket.

Also, knowing that someday I might want to upgrade my shop size, and that I may need to use a larger vacuum system if/when I do, I decided it would be prudent to design the vortex to support a 2" vacuum hose. Obviously this can be adapted down to the 1.25" hose I currently have very easily with either a purchase reducer or a 3D printed one (to be included in this project).

Other goals include:

- Reduce / eliminate the need for supports when 3D printing

- Keep the cost to print under the ~$30 mark I would spend if I were to purchase a commercial one

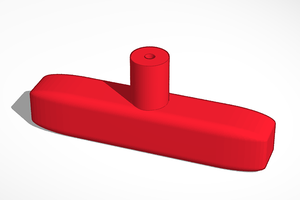

- Design the parts to fit together easily, and to stay together even if not glued together

Results:

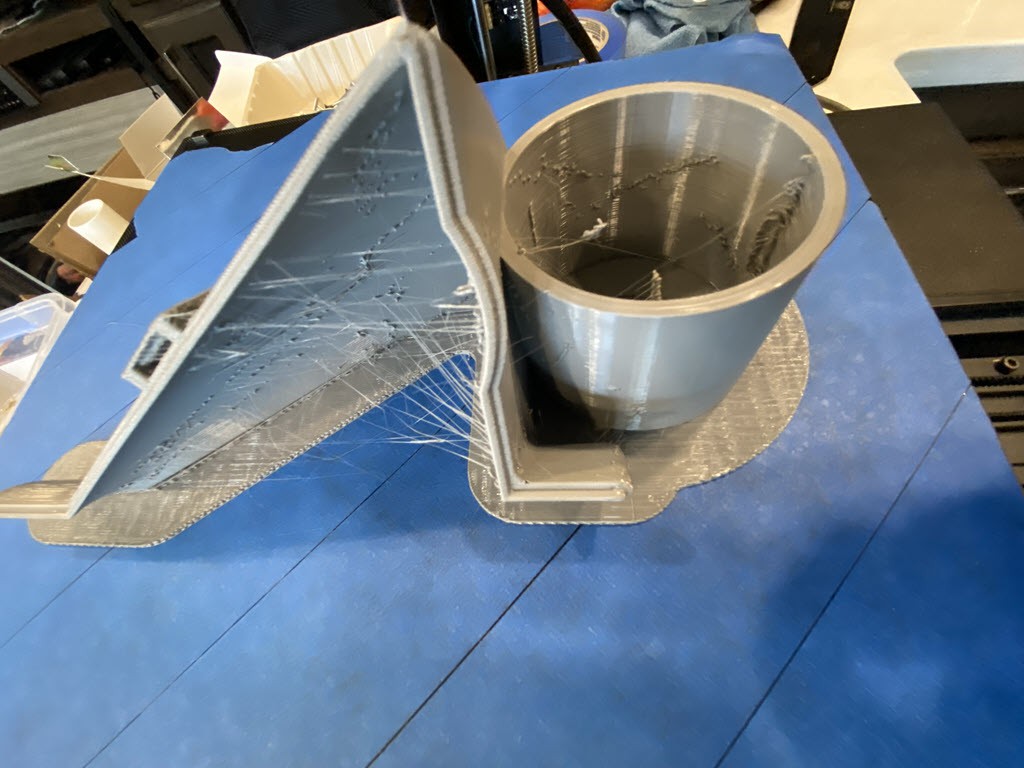

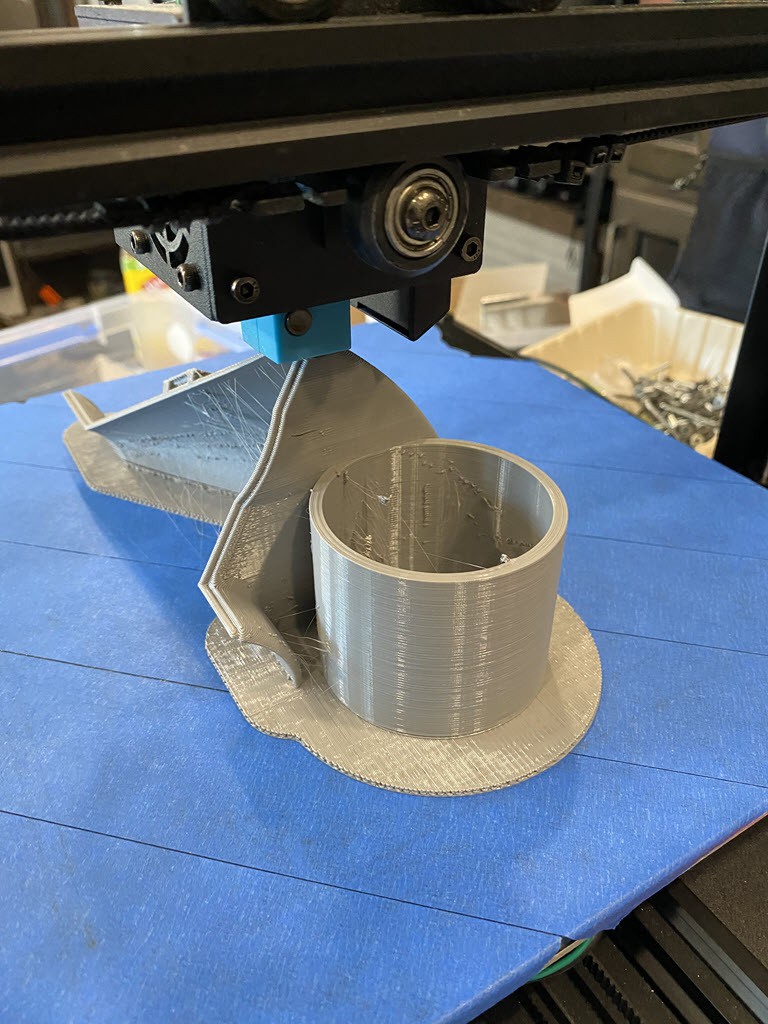

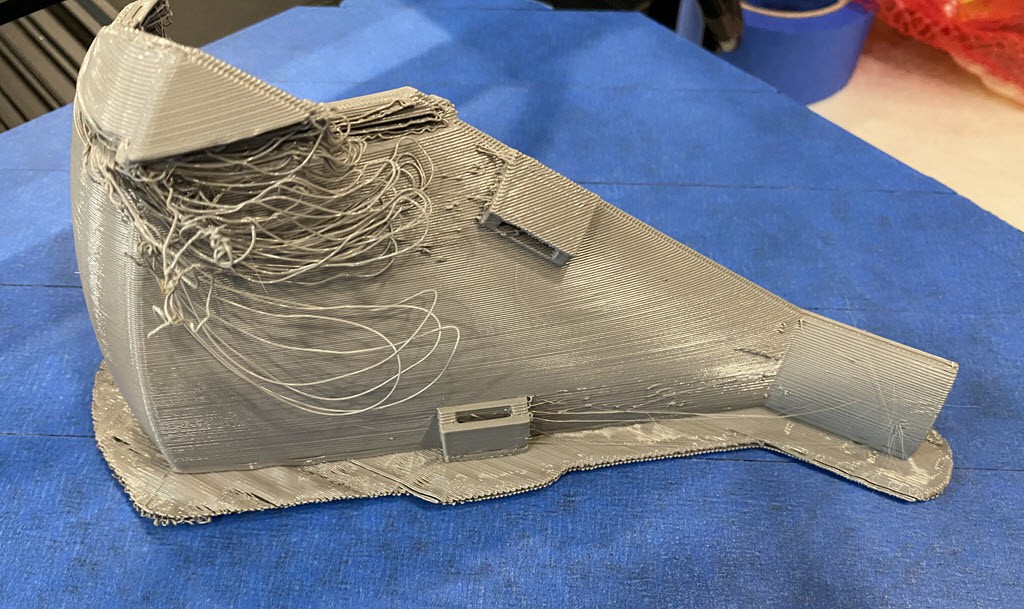

- No supports are needed...with a single exception. Using a raft when printing the Vortex and snap arm parts is HIGHLY recommended. I have a glass top bed that can be heated so I thought I should be good with printing normally (i.e. no raft, just a small brim w/ the bed at 60 degrees C). However, when I first tried printing the parts it would get to about layer 3 and then the part would detach from the bed! The parts were just too thin to have enough surface area to hold to the bed. This is especially true for the Snap arms. They won't have a chance of staying upright without a raft. And, if you lay them flat to print they will require supports which will necessitate much work after print to clean up. The solution (after much trial and error) was to use a 10mm raft 5 layers thick. It's possible it would have worked with a smaller width and less layers, but this is what I ended up using without any further issues. Note, I also added blue tape and (following a failed print of one of the larger slices) I sprayed the tape with hairspray! Overkill? Maybe! Solid! Definitely!

- Total PLA volume is roughly 600g. Seeing as how I paid $28 for 1kg, this puts the final build cost at ~$16.80. Of course this didn't include all the trial and error, and the fact that one of my pieces got bumped out of alignment in the middle of the night (still not sure what ghost did that!) causing it to fail.

- Partially successful at making it all go together easily. Here are the main issues:

- PLA tends to warp. This was minimized by using the raft, but still, some warping is likely to occur. I suspect this is due (at least in part) to how thin the pieces are (1/8"). I didn't want to make them any thicker to keep print volume down, nor did I think they needed to be any stiffer. This means I ended up with a minor amount of warping. As you'll see in the build process notes, this was overcome by trimming / sanding the parts after print to get a snug fit.

- Print resolution insufficient to make angles ideal - In other words, some trimming and sanding was needed after printing because the angles between pieces didn't match perfectly. As you'll see, this really isn't a big deal either.

- Though functional, the Snap design could use some improvements - If I were to try and sell this design commercially, I'd iterate a few more times on the snap design. In particular I think it might be easier to assemble if the snap arm wasn't a free-floating part. In other words, I think I would make it so the snap arm was connected permanently to one side of each slice. However, as you'll see this is easily overcome by gluing the arm into place during assembly. Still, I would design it differently if I did it over. Maybe I will at some point. Feel free to do so yourself!

3D Printer Requirements and Recommended Settings:

These settings (in Ultimaker Cura slicer) worked very well for me:

- Material:

- 1.75mm PLA (roughly 600g worth!)...

Aaron P.

Aaron P.

jon.knutton

jon.knutton

Alan Chambers

Alan Chambers