-

13D Printer Setup

These settings (in Ultimaker Cura slicer) worked very well for me:

- Material:

- 1.75mm PLA (roughly 600g worth!)

- I have an Anycubic Mega X printer. It has a print area capacity of 300mm x 300mm x 300mm. You will need at least 238mm (9.37") x 234mm (9.22") in the XY plane, and 89mm (3.5") in the Z (height) axis to print these parts as I've designed them (this includes a 10mm raft on all sides). Remember that you can rotate the part so it prints diagonally! In summary:

- Print Length Max (includes 10mm Raft): 238mm (9.37")

- Print Width Max (includes 10mm Raft): 234mm (9.22")

- Print Height Max: 89mm (3.5")

- Raft HIGHLY Recommended:

- Raft width (aka Extra Margin): 10mm

- Raft air gap: 3mm (to make it easier to remove the raft!)

- Raft top layers: 2

- Raft top layer thickness: 0.4mm

- Raft top line width: 0.4mm

- Raft top spacing: 0.4mm

- Raft middle thickness: 0.6mm

- Raft middle line width: 0.8mm

- Raft middle spacing: 1.0mm

- Raft base thickness: 0.48mm

- Raft base line width: 0.8mm

- Raft base line spacing: 1.6mm

- Raft top print speed: 7.5mm/s

- Raft middle print speed: 5.625mm/s

- Raft base print speed: 5.635mm/s

- Walls:

- Wall thickness: 1.2mm

- Wall line count: 3

- Fill gaps between walls: Everywhere

- Quality:

- Layer Height: 0.4mm (same as my extruder diameter)

- Initial Layer Height: 0.4mm

- Line Width (including ALL sub-settings in this category): 0.4mm

- Initial Layer Line Width: 100>#/li###

- Top/Bottom:

- Top Surface Skin Layers: 2

- Top/Bottom Thickness: 1.2mm (= 0.4mm height/layer * 3 layers)

- Top Layers: 3

- Bottom Layers: 3

- Infill

- Infill Density: 100% (because I want it as strong as possible and it's only 0.25" thick to begin with!)

- Infill Line Distance: 0.4mm

- Infill Pattern: Lines

- Infill Layer Thickness: 0.4mm

- Support:

- Note: I didn't need any supports. This was a design decision and it worked out very well. However, generally I have my Support settings set to the following so it will detect when I need overhangs:

- Support Overhang Angle: 65 degrees

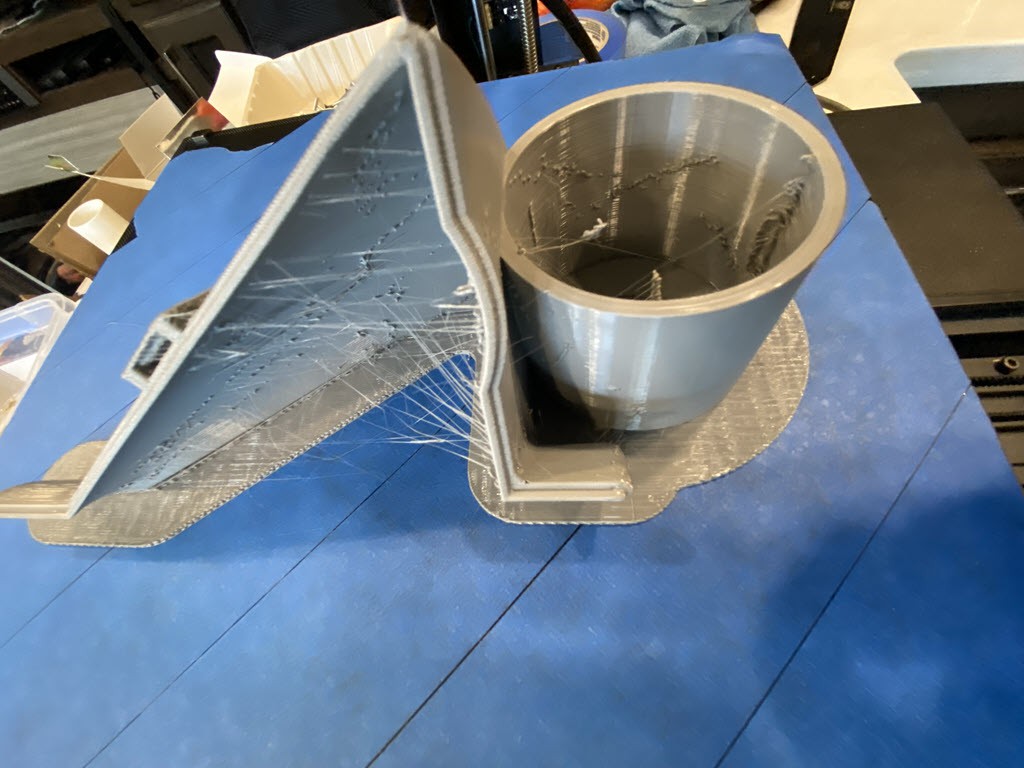

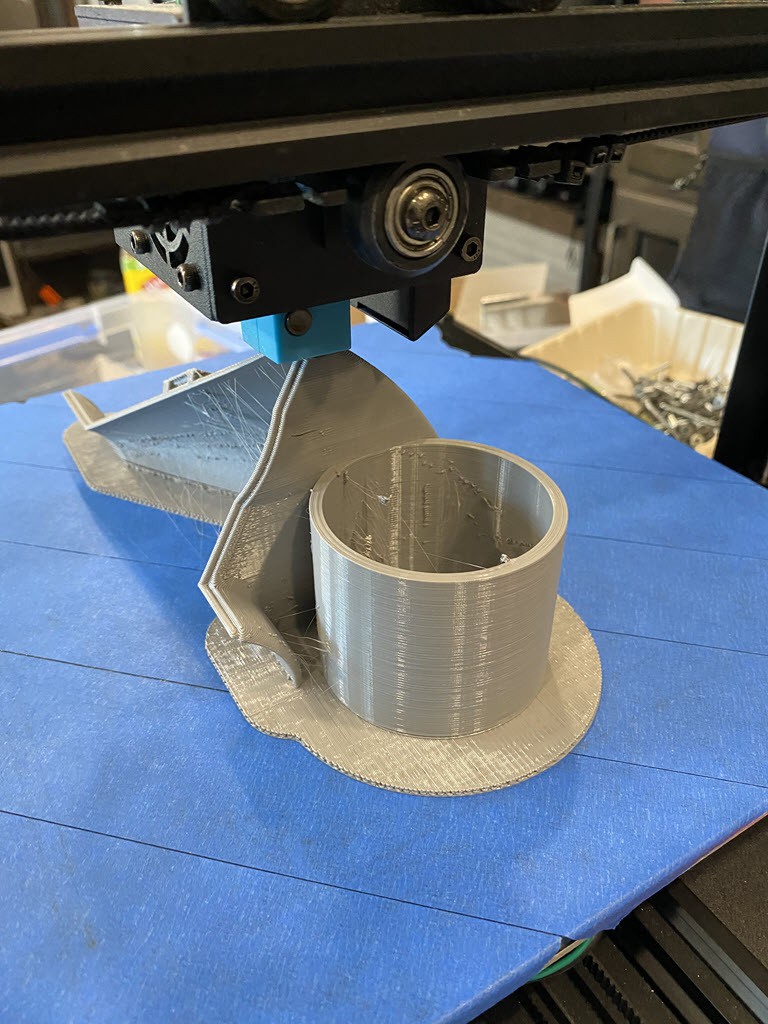

The goal is to get them to come out at least as good as these...

Don't let the gremlins move your cheese in the middle of the night...

- Material:

-

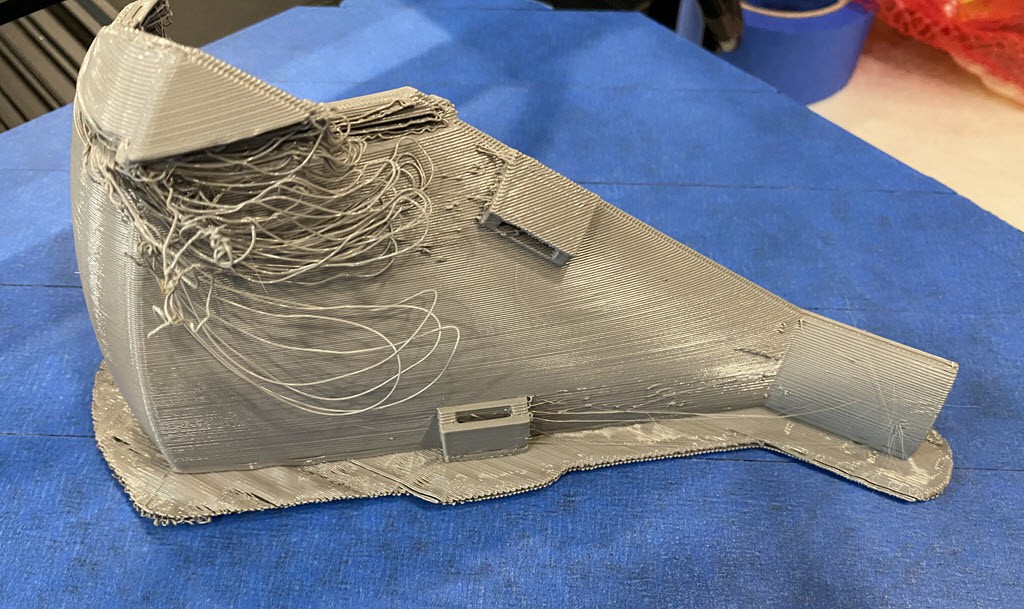

2Cleanup of Printed Parts

Huzzah! It's done printing! Now it's time to clean it up. I used a wood rasp, a metal rasp, a Dremel with a sanding drum, an xacto knife, and of course a cutting board.

Here's a side-by-side comparison of before and after using the knife and rasps only:

Work in progress...Stay tuned!

-

3Vortex Bowl Assembly

TBD

-

45 Gallon Bucket Lid Assembly

TBD

-

5Whole System Assembly

TBD

3D Printed Vortex Particle Separator for Shop Vac

A small(er) Vortex Particle separator that can be easily 3D printed. Use with a 2" or 1.25" (adapters needed - can be printed) vacuum hose.

Aaron P.

Aaron P.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.