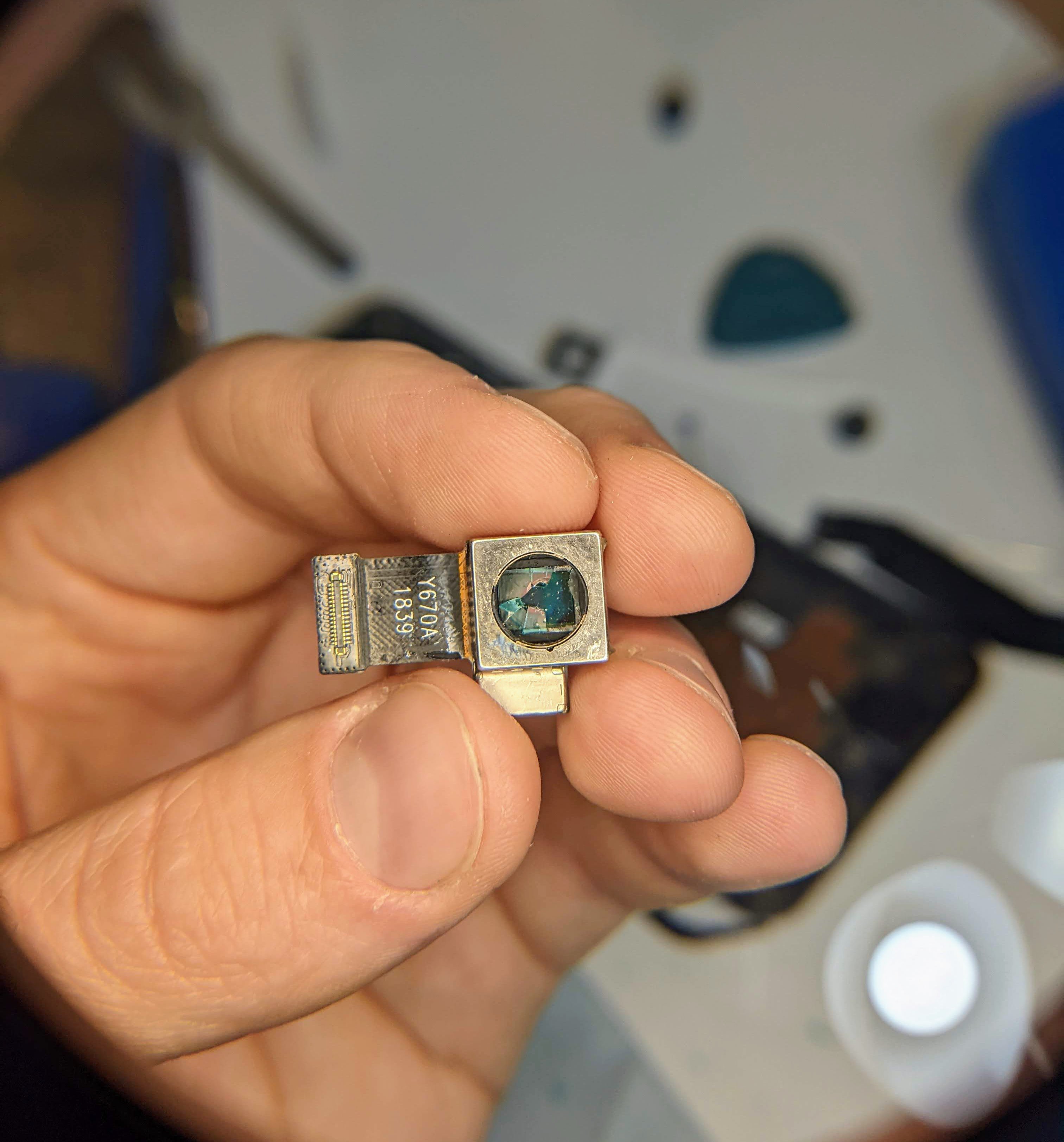

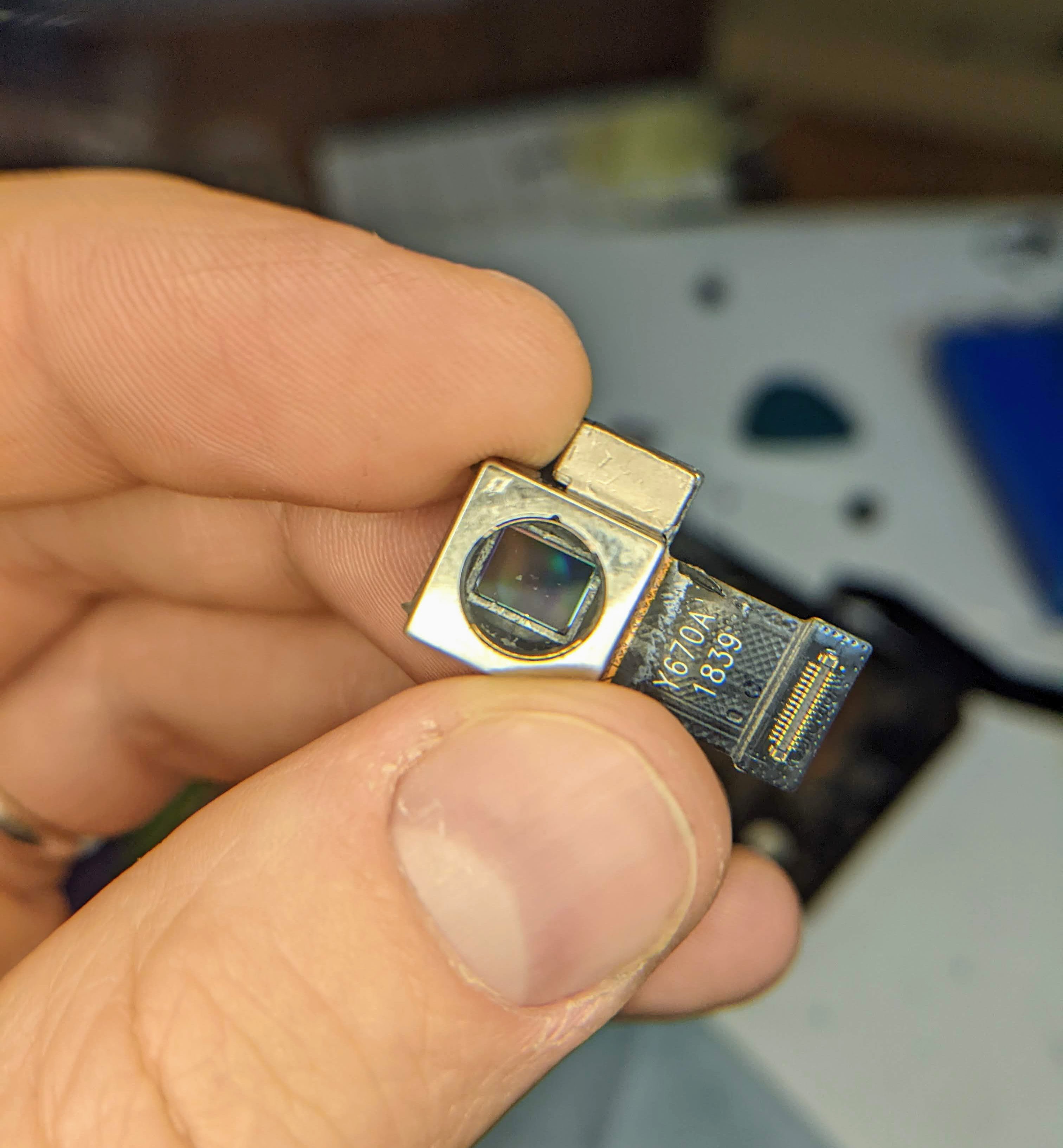

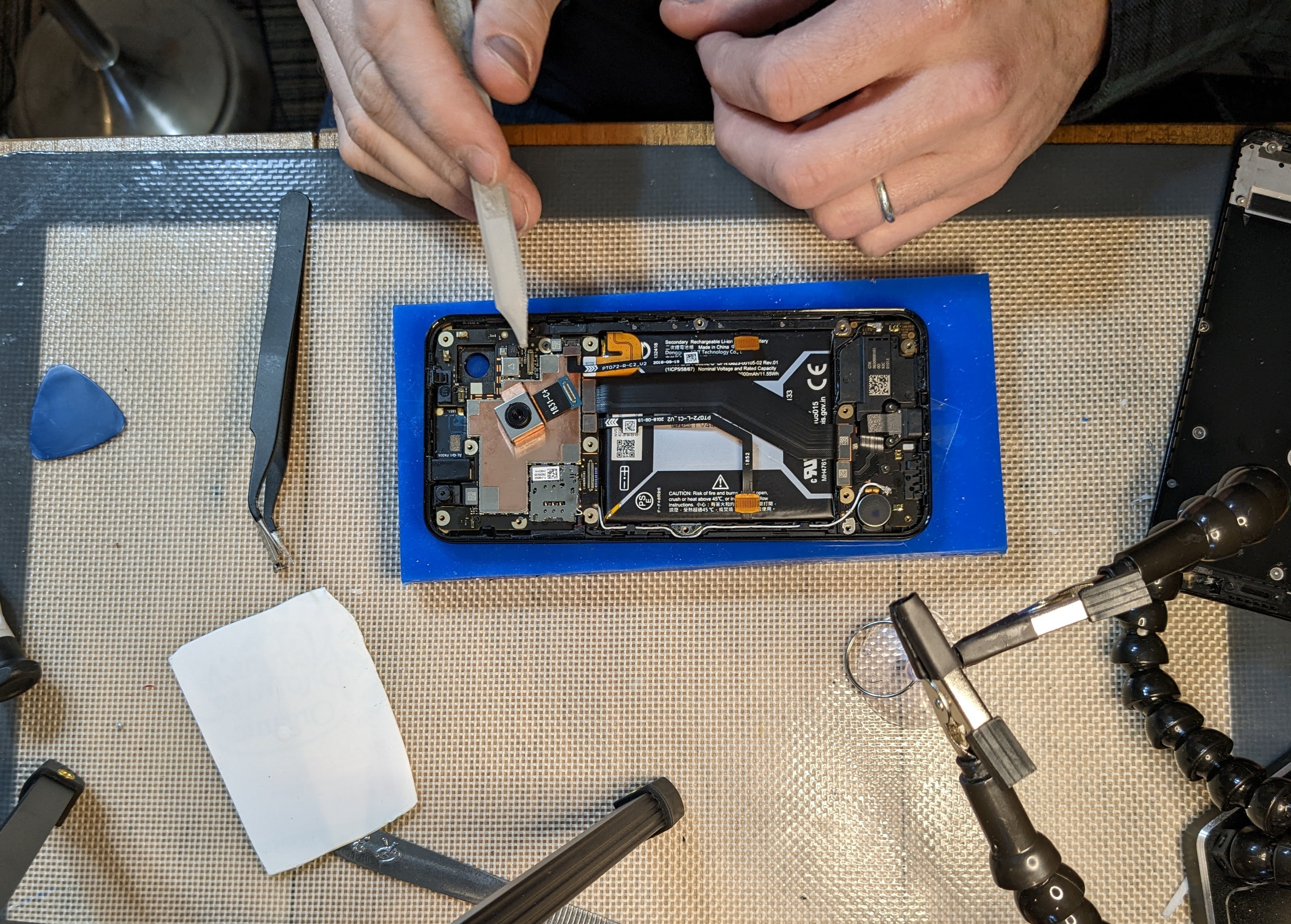

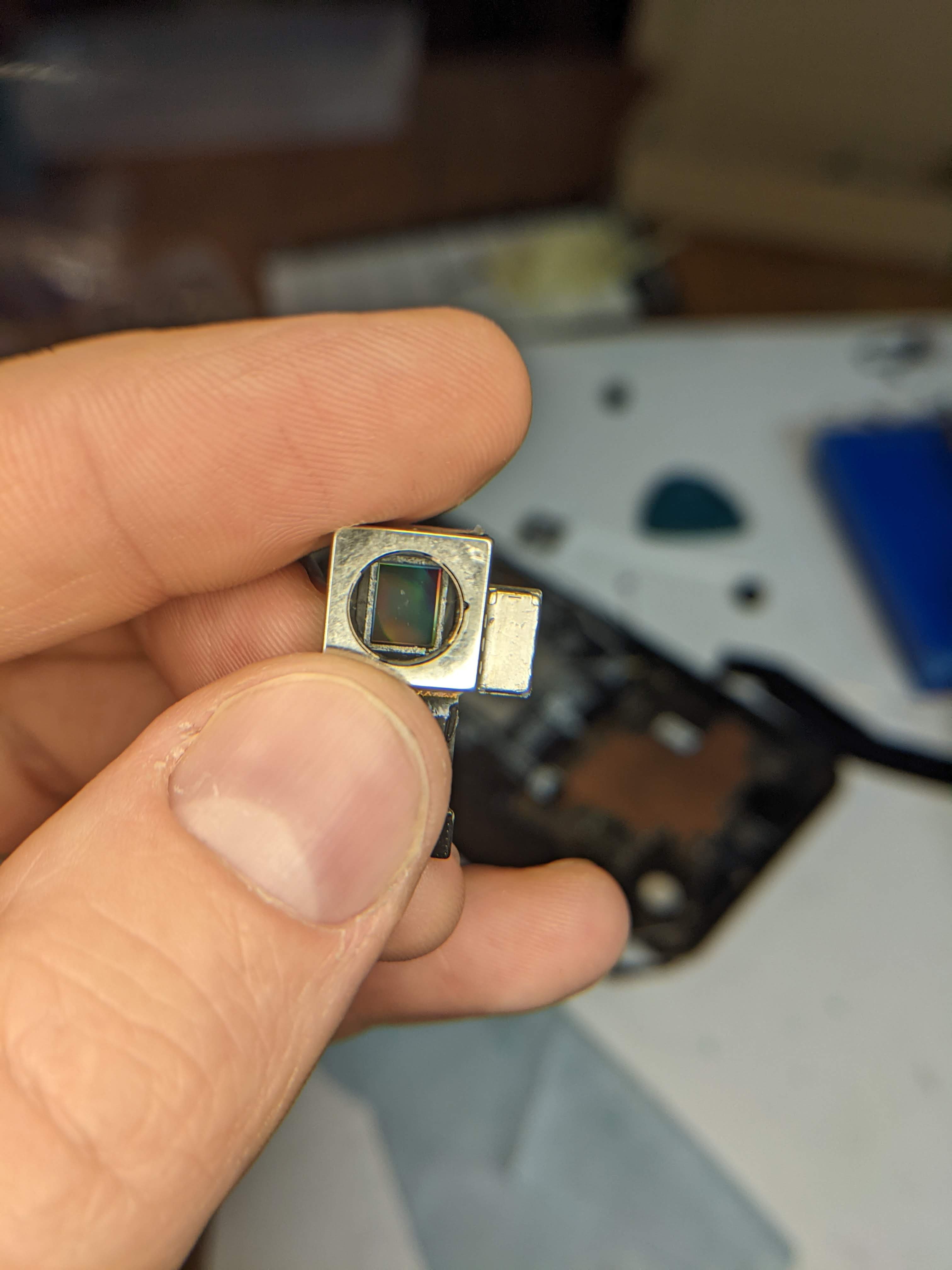

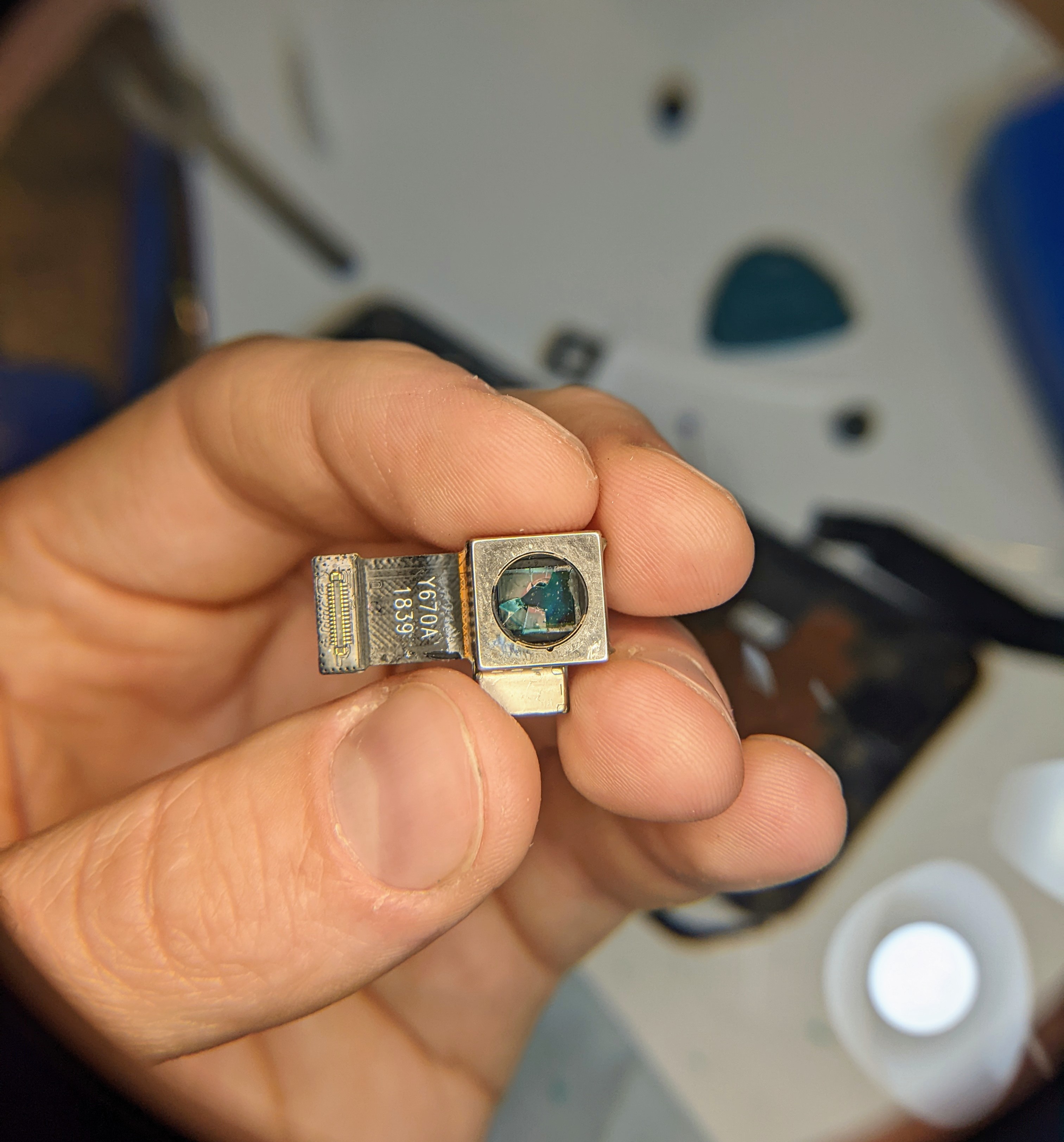

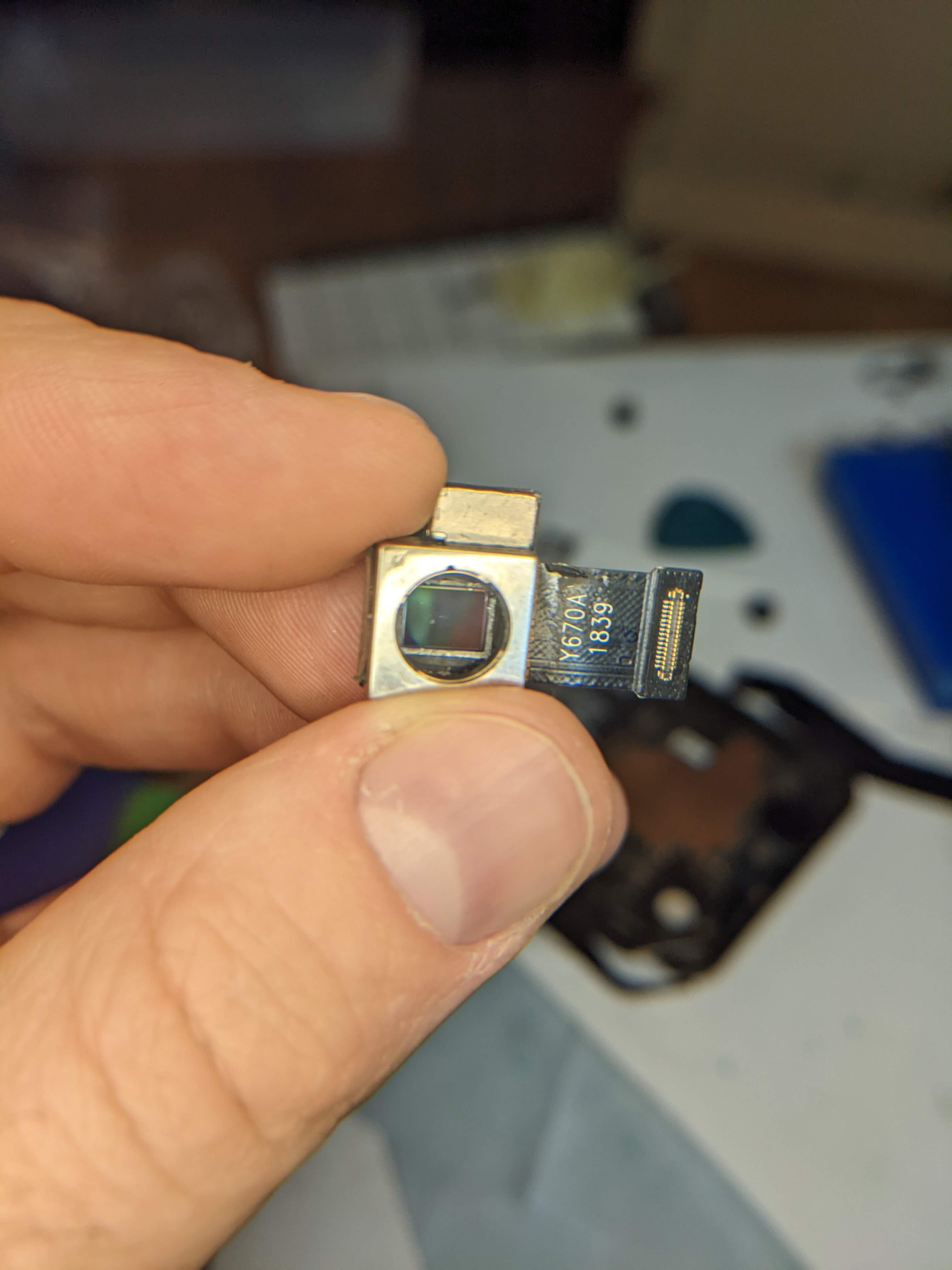

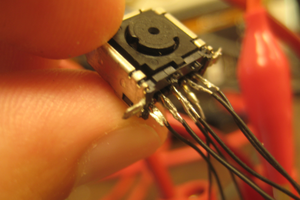

This project started with utilizing a separate USB camera module, removing the IR filter, and interfacing with a smartphone with an app. That turned out to be a lot easier than modifying a smartphone, but was limited to the lower-quality cameras and USB camera software. I've gone through about a couple dozen smartphone camera modules to find ones that were able to be modified and the method by which to do so.

Finally, it's starting to work.

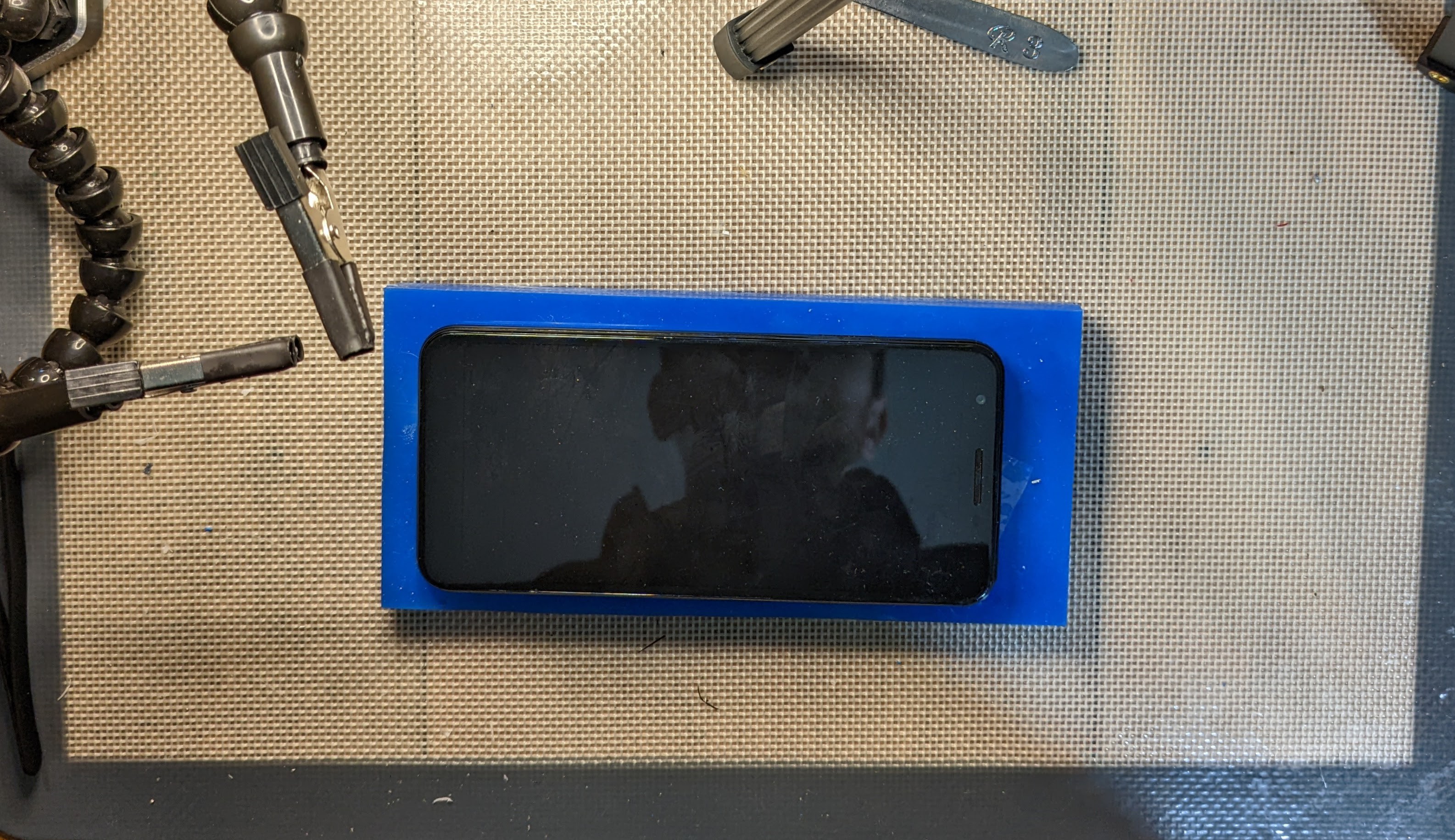

I've been using the Google Pixel 3a because it has great camera software, excellent night and astrophotography modes, and used versions are available very affordably.

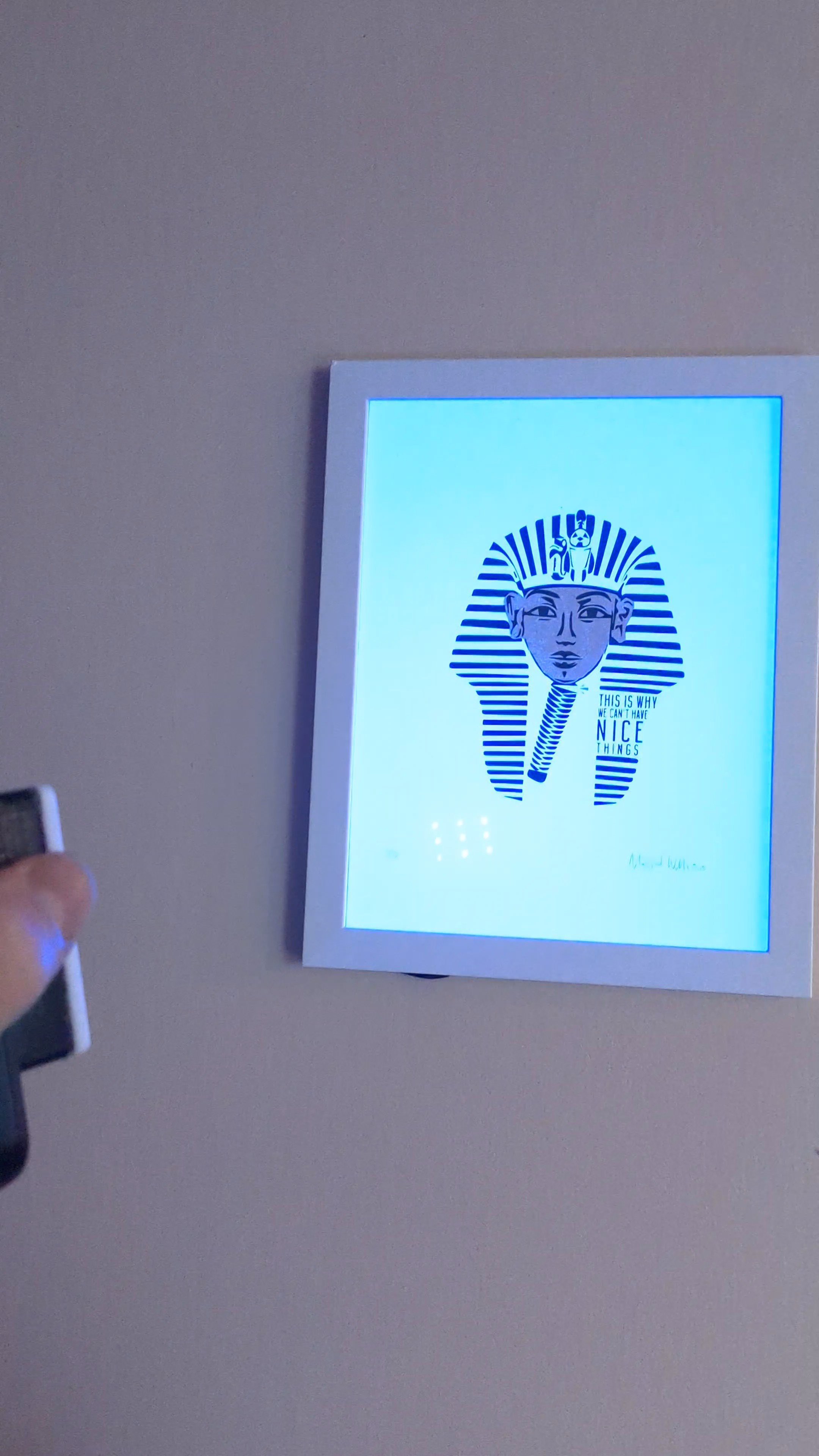

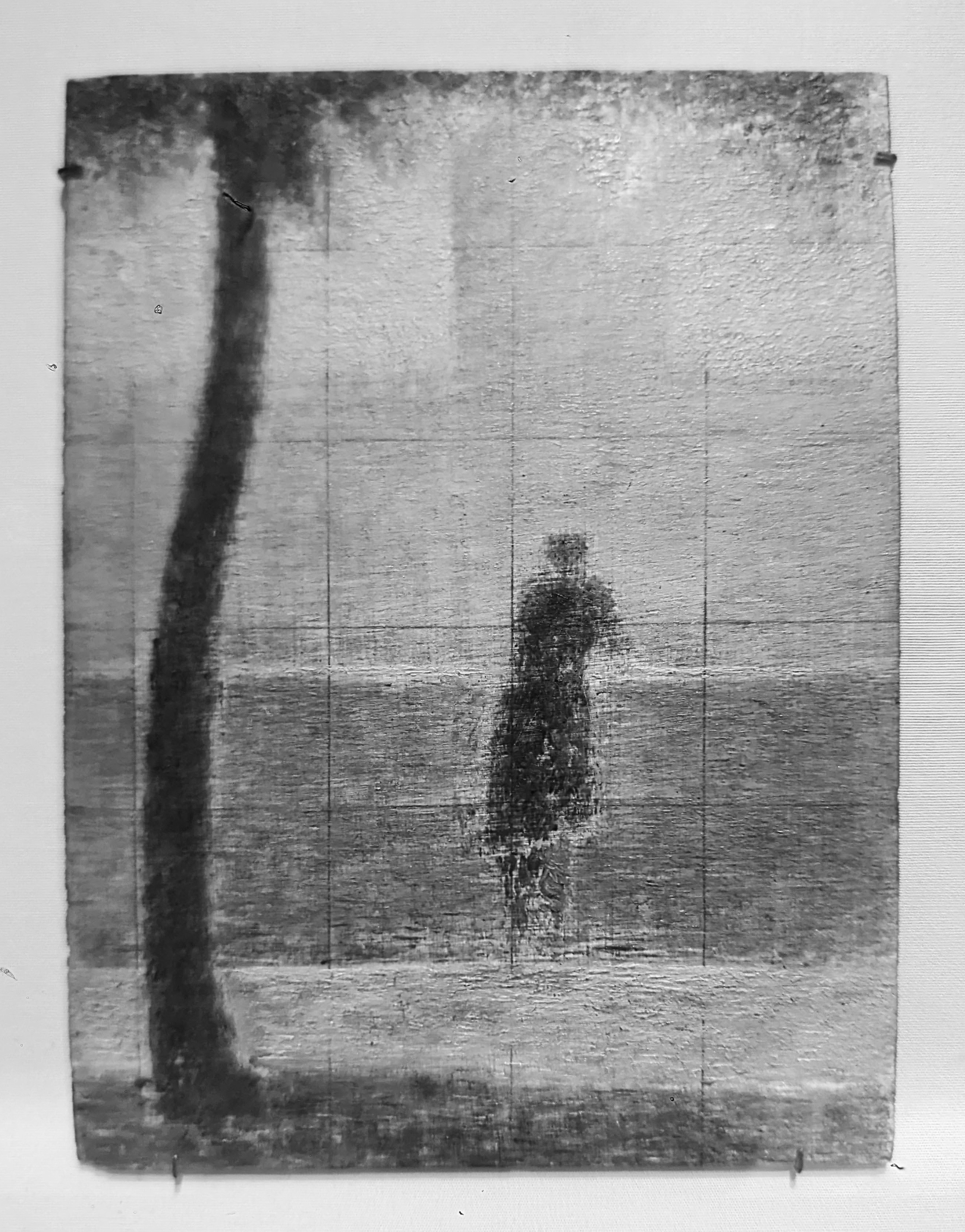

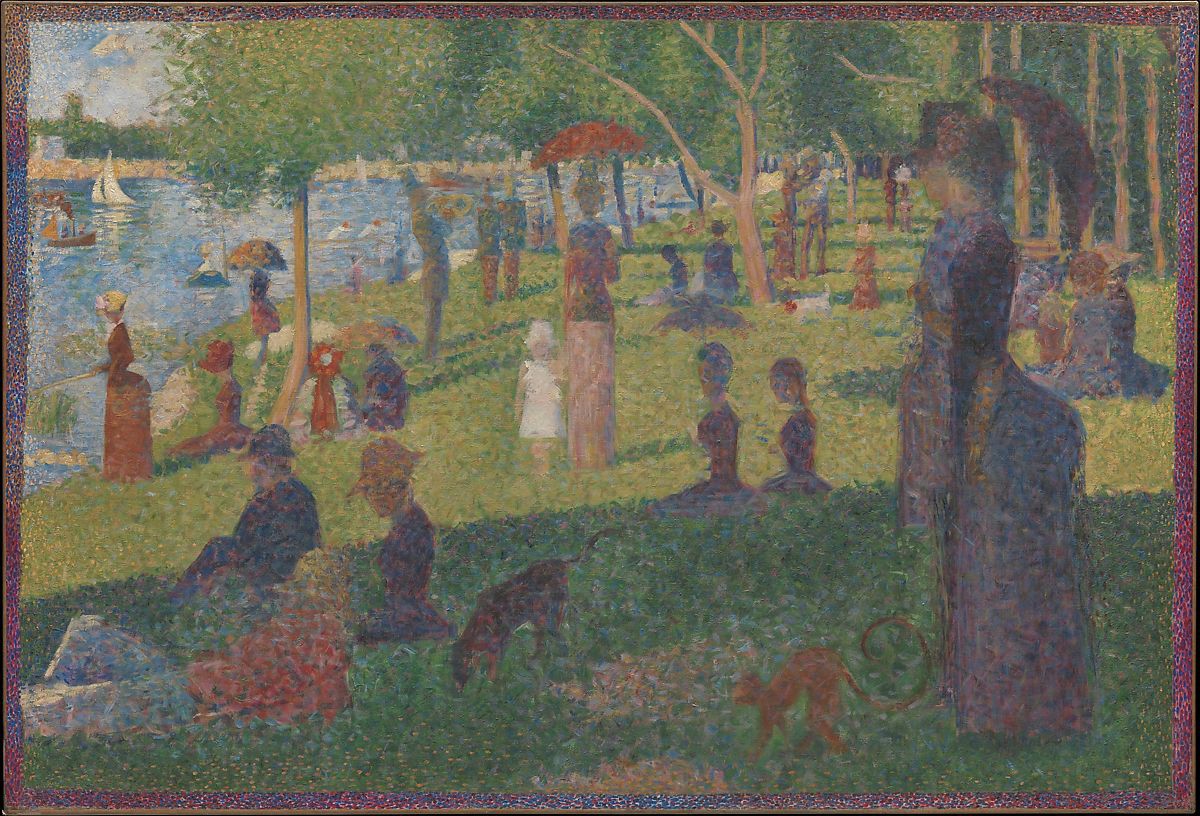

Here's the first working version in action on an oil painting:

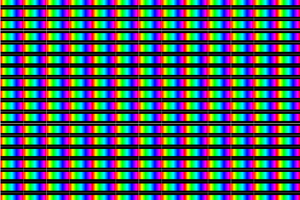

What we're seeing here is

1) Infrared long pass filter--this filter doesn't allow light below approximately 760nm through. Often, this is used in art conservation for IR reflectography to see drawings on the canvas below the paint. Certain paints/pigments that are opaque in visible light are transparent in IR.

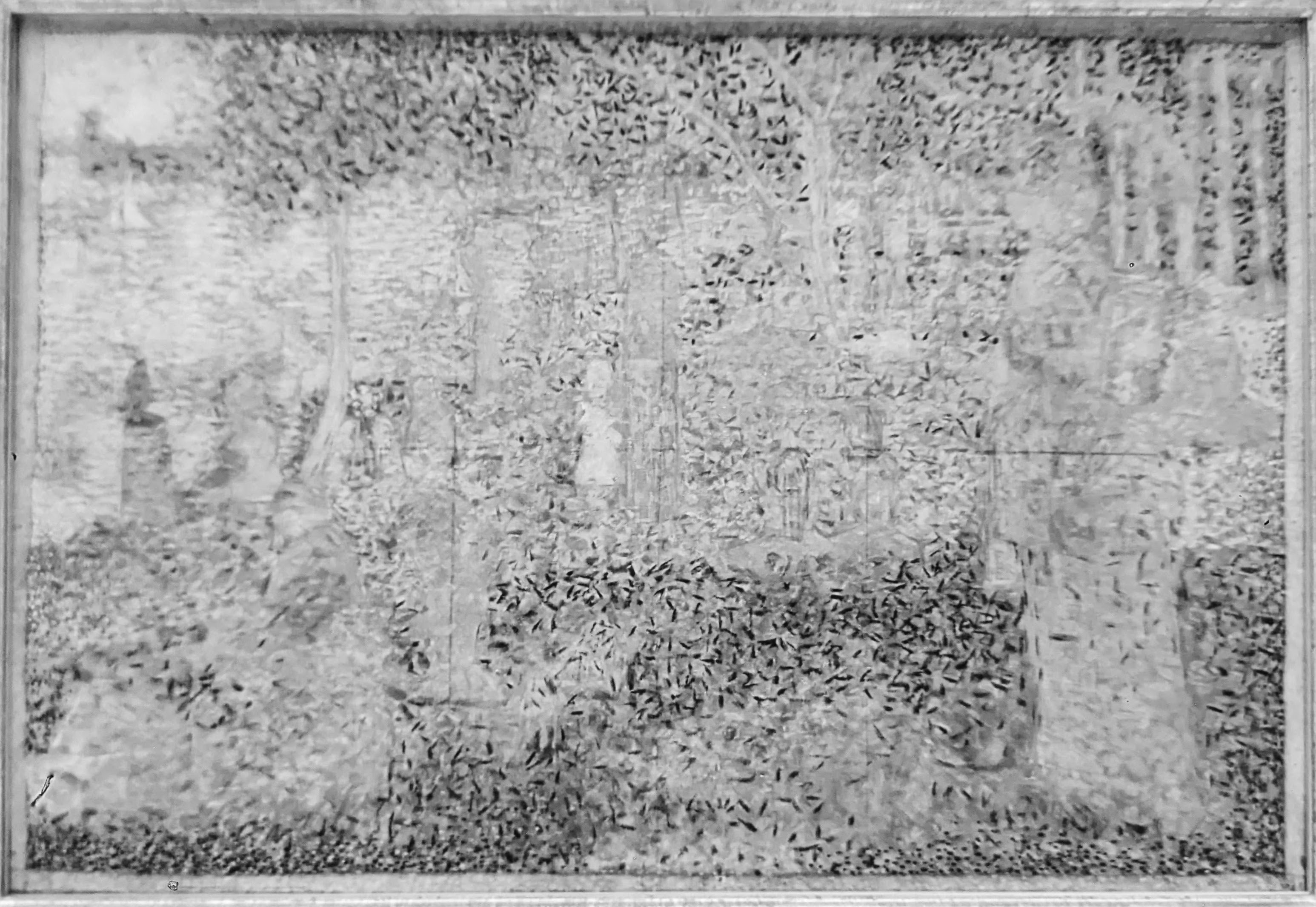

2) UV short pass filter--this is typically used in art conservation to differentiate certain paints: lead white (which has been used for centuries) shows up as white in UV reflectography. Titanium white (which was developed much later) shows up as grey. A handy way to determine if paints are historical or not.

3) Polarized--often used for reflective objects or if a painting has a high gloss varnish over it. Makes it easier to see true colors and some previous restoration. In the current version, I need to cement a visible light pass filter to the polarized lens, otherwise, it lets in everything from UV to visible to IR.

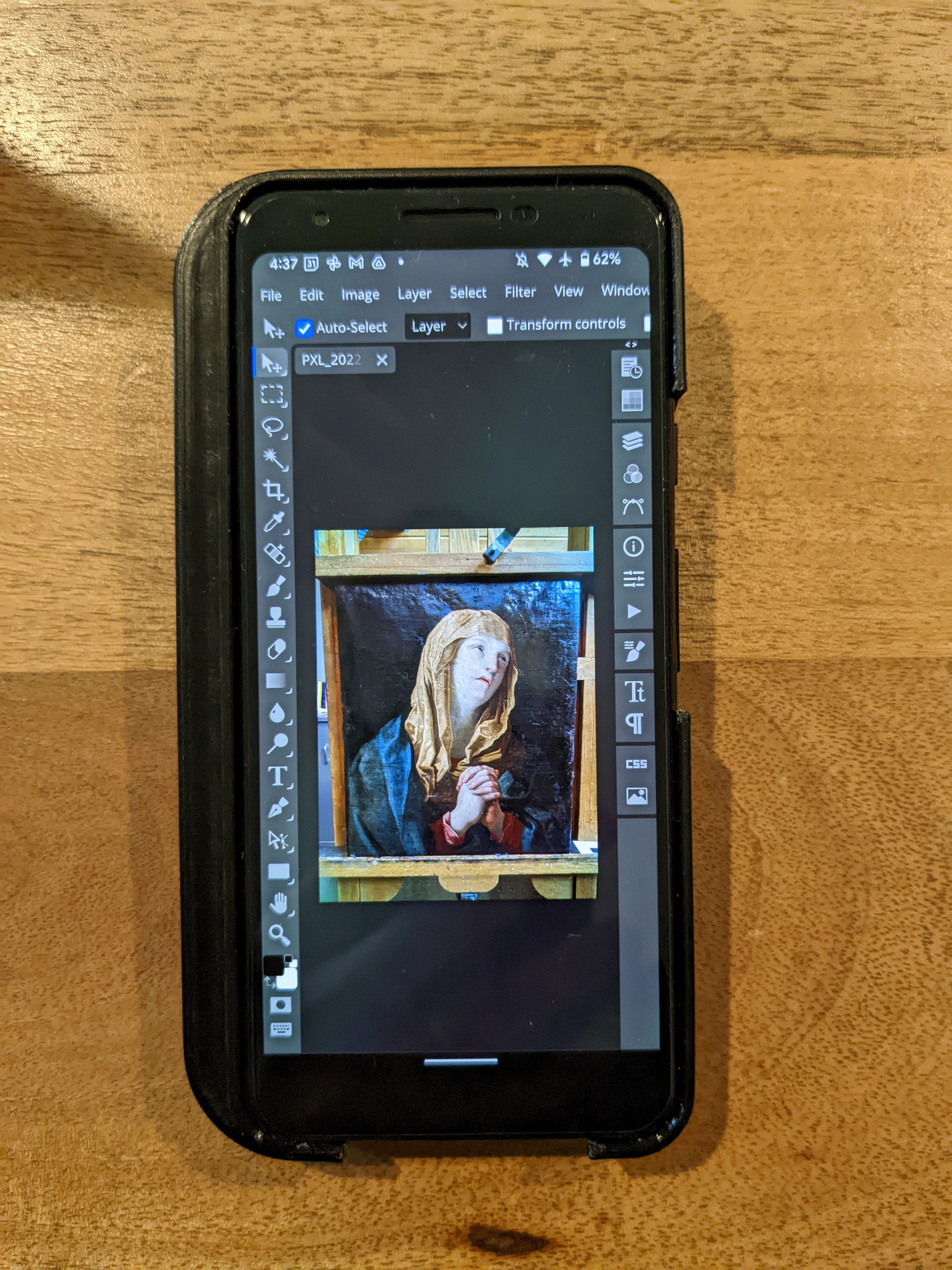

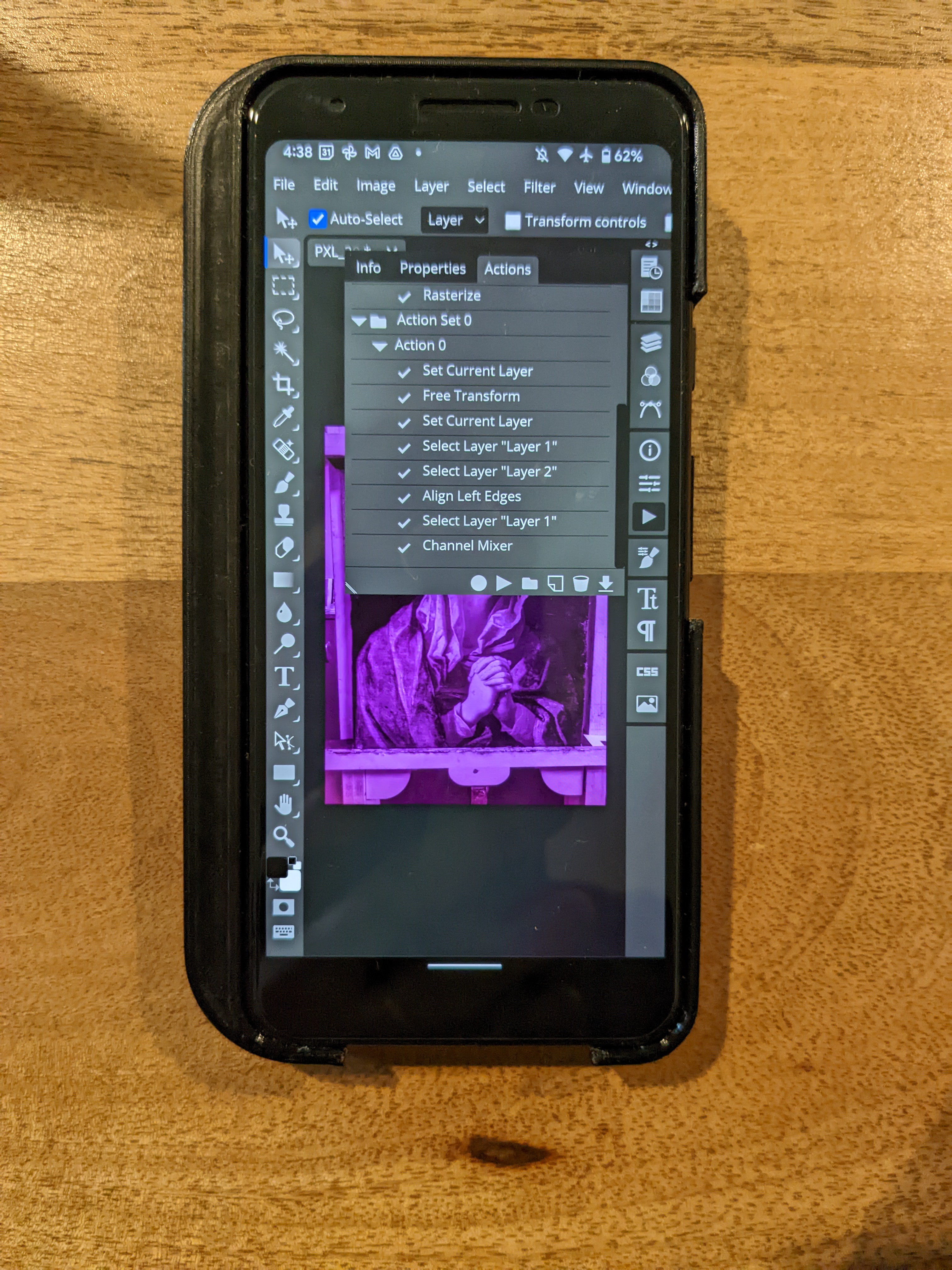

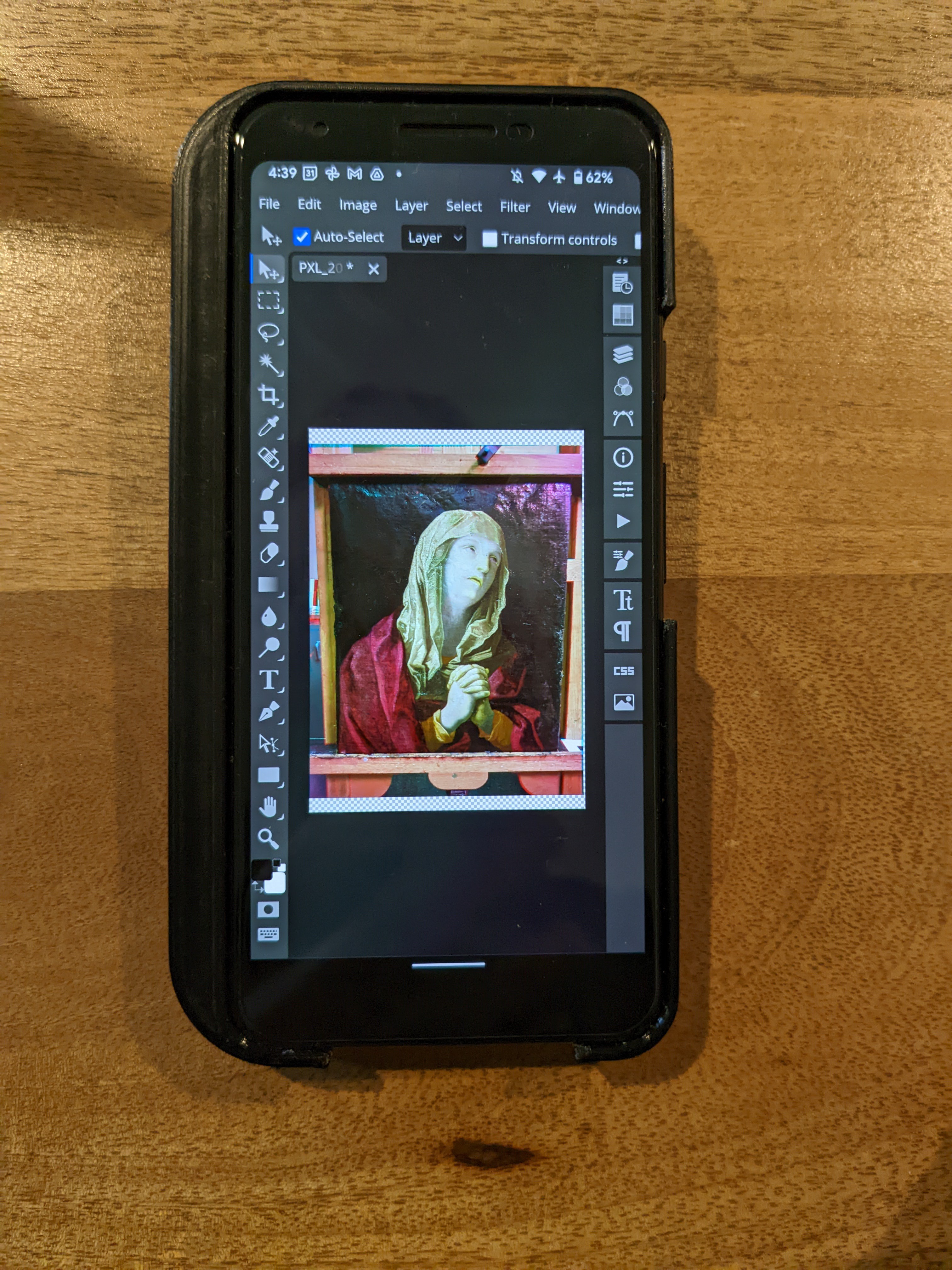

Update 6/28/2022: Using the camera and case w/ tripod mount to snap coinciding visible light and IR photos, which reveals the underdrawing (the pencil sketch on the canvas under the paint).

My goal is to create an entire analysis system that uses a smartphone for the user interface and the processing power. I am working on building swappable filter wheels for different analysis methods (sets of bandpass filters for subtractive imaging, etc.), wheels for macro photography/microscopy, and interchangeable modules for led lights, sensors, and spectrometers.

Sean Billups

Sean Billups

Same painting in UV reflectography. Note the difference between 2 different white paints.

Same painting in UV reflectography. Note the difference between 2 different white paints.

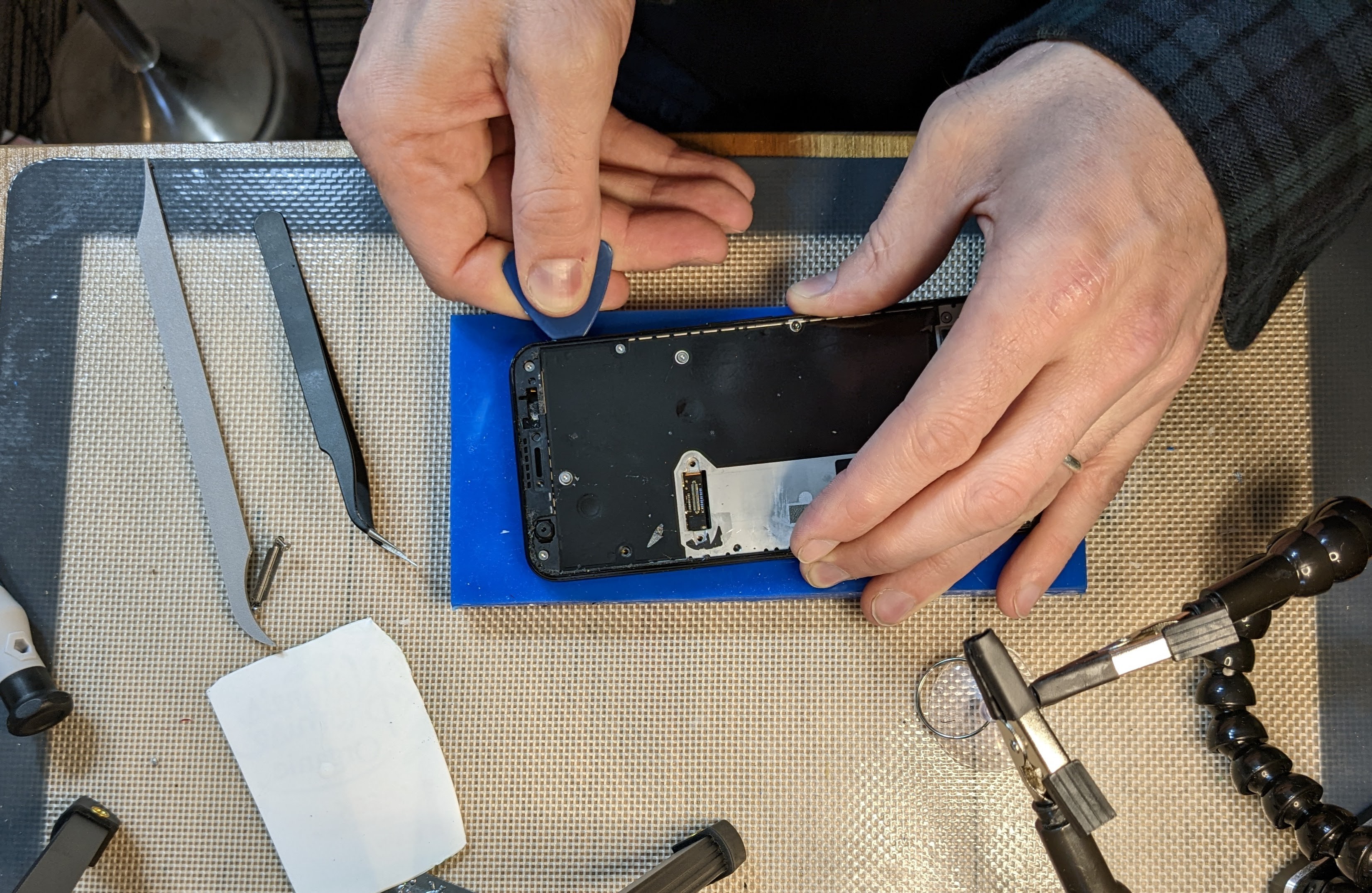

Lift the screen away from the body. The adhesive tape is the only thing holding the screen on. No screws or snaps.

Lift the screen away from the body. The adhesive tape is the only thing holding the screen on. No screws or snaps.

ReVision

ReVision

Chris Hamilton

Chris Hamilton

Eric Jacob

Eric Jacob

Kevin Kadooka

Kevin Kadooka