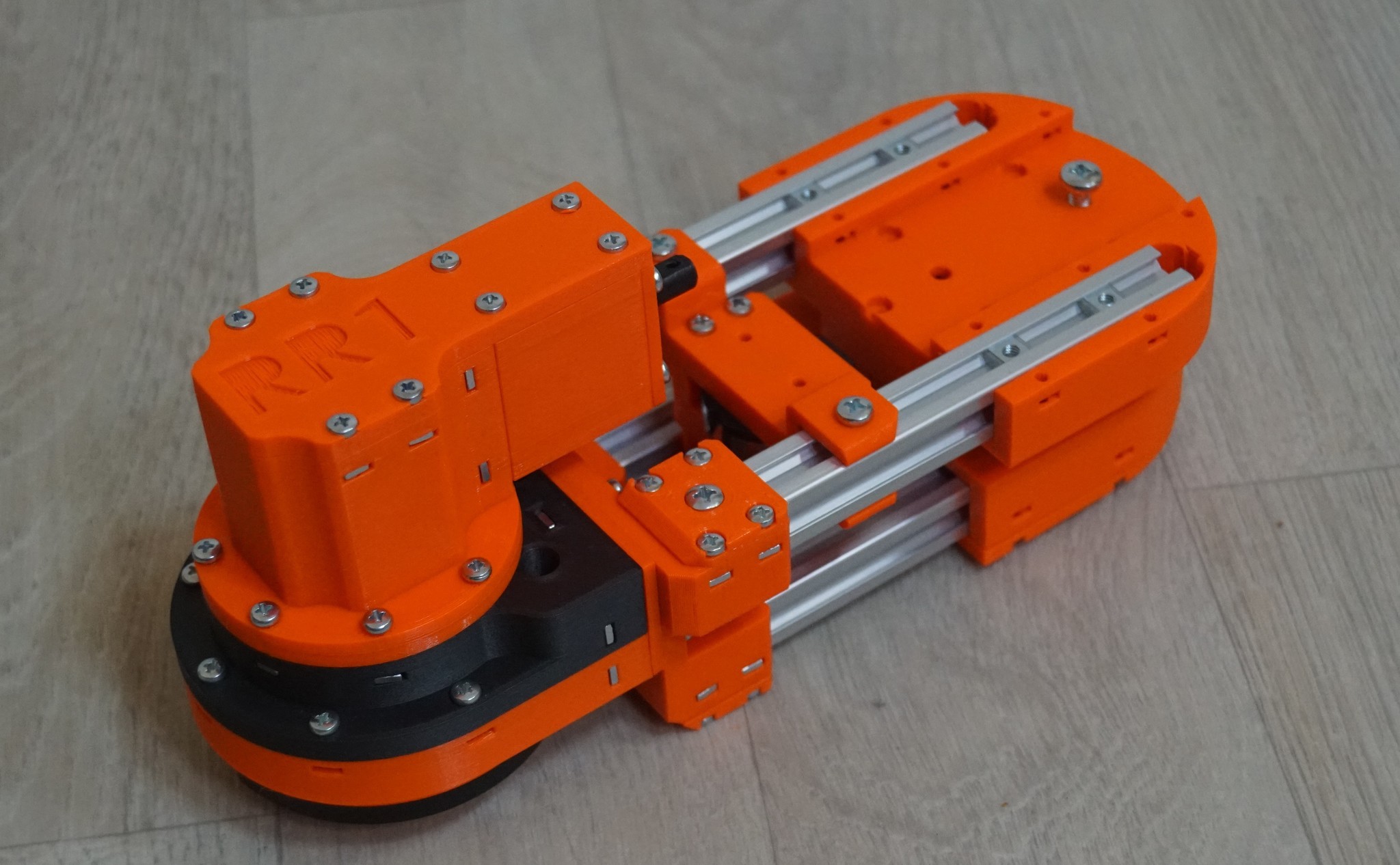

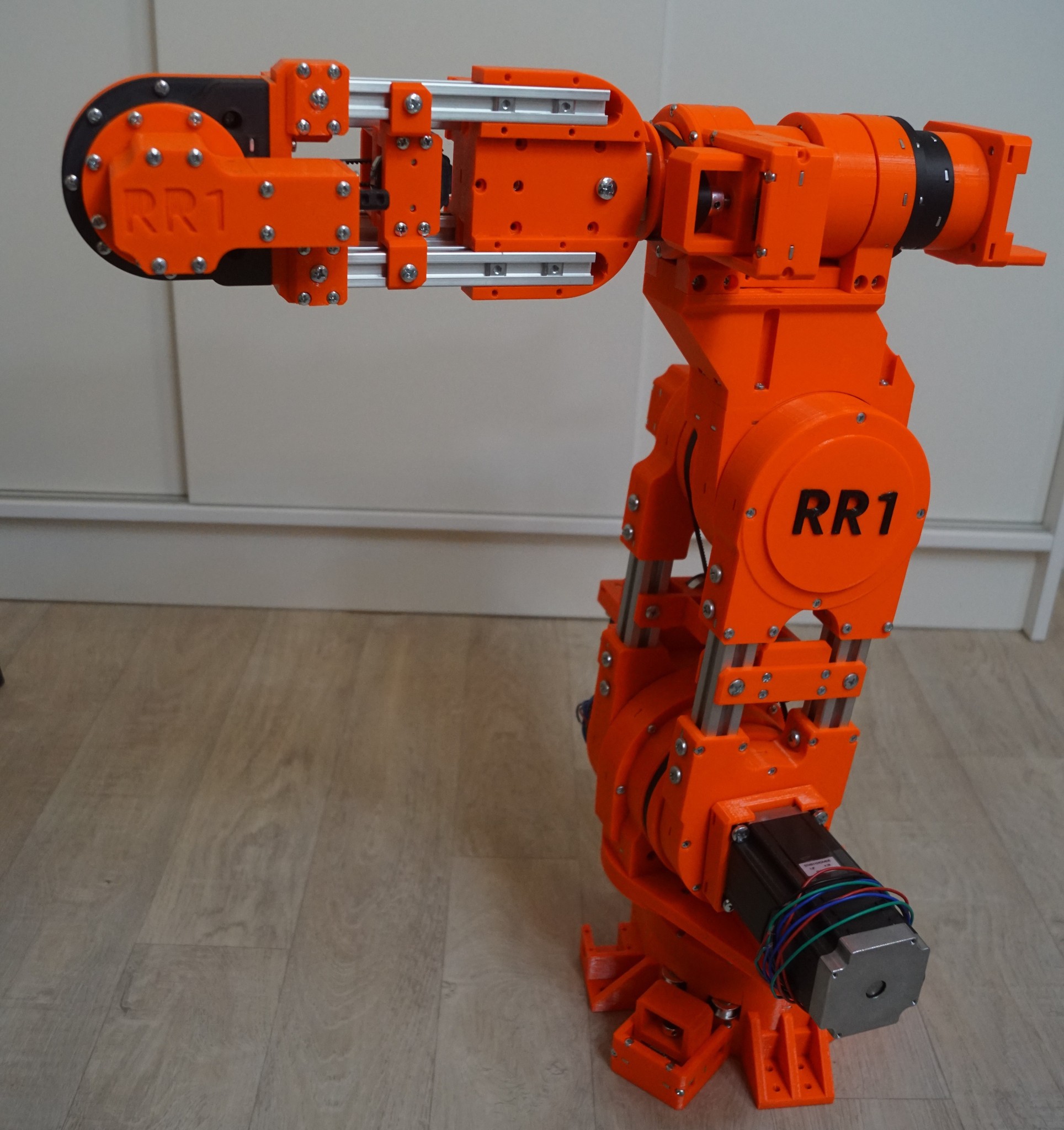

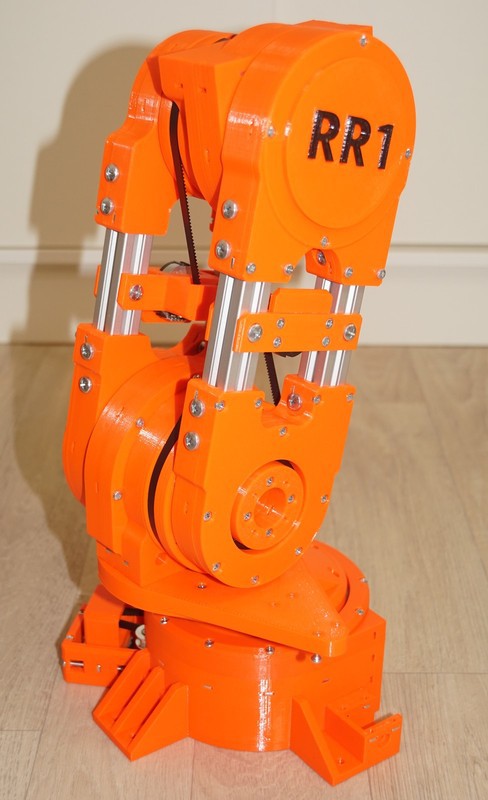

RR1 is a DIY desktop robotic arm, my big project in robotics. The overall design follows the idea of being able to produce more of these robots so that multi-robot coordination on the desktop is possible. I think, having a small scale Industry 4.0 on the table could be great for research and testing.

The robot itself is bigger and more capable than toys but it is not too big like industrial robots and not that expensive so you don't need to have a budget for building a factory if you want 10 of these robot.

Thanks to its small size RR1 is not dangerous like industrial robots that need to be enclosed in an inaccessible area. RR1 can be well used as a collaborative robot.

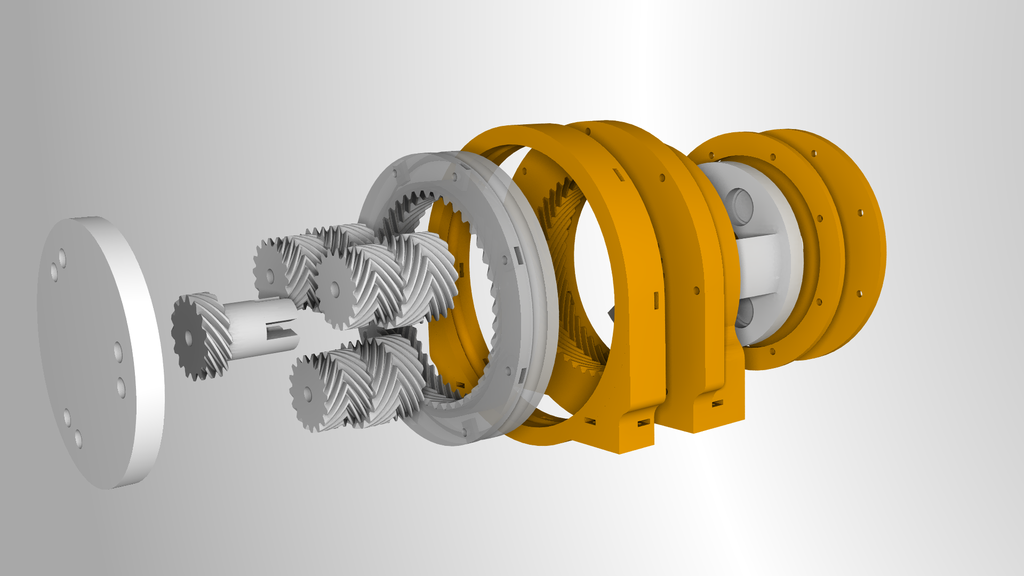

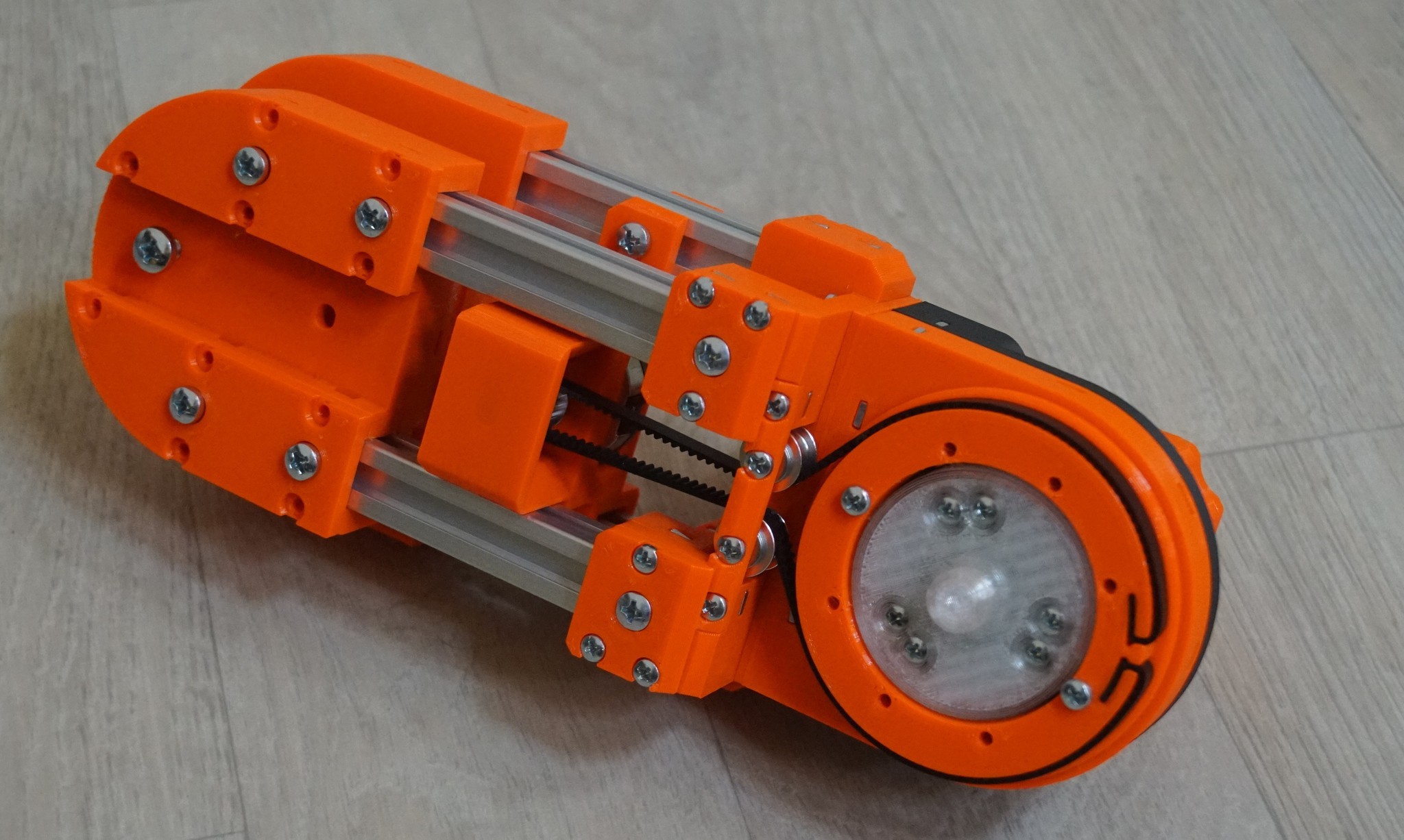

Unlike other robotic projects of similar size, RR1 does not use any belt for torque transmission. All the torque transmission in RR1 is done via gears. All reducers are custom built based on 3D-printed split-ring planetary gearboxes. Each joint has its own planetary gearbox, so altogether there are a total of six similar gearboxes of various sizes across the robot. In addition to this, there are three bevel gearboxes to transmit torque through 90° from the motor shaft, also mostly 3D-printed.

The robot is powered by stepper motors, 4 big (nema 23) and 3 small (nema 17). The lower main joint is powered by the biggest nema 23 stepper motor available (112mm length) generating 3Nm connected to 1:40 reducer which in theory generates torque of 120Nm in the main joint, pretty enough to move the robot.

The reducer for the main lower joint is shown in the following figure. It is a split-ring planetary gearbox consisting of 3 planets - herringbone gears - and one middle sun gear connected to the motor axle. There are two ring gears - one fixed (the orange one) and rotating (the grey one). The rotating ring gear that moves the arm is fixed using bearing balls into the groove in the front orange part (balls and bolts are not shown).

NOTE: I often use the term planetary gear box for the split-ring planetary gear box. There are only split-ring planetary gear boxes in RR1 rev. 1 and also in RR1 rev. 2. The advantage of splitting the rings in the gear box enables higher reduction ratios.

The following video shows the assembly of the split-ring planetary gearbox from 3D-printed parts. The assembly process focuses on smooth rotation and backlash elimination at the same time which is a very challenging task.

The robot currently exists as the first prototype called "revision 1" or "rev. 1" in short. There is still some backlash in the joints of "rev. 1", I expect to eliminate it in "rev. 2" (almost zero backlash has been indeed achieved in the above video). The repeatability is still improving.

Update: The following video shows a surgery and analysis of a broken planetary gearbor of the main shoulder joint. The damage happened during the Maker Faire 2023 exhibition in Prague. The damage gives an important lessons for the future designs and will be reflected in "rev.2".

Tests and findings with the first prototype "rev. 1" are posted below.

Another video showing articulation of the robot follows. This test is also focused on checking if all cables are long enough to allow the arm to twist round.

I also did some preliminary weight-lifting tests in which RR1 lifts a water barbell. I was wondering if the robot can handle the full 1kg barbell - in theory it should. The following videos shows the test. The next video shows motion test with...

Read more » Pavel Surynek

Pavel Surynek

Dimitris Xydas

Dimitris Xydas

Andreas Hoelldorfer

Andreas Hoelldorfer