-

TEST BUILD: Desktop

08/20/2014 at 06:50 • 1 comment![]()

-

TEST BUILD: Maker Faire

08/03/2014 at 18:21 • 0 commentsI'm exited to announce that the first DYNABRIX build to leave its birthplace (my home) was a featured booth at a local Mini Maker Faire! The event was sponsored by an all-around great local teen maker space named LevelUp. The build was considerably slow, but it was great to meet and field questions from a variety of engineers, students, parents, as well as a few military and professional leaders! Now, on to putting into effect several design improvements!

![]()

-

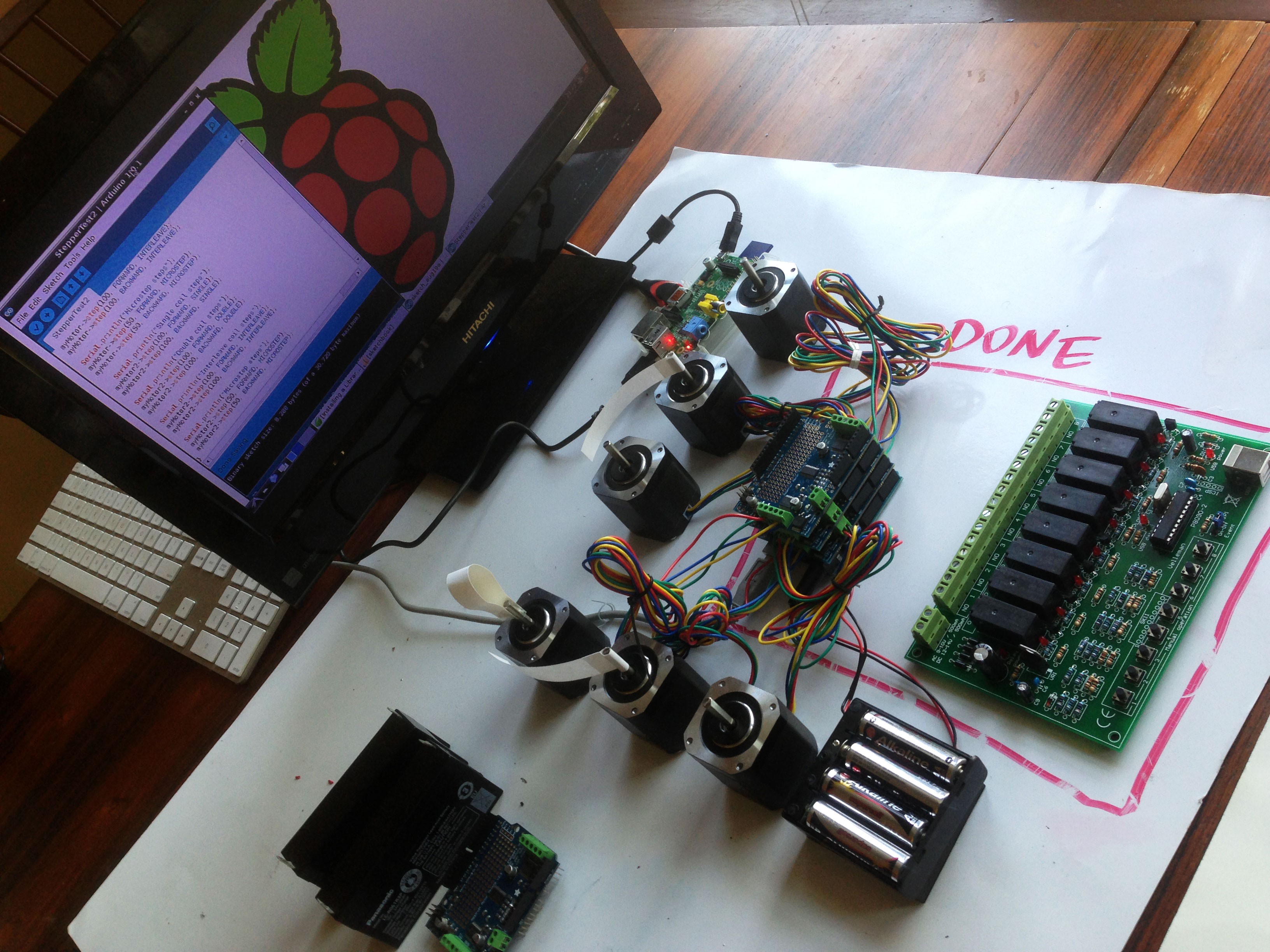

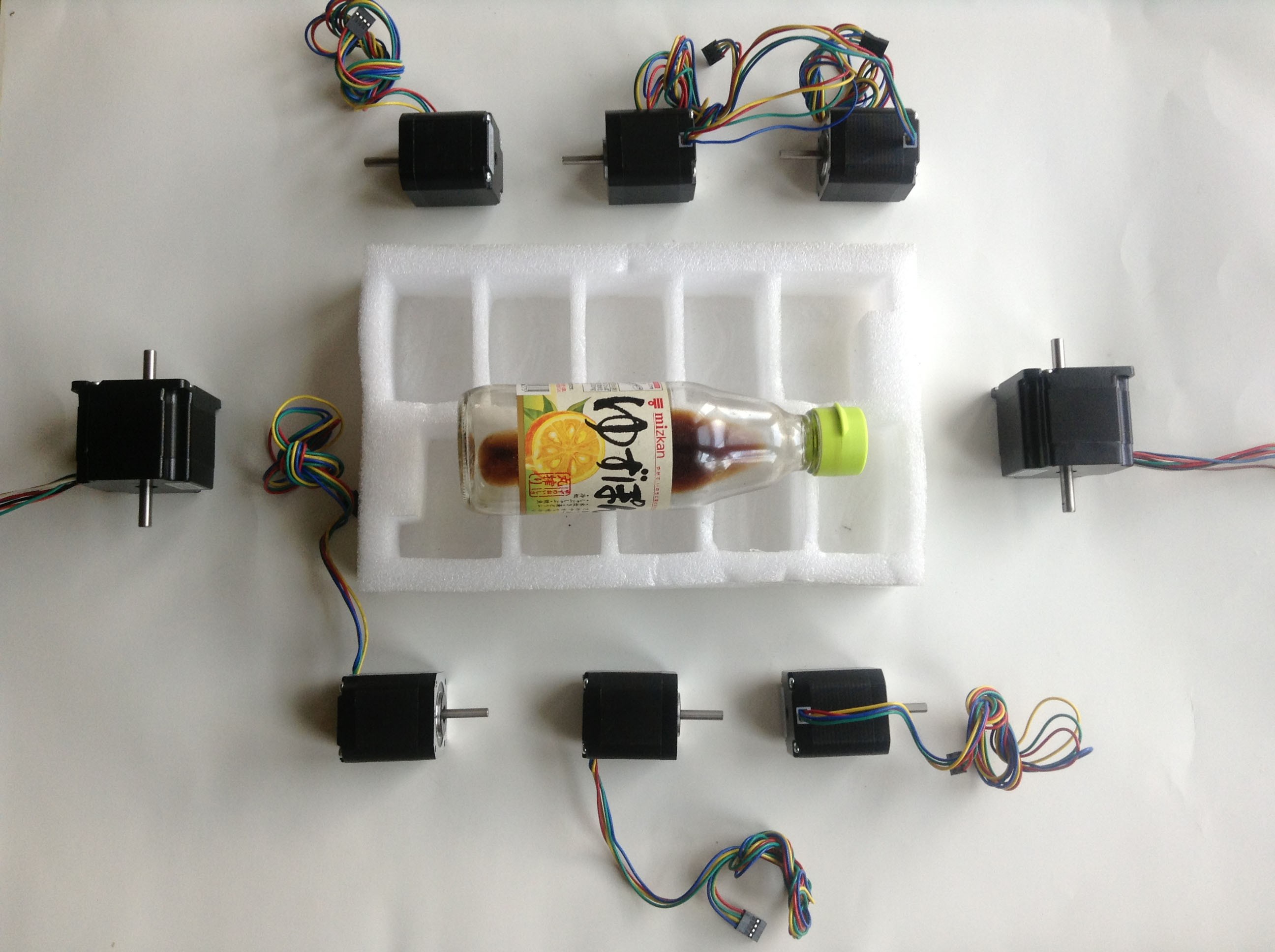

TRIAL 7-8: Actuator Selection and Chopper Array

08/01/2014 at 08:35 • 0 commentsNEMA 17 -type steppers have been picked up locally and placed where gantry/slides/gimbal for dynamic moulding has my design "optimize" their number and position. Four stackable motor shields from a company that shall forever remain nameless are being wired for control of the EIGHT motors in this subsystem. An alternating blade shaft and motor from a common 450 W food processor/blender will serve as one unit in an array of three within another, chopping-preprocessing system. Any sort of substantial build for the Maker Faire in which I'm registered for tomorrow seems more and more likely to disappoint the kiddies...

I have to keep pushing for them!

![]()

![]()

-

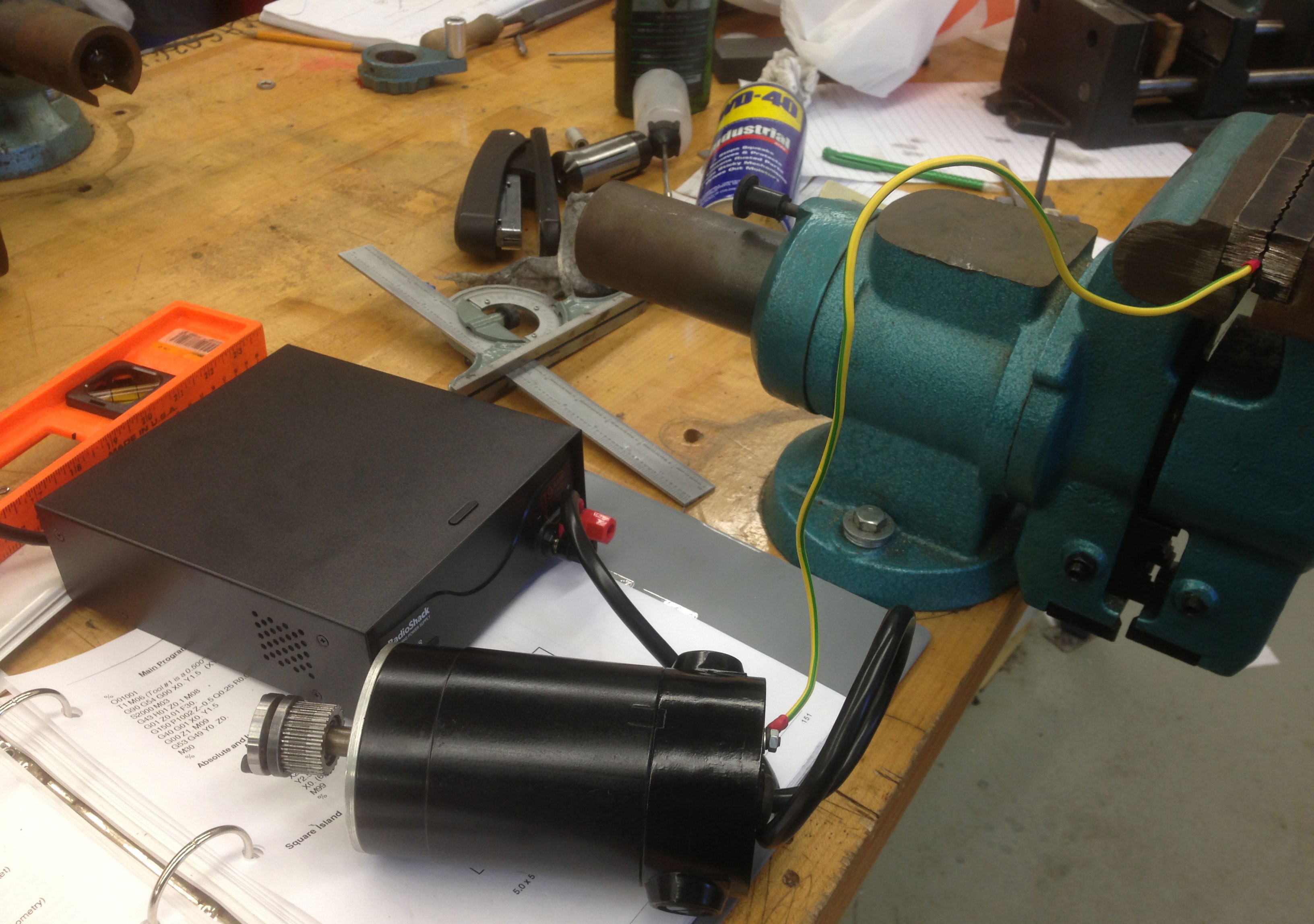

TRIAL 5-6: Motor, Aggregate-Foam Testing

07/27/2014 at 04:36 • 0 commentsMy lack of having much remaining time has necessitated bringing on a good friend that also helped in making my CNC router over 4 years ago! I've also spent a whole workday (at work) deciding to scrap an old, well-made, rigid, but easily-overheated AC motor and deciding on the best AC/DC inverter or bridge rectifier to use with several reclaimed DC units for interfacing with home outlets. During the proceeding day, I conducted the next-to-final phase of deciding which aggregate-foam mix (and sequence) to use in forming DYNABRIX. In other news, my CAD workflow- which I'd hoped to hone in order to more clearly lay out an overview of both the system and main machine build- is dripping like winter molasses. At least I've solidified the schedule for the YouTube video production and upload!

![]()

![]()

![]()

![]()

-

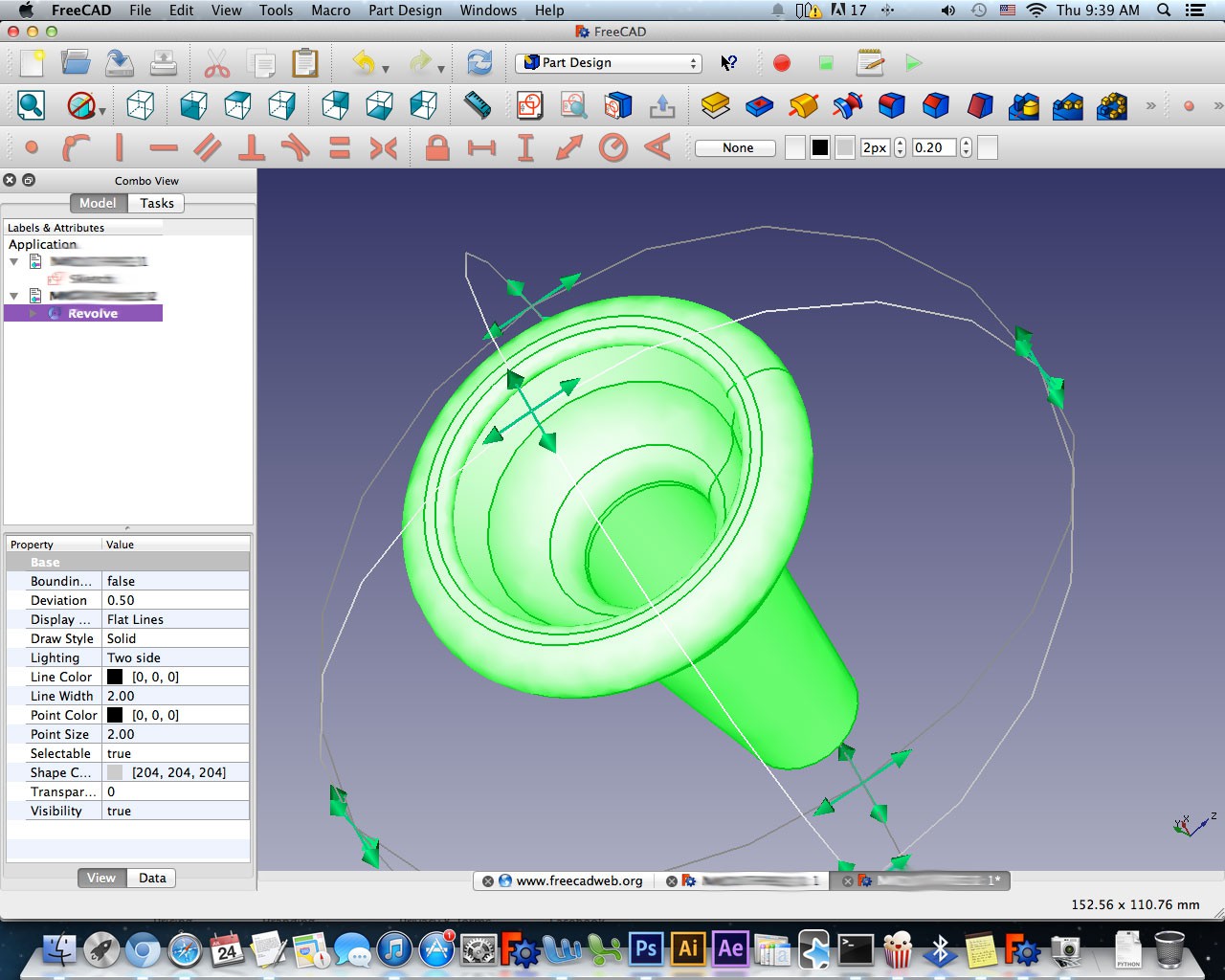

TRIAL 2-4: Polymer Testing, Schematics Designing and Electronics Fitting

07/24/2014 at 14:48 • 0 commentsThe DYNABRIX pieces will be optimized by injecting polyurethane foam around a semi-cured trash-aggregate shell. FreeCAD is proving to have a somewhat arduous learning curve. I've also been fitting electronics components into a found, neighborhood recycling bin that no one was using. It's "recycling the recycler," I guess...

![]()

![]()

![]()

-

TRIAL 1: Brix Forming

07/18/2014 at 04:57 • 1 comment![]()

![]()

![]()

![]()

![]()

![]()

![]()

Type 1 Civilization Builder

Futuristic dwellings & new types of efficient structures made by dynamic "Bottle Brix" : trash composites found anywhere, used everywhere!

Mink Stacktrane

Mink Stacktrane