First, a bit about stiff TPU

I've done a bit of thinking, and for me, the most important feature I need in a printer is being able to switch between stiff TPU and support material, reason being that TPU has some of the best interlayer adhesion and stiff TPU (such as the Kexcelled 64D) should have more nylon-like stiffness, resulting in parts that aren't floppy.

Stiff TPU should also be able to extrude via the BMG clones I have. One thing I learned in the last few months of my degree is that these clones really can't push the usual 90A TPU. I could never get it to print for more than 1 minute on a "short Bowden" (a.k.a. almost a direct drive but there's an approx. 5cm PTFE tube between the extruder and hotend), and one time I had to disassemble a Bowden extruder because another student obviously assumed it would work better than some cheap-looking stock Ender-3 extruder. I need to write up my master's project to #SlimeSaver [gd0105] one of these days, but against all expectations, a stock Ender-3 extruder and its Anycubic Ultrabase clone print-bed allowed me to print the TPU dispenser/scraper 2-in-1 prototypes I needed to progress.

Anyway, I need drastically faster changes

I recently saw someone with a Sovol SV08 that's been modified to have both IDEX and TIDEX, or put another way, 2 extruders on the first X gantry and a third extruder on a second X gantry. This allows relatively quick changes of 3 materials:

I saw this and naturally thought of the Cetus2, which most likely is the limit of FFF transition speed:

Additionally, I watched the following video about the current landscape of MMUs and tool-changers:

Many comments share the sentiment that the Bondtech INDX is taking all the air out of the room. Using the prices Bondtech said they were targeting, one redditor calculated that a 5-tool SV08 would cost merely $995, bringing its overall feature set extremely close to a Prusa XL.

What's the current market of dual-material printers?

Now that I'm now a "recent graduate", I can't just stroll in and use the 3D printers my uni just happened to have... which is part of the reason I even went there in the first place actually 😂. In 2021, all my printers were varying degrees of broken, and in 2025... nothings really changed if I objectively look at things in black or white, working or not working. So obviously, "as [any] 21st century kid would", I went online window shopping.

Other than the (out-of-business speedrun) SCEOAN and their Windstorm S1 (see below), the sleekest 3D printer -- maybe even the sleekest machine -- I've ever seen, I couldn't find anything notable, certainly nothing that could print with dedicated support material on the regular. The multi-material market feels the same as in 2019, just with the Prusa XL and Bambu Lab H2D sprinkled in. If anything, it feels like there are slightly fewer options than the last time I checked all those years ago. Allegedly there used to be a Sovol SV04 but I don't see it on their website today.

It honestly looks like a prop made out of silver and black cardboard. BigTreeTech TFT interface, magnetic bed, auto bed levelling, linear rails, direct drive with a hotend that uses those new ceramic rectangle heaters... if this had IDEX I probably would've bought 3 already because £329 is the price I would've expected for a single pringle.

Back to press-fit tubes

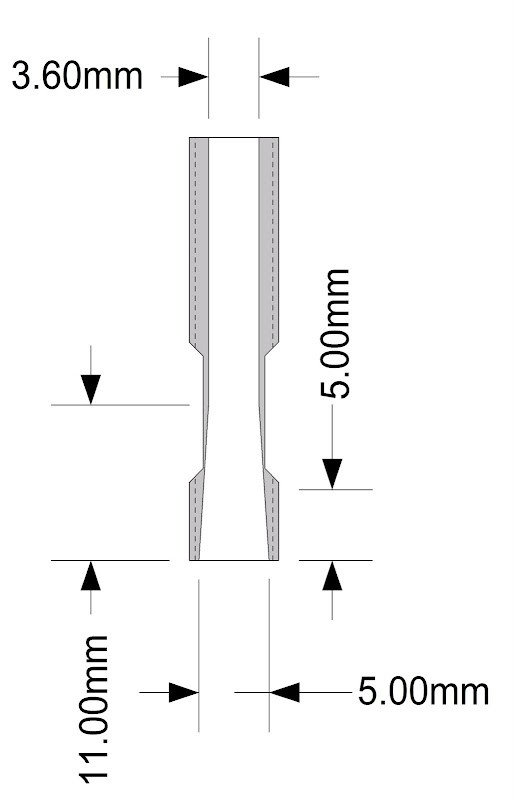

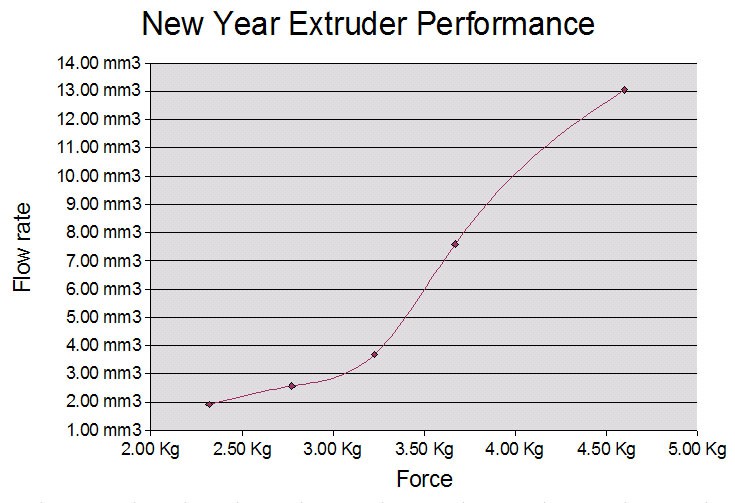

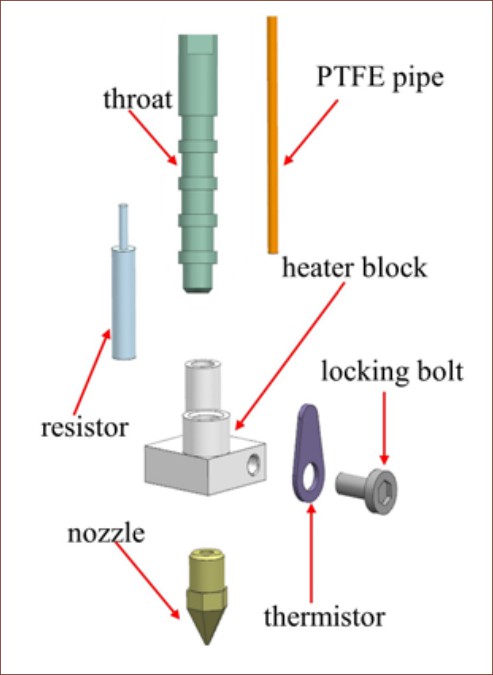

I asked, and my PCBWay service rep recommended at least 0.8mm walls for printing stainless steel, so the print-in-place strategy is out. At the same time, I've been looking into the literature of heatbreaks to find out why they're 2mm -- it's to reduce the friction area of the rubbery-consistency filament between its glass transition and melting temperature -- and I found a blog post from 2009 that confirms what I've always wondered: Would a taper improve performance, similar to draft angles in injection molding?

It seems that a tapered heatbreak is particularly well suited to reduce required forces when low flow rates are required, which would naturally be the case for a mixing hotend as any individual input may only contribute a fraction of the final mix.

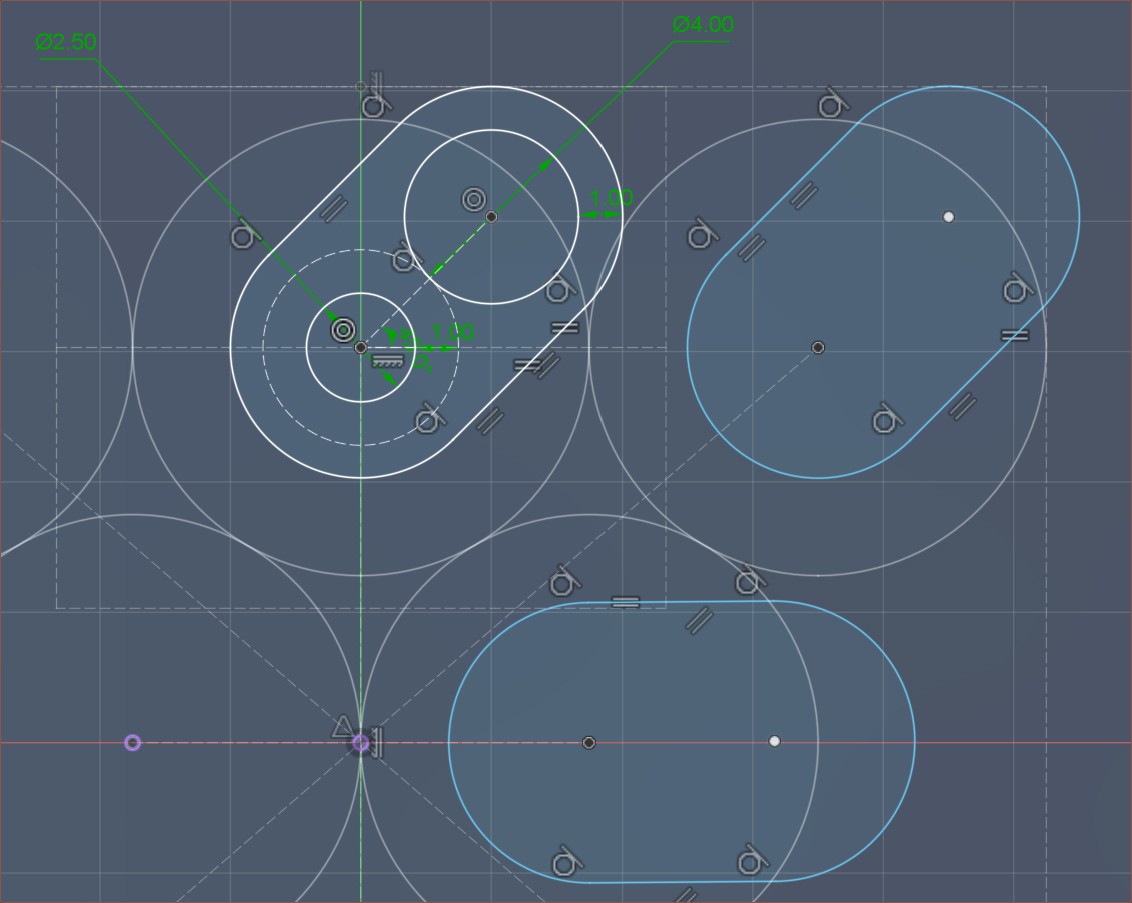

I remember Deckingman documenting having issues with heat creep, even with PTFE-lined hotends. This idea could be one more thing to increase reliability to an acceptable level.

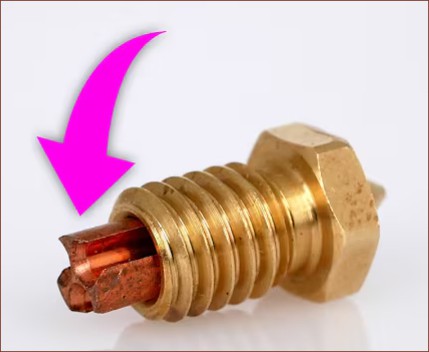

Moving on, the main idea I've been thinking through is to have the press-fit heatbreak tube go through the entire hotend and stop a bit before the nozzle tip so that the purge volume is relatively tiny. However, this requires very good alignment of the nozzle and the tube, as well as a nozzle that has a larger ID hole. My hope was to use the Bambulab high-melt CHT clones and remove the copper insert and then have two tubes, one acting as alignment. Using pixel sizes, I estimated that the ID of these nozzles are 3.7mm.

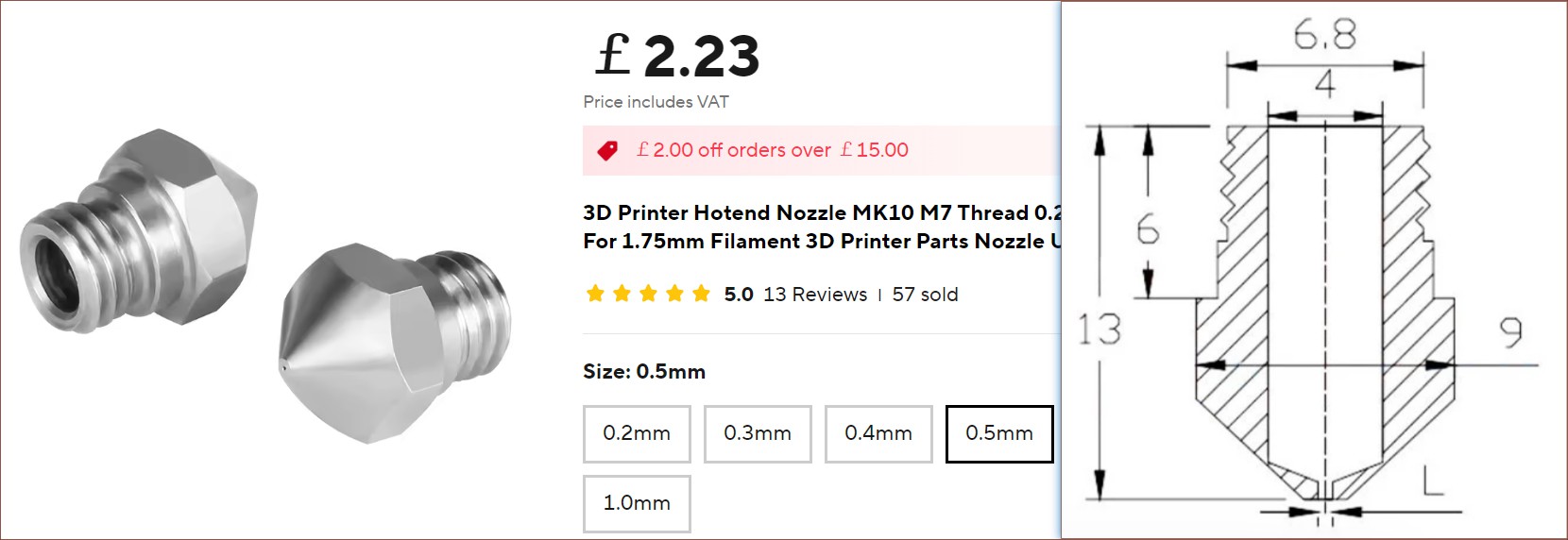

But not all hope is lost. I found a stainless steel MK10 nozzle that conveniently comes in 0.5mm which hopefully gives a bit more resolution than 0.6mm and a bit more flow than 0.4mm:

The outer 4mm OD tube would seal from the inside of the nozzle. The drawback would be that additional length would be needed to hold this tube in place. One of my worries is if this strategy is wise considering that it will essentially double the nozzle length of the coating path.

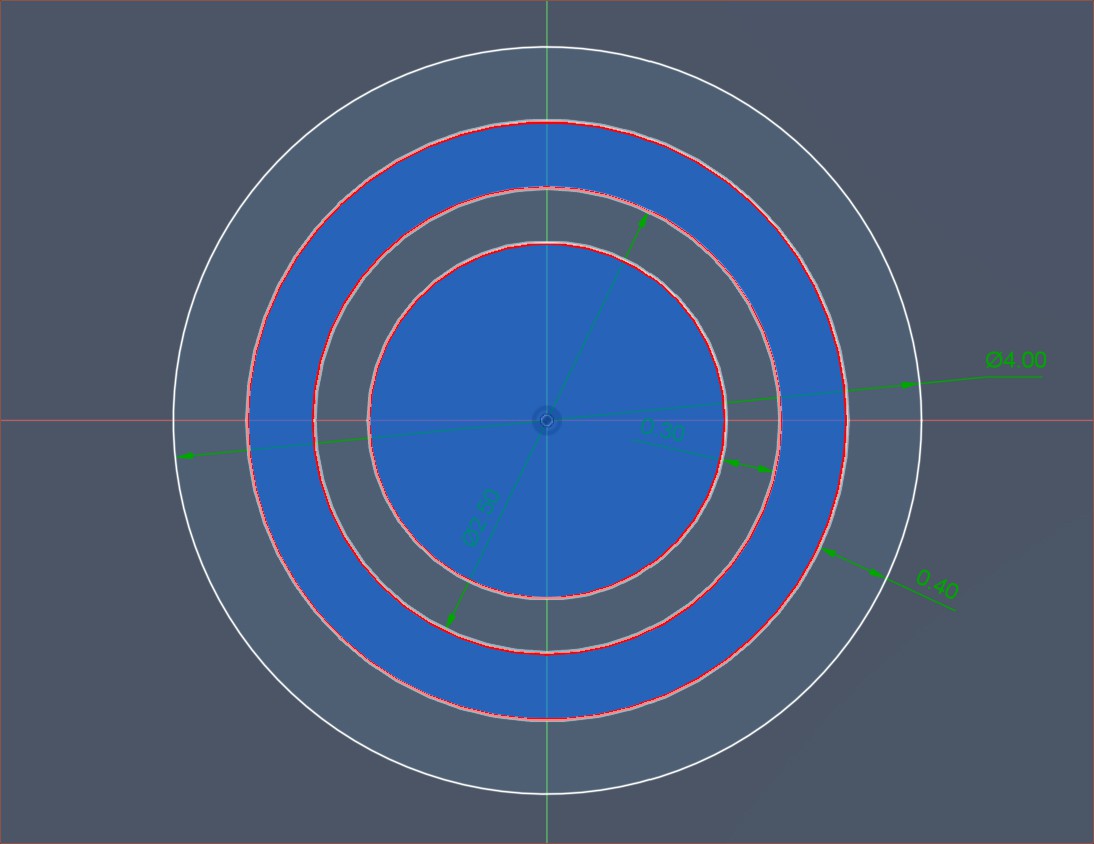

I found the cross-section of a nozzle collaboration between E3D and Creality, and estimate that the tube OD is 2.7mm and extends 4.5mm into the nozzle:

To keep the cross-sectional area approximately the same, I'd be looking for a tube that's 4mm OD 3.2mm ID.

Wait a second. Now that I'm looking at the nozzle again as I type this, perhaps it's possible to use that cylindrical section to center the nozzle? That could at least open up the possibility of having 3 coaxial channels inside the nozzle, though that may require the innermost tube to be 2mm. The cylindrical section is also only 1.5mm, so tolerances for everything to fit might get tight. Similar tolerances worked for the Bowden couplers and heatsinks, so perhaps it's fine?

Another question mark would be how the multilayered molten material will move around. Will it coaxialise as desired or will there be some "clipping" of layers?

Thinking back to the very first video of Nozzleboss's #Co-Extrusion mixing nozzle for FDM prints, the changes already looked rather sharp, so I wonder if this additional complexity is reasonable.

And lastly, I'm still unsure about the heatvalves

I don't think I want to bother with thermistors and MOSFETs and critical-safety C++ systems and power management, so I want to use a heater that only has around 20W of output power so that the hotend uses around 160W if all 8 inputs are active. At the moment, the only (financially reasonable) option at 24V is to use the 30-ohm RP1010, but I can't find anything that these relatively small heaters are even used in, so I don't have any mounting solutions. Sellers are selling them and buyers are buying them, but for what, I don't know.

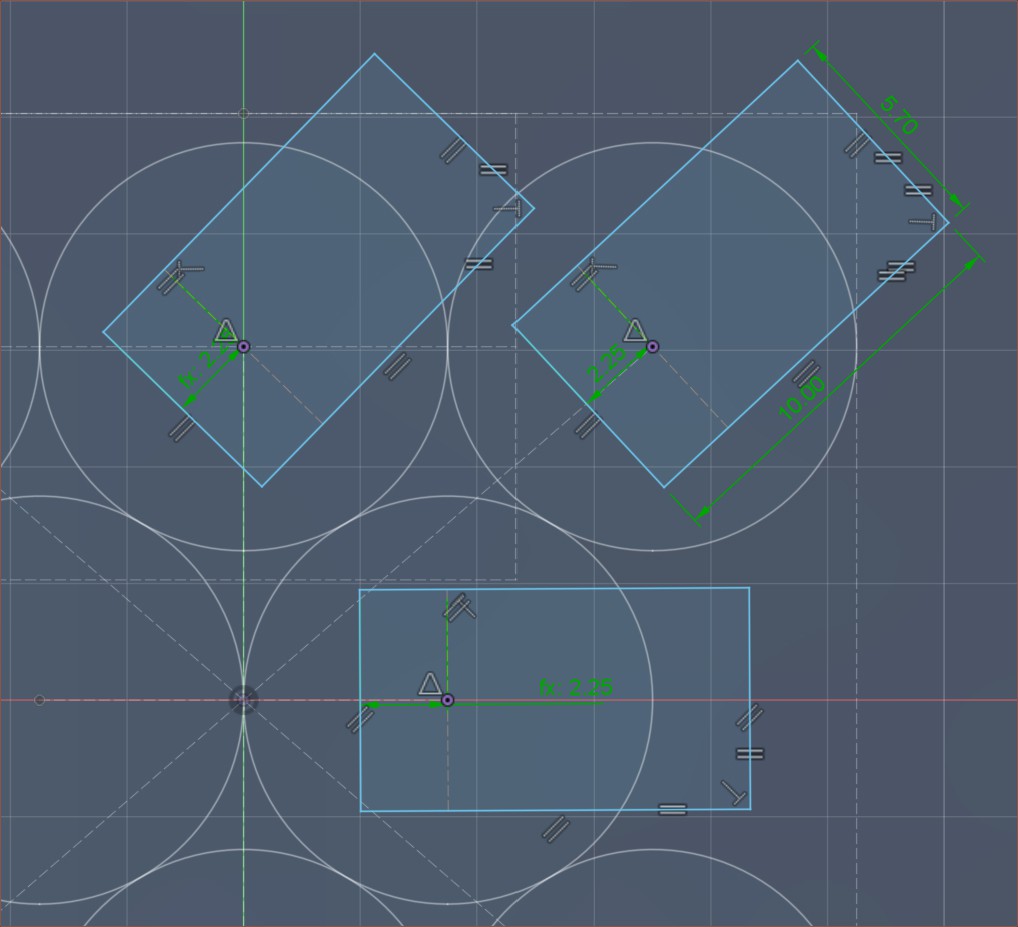

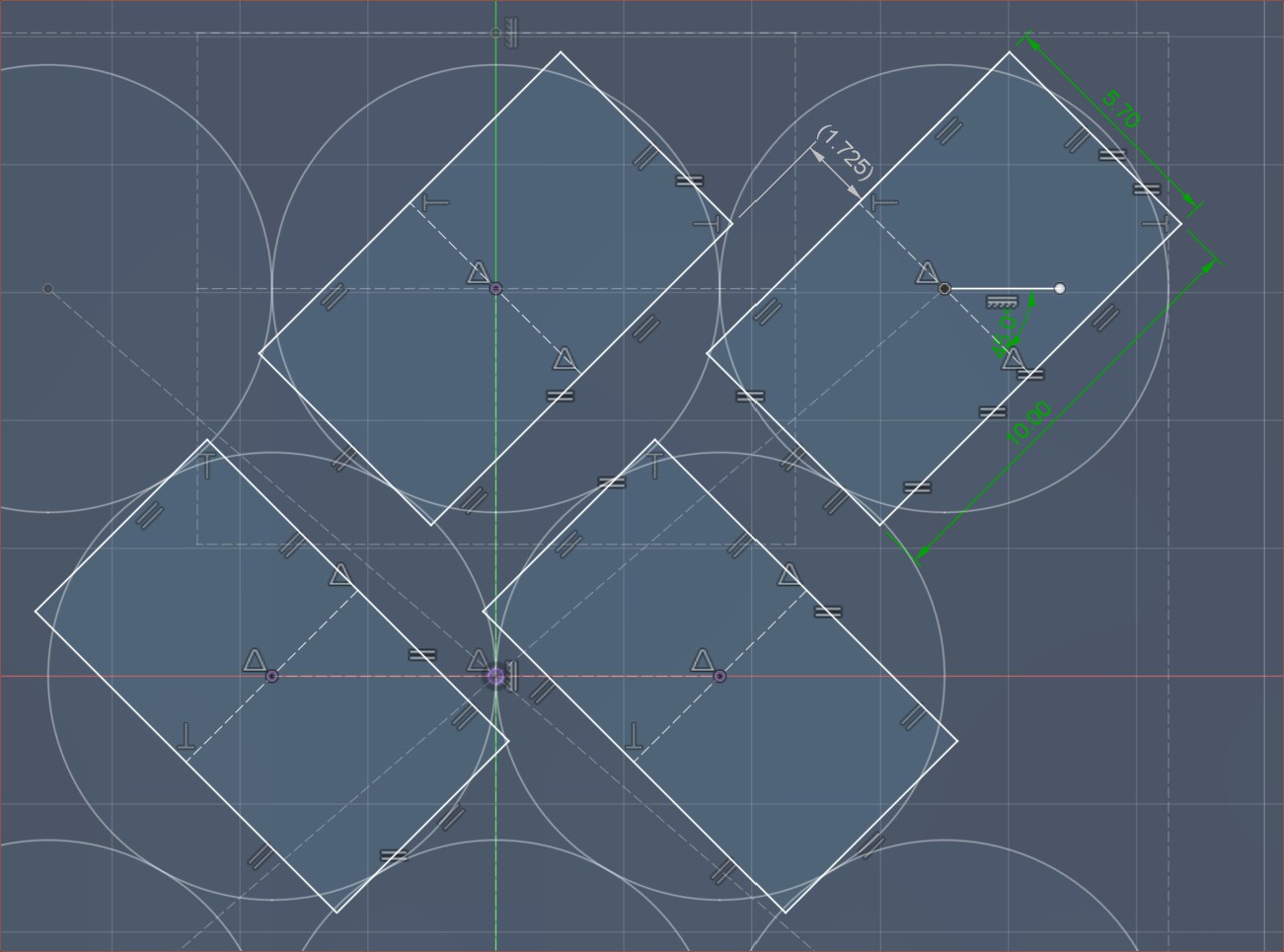

Anyway, I did some best-case sketches to see if a solution could ever exist:

The current cheapest 24V 25W 4mm cartridges are over £15 each on places like AliExpress and allegedly $5 from RobotDigg directly. There's also a 3.8mm MCH (which I presume means Micro Ceramic Heater) but the highest resistance on offer is only 10 ohms.

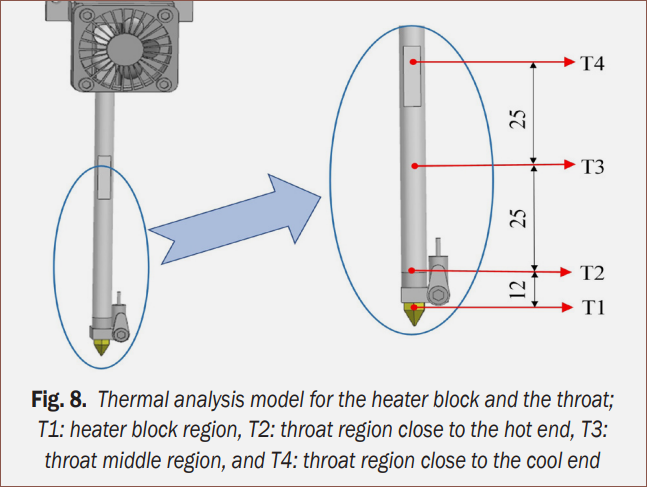

From what I understand, air flow speed has the greatest effect on the temperature gradient, followed by the amount of the bumps seen below. They only tested to a maximum of 5 and concluded that it was the best. The evidence is only partially conclusive since they never tested 6+ bumps.

From what I understand, air flow speed has the greatest effect on the temperature gradient, followed by the amount of the bumps seen below. They only tested to a maximum of 5 and concluded that it was the best. The evidence is only partially conclusive since they never tested 6+ bumps.

Conclusions

One of the overarching "issues" I've experienced with the Coaxial8or is simply that I go and create a revision knowing that there will be an issue and then grumbling because the issue indeed is an issue. For example, I knew that I had designed the R0 such that it would be hard to clean up after a leak and, sure enough, a leak occurred and it was game over. Thus, it feels imperative that I don't even bother unless all issues I expect are addressed.

Due to the high bar, this project is on thin ice compared to the alternative of sell everything off and waiting for the "Tronxy X5SA 400 ft. Bondtech INDX" to drop. Below is the list of all the issues I'm aware of:

- Threaded heatbreaks are prone to leaks when there's 8 potential leak locations, especially when materials with differing thermal expansion coefficients are present in the assembly.

- Printing when a channel isn't loaded will cause a clog.

- Unused inputs are expected to clog after about 30-45 minutes of inactivity due to heat creep.

- Transitions need to approach that of Cetus2 for at least 2 inputs.

- New power supply and electronics enclosure; I can't be using that massive 1500W PSU forever, nor can I have the electronics just sitting on foam forever.

- Compact holder for 8 filament spools.

- Part cooling needs to be redesigned.

- The pre-melt zone needs to be around 20mm long for reasonable flow rates.

- The costs because of the arbor press and custom heatsink and heatvalve components.

- Attaching a low-cost heater to the heatvalve such that the heater can be replaced in the event of a fault.

Trivia: I've been thinking and writing this log from 7:30am to 3:45pm. That's 8+ hours. I've been listening to Burn Water - Eunoia (Nostalgic Beauty) so it's felt pretty chill.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.