-

Groover modifications

10/02/2023 at 07:33 • 0 commentsFirst, the good news:

- This summer, Stephen recorded a 41+ meter dive with the goggles, confirming that the design is sound. He complained about aberrations in his visual field that I have not had time to investigate myself yet. This will be a topic for the v2.

- The chinese groover arrived last august

![]()

Of course, since I did not have any spare lens to groove, I had to wait until the fablab re-opened in september, and, then, getting finished with my day job for the past 12 years became a priority until september 15th when, suddendly, plenty of spare time became the new normal.

To make this story short, I cut a new lens, attempted to groove its side, and this is when I discovered that I missed a critical parameter when I bought this nice little machine: the minimal lens diameter that can be grooved is 28mm while the smallest diameter of my lenses is 21.8mm... Ouch.

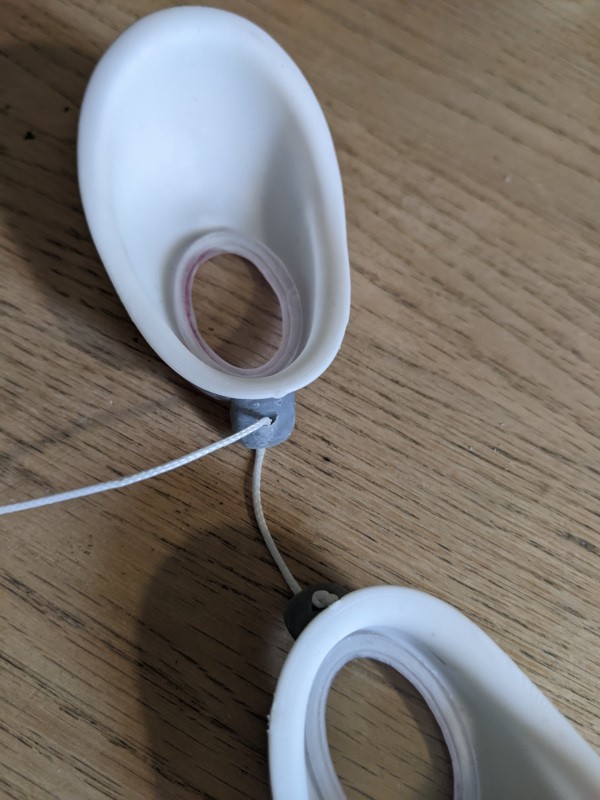

Hopefully, none of this can't be fixed. I made a couple of cutting, grinding, and 3d-printing modifications to the groover until I was able to groove my first lens yesterday. The result ? On the left, a lens with the old DIY groover, on the right, the modified chinese groover: the one on the right has a noticeably more uniform depth. It looks terrific !

![]()

The next step will focus on more modifications to the groover to make it possible to control the width of the groove in a repeatable way.

-

First 25m dive

07/30/2023 at 09:41 • 0 commentsThank you Stephen and Mehdi :)

-

4th working pair

07/29/2023 at 13:36 • 0 commentsBefore the sofab closes for summer, I had time yesterday to print one last pair of alternate shell designs a inject a pair of skirts. Time for assembly !

![]()

First, there is some flash to remove:![]()

A knot, and this gives us the first shell designed for assembly without an elastic band:![]()

We have a pair:

![]()

It's missing only the elastic band:

![]()

but the band is too short for the classic single-clip attachment so, I had to improvise a bit with two clips:

![]()

And this is a winner down to 10m on the first attempt :)

The lens clips need adjustment after the latest run of oversized lenses to improve fitting and water tightness. I will have to wait until sept 4th to be able to launch new prints at the lab.

-

Alternate approaches to Equalizing goggles

07/28/2023 at 06:21 • 0 commentsYesterday, someone pointed me to an alternate DIY approach to equalizing goggles. Beware: facebook link. This alternate design has a fairly long tradition.

Yet, somehow, someone managed to get patent FR2979610A1 and patent US20040177432A1 for that. fXXXX up patents.

-

PC vs PMMA

07/26/2023 at 07:09 • 0 commentsHistorically, I have been using 5mm or 6mm PMMA sheets to make lenses for the goggles. One of the most challenging part of making these lenses is grooving the side so that the assembly clip can slip in place easily: position from the side of the lens, depth and, width are all important to ensure a water-tight fit for the lens on the skirt. So, historically, my DIY groover worked well for PMMA sheets but the resulting lenses were easy to scratch. Picture water, sand, waves, etc.

Eventually, I ordered a set of different types of Polycarbonate sheets to make scratch-resistant lenses because, PC, is a lot tougher than PMMA...

Sadly, what makes PC so much better from the point of view of being scratch-resistant, makes it so much less fun to groove with my DIY groover: the distance, and depth parameters keep going off. It takes at least 10 to 15 minutes to groove a single lens. I have no doubt I could learn to groove PC faster and more accurately but, really, now is the time to order a GM-150 groover from aliexpress. Hopefully, making new lenses will become less painful.

Mathieu Lacage

Mathieu Lacage