====== Project Status ======

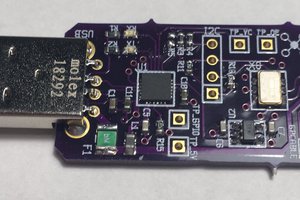

Schematic -------------------- ( ✓ )

PCB Layout ------------------ ( ✓ )

Documentation ------------- ( ✓ ) - See HAS

Order + Assemble --------- ( ✓ )

LAB: Sparkup ---------------- ( ✓ )

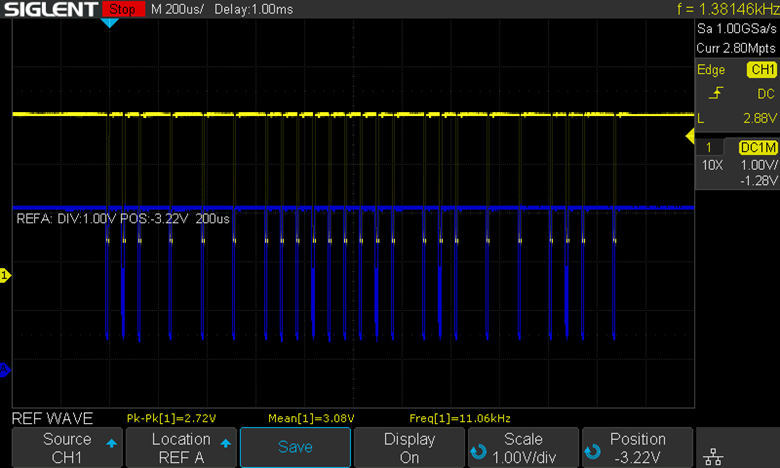

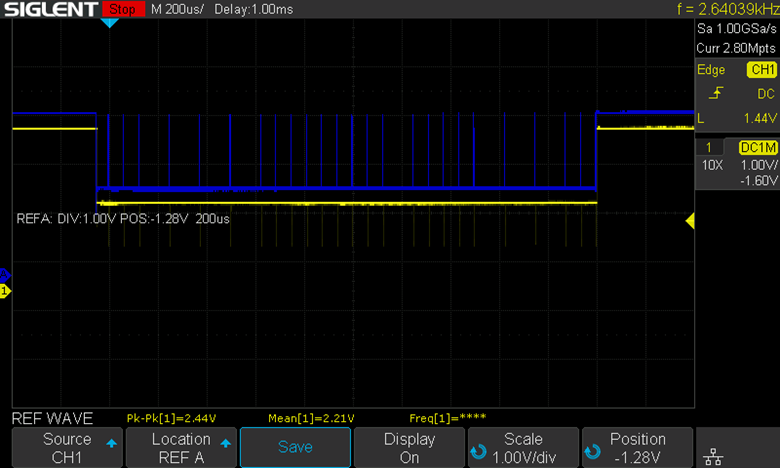

LAB: SI Analysis ------------- ( ✓ )

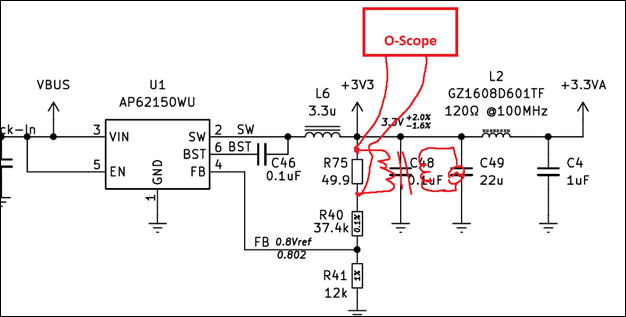

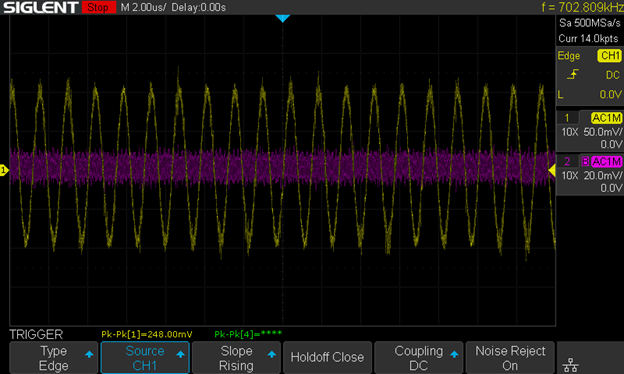

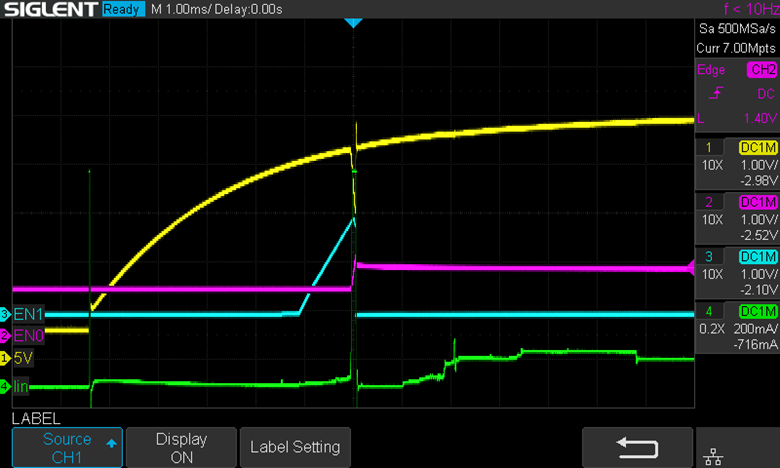

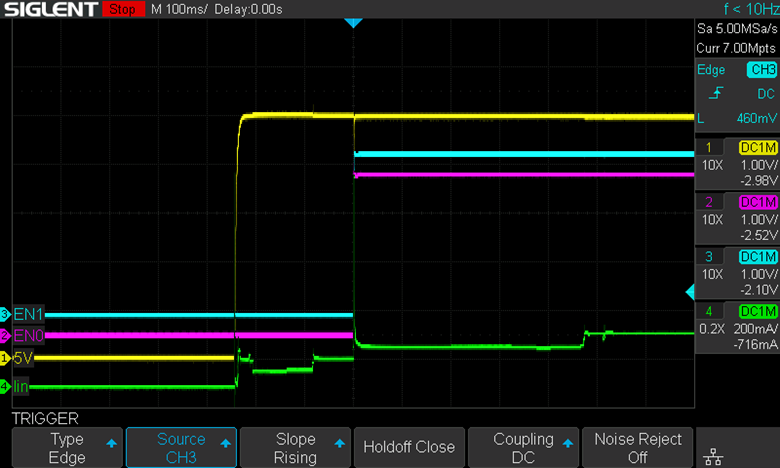

LAB: Power Analysis ------ ( ✓ )

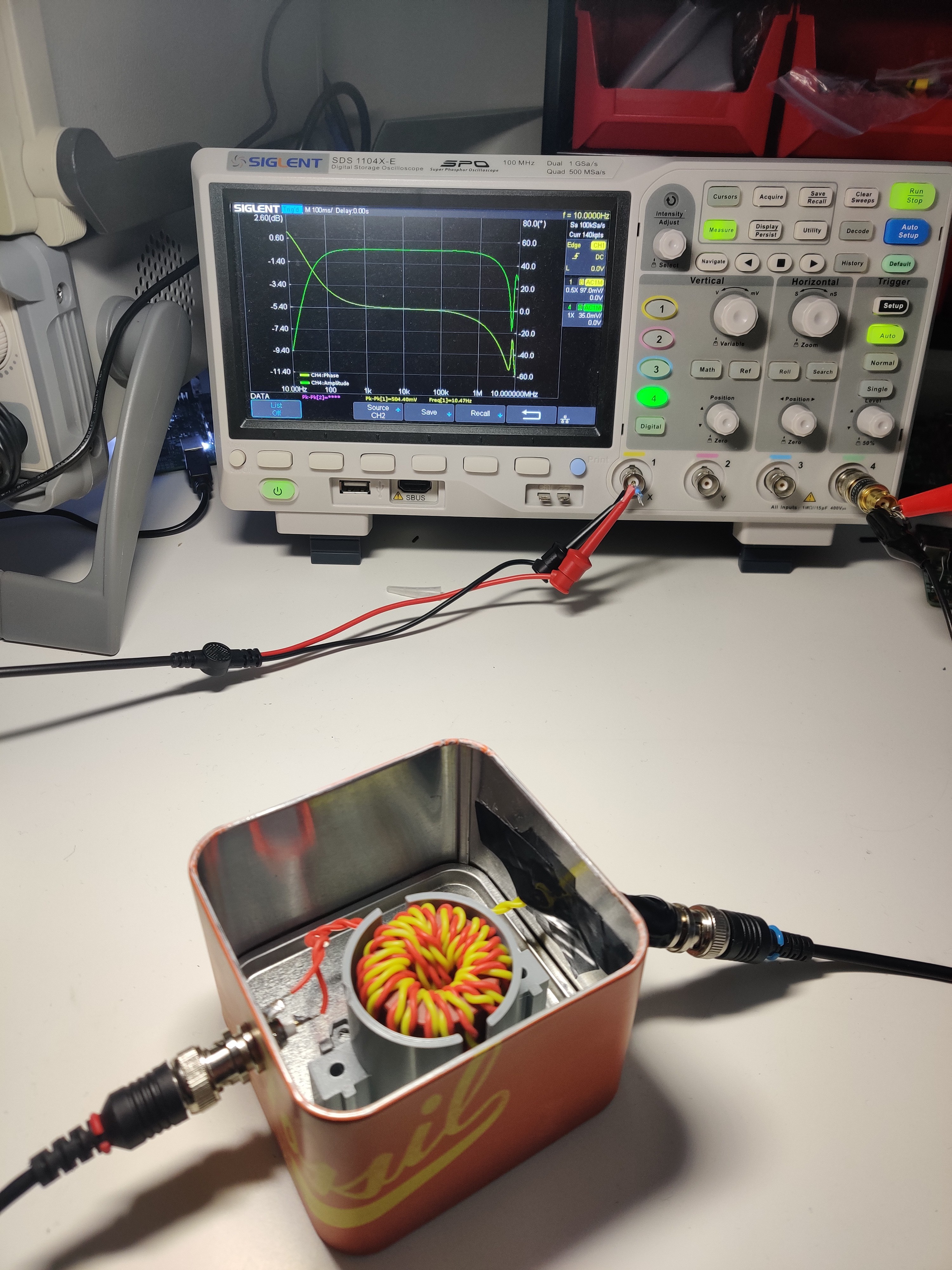

Derisk Capacitive XFRM - ( ✓ )

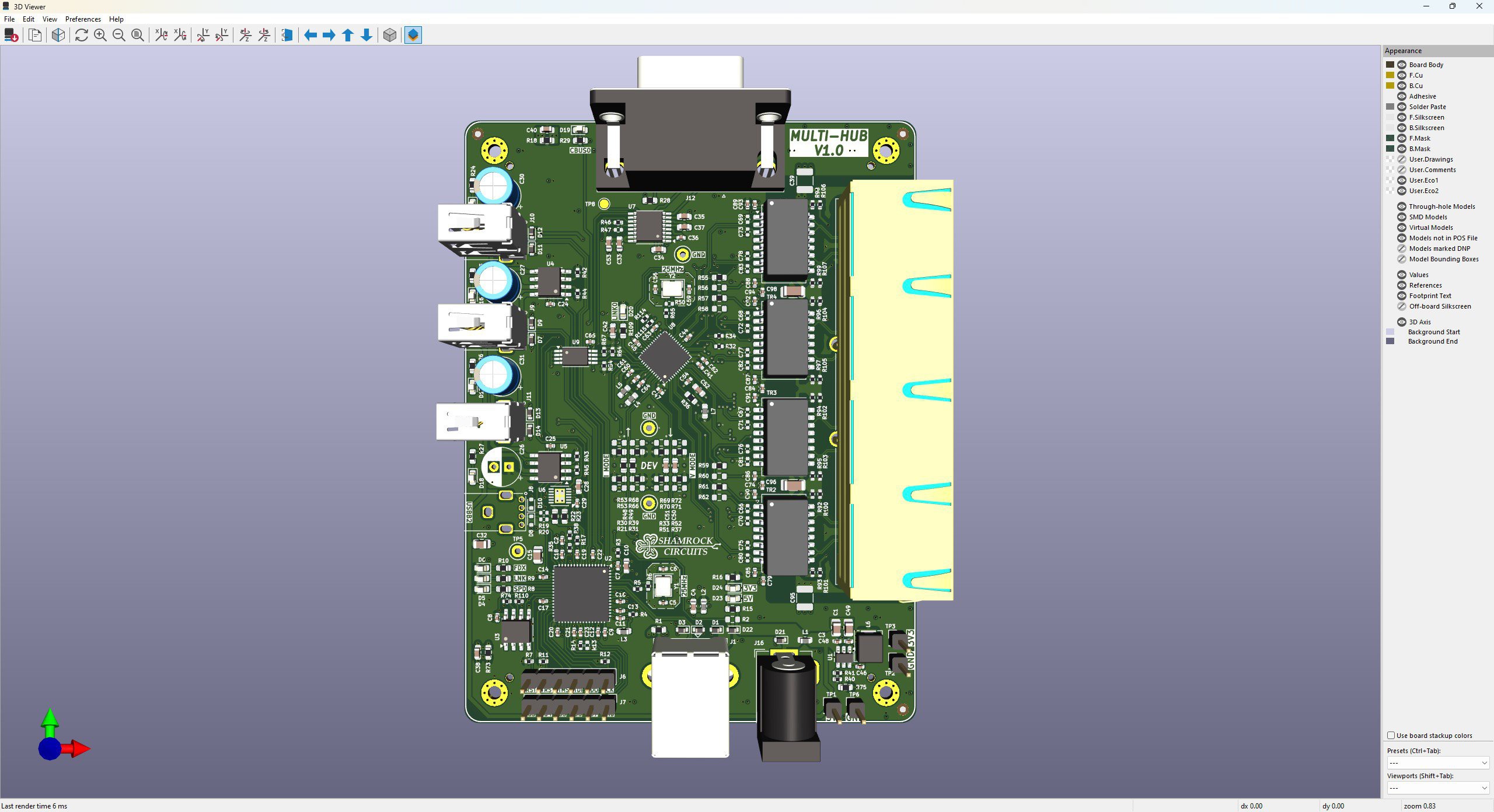

====== REV 01 ======

Schematic Update --------- ( ✓ )

PCB Update ------------------ ( ✓ )

Order + Assemble --------- ( ✓ )

LAB: Sparkup ---------------- ( ✓ )

LAB: SI Analysis ------------- ( ✓ )

LAB: Power Analysis ------ ( ✓ )

====== REV 02 ======

Errata Items Address ------ ( In Progress )

Schematic Update --------- ( In Progress )

PCB Update ------------------ ( )

Design Review -------------- ( )

Order + Assemble --------- ( )

LAB: Sparkup ---------------- ( )

Documentation ------------- ( )

Jesse Farrell

Jesse Farrell

Carbon

Carbon

Ben Holmes

Ben Holmes

Nick Sayer

Nick Sayer