-

Topward TPS 4000 - PSU Repair

10/23/2025 at 19:56 • 0 commentsI recently saved a faulty PSU from the landfill, but I inherited a new project as a result. The device is a “Topward Electric Instruments Co., LTD / Model TPS-4000 / Dual-Tracking DC Power Supply”. This is an old and sturdy power supply with a surprising amount of weight behind it (or perhaps not surprising given its vintage).

Note – I’ve organized this post somewhat backwards: the key fault/solutions are shared first followed by the troubleshooting steps that led me to these findings.

Solution

- Burnt Parts – Generally need to be replaced but not necessarily “the” issue

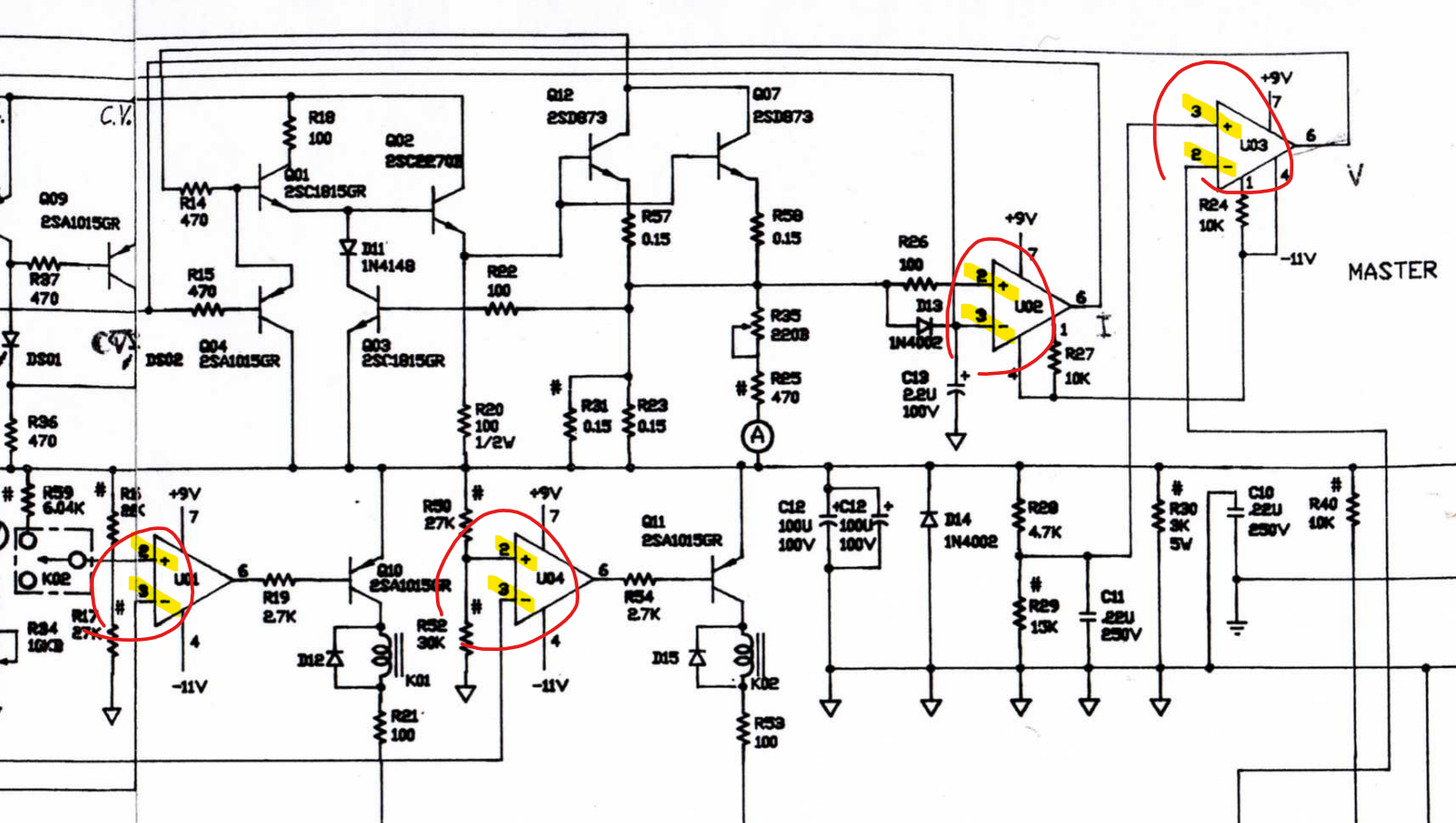

C10 – 0.22 µF 250 V Mylar Capacitor, that connects master negative to chassis GND. C23 – 0.47 µF 250 V Mylar Capacitor, which might be playing a dual role to suppress transients seen by U03 while simultaneously slowing the response of the tracking mode configuration. R40 ×2 – 10 kΩ Metal Film 0.25 %, used as a resistor divider for U03 when in tracking mode.

- Scratchy Potentiometers – Replace R08 & R12

Both CC/CV potentiometers are in varying states of decay causing sporadic changes in their resistance. I had some success cleaning with isopropyl alcohol, but decided to swap them out entirely in the end. I grabbed some footage of the “scratchiness” – take a look below.

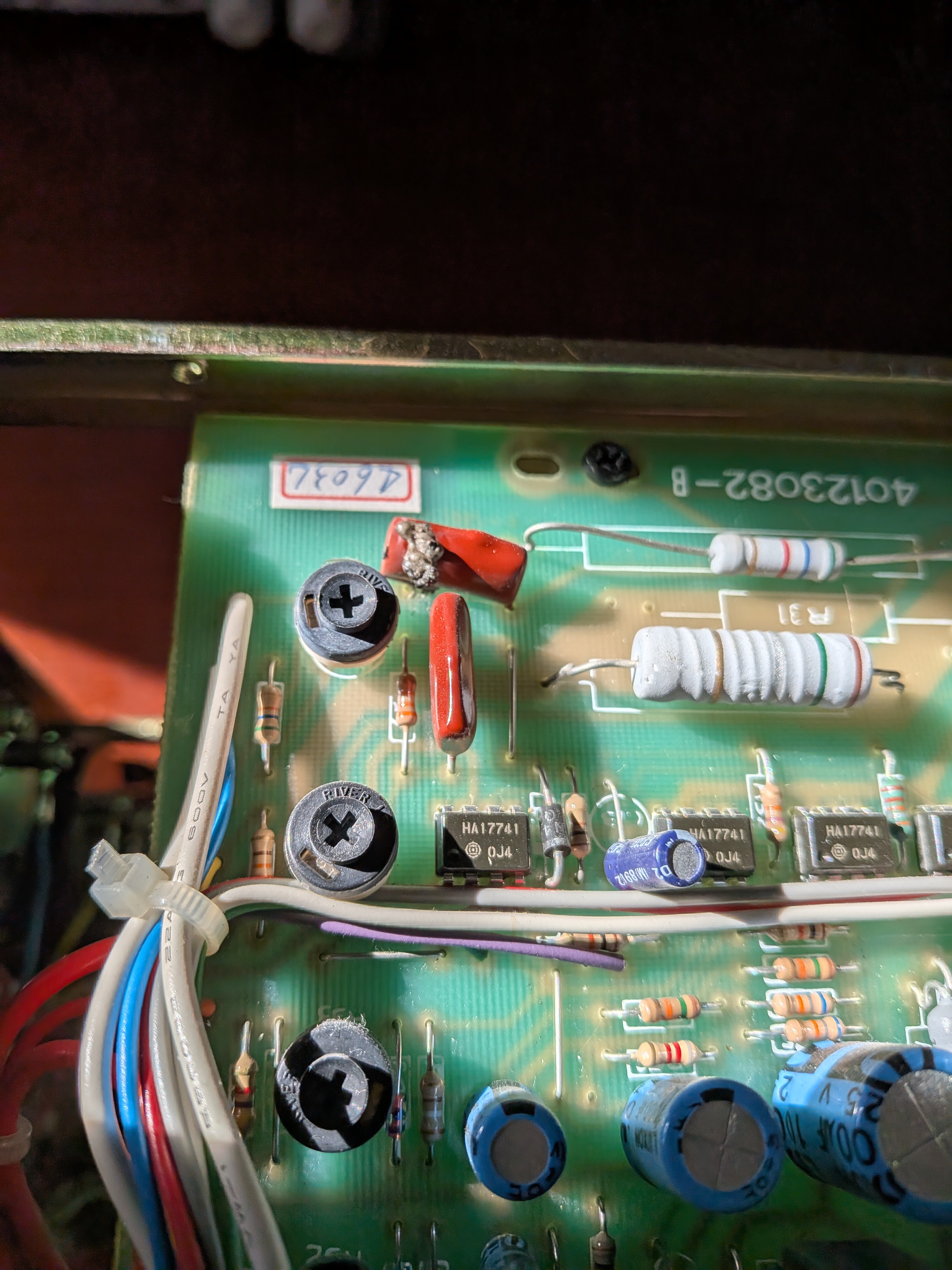

- Faulty U02, 741 Op-amp – Replace Faulty Component

This still has to be tested/validated. The inverting input seems to be drawing ~3× more current than its rated maximum input bias current. As a result it’s dragging the voltage at the input low with respect to the non-inverting input.

Pending Work

- Test U02 fault op-amp theory - DONE

- Replace C10/C23/R40/R08/R12 - DONE

- Calibrate PSU - DONE

Troubleshooting

The TPS-4000 “Slave” channel is faulty. The symptoms of this fault are as follows:

- Sporadic voltage jumps, typically while adjusting CV / CC.

- Fast relay clicking typically during adjustments (changing voltage ranges).

- CC mode engaging intermittently (sometimes getting stuck – I didn’t actually notice this until later).

- Oddly, most of these issues disappeared in tracking mode.

Faulty PSU Before Repair – https://www.youtube.com/watch?v=vE3p9F3KMP0

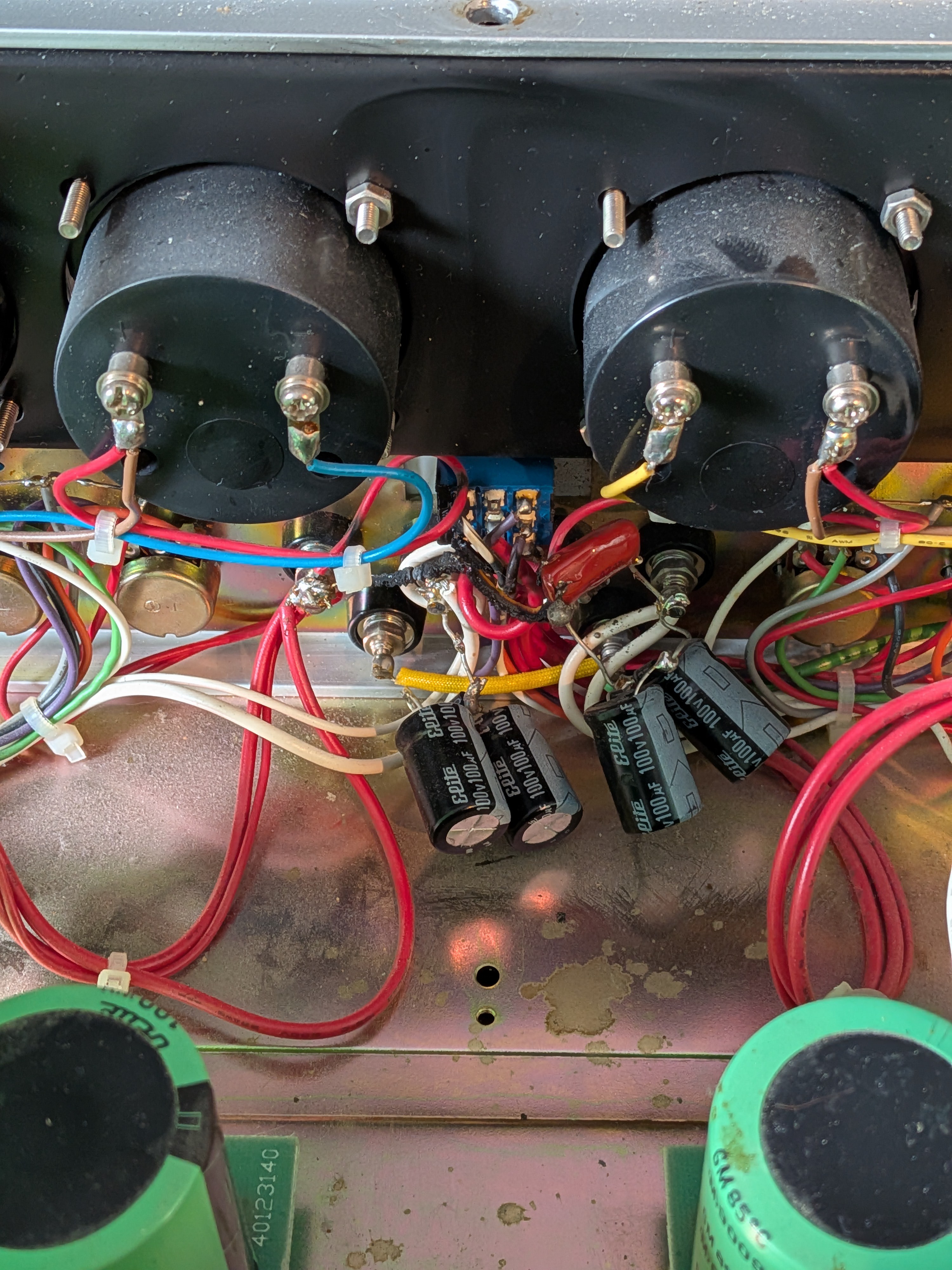

The first and most obvious fault was a blown film capacitor and some burnt wire on the back of the front panel. I later found one more bad film cap on the “Master” channel, this time mounted to the PCB. After going through a visual inspection I checked that both channels of the PSU had all their rails present. I also verified some key transistors and diodes weren’t blown.

![]()

![]()

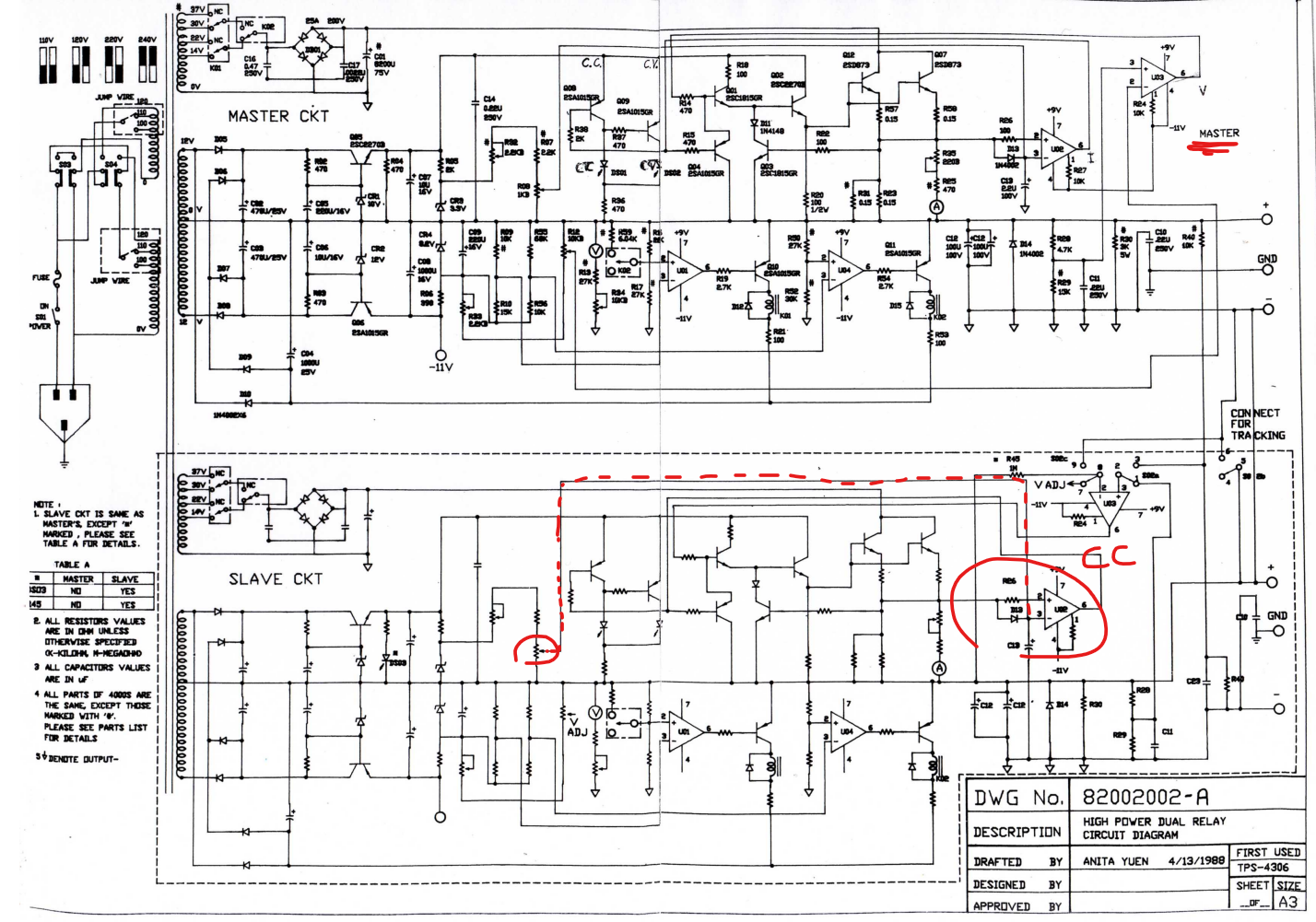

I started to go down a few rabbit holes to understand where each terminal of the rocker switch (which seemed to be the epicenter of the burn) connected to. Luckily, I managed to find some schematics online, saving myself having to reverse-engineer the circuit (maybe next time…). The schematics aren’t for my exact model but it seems close enough.

![]()

I’ve heard of scratchy potentiometers but I’ve never actually seen one during my repairs. I opened up the pot casing and cleaned it with isopropyl alcohol. The results speak for themselves.

Video before cleaning

Video after cleaning

Having repaired the scratchy potentiometer, the output was now MUCH more stable. Now the unit remained locked in current limiting mode, despite the lack of loading on the output.

For a while I was convinced that U02 was COMPLETELY HOSED… But later found I was being misled by the schematic. All op-amps here are exactly the same 741-op-amp, but the schematic labels U03 differently from U01/U02/U04. The correct labeling has the inverting input as pin 2 followed by the non-inverting input on pin 3. This means all U01/U02/U04 are mislabeled. Knowing that I was probing the incorrect node subdued my U02 suspicion, but not for long…

![]()

Before I get to the new issues with U02, I’d like to take a short tangent to talk about the signal GND and referencing on this...

Read more » - Burnt Parts – Generally need to be replaced but not necessarily “the” issue

-

Rotek 8000 - Command List / Programming Manual

09/23/2025 at 03:26 • 0 commentsI had a terrible time trying to find the command list / programming manual for the Rotek 8000. I eventually managed to pull the information from some old LabVIEW VIs at work. I’m sharing them here in case someone finds themselves in the same predicament down the road.

- Output State

- OUTP? → Query output ON/OFF state

- OUTP ON / OUTP OFF → Turn outputs ON or OFF

- Current

- CURR1 1.23 → Set current on channel 1 to 1.23 A

- CURR1? → Query current setting for channel 1

- Current Phase

- CURR1:PHAS 1.0 → Set phase offset for current on channel 1

- CURR1:PHAS? → Query current phase setting

- Voltage

- VOLT1 120 → Set voltage on channel 1 to 120 V

- VOLT1? → Query voltage setting for channel 1

- Voltage Phase

- VOLT1:PHAS 0.0 → Set phase angle for voltage on channel 1

- VOLT1:PHAS? → Query voltage phase setting

- Frequency

- FREQ 60 → Set system frequency to 60 Hz

- FREQ? → Query system frequency

- Output Terminals

- ROUT1:TERM FRONT → Route channel 1 output to front terminals

- ROUT1:TERM REAR → Route channel 1 output to rear terminals

- ROUT1:TERM? → Query active terminal set for channel 1

Note – This list is not official and may be incomplete. I excluded the generic SCPI commands (IDN, RST, etc.) and only included the Rotek-specific ones I was able to confirm. If you discover additional commands or different behaviors, please share — it would be great to build a more complete reference for this instrument. Maybe someone has the original programming manual...?

![]()

- Output State

-

Masterbuilt Smoker - Front Panel Repair

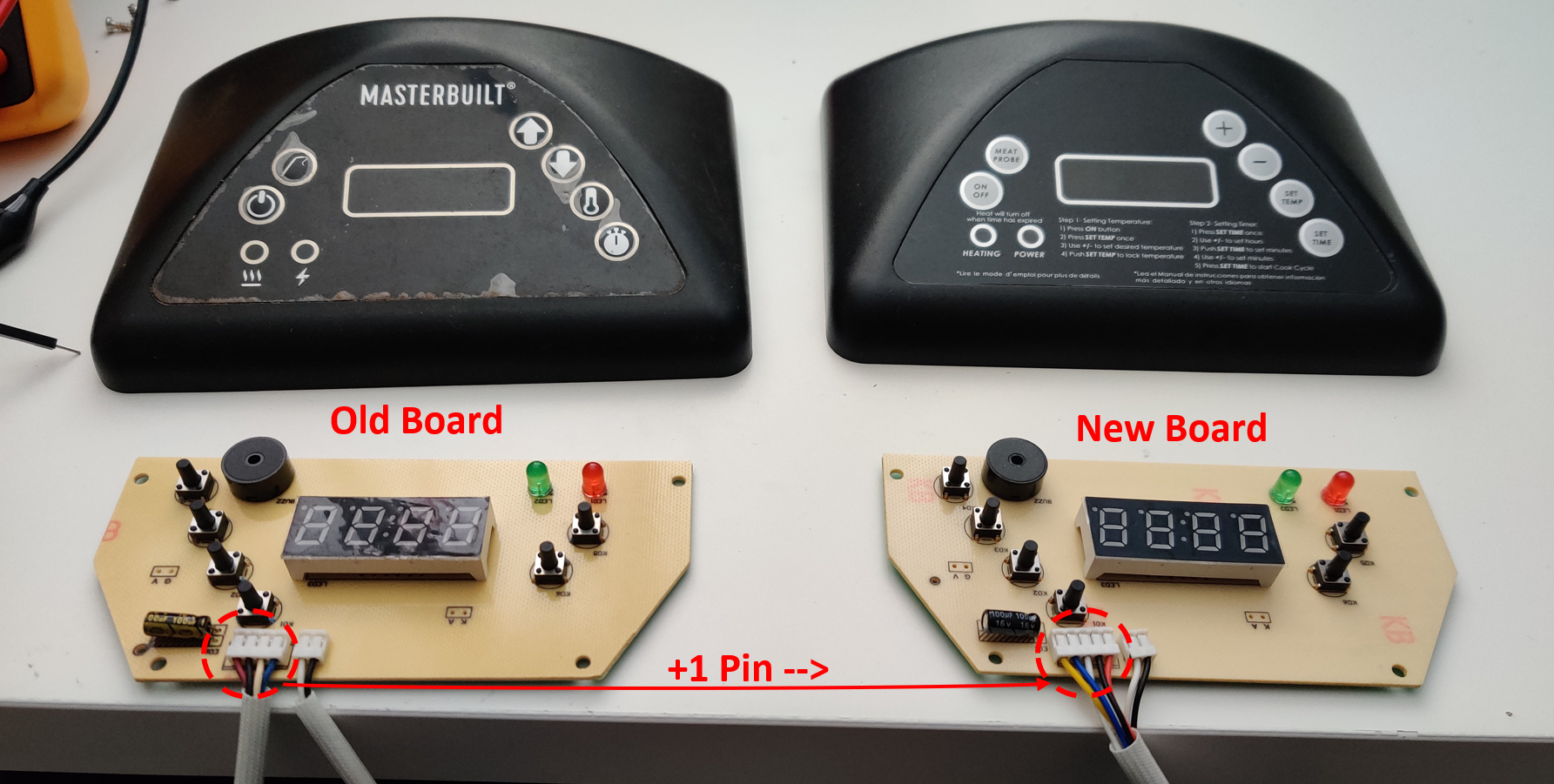

07/25/2024 at 05:46 • 0 commentsA friend of mine has a smoker, who’s front panel circuit recently gave up the ghost. He bought a new one that he thought was compatible but sadly it had an incompatible connector. When I asked him about the symptoms, he said that it couldn’t set the temperature anymore. It was pretty clear on closer inspection that the likely culprit was a mechanical fault on the “set temp” button.

I believe the model of the smoker is “Masterbuilt MB20071117” or something very similar, and the replacement he bought was a “Digital Control Panel Kit Replacement” that seems to be compatible based on the amazon listing… clearly not though, one review even complains “20071117 is a 4 prong connector. This panel has a 2 [and] 5 prong connectors and is not compatible.”

Anyways, here I sit in my lab with a peculiar Masterbuilt smoker panel, and a not so compatible clone.

![]()

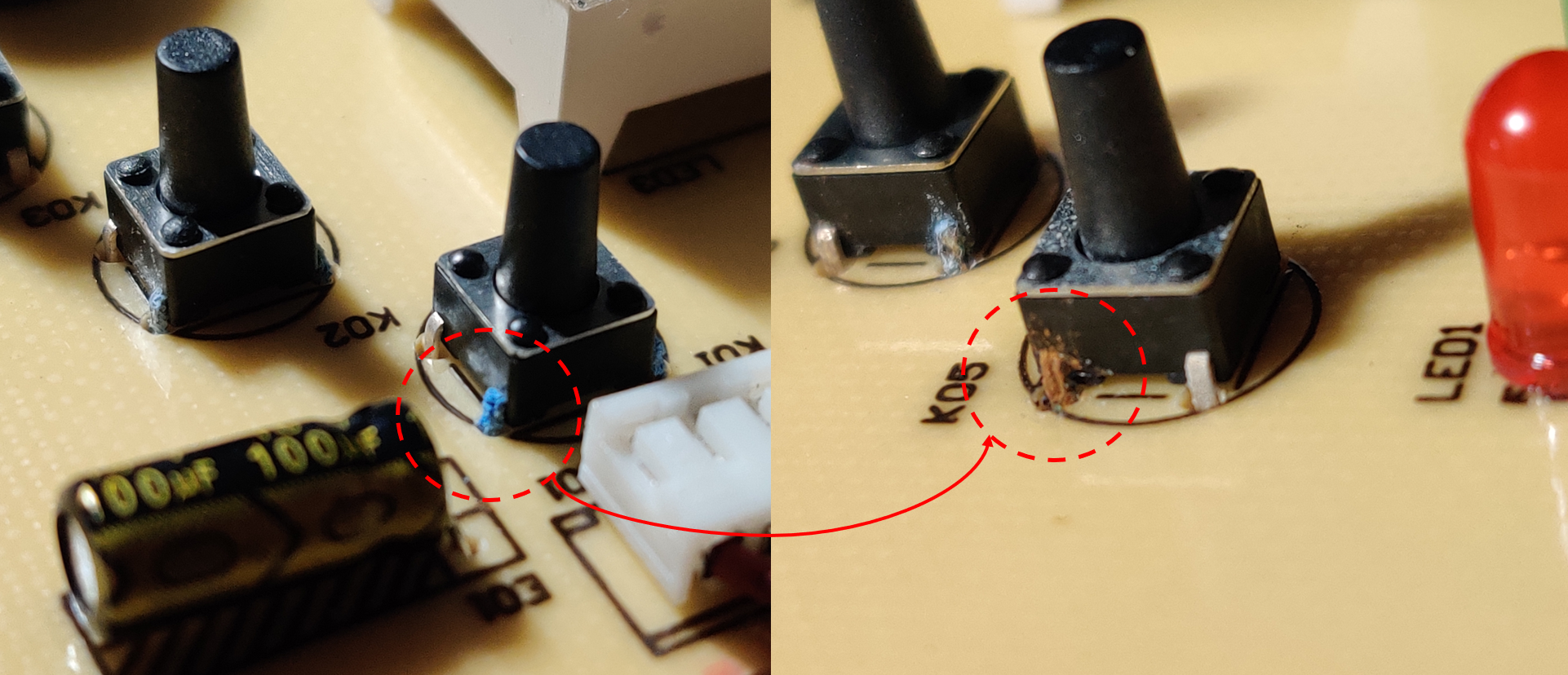

Busted Buttons

Probing the buttons… I’ve never seen buttons this busted. Scraping away the oxidation I can’t even get a consistent “short” when the button is depressed. All my measurements are in the MΩ range.

![]()

Clearly then this is the issue… I have some replacements, but they’re all the shorter style. Alternatively, I could raid parts from the “replacement” new board. Neither of these methods sounds very fun. The boards are covered in conformal coating that can be a pain to solder through.

Alternatively, I could check the circuits and see if I can make the replacement work. This seems more fun so I’ll take this path...

Spider Man Pointing Meme

They’re the same board. It looks like the fab house maybe took some liberties with the copper pours and tooling holes, but other than that (and the extra pin on the connector!) the two circuits are identical.

Gerbers are largely the same, even the silkscreen and ref designators are identical. The only immediate thing that jumps out is C02 doesn’t use a capacitor on the old board… weird. Other than that there’s the following BOM value changes.

Description

NEW

OLD

Should I Care?

R36/35 (LED Limiter)

511 (510 Ω)

201 (200 Ω)

No

R27/26/25… (BTN PU/PD)

222 (2.2 kΩ)

222 (2.2 kΩ)

No

R04/05/06… (7Seg Limiters)

511 (510 Ω)

201 (200 Ω)

No

C02 (Unknown, debounce?)

5101 (5.1 kΩ)1

???nF

Yes

Note 1 – Wasn’t sure if 1015 or 5101. Measure in circuit as 5.09k so I’ll guess the latter.

The good news is the 4th pin isn’t used anywhere. The bad news, they completely changed the wiring so we’ll need to do some pin pulling. Lastly, the confusing news, why is C02 a resistor on our new board?

![]()

I’m not too sure what the 2 remaining pins do on the connector. One is power, another is ground and then the remaining 2 go to the IC. One through this CR filter, the other just through a 10k. There’s also that 2wire bundle (black and yellow) that seems to have the same CR filter (now including the 5.1k PD).

My best guess is they’re clock and data lines. Maybe the designer wanted to soften the edges of the signal. (I later realized that one of those signals was for an analog input from a temprature sensor).

Power Up

Lets power the thing up cuz I’m curious. The name on the IC has been removed so I can’t get any help there…. Just by looking at the circuit it seems like the white wire is ground, leaving red as the likely culprit for VCC. I set a low current limit at 3V3, and saw nothing. But the board came to life around 3.7V with a short beep.

When I try to probe the signal connected to C02 (looking for activity maybe), I put the panel into some error mode “EAA1”. Looking into it, it seems to be related to the “smoker's ambient temperature sensor reading too low of a temperature”. The error state latches until you power cycle it.

Ok lets treat it like an input then… I wired it up to my function generator and applied 500mV and...

Read more »

My Projects

My Pages

Projects I Like & Follow

Share this profile

ShareBits

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Jesse Farrell

Jesse Farrell

haas

haas Andy Geppert

Andy Geppert Jon

Jon Thomas Flummer

Thomas Flummer OK Design

OK Design Dan Julio

Dan Julio Michael

Michael Teapot Laboratories

Teapot Laboratories gokux

gokux Nasser

Nasser Jasper Sikken

Jasper Sikken Erik@EDrTech

Erik@EDrTech Makestreme

Makestreme Tim

Tim bru3s

bru3s photondreams

photondreams tobychui

tobychui