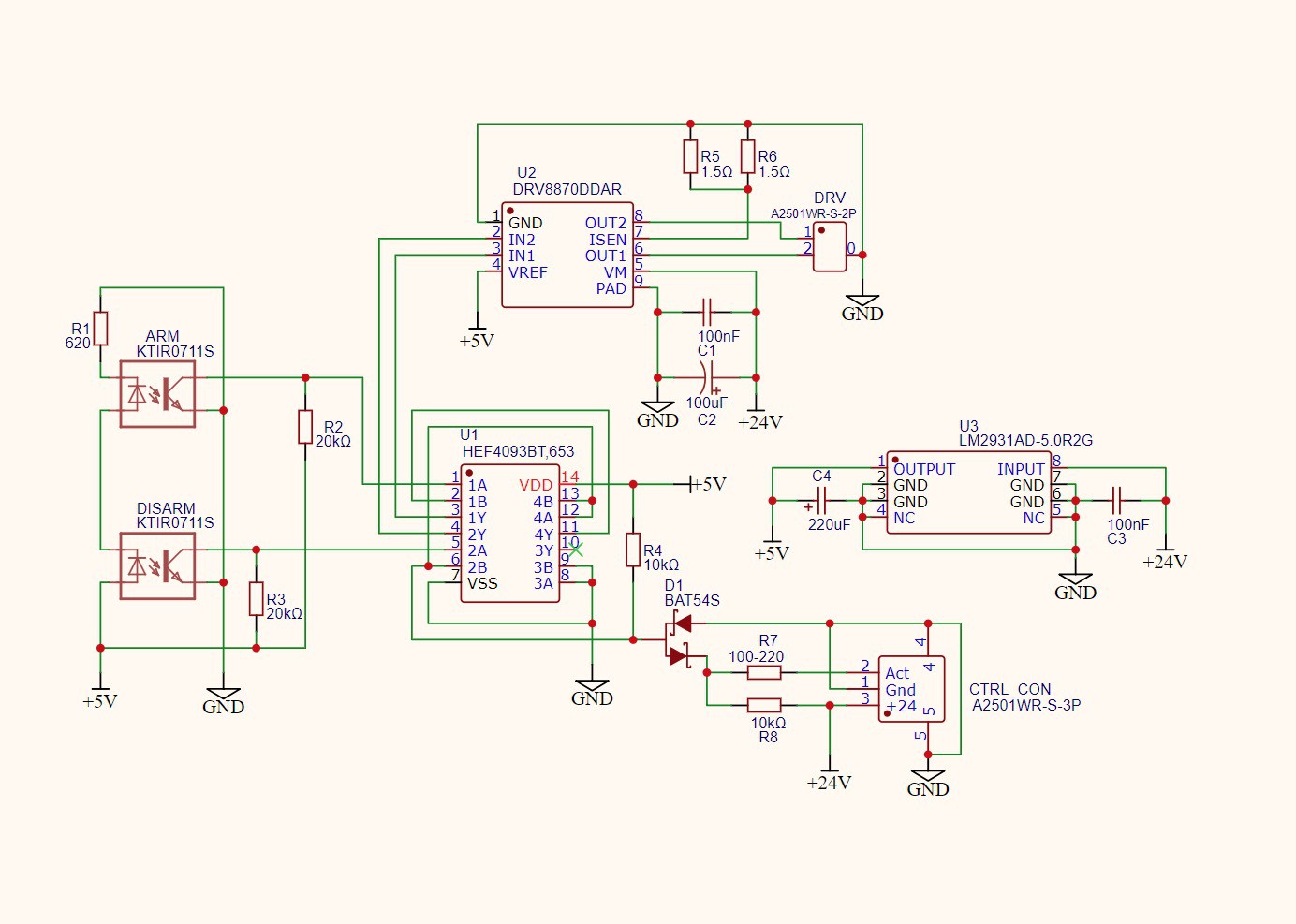

A board from another developer uses a three-pin connector. This is a very simple and inexpensive solution. The pin-out of the connector is shown below.

- GND - the ground for power and signal

- +24V - the power for the servomotor

- DIR - the direction signal: 0 - rotate CW, 1 - rotate CCW

The motor stops by itself when the marker reaches the optical sensor.

The disadvantages of this are:

- The control controller has no status from the servo motor;

- If the device is suddenly de-energized, the servo motor will start moving in the default direction when power is restored. This somewhat makes the process of powering up the device a bit daunting for the user

Solution 1 - With RS485

For more complete control you can use RS485 interface. Then there will be a pinout.

- GND - power ground

- +24V - power

- A - RS485

- B - RS485

However, this will require a microcontroller and interface converter to be installed on the board. This makes the construction more expensive.

Solution 2 - With I2C

It will be a little cheaper if you use I2C interface.

- GND - power ground

- +24V - power

- GND - signal ground

- SCL - I2C

- SDA - I2C

Solution 2 - Passive

In this case only the motor driver is installed on the board. Then the pinout will be as follows.

- GND - power ground

- +24V - power

- GND - signal ground

- M1 - motor in1

- M2 - motor in2

- S1 - sensor 1

- S2 - sensor 2

Conclusion

Tough choice considering the connectors and wires cost their money too. However, the RS485 option looks like the most noise-protected and therefore reliable option.

h2w

h2w

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.