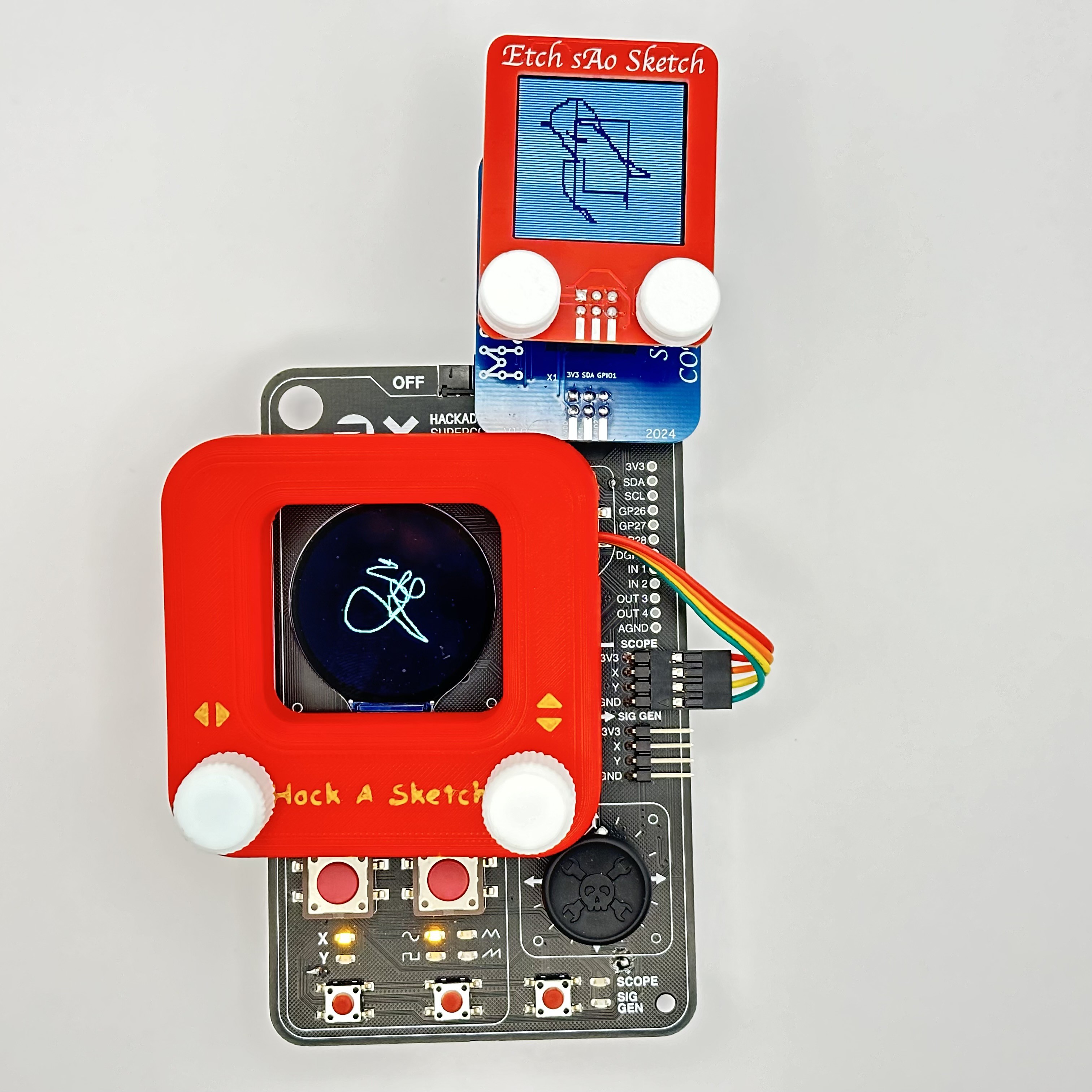

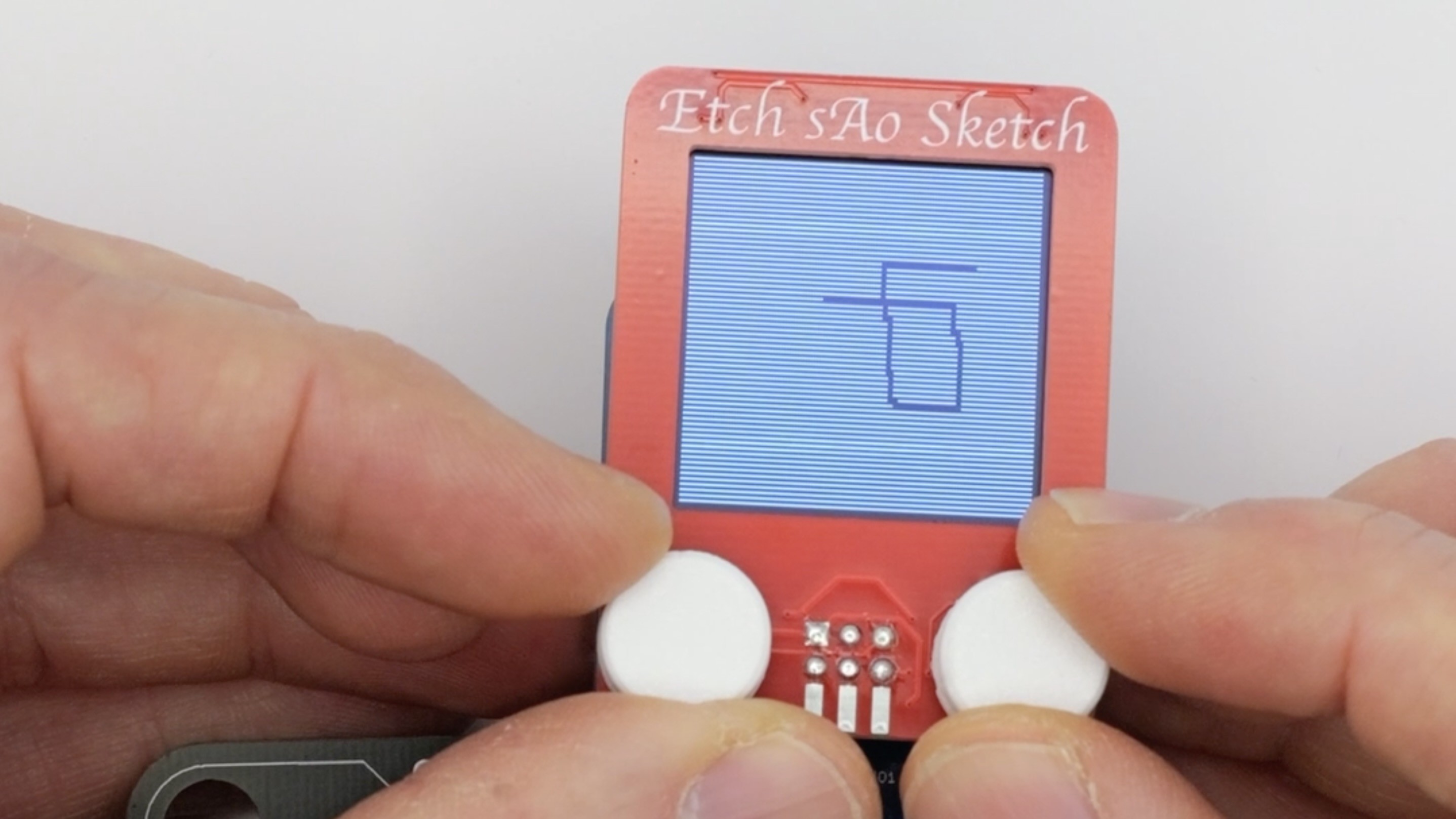

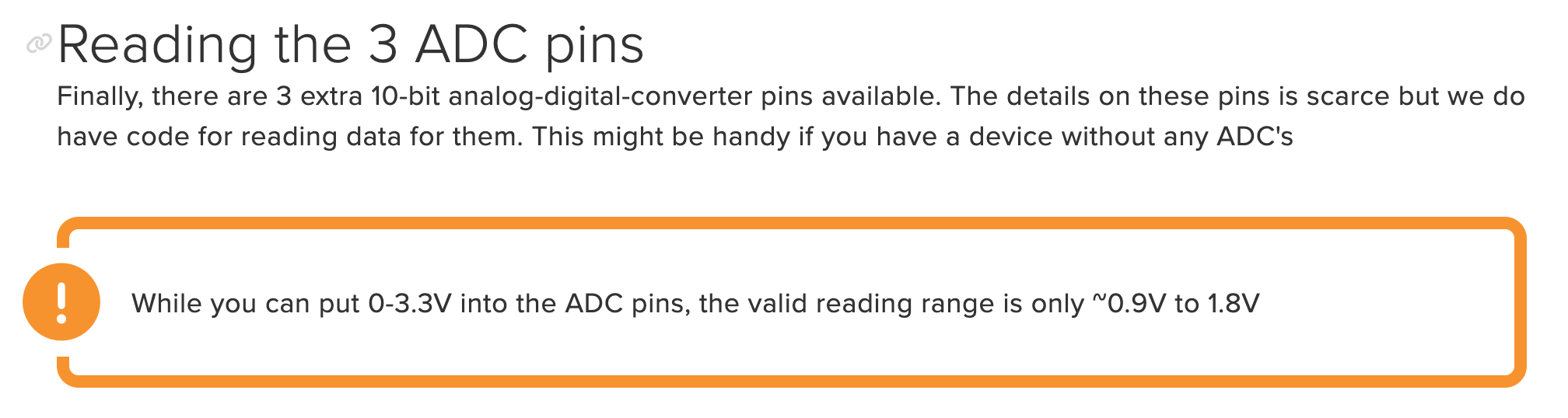

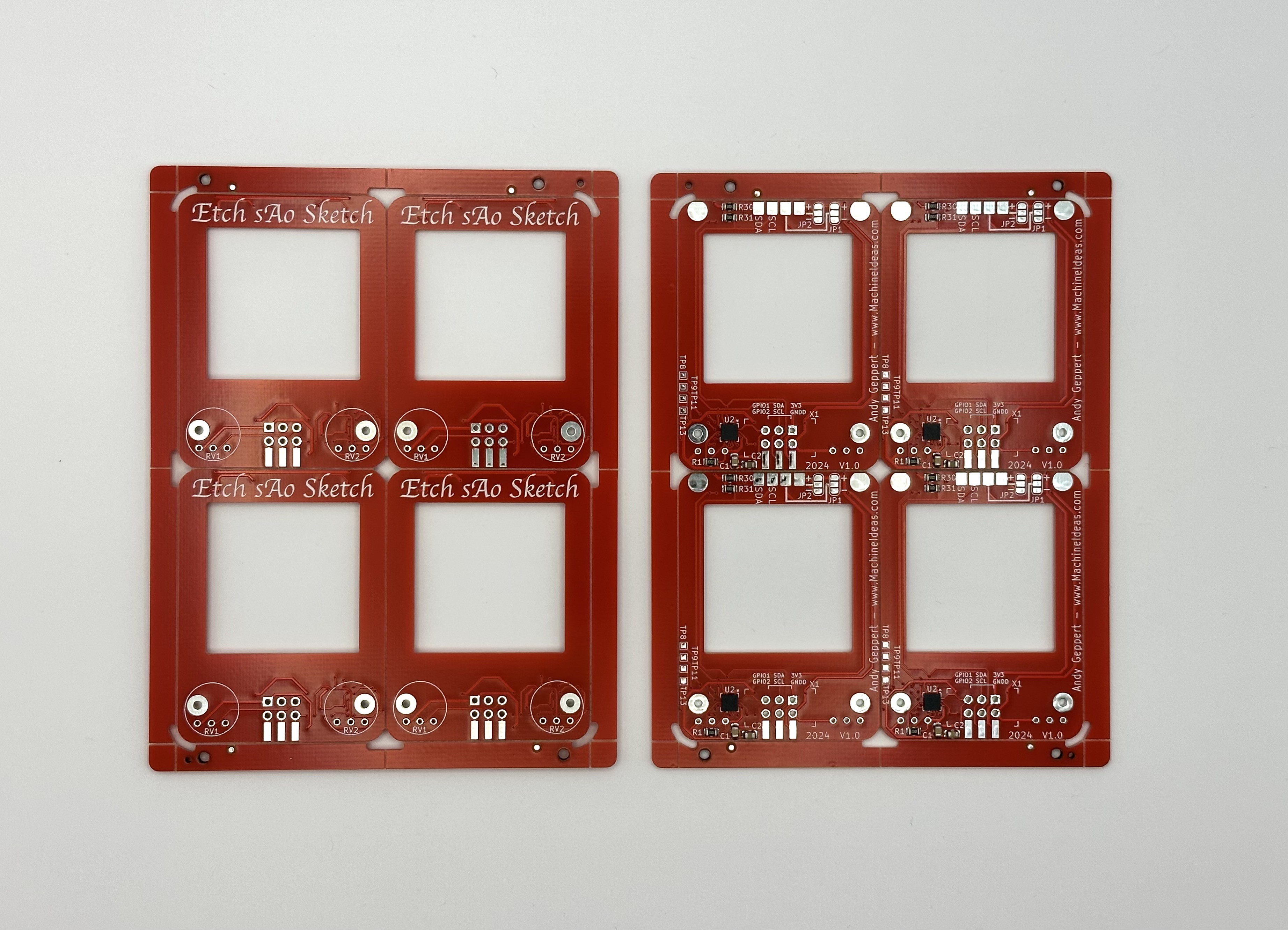

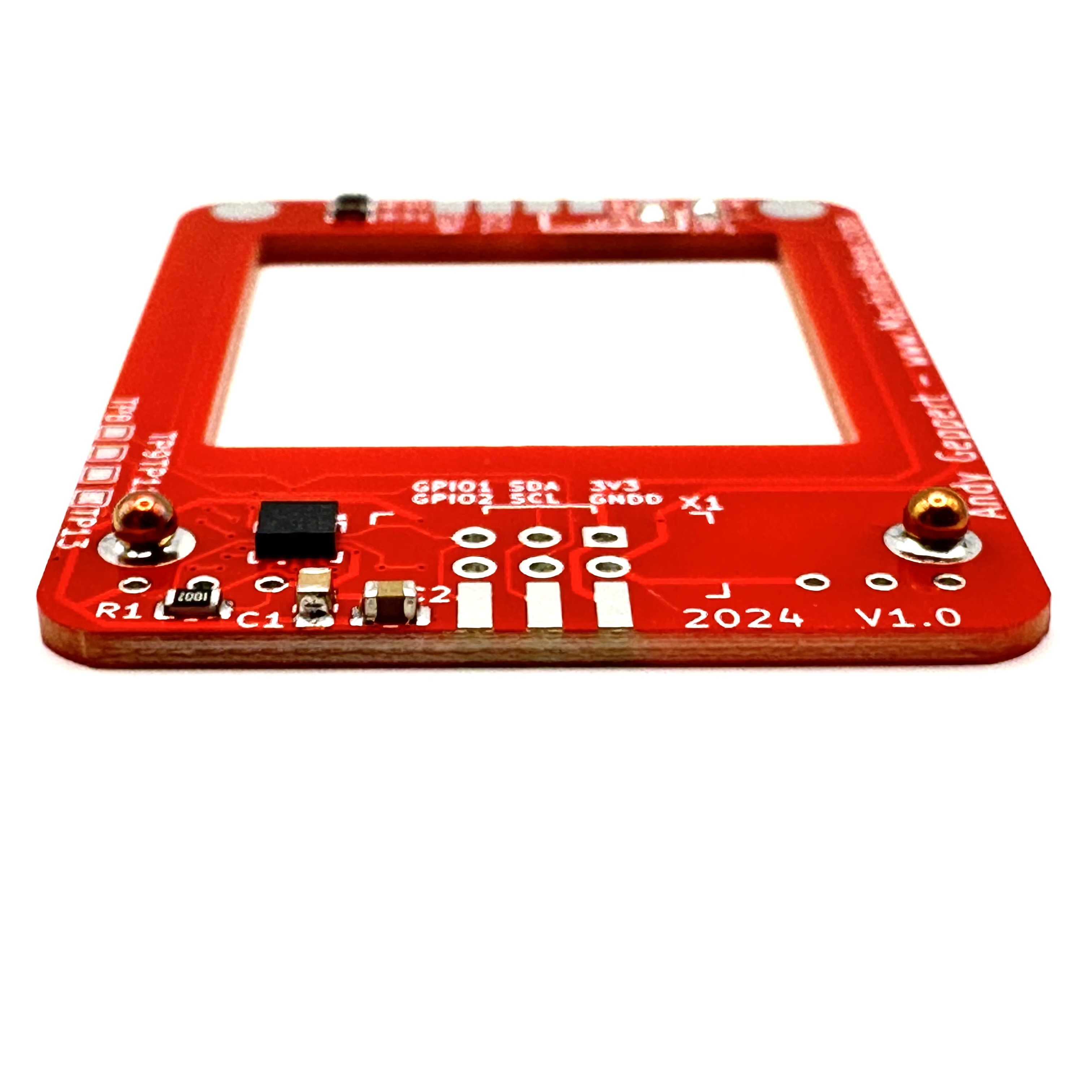

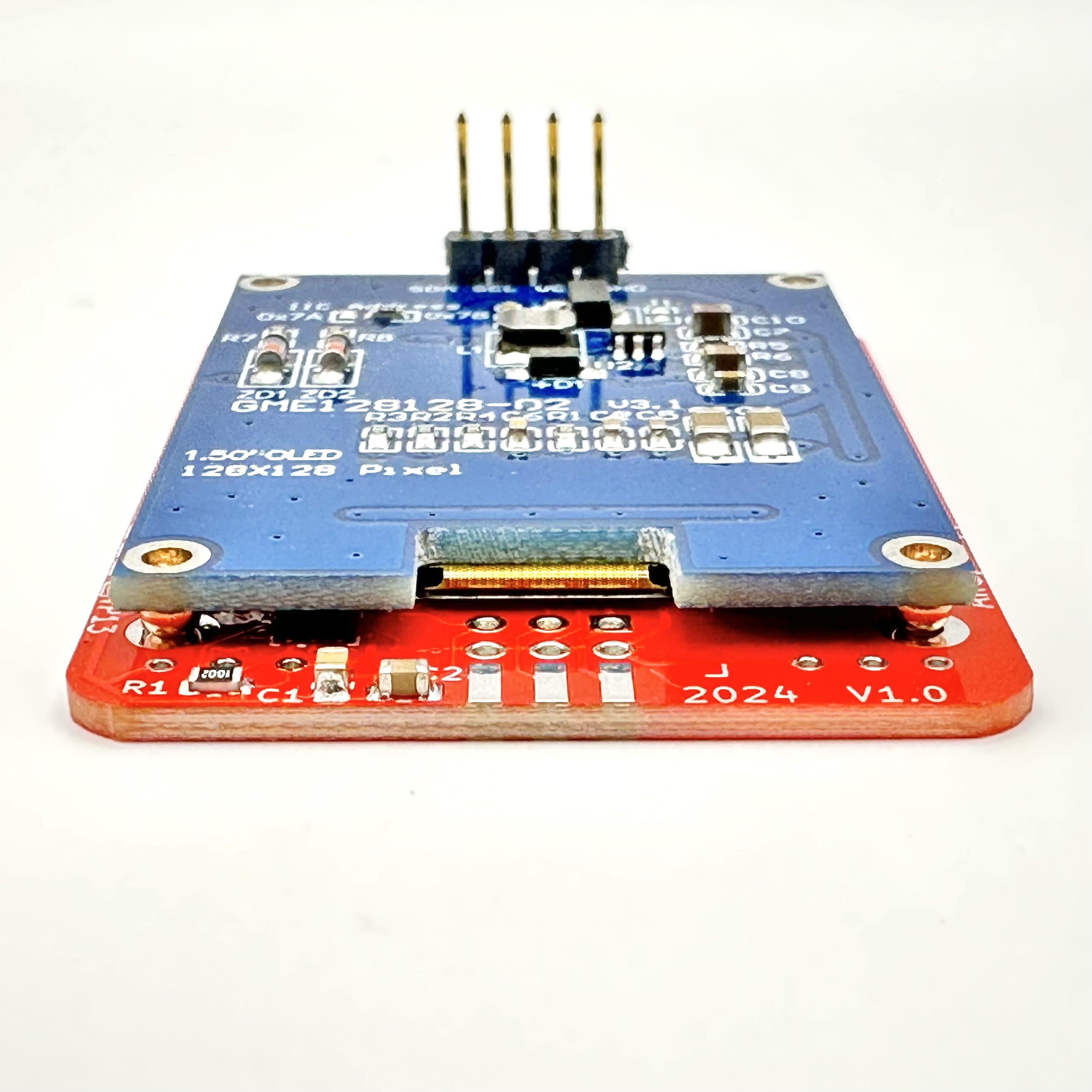

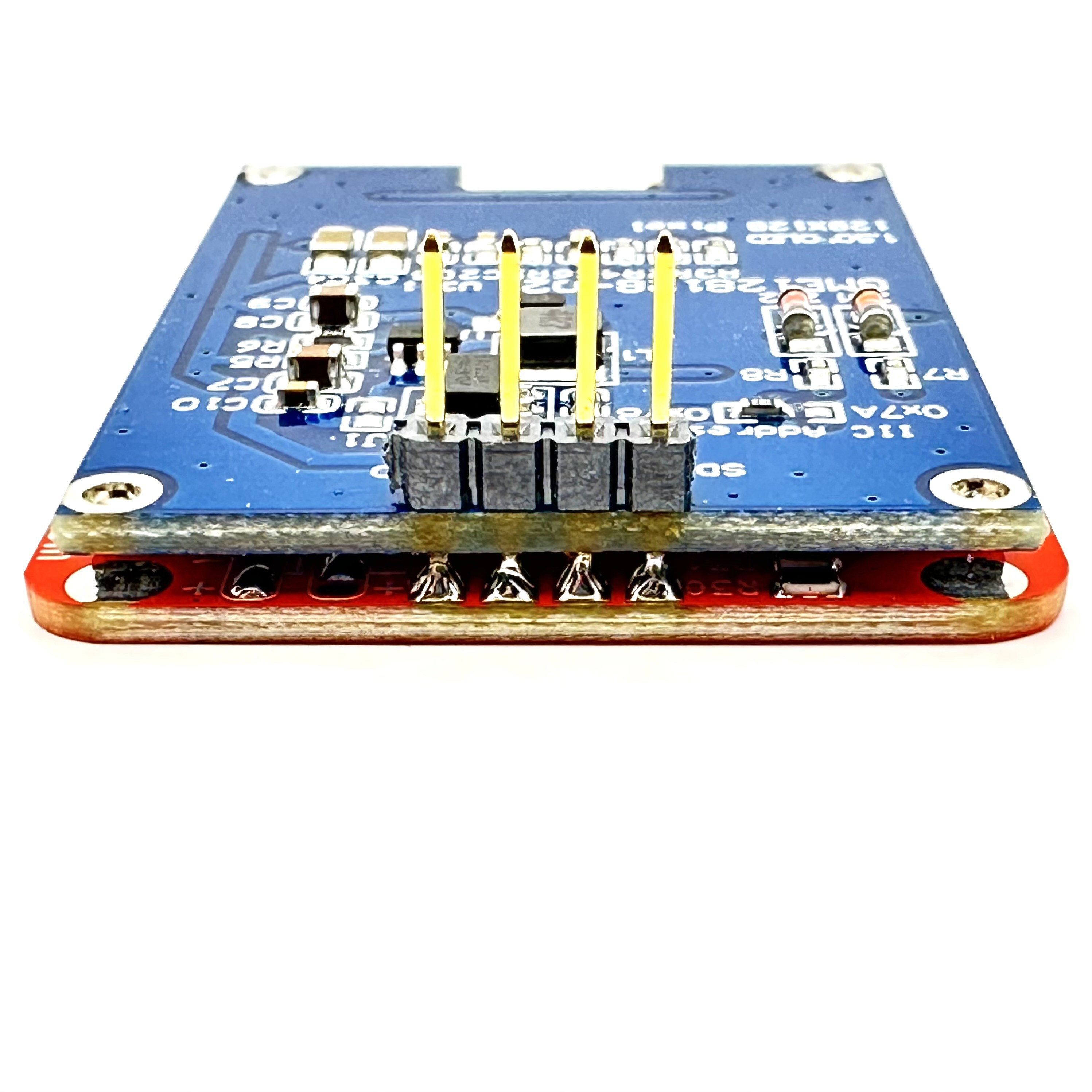

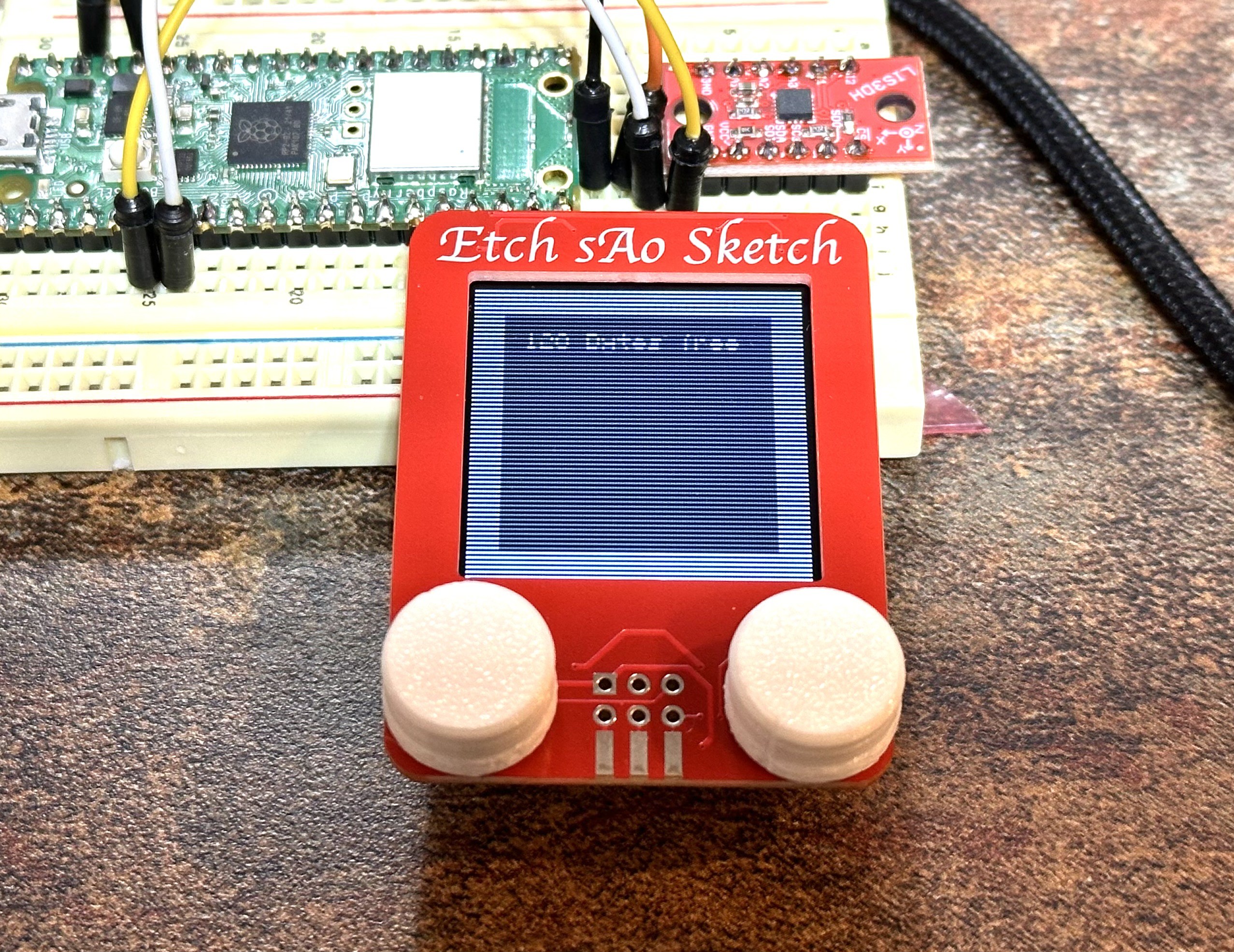

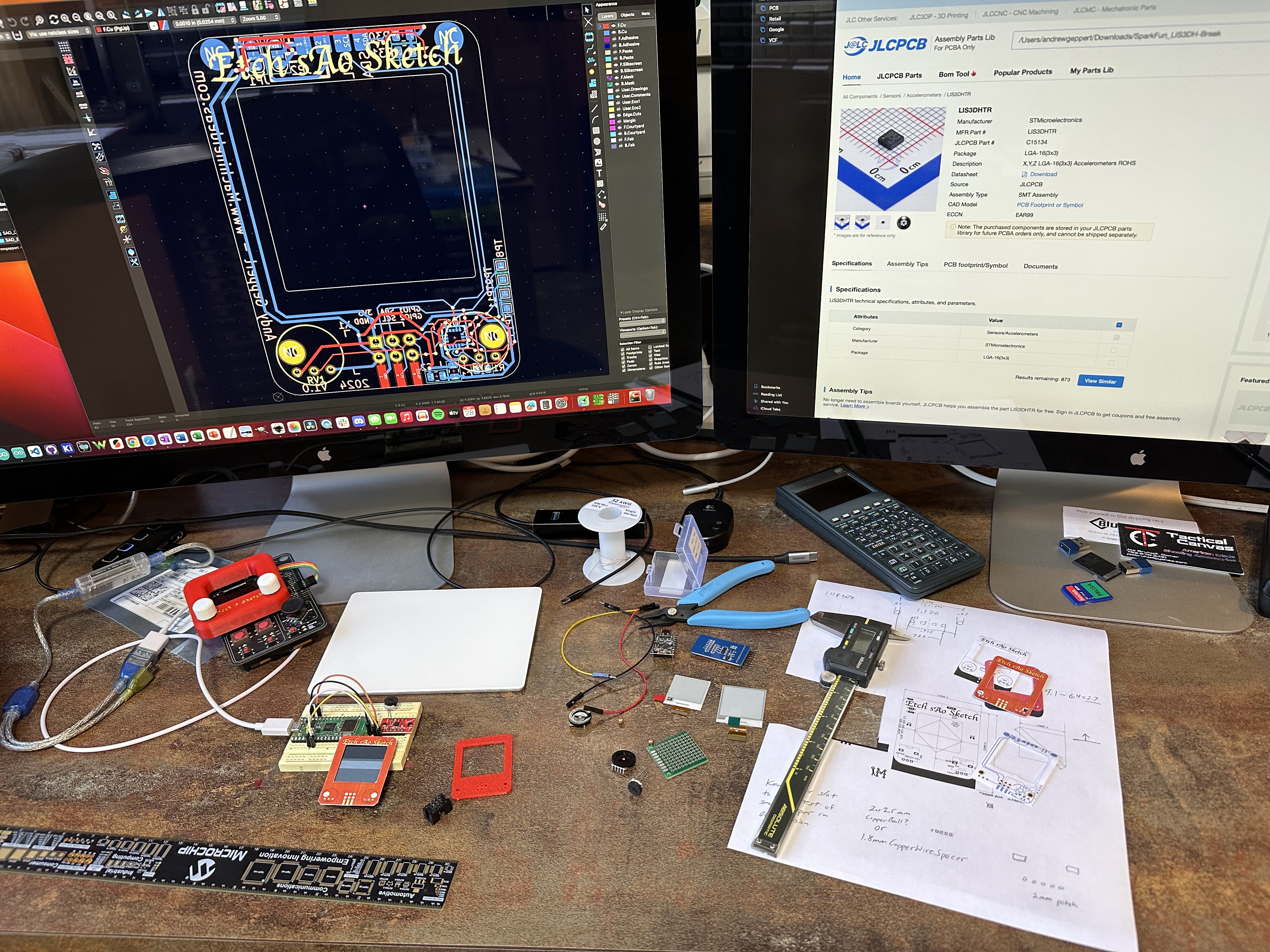

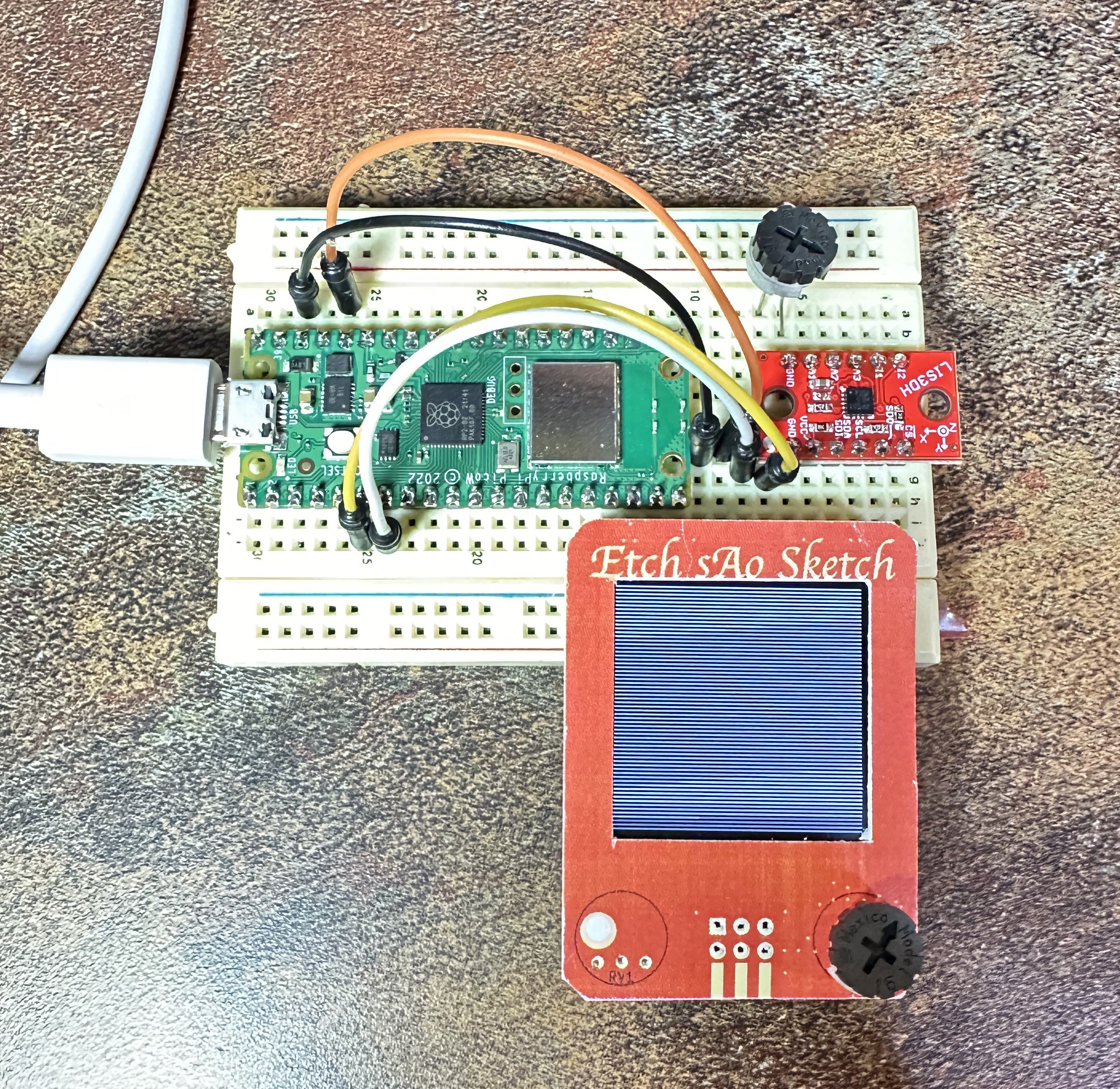

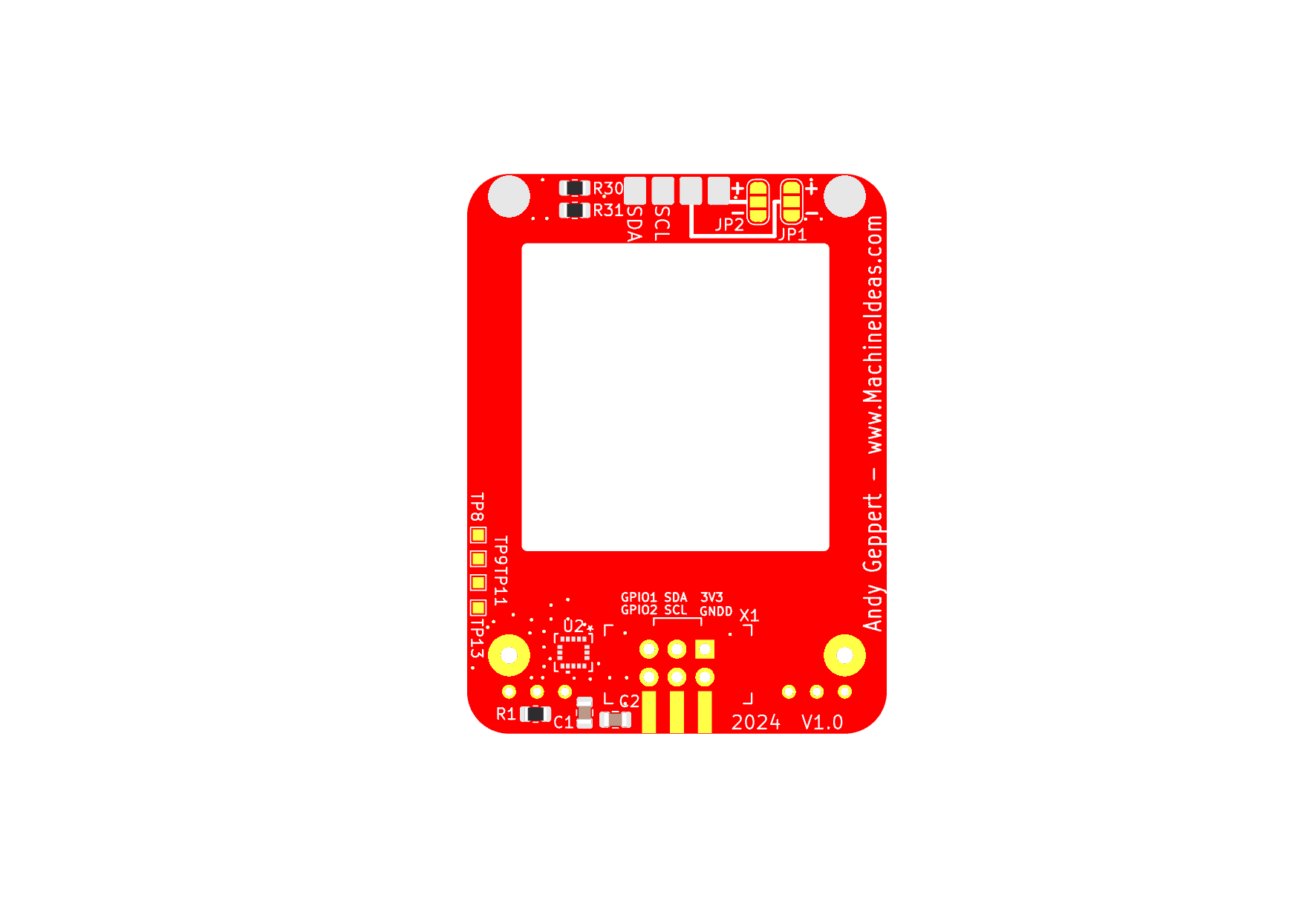

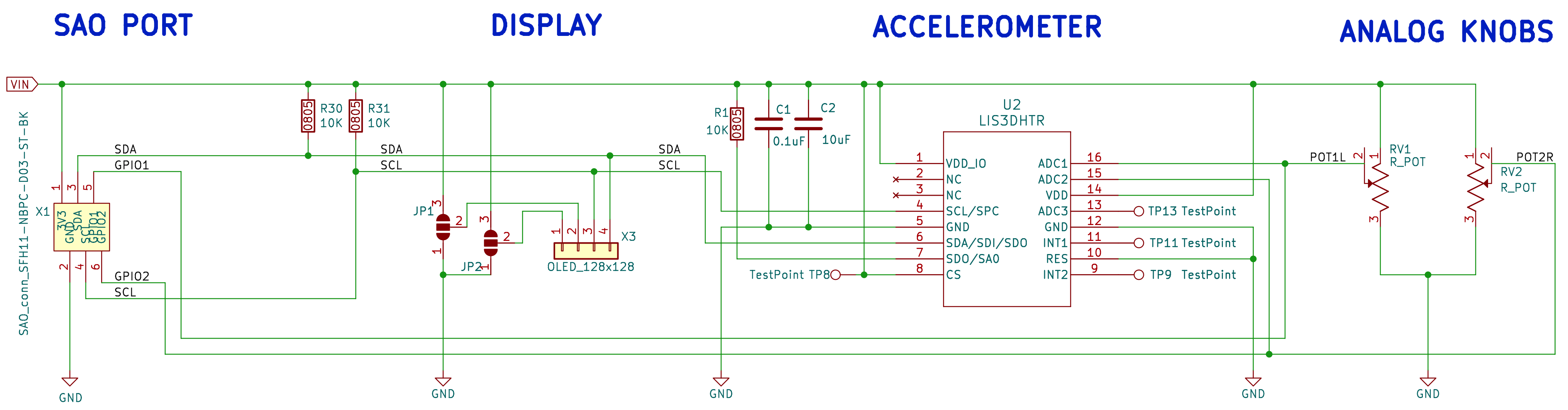

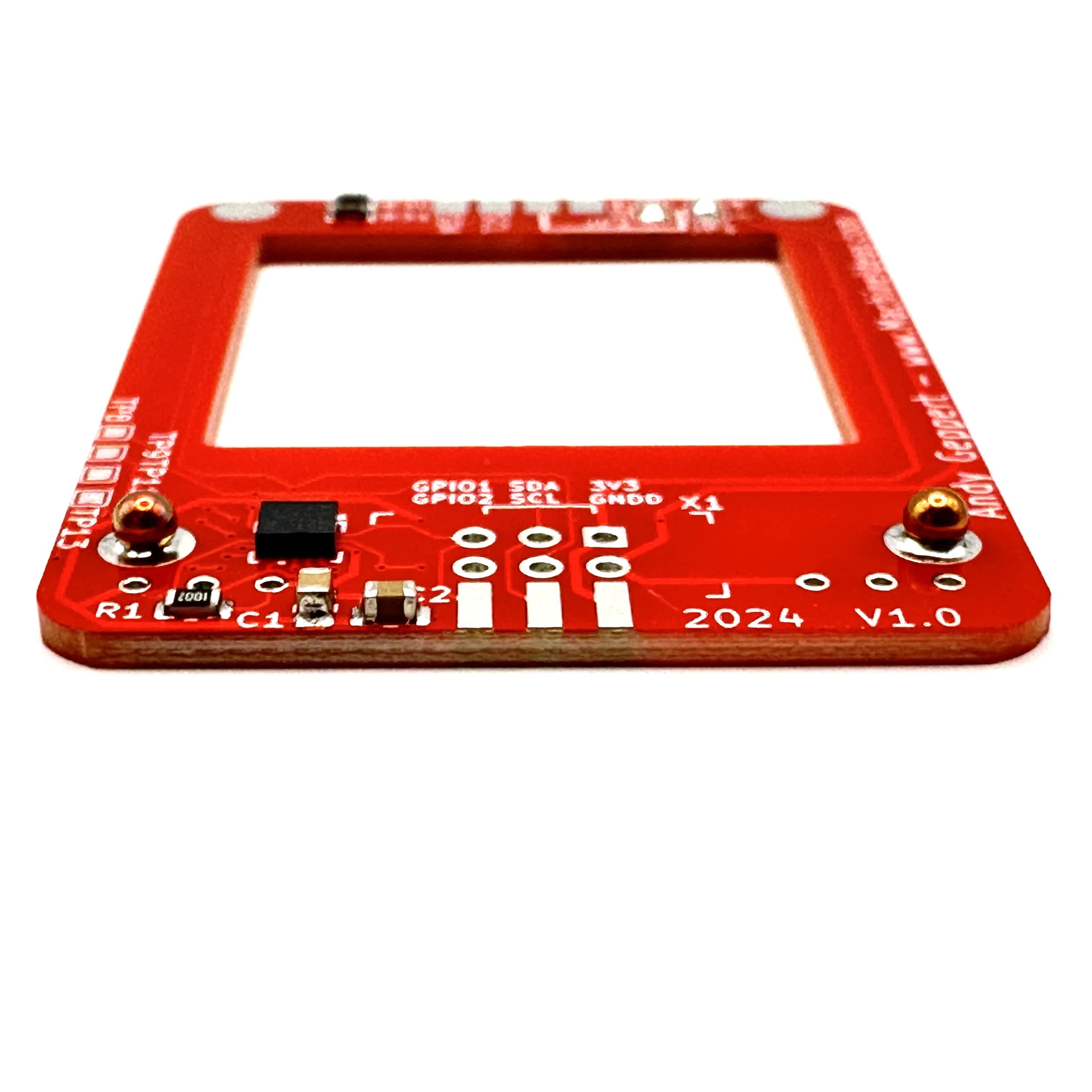

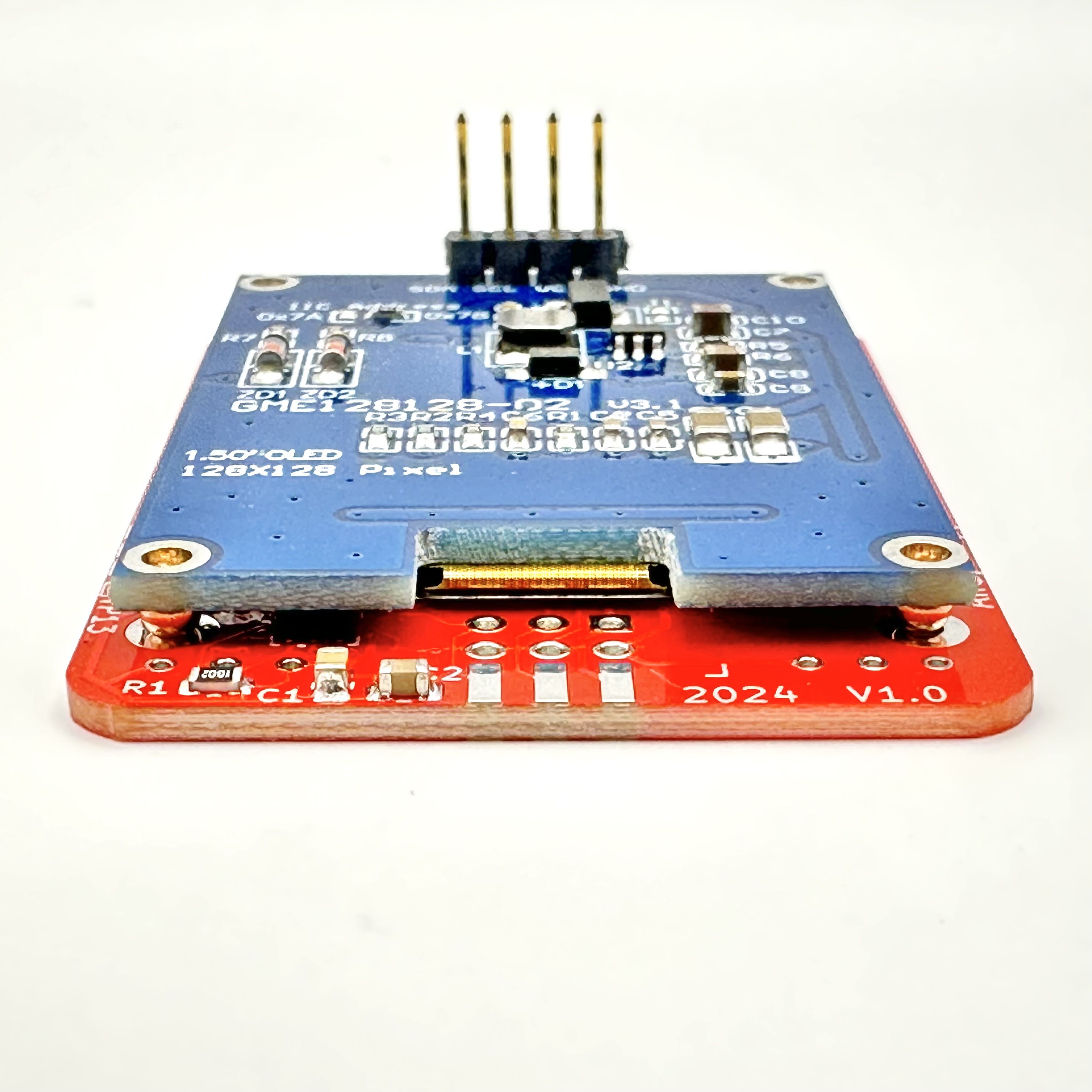

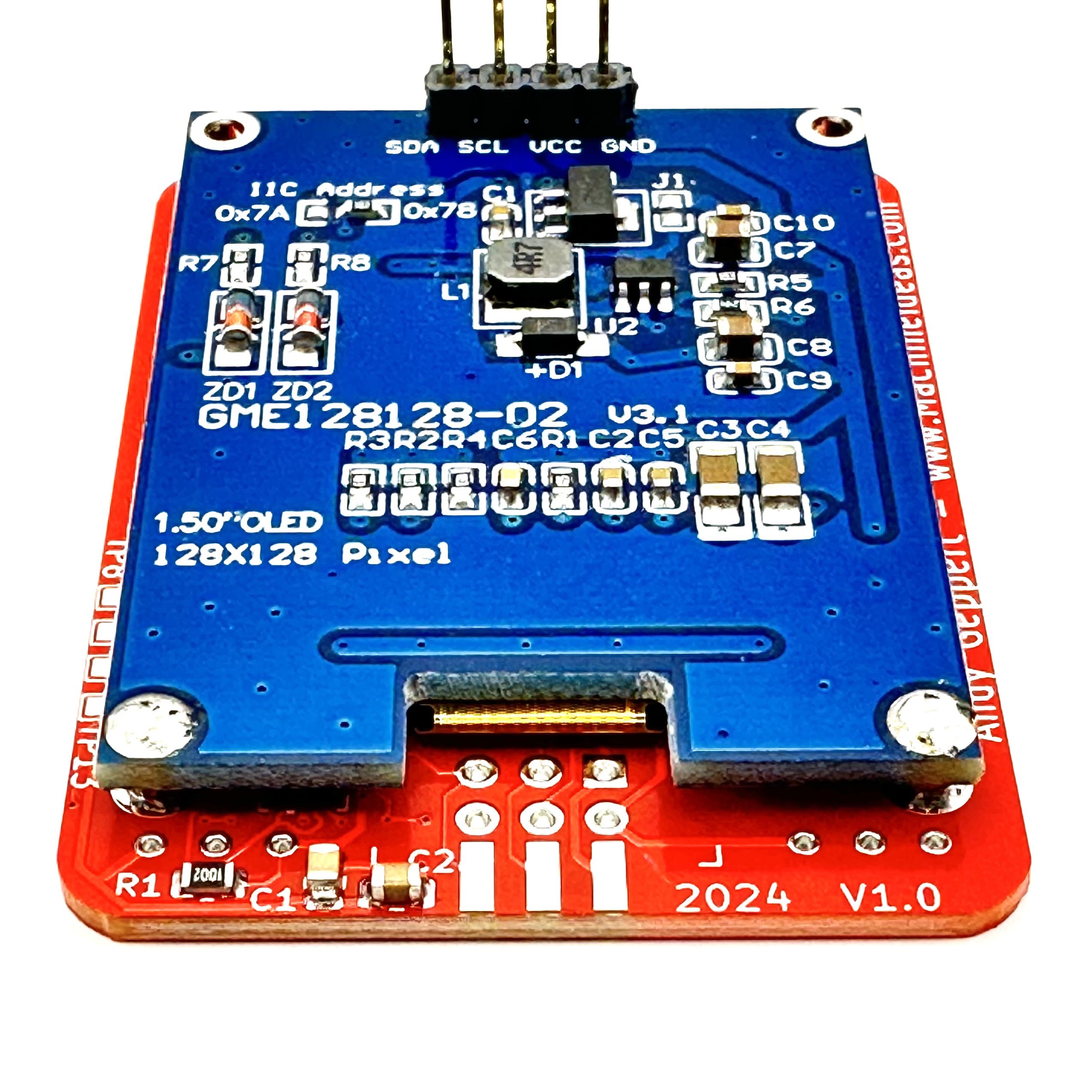

This SAO features an 128x128 pixel OLED screen controllable with I2C along with a 3-axis accelerometer to enable more creativity for games and applications. The two analog potentiometers are accessed through the GPIO 1 & 2 pins of the SAO port. This is a crispy fresh (unbroken) screen:

Video Demo (before I discovered I was using a broken screen sample - oops!):

Control is external, from a badge or other I2C MCU. Might I suggest the SAO Demo Controller... That's what I'm using in the demo.

As shared at Supercon.8 2024!

A version with ePaper is planned later...

Andy Geppert

Andy Geppert

Aaron

Aaron

daniel.bryand

daniel.bryand

deʃhipu

deʃhipu

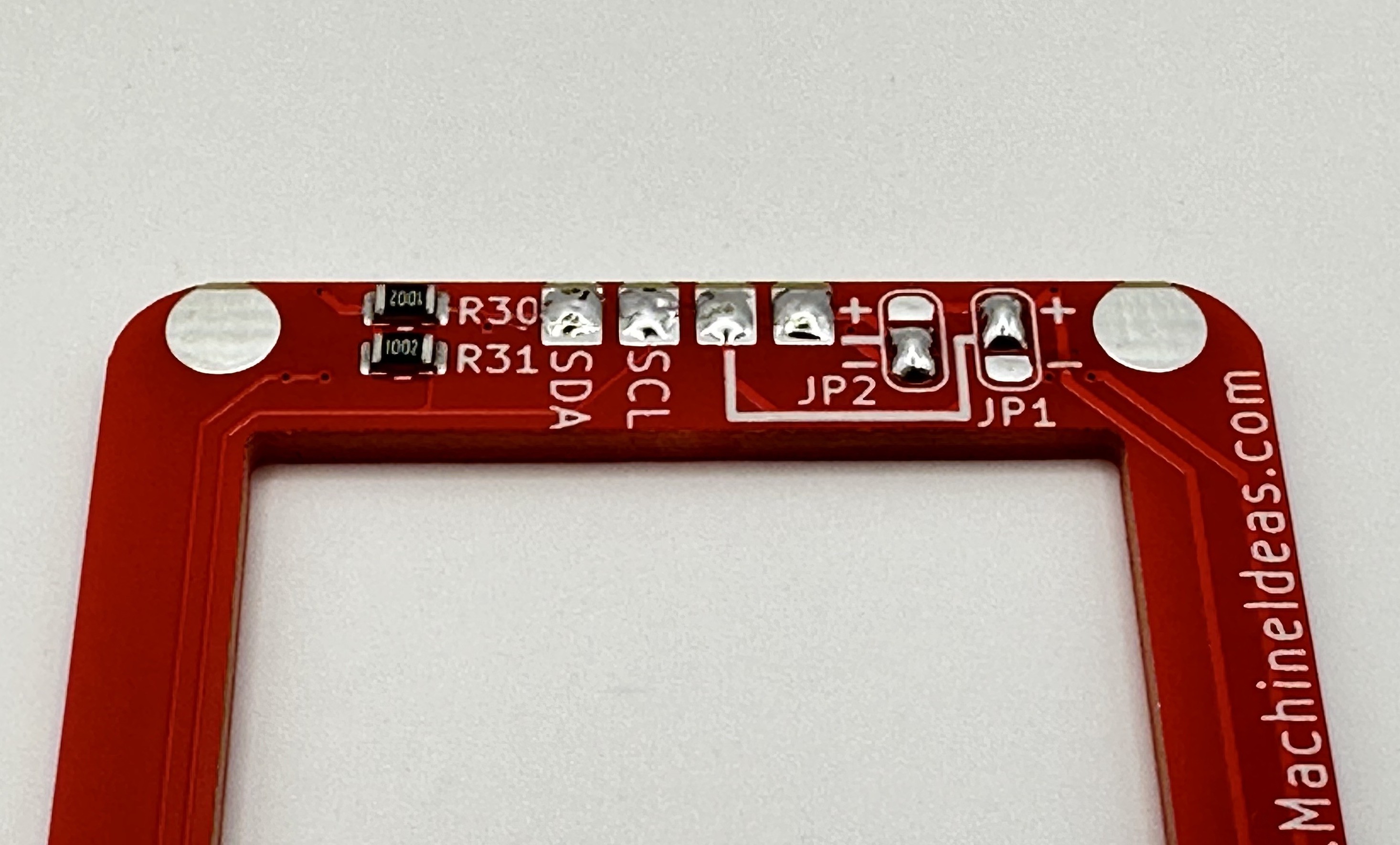

The "alignment spheres" for the display are blowing my mind. The whole design is awesome.