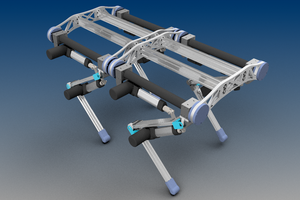

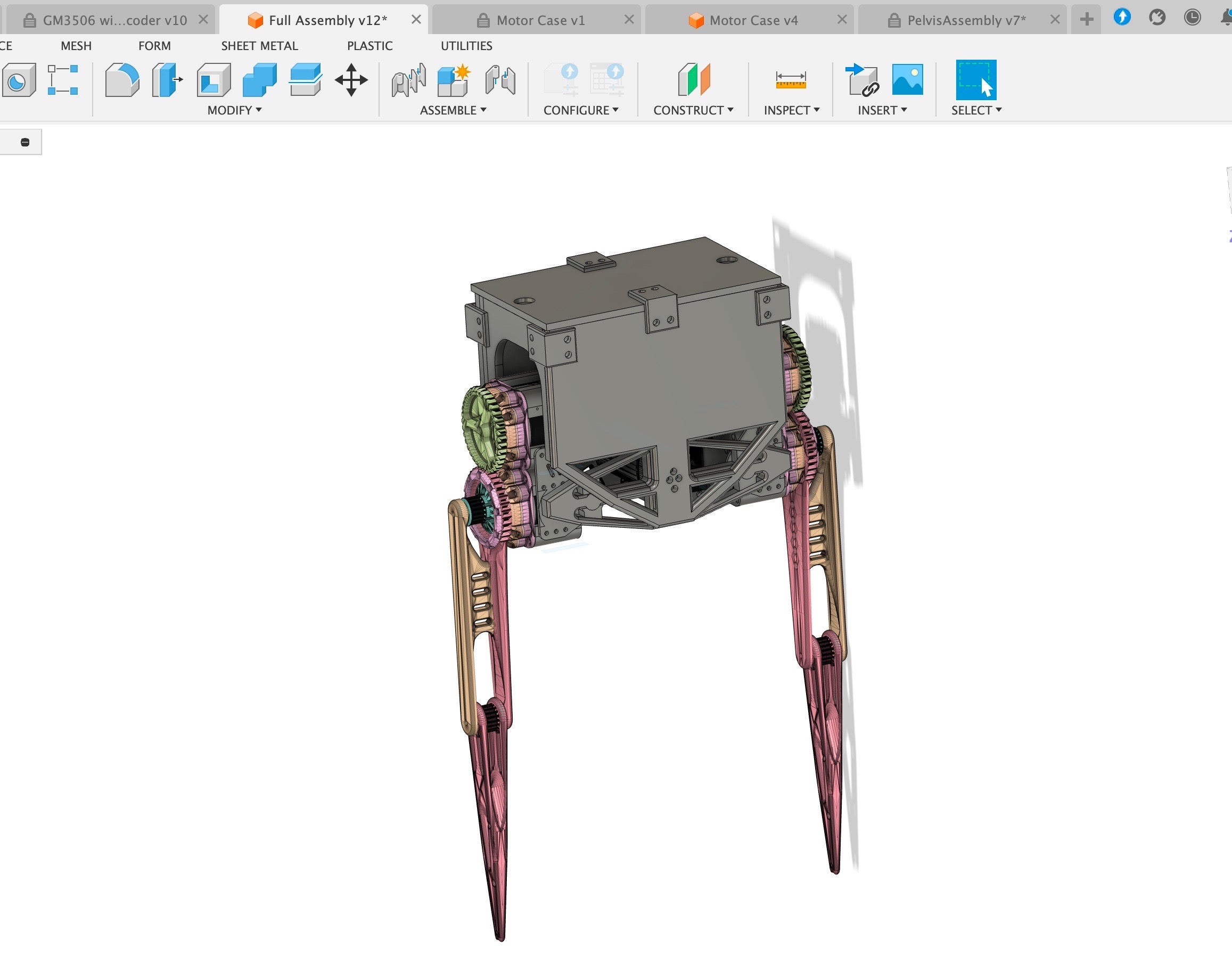

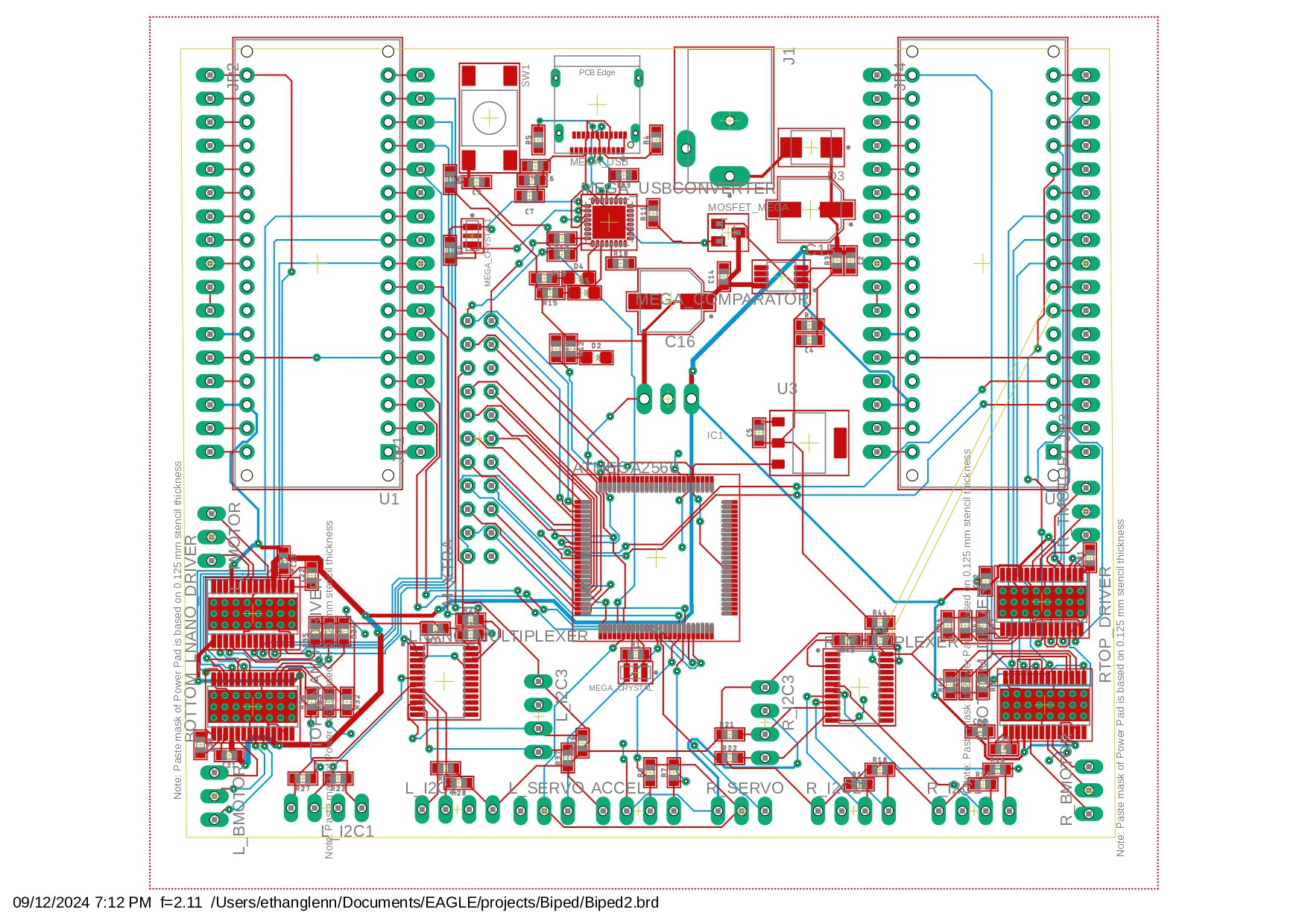

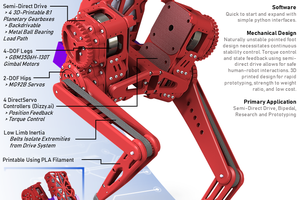

Objective: The idea is to build a compliant robot that, through machine learning, can stand whilst resisting forces and walk without any supporting structures. This project is outside of my knowledge sphere, so I hope to learn more about programming and machine learning through the challenge of this project.

This project is based on inspiration from two other projects linked below:

Gabrael Levine’s Blackbird Biped

Darren V Levine: Biped and Actuators

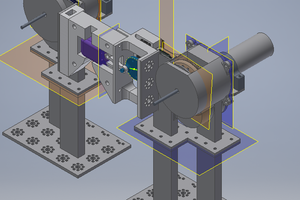

The legs (actuators, hips, upper legs, and lower legs) are of Darren Levine’s design, slightly modified to work with my GM3506 motors and AS5600 magnetic encoders. However all hardware, software, and upper body components are of a new design, though I did take a similar approach.

Ethan

Ethan

Silas Waxter

Silas Waxter

Darren V Levine

Darren V Levine

JoeCat1207

JoeCat1207