Features

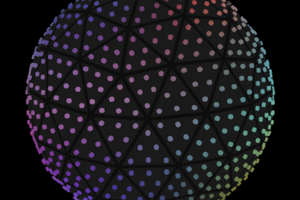

- 12 unique wavelengths of LED + 4 temperatures of white

- Includes a really cool 505nm LED which is a color coming from an LED you've probably never seen before

- I2C brightness control

- [coming soon] No badge needed: onboard MCU!

- Probably won't overcurrent your badge

- Eventually cool color mixing tricks. Currently very good at turning on and looking pretty.

- If colors aren't your thing, I've been told the shape looks like a Star Trek badge or half of a pair of furry ears

- Impossible to photograph properly, since cameras and monitors can't reproduce its range of colors

Using It

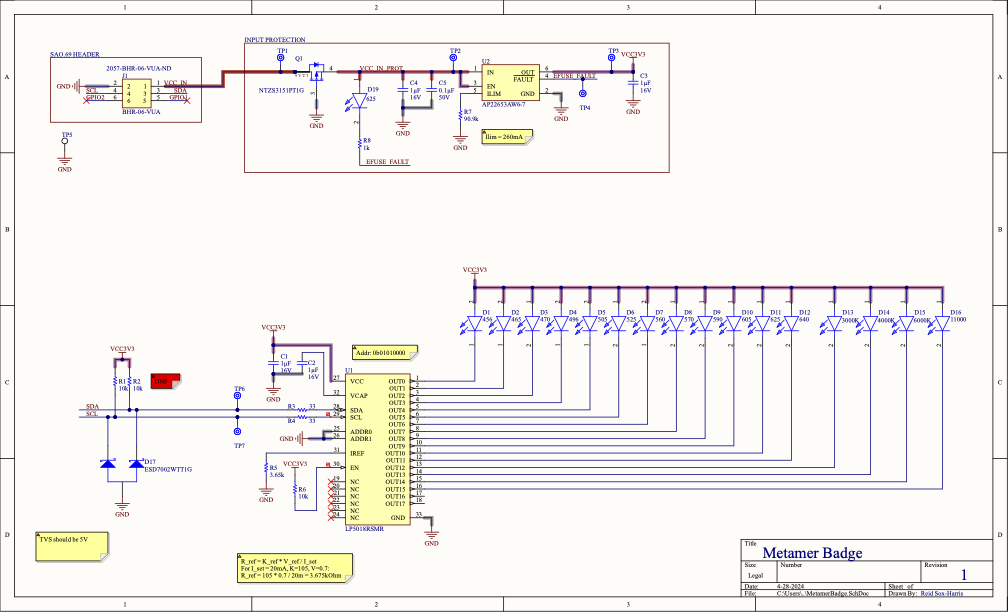

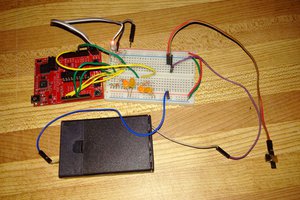

The heart of the SAO is the LP5018, an RGB LED driver from TI. Accessible over the SAO I2C bus at address 0b0101000, the first 16 channels correspond to all of the LEDs in increasing wavelength (i.e. blue to red) followed by the white LEDs from warm to cool. Schematics and board files available over on GitHub along with some generator code, and soon-to-be instructions on how to talk with it yourself.

Metamers?

Metamers are a really neat concept where our eyes only have three channels worth of detection, corresponding to the short, medium, and long cones in our eyes. As a result, two different spectra of light will look the same to our eyes if they happen to stimulate the three types of cones in the same way -- this is part of how a computer screen is able to reproduce all of the complex colors that we see in the real world. I go into a lot more depth (including answering "why even care?") over here. TL;DR, colors are cool, the way eyes interact with colors is cool, and RGB isn't the end-all and be-all of color mixing.

Reid Sox-Harris

Reid Sox-Harris

Petri Varsa

Petri Varsa

OK Design

OK Design

davedarko

davedarko

Steve Pomeroy

Steve Pomeroy