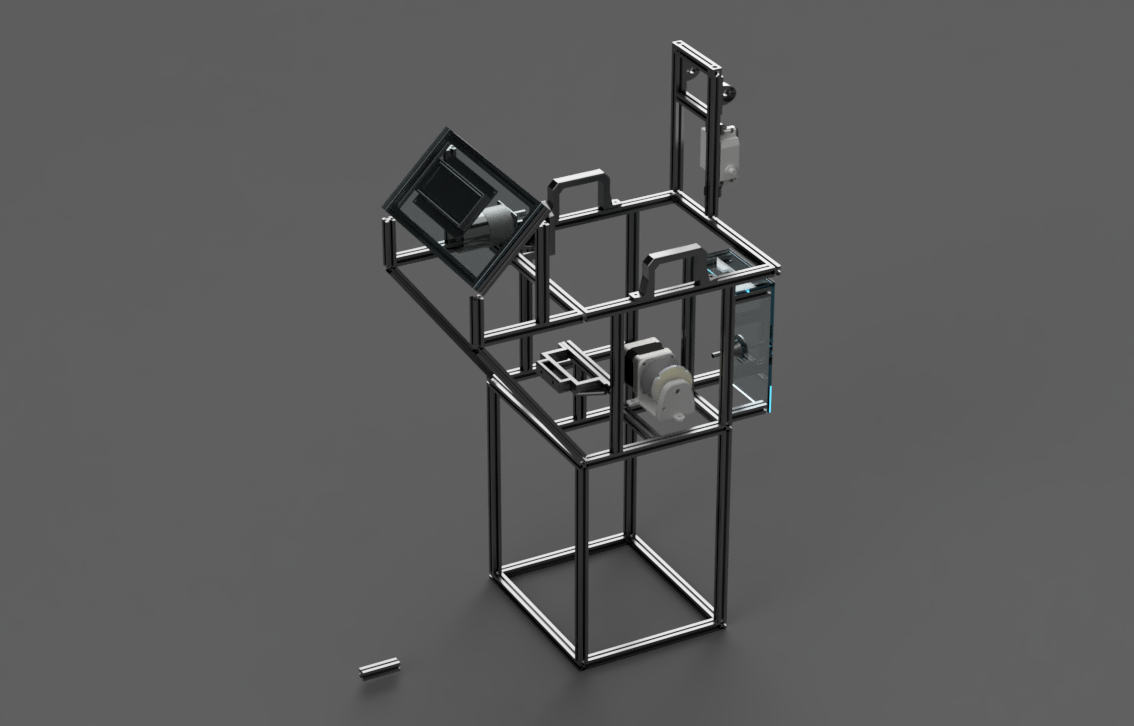

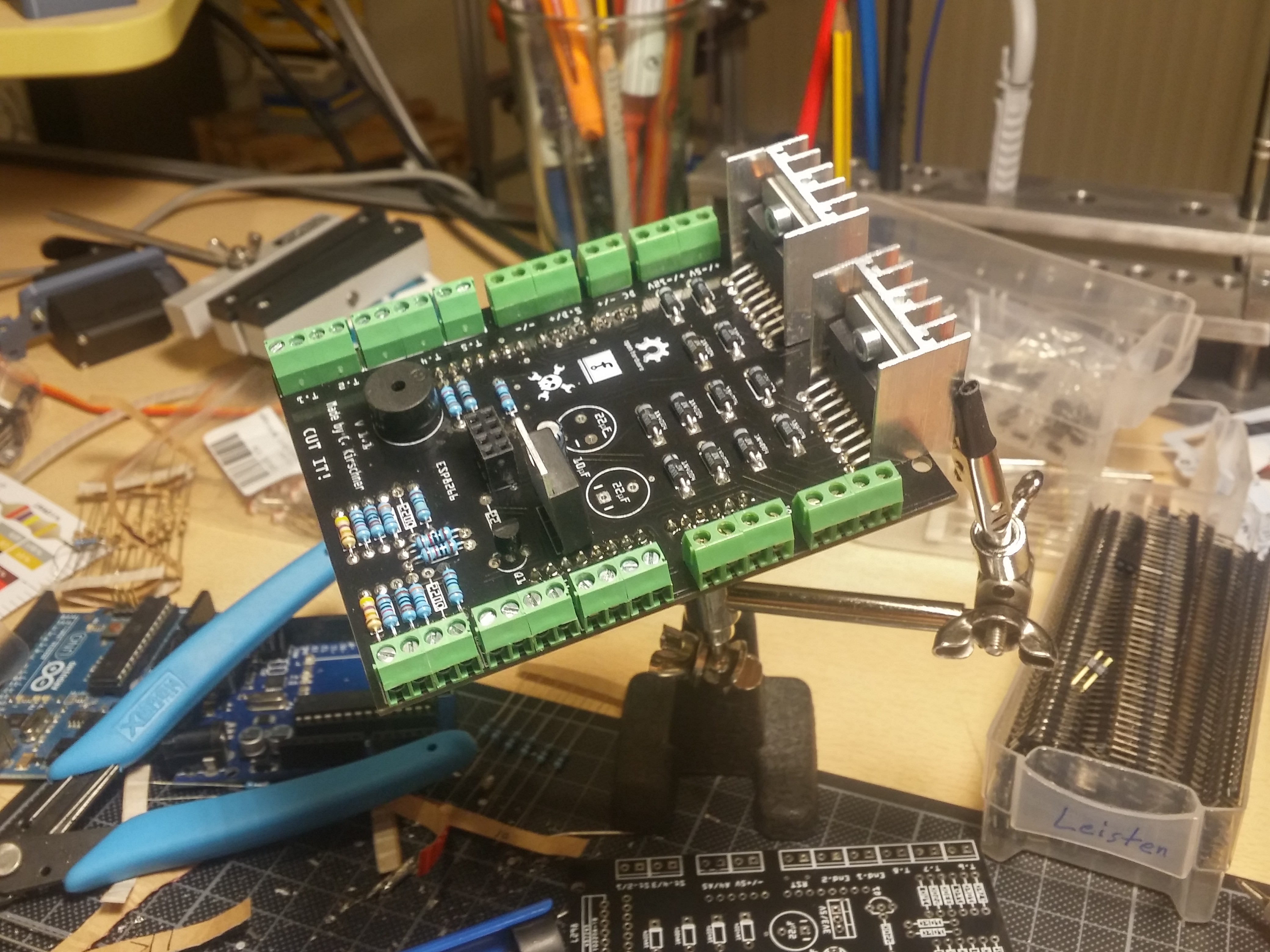

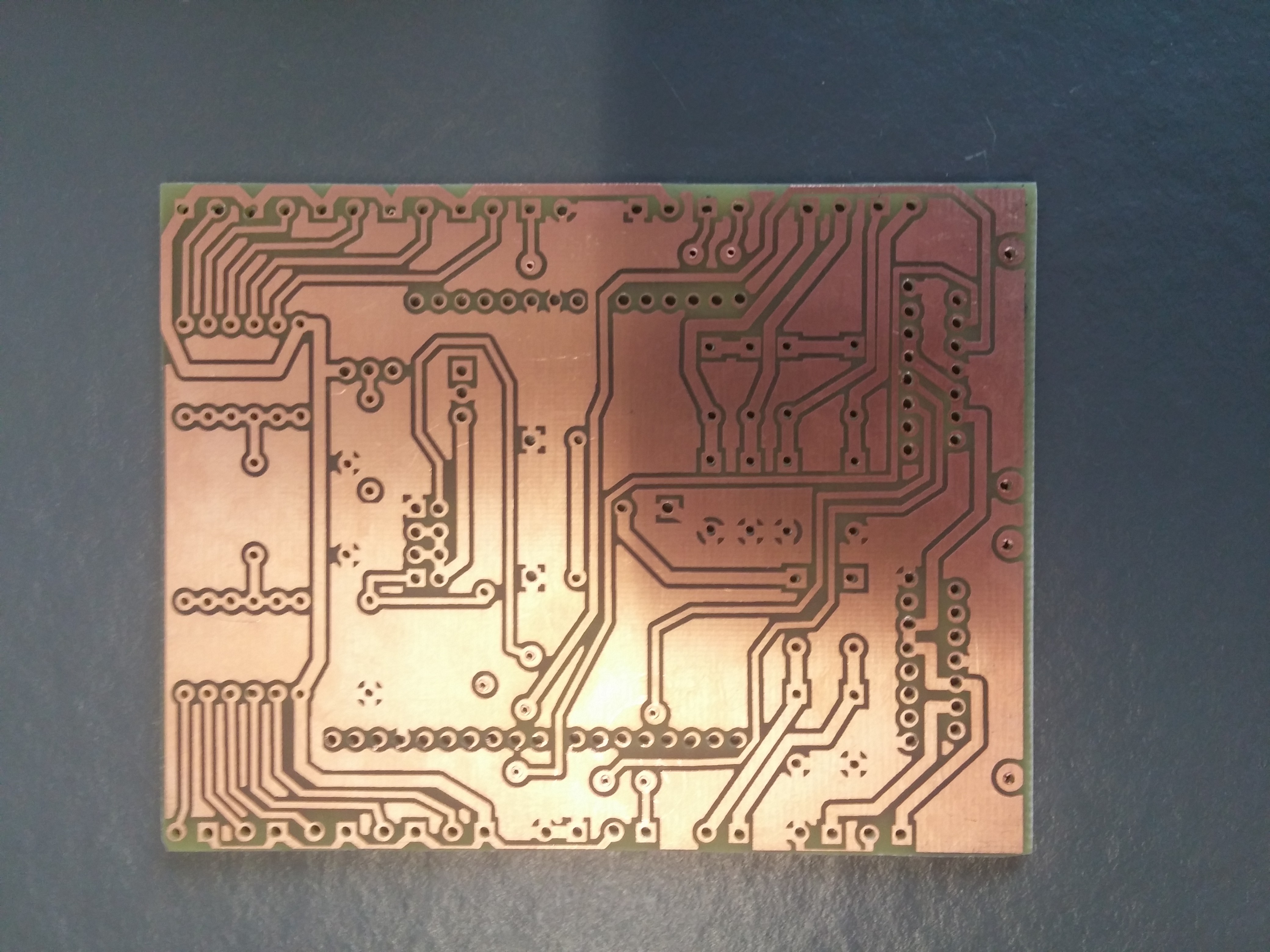

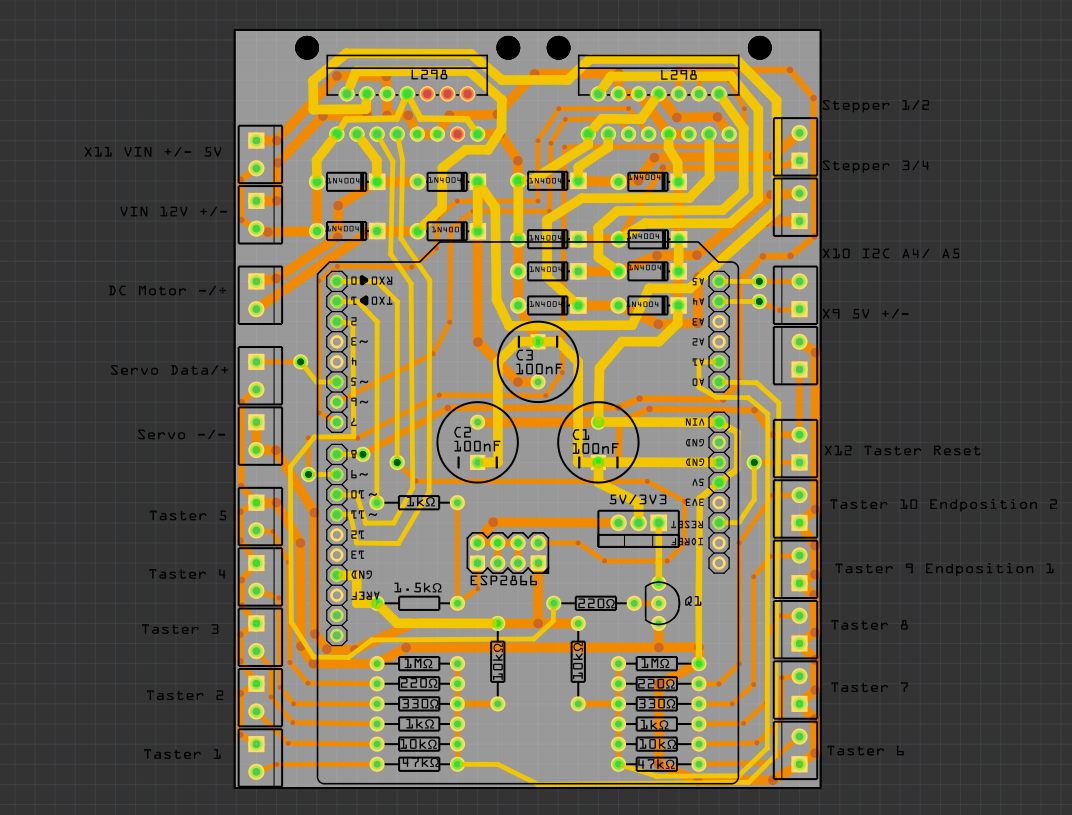

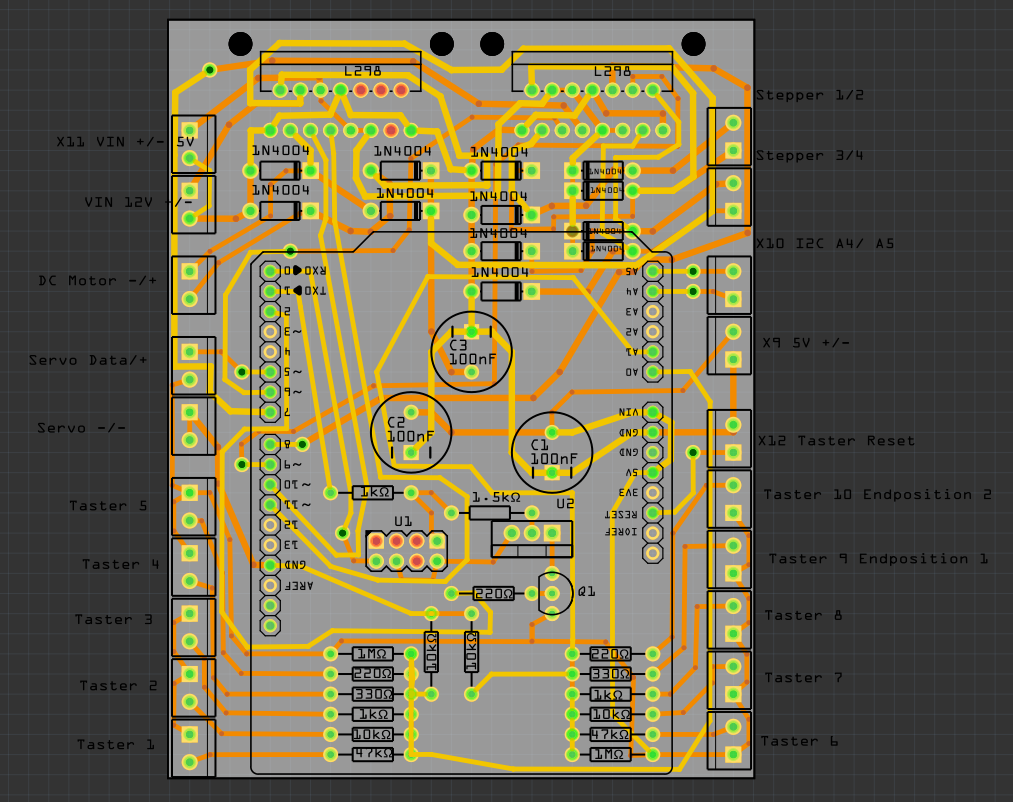

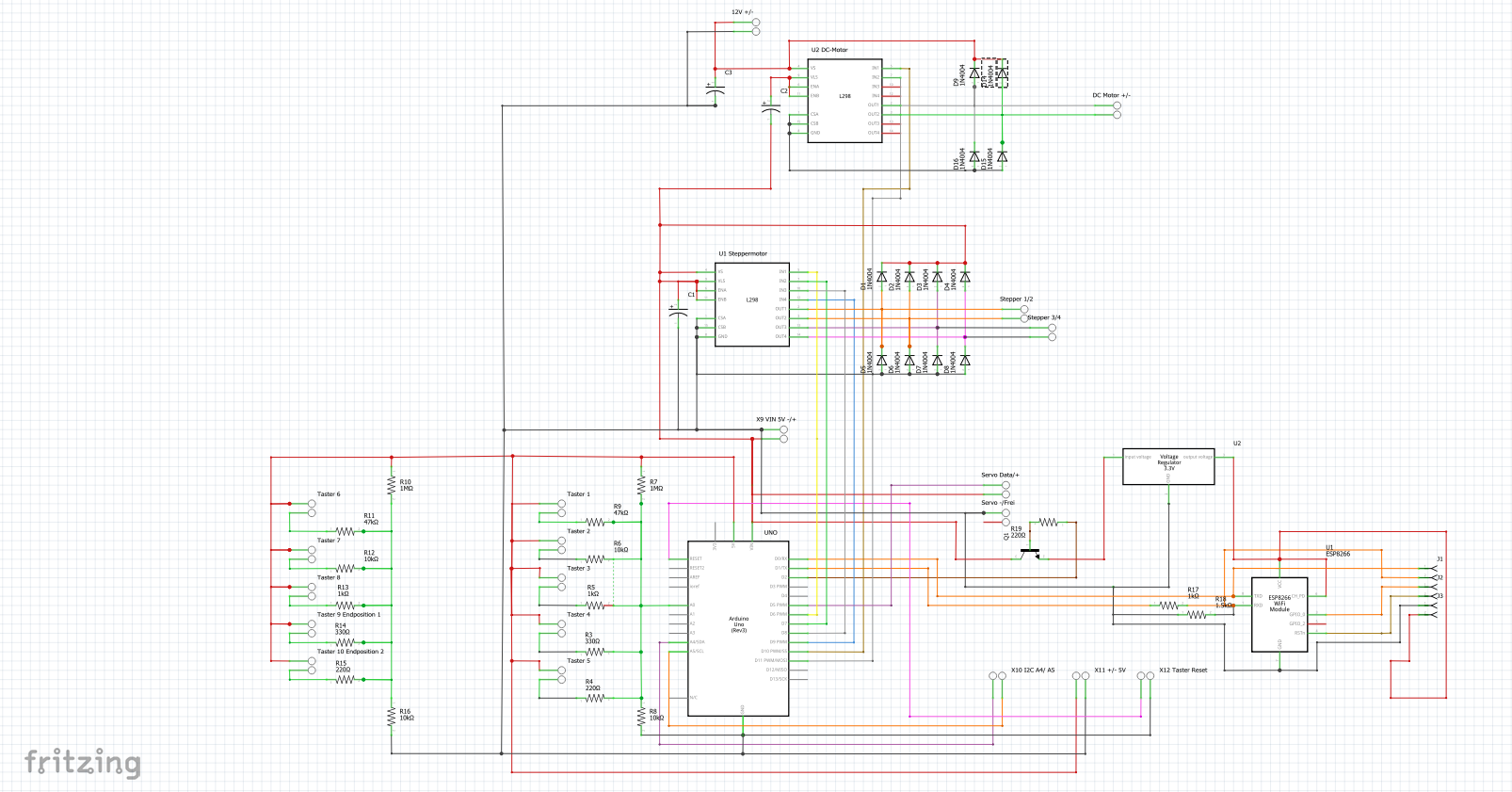

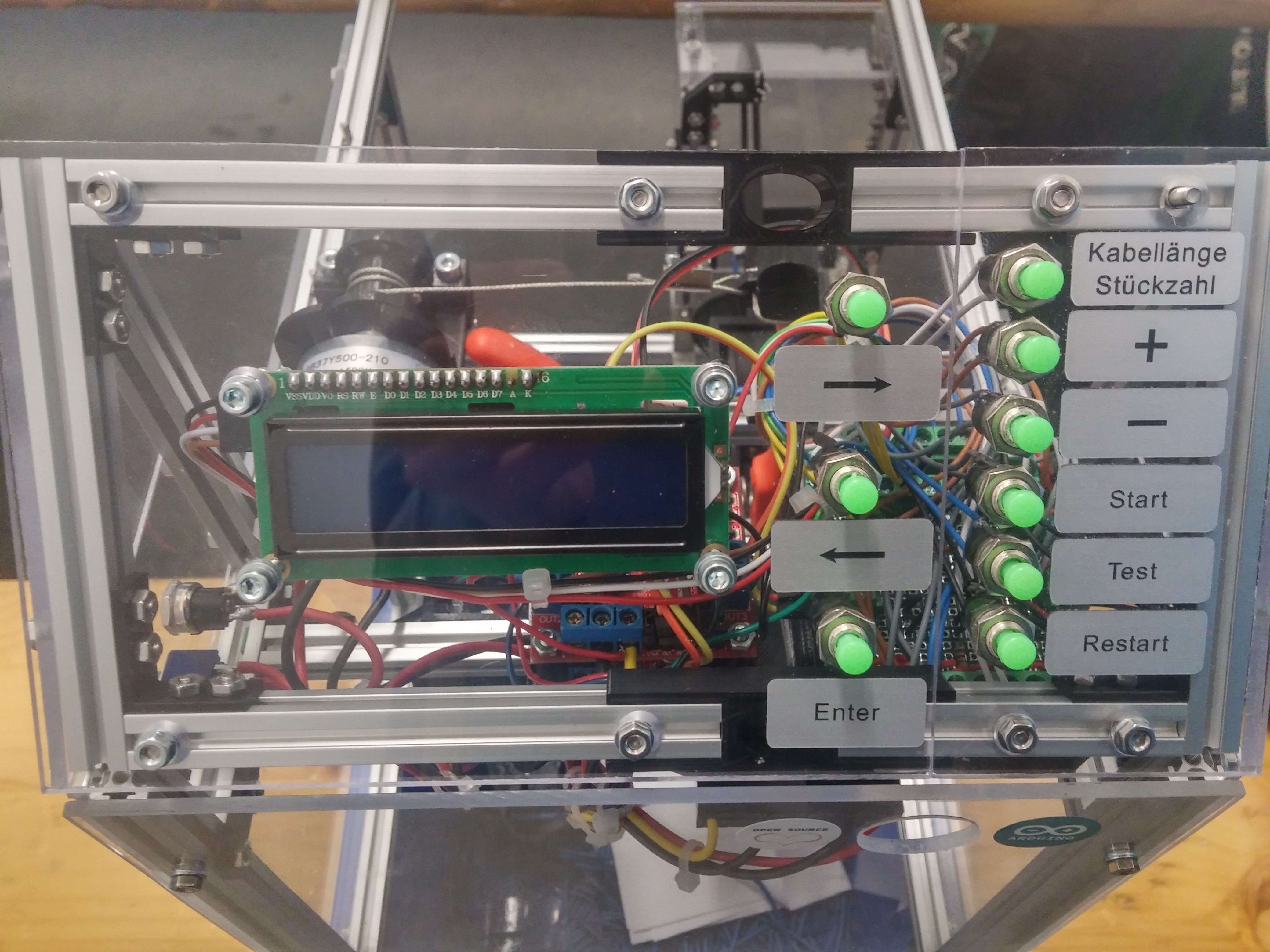

With my project you can cut cables with sizes of 0.75 mm2 up to 2.5 mm2 and i also think that it would handle 4 mm2. The length is mutable from 1 cm to 1 m and you can order up to 100 cables. The accuracy is pretty high, the lentgh varies only about one or two millimeters. I integrated an LCD and a few buttons, where you can set your cable-parameters. When all parameters are set and you press start, the stepper motor will insert the cable from the spool in the wished length. If the cable has reached the right length an slow but powerfull DC-motor will tighten a cable plieres till it's complettly closed. If it's closed it touches an microswitch and the motor runs in the reverse direction till it's open again. This procedure is repeating until the right number is reached. The hole thing is driven by a 12 V powersupply and a DC-DC converter is providing the steppermotor. After all the biggest plus of my machine is the low prize. For most professional Cutting-Machines you pay about 1500€ or even more. For the materials of my selfmade one you only have to pay about 200€.

Cable-Cutting-Machine

No more boring and endless cable-cutting-sessions.

Kirschner Christoph

Kirschner Christoph

ElectronicABC

ElectronicABC

But wait ..... Does this machine not make you unemployed? :(