-

Construction Continued

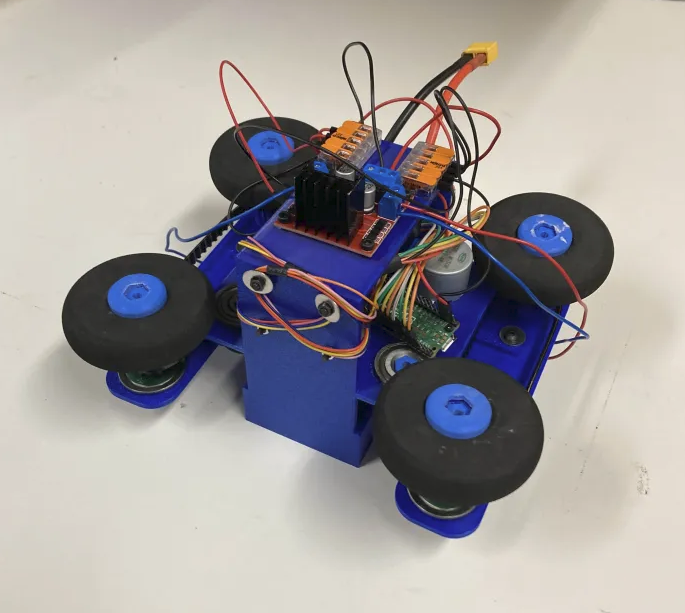

03/01/2025 at 19:08 • 0 commentsFebruary 21st. The day had finally come for the critical design review (CDR) presentation of all of our progress up until this point. When all was said and done, we were able to securely attach one of the arms to the robot and write a quick Thonny script to actuate the wheel motors and demonstrate the "flapping" system.

![]()

Next, we will be looking to reprint timing belt pulleys (heat inserts kept falling out of previous prints), assemble and attach the other arm, and determine a method for experimentally measuring the pressure needed for the robot to remain put in the pipe.

-

Production of Parts

03/01/2025 at 19:00 • 0 commentsWe started printing parts and the parts we ordered came in. There were some initial issues with hole size tolerances, expecially between the different types of printers we were using. Also, some of the hole distances didn't fit completely with the electronics we ordered, so we needed to adjust for that.

![]()

Then we did a rough assembly of the robot to make sure everything fit and finished the majority of the electronics.

![]()

-

CAD Progression

03/01/2025 at 18:22 • 0 commentsFebruary 2nd: In our first iteration of the CAD (image 1), we attempted to provide compression on all 4 sides of the robot through the use of spring loaded castor wheels, however we determined with our instructor that this would overcomplicate the design. So, in the next iteration (image 2), we relied on only the compression from the motor-driven wheels.

![]()

Image 1

![]()

Image 2

-

"Physics" and "Cookies"

02/07/2025 at 03:16 • 0 commentsIt had been yet another grueling but rewarding day of academics when the next leap in progress was made on the night of January 24th, 2025.

We would soon need to create a parts list, but of course the specs of the bulk of those parts would not be known until after the CAD model was complete. There was one component, however, that we knew we would need: compression springs...or so we thought—cue dramatic foreshadowing.

Thus, we tried our hand at calculating an estimate for the minimum spring constant required to keep the robot centered in the pipe:![]()

![]()

This was quite tedious and confusing work for a Friday night, so a quick trip to Target seemed appropriate.

![]()

The cookies did not last long. And the "physics" soon became unnecessary in the face of good old fashioned trial and error. Onto the CAD model!

-

A Trip to the Library

02/07/2025 at 02:57 • 0 commentsThe tale of a surprisingly complex project began soon after midnight on January 16th, 2025. The desired outcome was simple enough: construct a robot capable of traversing gutter pipes and cleaning them (ideally).

We quickly realized that such a "simple" idea was really quite demanding.

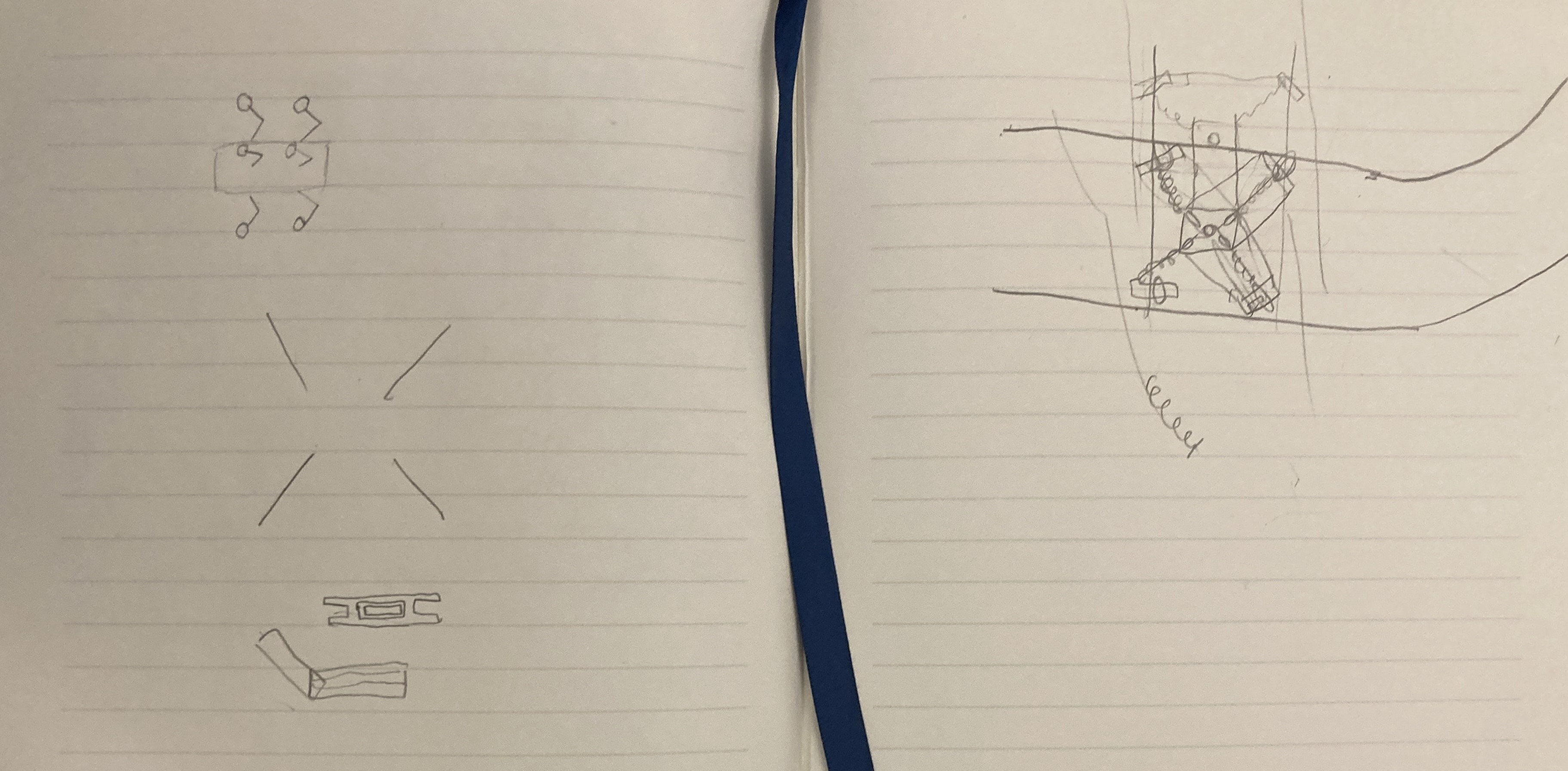

From two hours of research, deliberating on whiteboards and paper, and discussing our design ideas,![]()

![]()

a *very* rough sketch was born:

![]()

Caster wheels perpendicular to the robot's motion would stabilize its position in the pipe while two side arms with wheels driven by motors on either end would drive it forward/backward. In order to account for differing pipe diameters, those side arms would soon become four-bar linkage systems to allow the robot to shrink or grow as needed.

All that was left to do now was CAD the thing and discus the design with our course's instructor.

Pi Fly 7

A robot that utilizes compression springs and BLDCs to navigate various pipe structures.

jfries

jfries