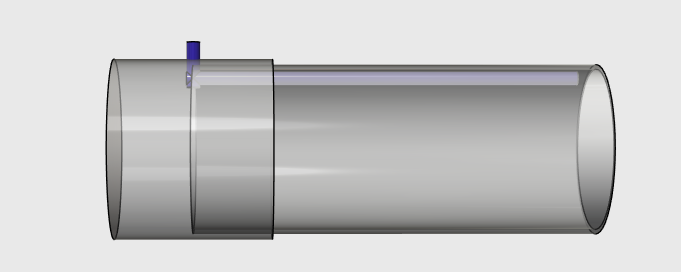

DIY PVC Submarine with Ballast and Jet Propulsion

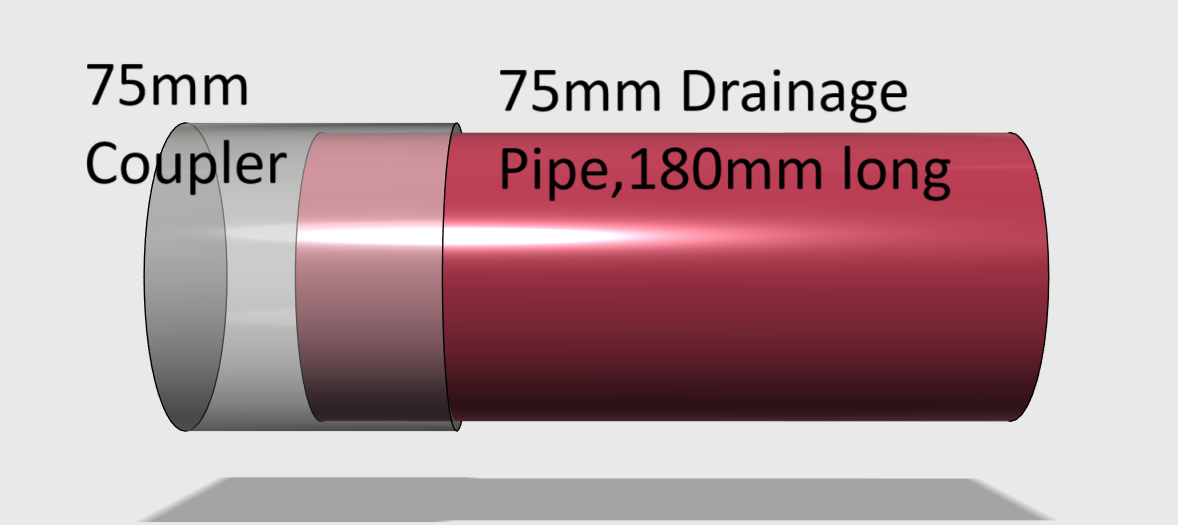

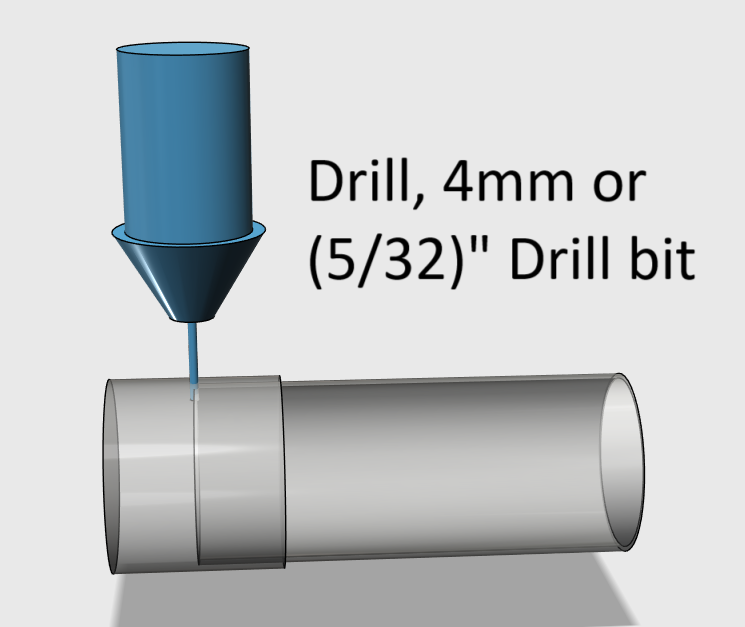

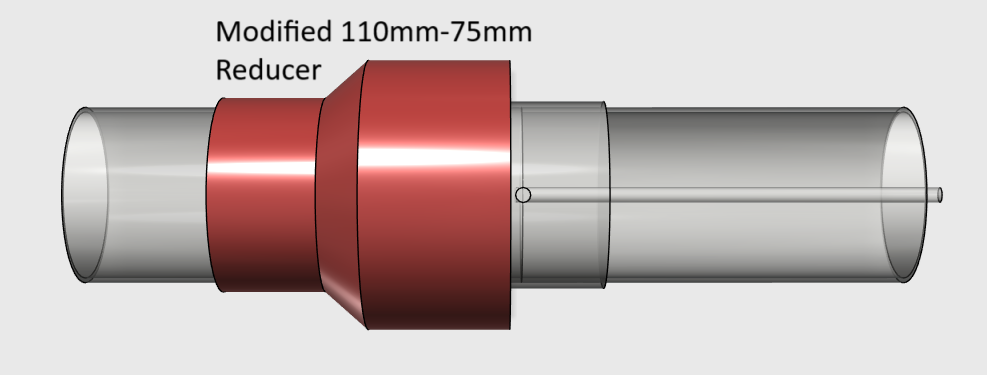

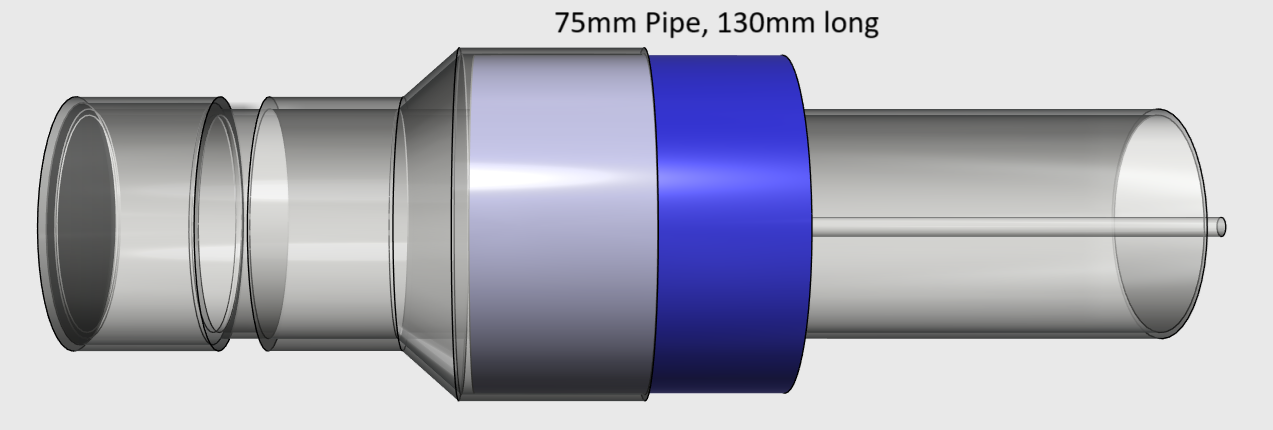

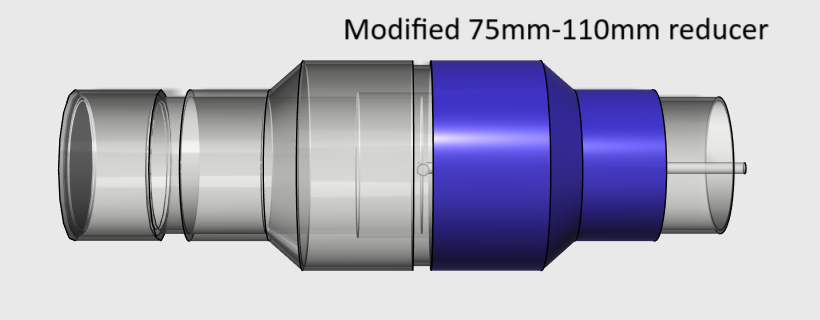

This is a fully functional model submarine built using common PVC drainage pipes. Weighing about 2.4 kg in air, the submarine is designed for simplicity, ruggedness, and full manual control — making it a great exploration of underwater mechanics using off-the-shelf parts.

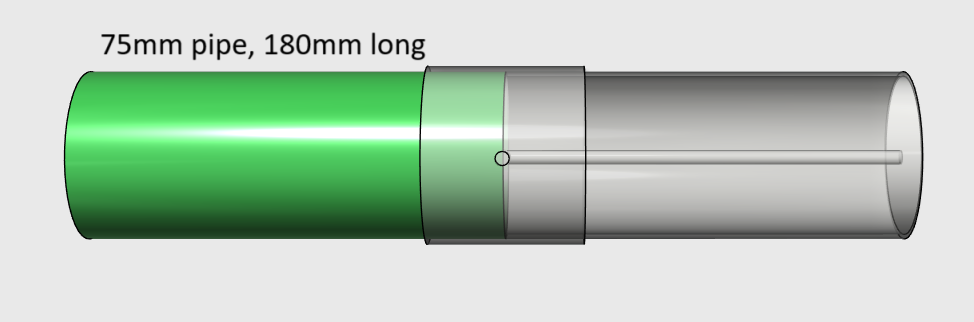

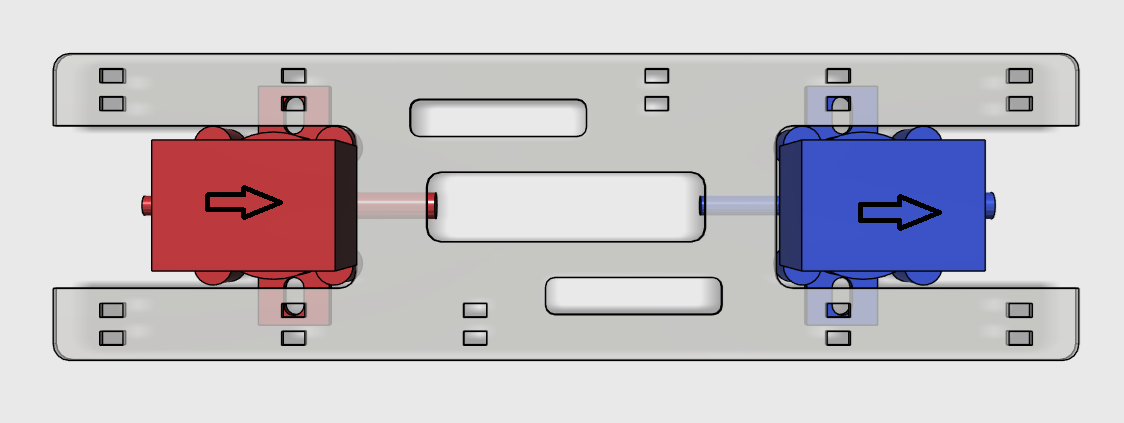

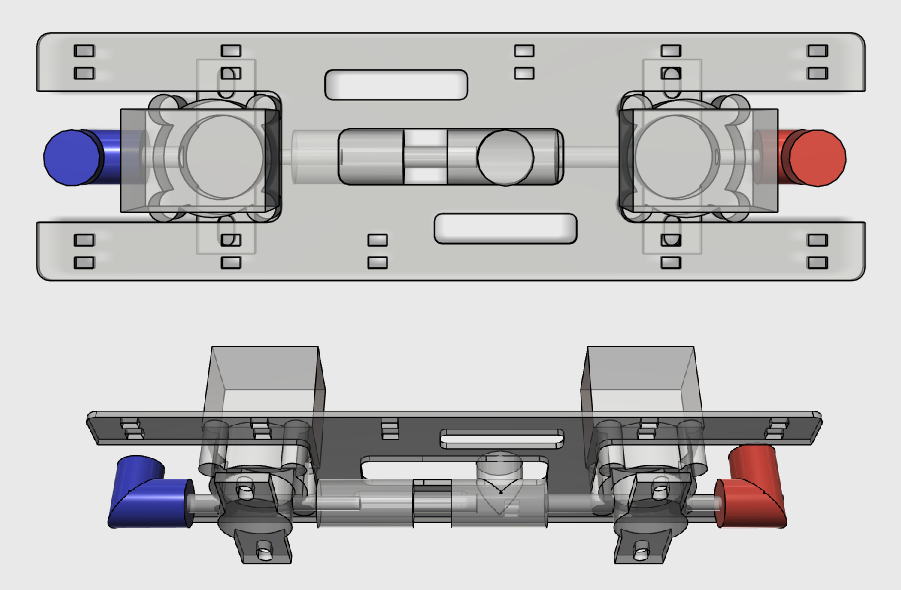

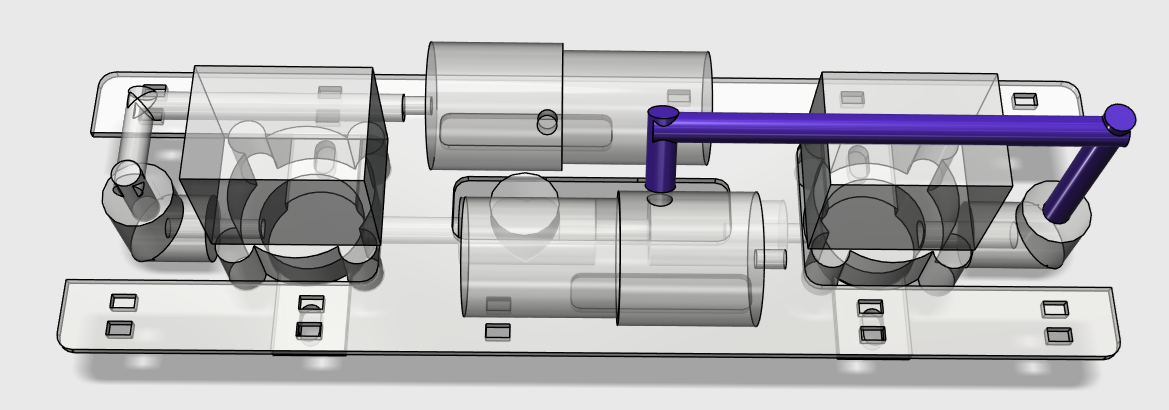

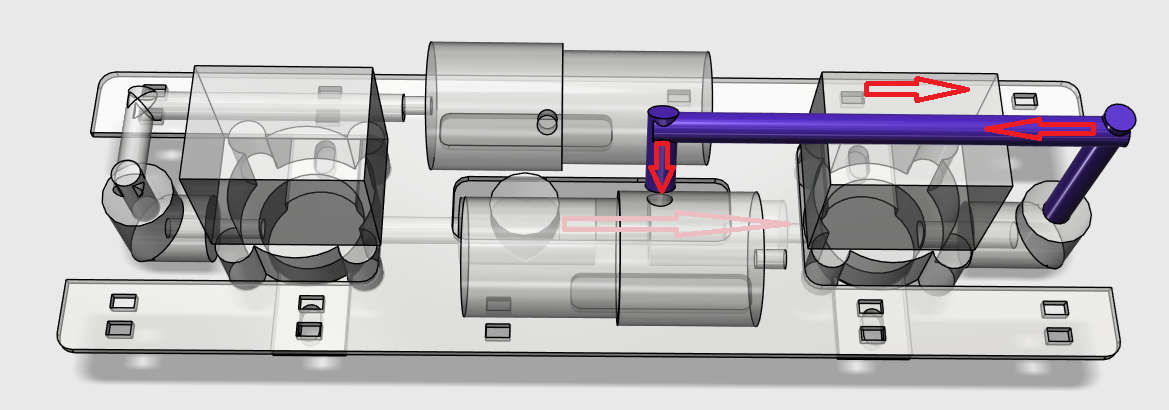

Ballast Control System

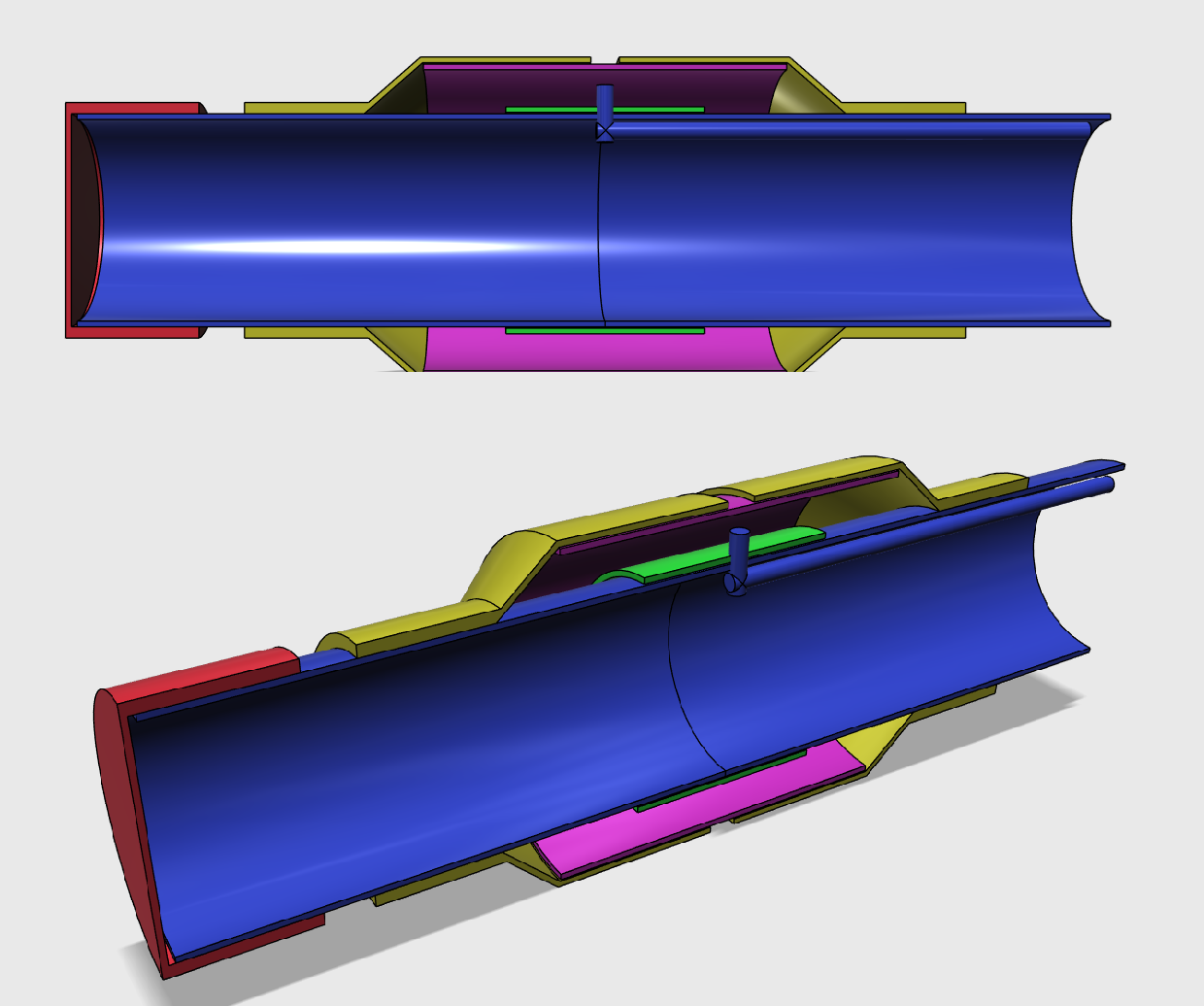

The submarine’s dive and surface capability is managed via a dual-pump ballast control system:

-

Diving: One pump evacuates air from the ballast tanks, storing it inside the sealed body of the submarine. As air is removed, water enters the ballast chambers, increasing weight and causing the sub to sink.

-

Surfacing: A second pump returns the stored air into the ballast, displacing the water, and decreasing the overall density of the sub — allowing it to rise.

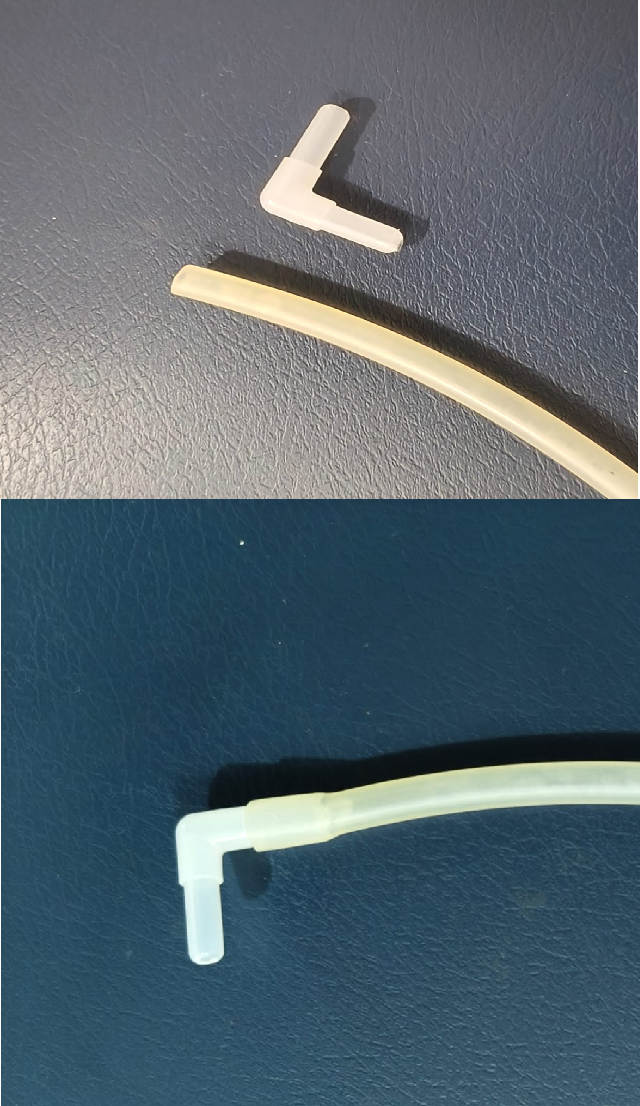

This air-water exchange system avoids the need for compressed gas tanks or valves, and keeps everything electric and easily reversible.

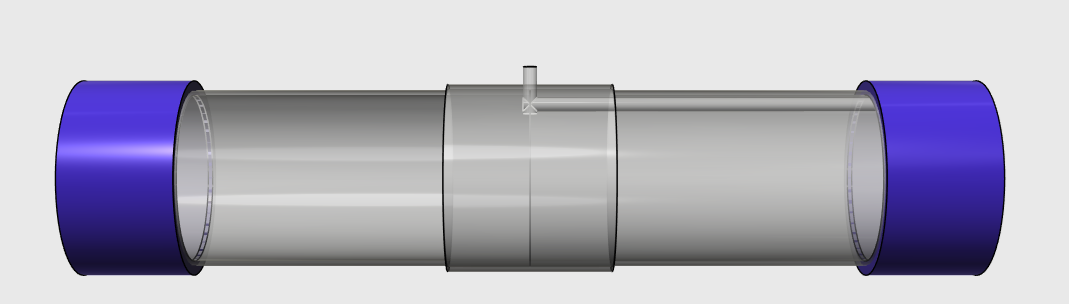

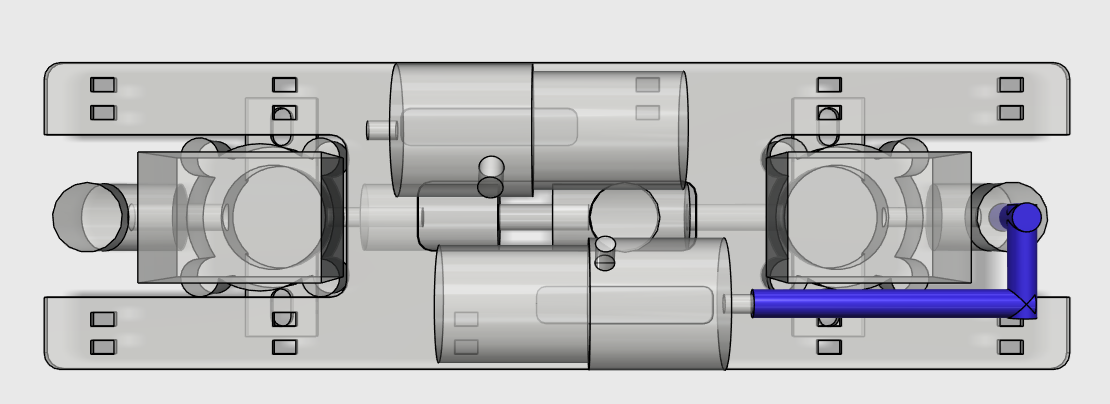

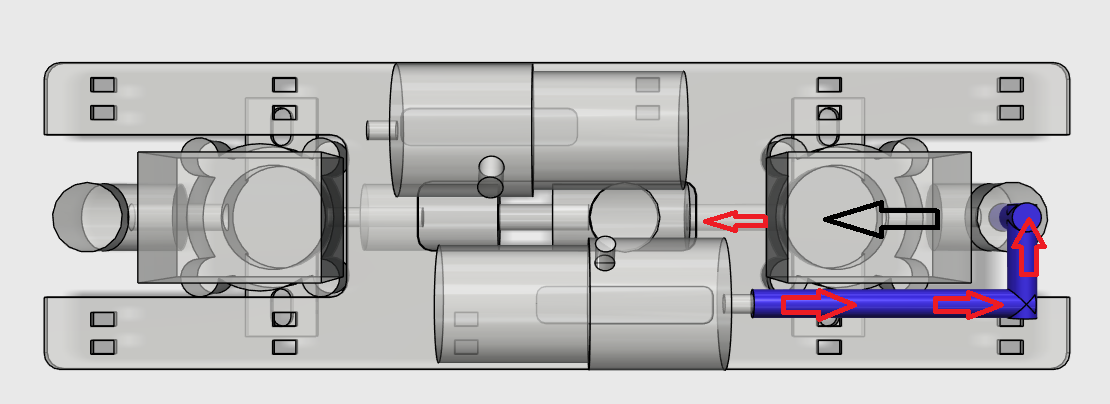

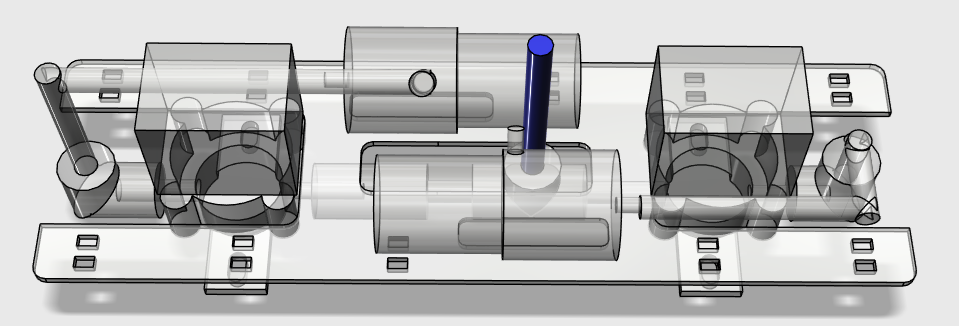

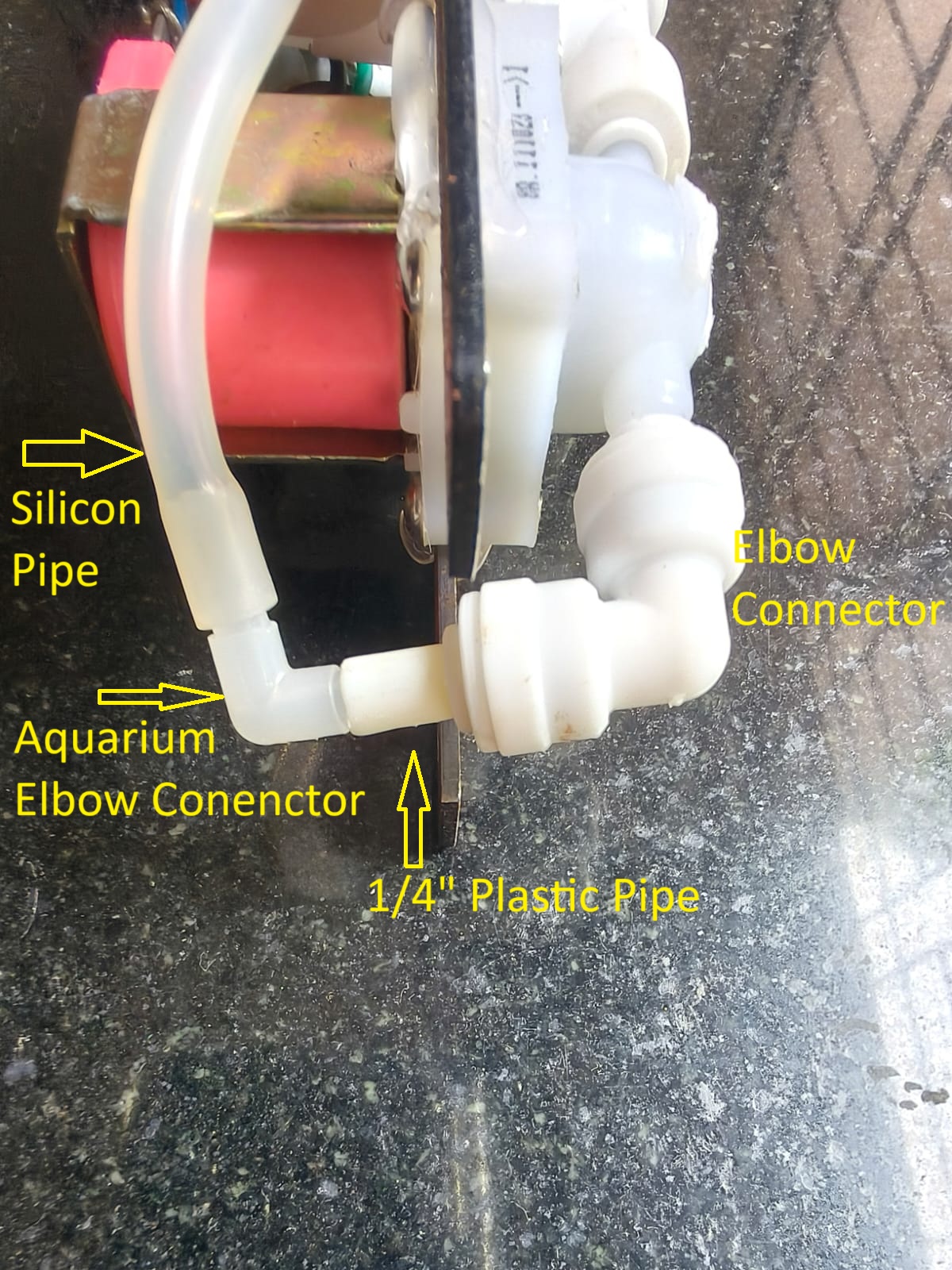

Propulsion & Steering

Three 12V water pumps located at the rear of the submarine provide propulsion:

-

The center pump provides forward thrust.

-

The side pumps are used for directional control, allowing for basic steering by turning left or right through differential thrust.

Control Interface

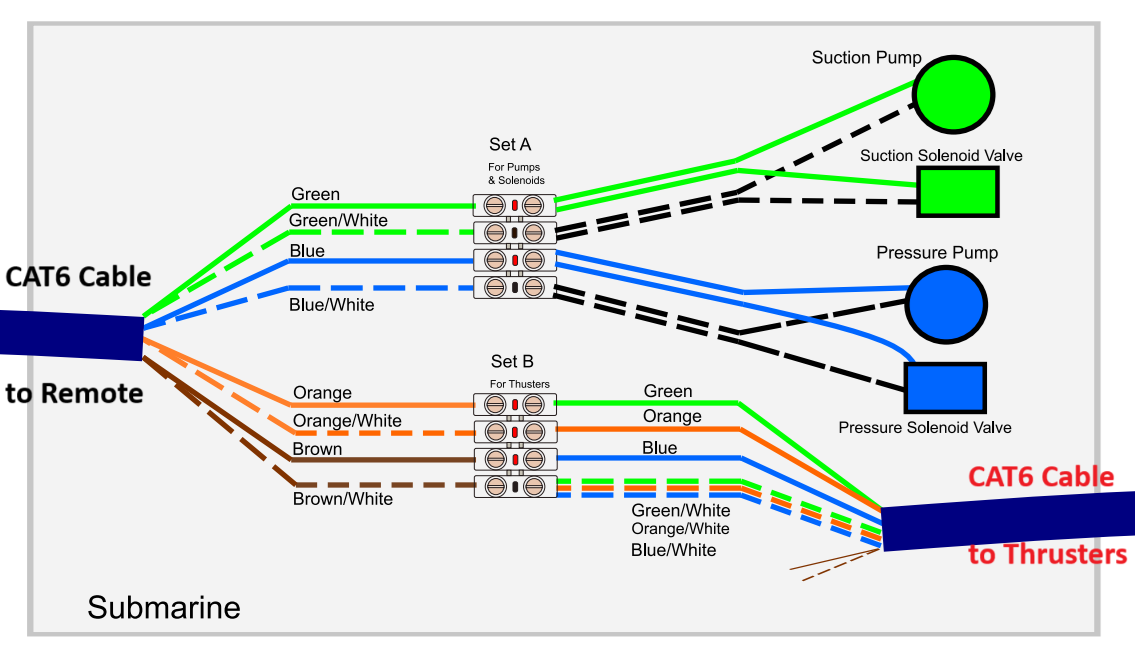

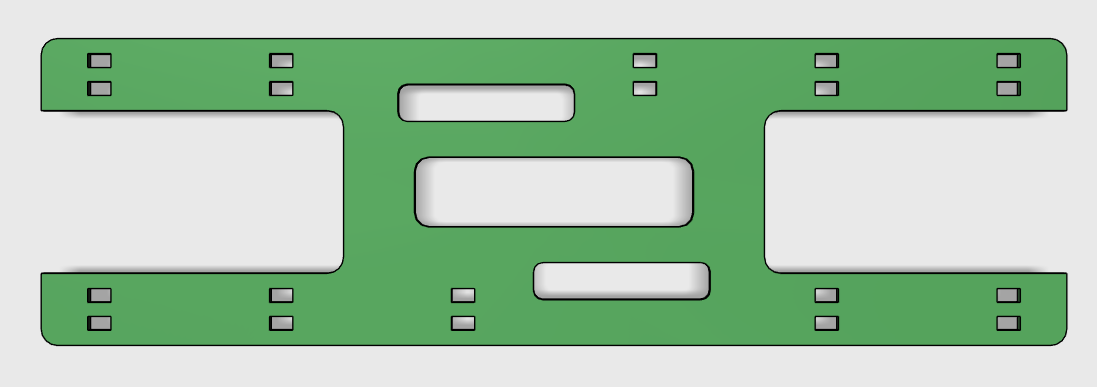

All functions are controlled through a custom-made wired remote using a CAT6 cable that connects to the submarine:

-

Standard DPDT switches control each of the pumps.

-

Each device runs on 12V, allowing compatibility with common battery setups and switches.

-

The manual interface emphasizes simplicity and real-time human control, perfect for testing and tweaking underwater behavior.

Rupin Chheda

Rupin Chheda