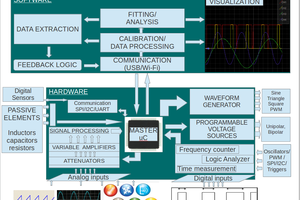

Features include:

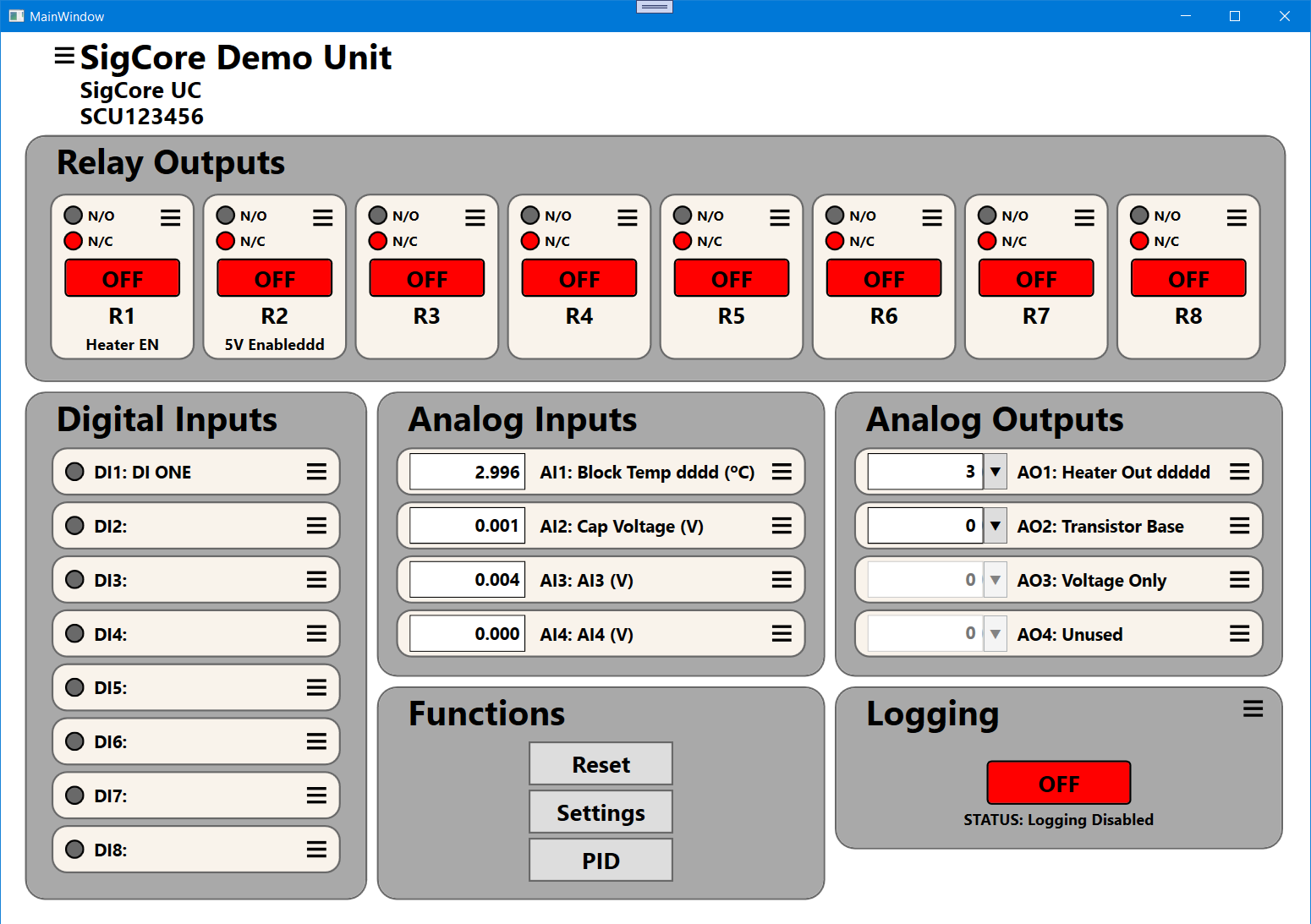

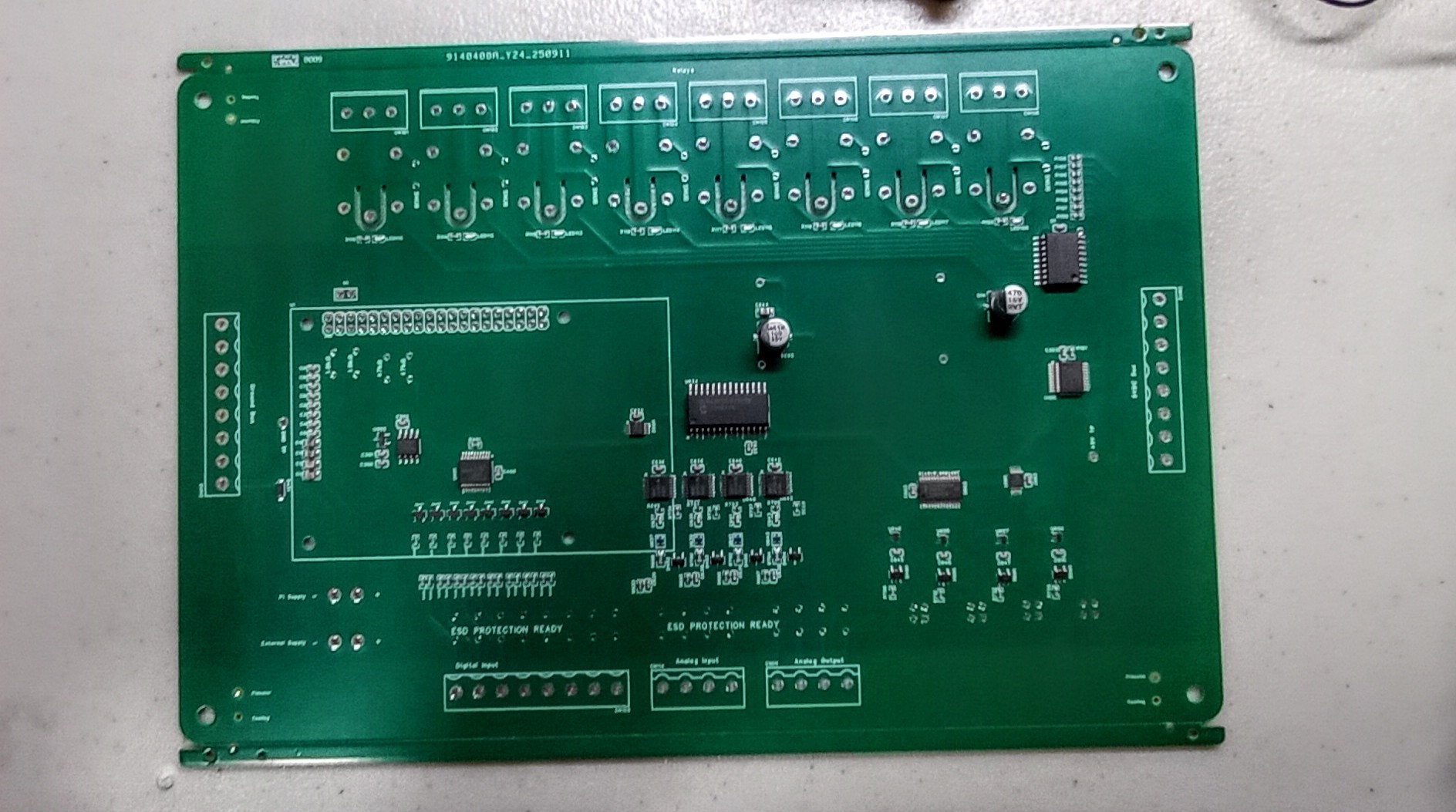

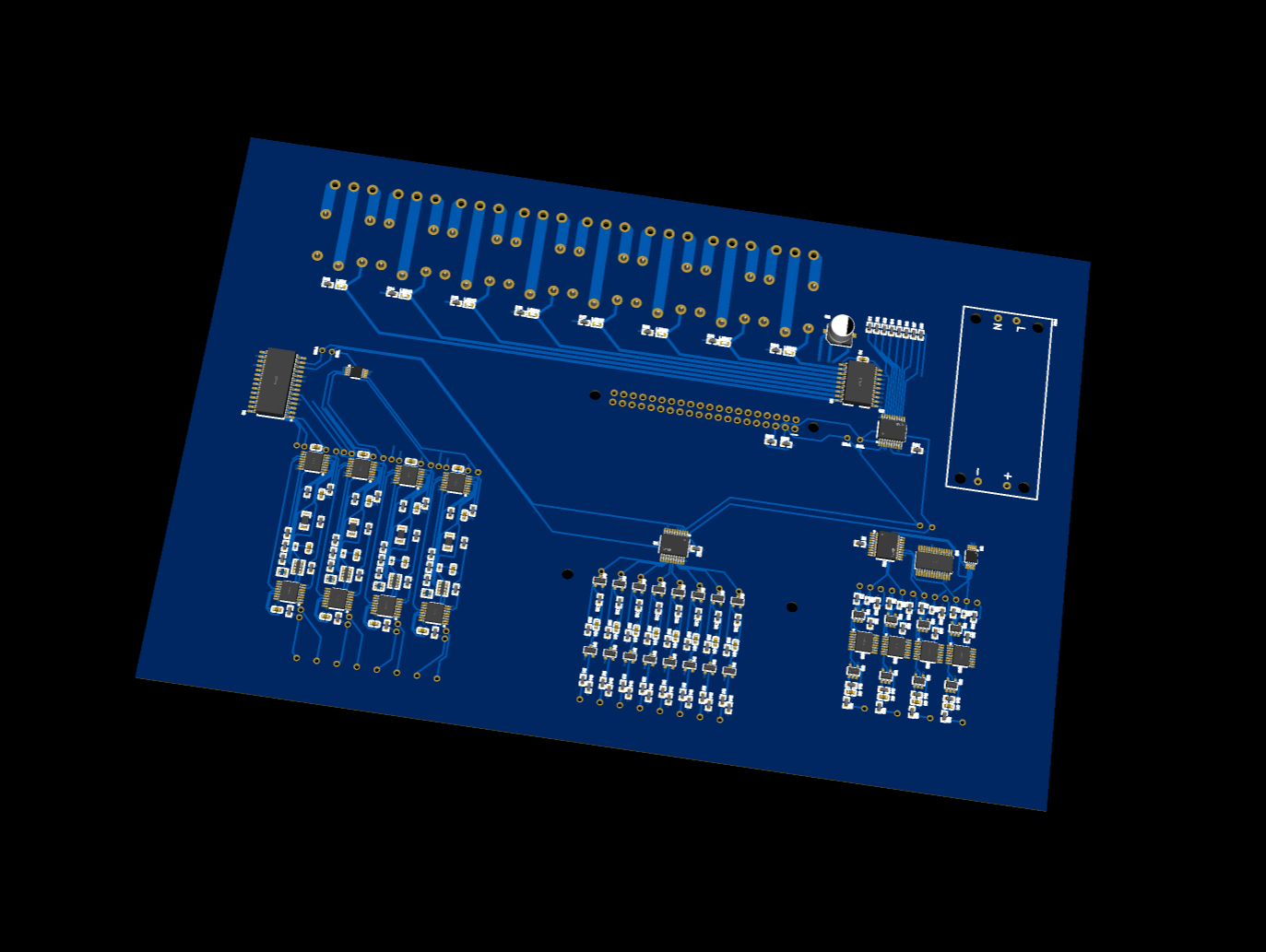

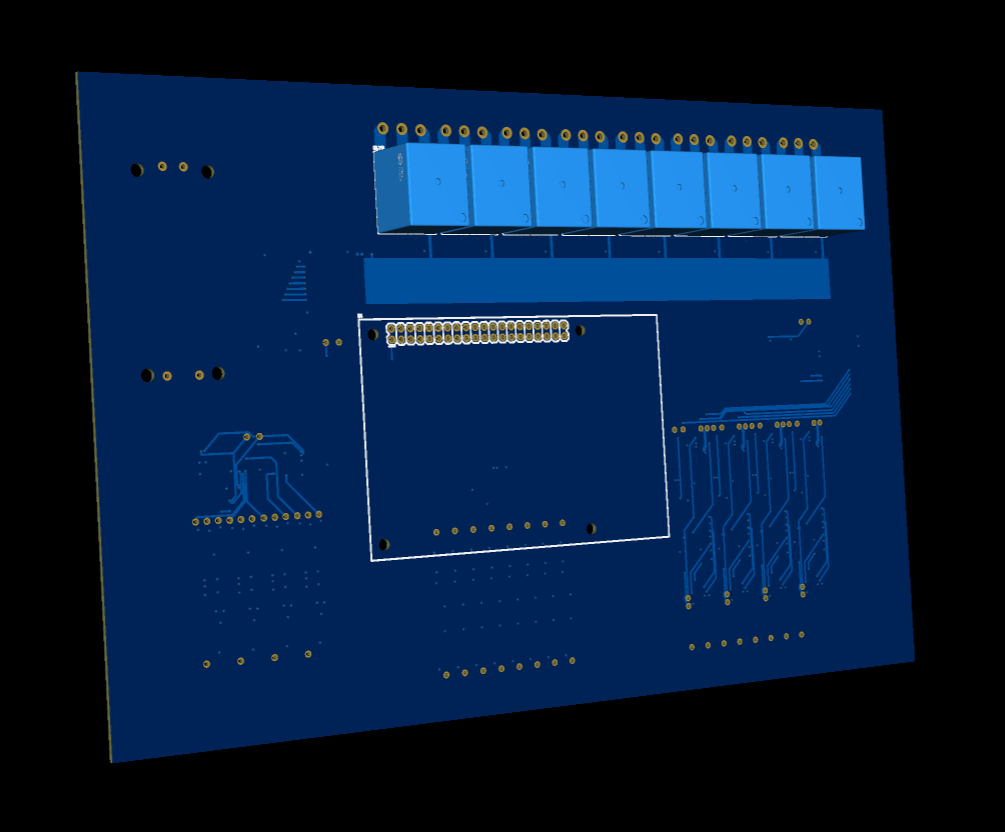

- 8 digital inputs (3–30V)

- 8 relay outputs (SPDT)

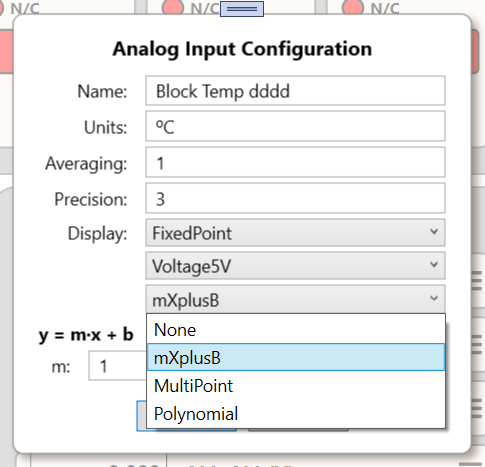

- 4 analog inputs with calibration and filtering (mV to 10V, 4-20mA)

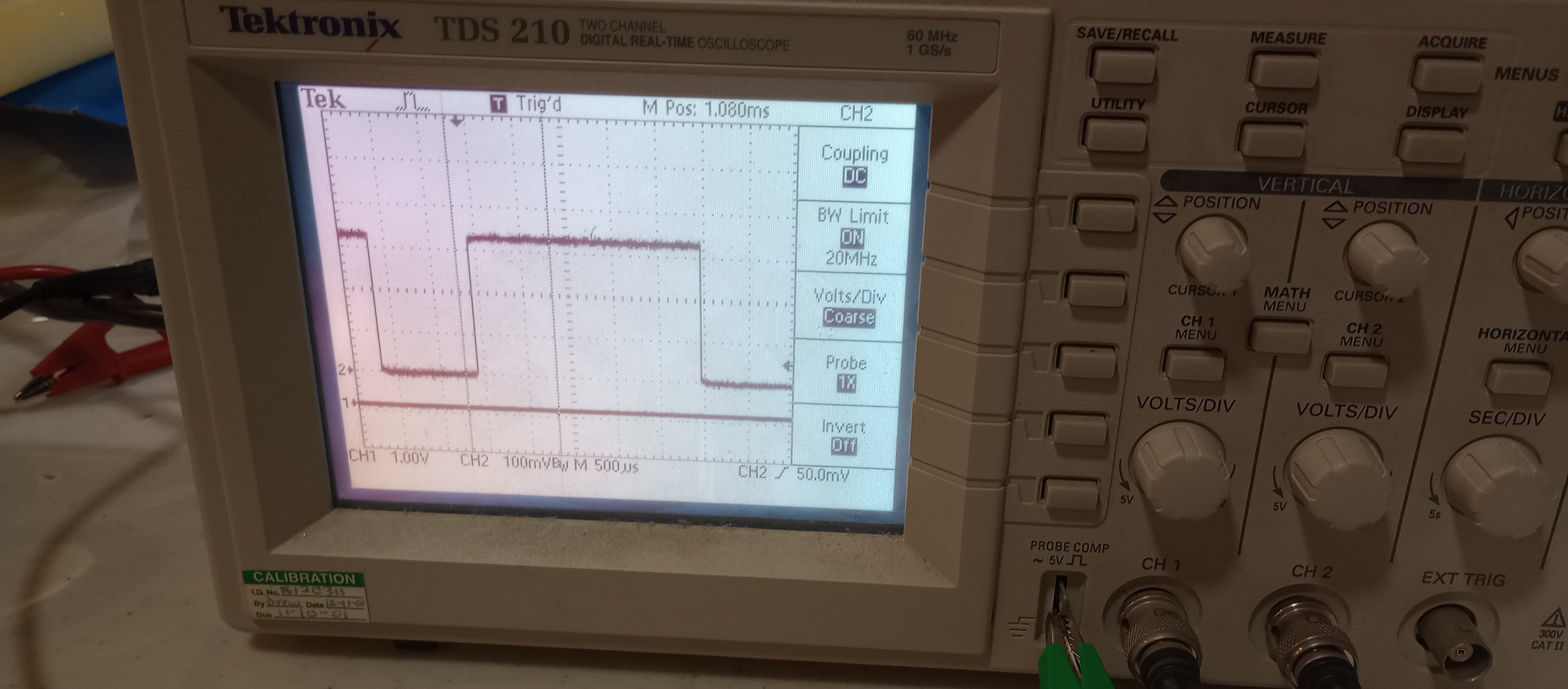

- 4 analog outputs (0-5V, PWM)

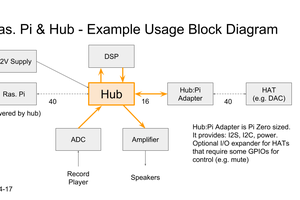

- Ethernet connectivity

- CE-ready enclosure with professional-grade labeling and documentation

Designed for rapid deployment, open development, and robust performance in edge control environments.

Subscribe to my project on Crowd Supply for launch notification

Edward

Edward

smartroad

smartroad

Jithin

Jithin

Andrew Bolin

Andrew Bolin