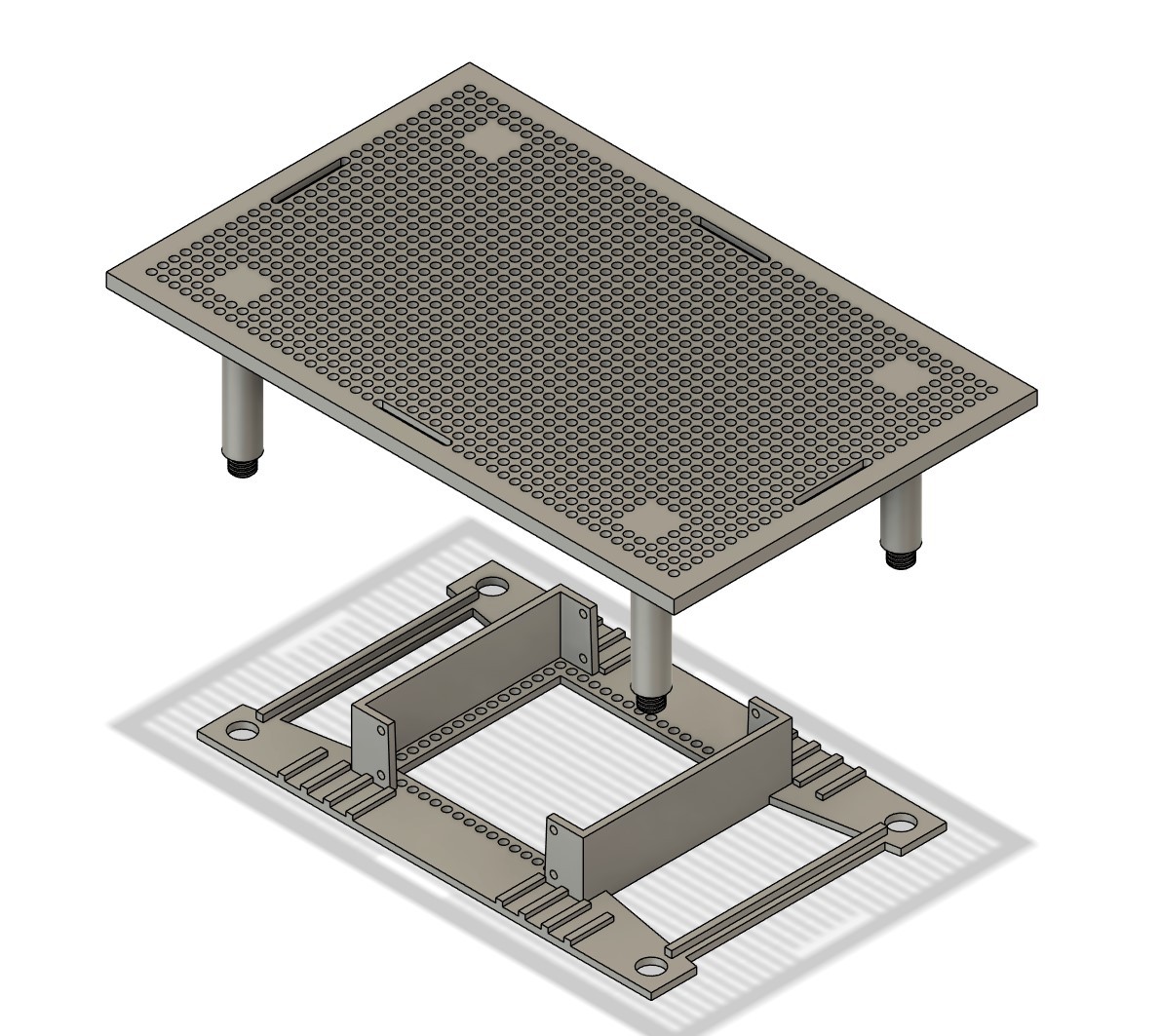

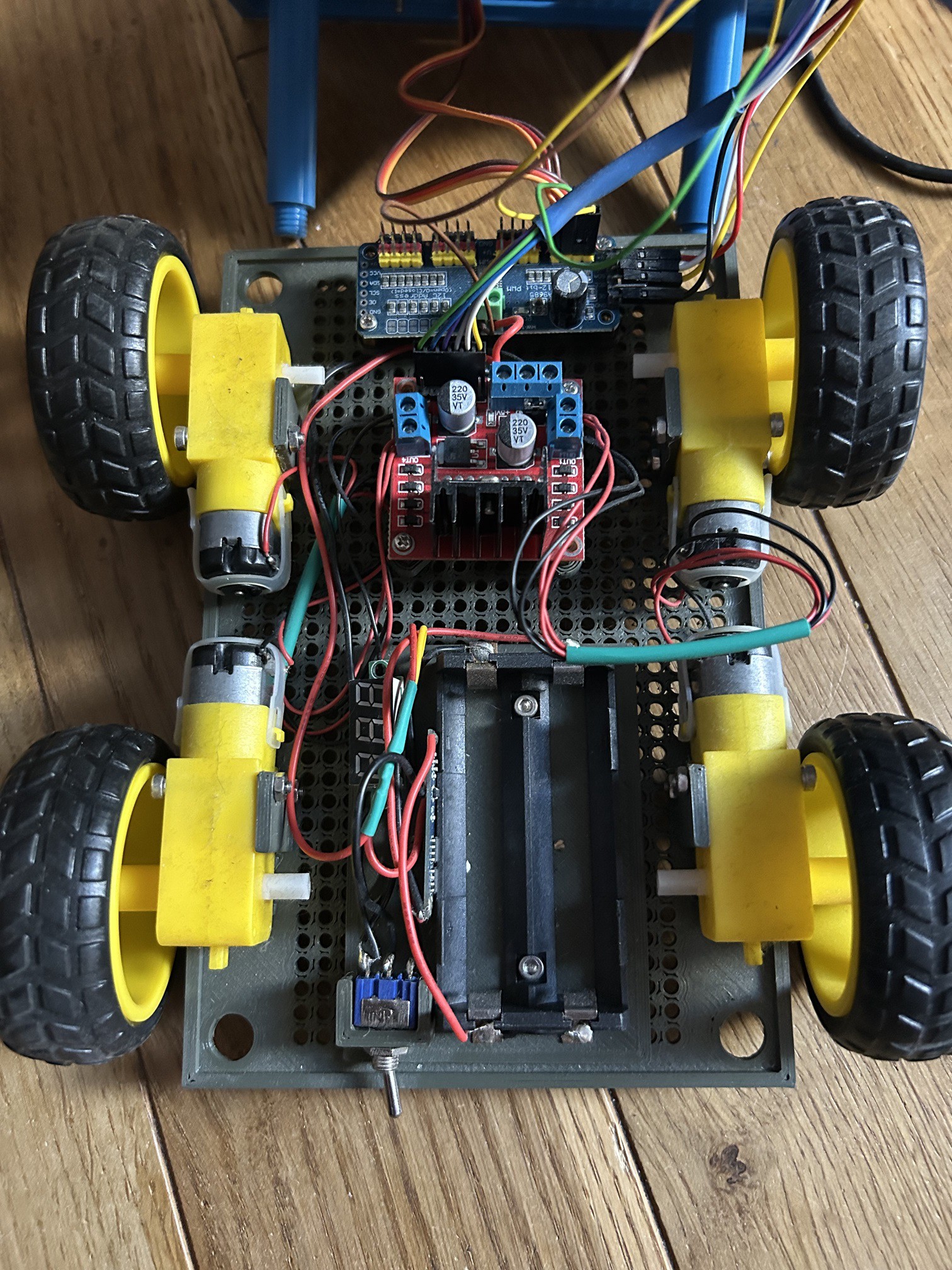

The latest itteration of the car inculdes:

- Raspi Zero 2 as central component,

- Astro PI shield for some extra sensors and the LED Matrix

- I2C controler for the servos

- L298N H Bridge as motor controler

- some Grove I2C components

- 2 Custom build 18650 based battery packs

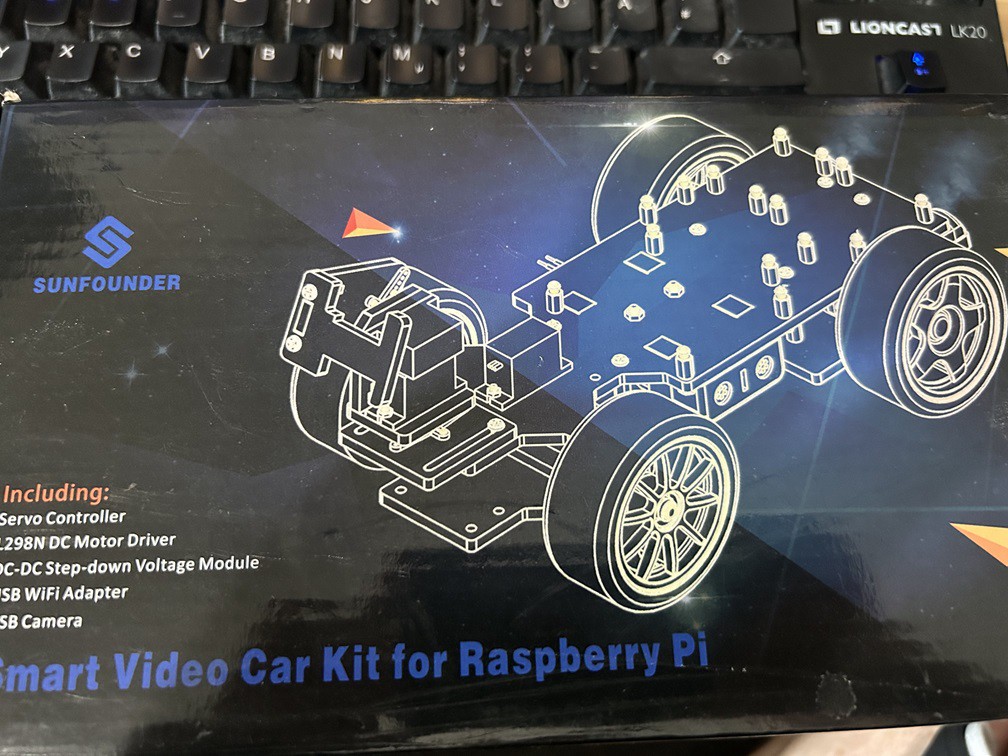

The modular learning car project

There are tons of arduino or raspi car kits out there but they are not very flexible. With this I want to share my learning journey

alnwlsn

alnwlsn

Bob Baddeley

Bob Baddeley

ric866

ric866

8bithalfadder

8bithalfadder