-

Welding

04/11/2017 at 09:46 • 0 commentsWe will continue with metalworking and give our arm a shot at welding

This turned out better than I would have imagined! It's a better welder than I am.

Welder was a standard 110V handheld welder with flux wire.

See more details at this project's page

-

Plasma Cutting

04/07/2017 at 11:22 • 0 commentsToday we plasma cut the letter E out of sheet metal.

The toolehead is a standard handheld plasma cutter. I used a small solenoid for the trigger mechanism.

The material is 12ga mild steel.

The toolpath was created in inkscape

See our blog post on this job at http://evezor.com/plasma-cutting/

-

3D Contour MIlling

04/06/2017 at 23:08 • 0 commentsToday we Milled the letter P from our Open Source letter series we've been doing

Our toolhead today is a full size 2hp router with a 1/4" ballmill.

The stock material was a piece of brazillian cherry.

The toolpath was created with Kiri:Moto. With all these projects, for better or worse, I tried my best to use open source software. I would have made a tutorial on this if I didn’t have such a bad experience using the software. It’s not the worst software ever but made some unusual decisions with some of its toolpaths. I will be looking for some better software, if you have some suggestions please leave a comment.

-

2.5D Milling

03/29/2017 at 10:42 • 0 commentsToday we milled the Open Source Initiative's Logo

Our toolhead today is a full size 2hp router with a 3/8″ 2 flute bit.

The stock material is a laminated piece of brazillian cherry between two pieces of pine.

The toolpath was created with Kiri:Moto. With all these projects, for better or worse, I tried my best to use open source software. I would have made a tutorial on this if I didn’t have such a bad experience using the software. It’s not the worst software ever but made some unusual decisions with some of its toolpaths. I will be looking for some better software, if you have some suggestions please leave a comment.

-

Laser Cutting and Inkscape Tutorial

03/27/2017 at 07:13 • 0 commentsToday we lasercut the letter E into some cardstock

We used Inkscape to create the gcode for this letter.

We also created a tutorial so you can learn to make patters of your own. See it here.

Our toolhead here was just a little diode laser we source online that we put into a CPU heatsink and clamped to our arm.

-

Glass Etching

03/22/2017 at 20:07 • 0 commentsToday we etched the letter U into glass

Our tool post, once again, was just a hunk of 2X4. Then we used a hose clamp to secure the rotary tool to the tool post.

We used a diamond bit to do the glass etching and some lightly soapy water as coolant.

The toolpath and design was created in Inkscape.

-

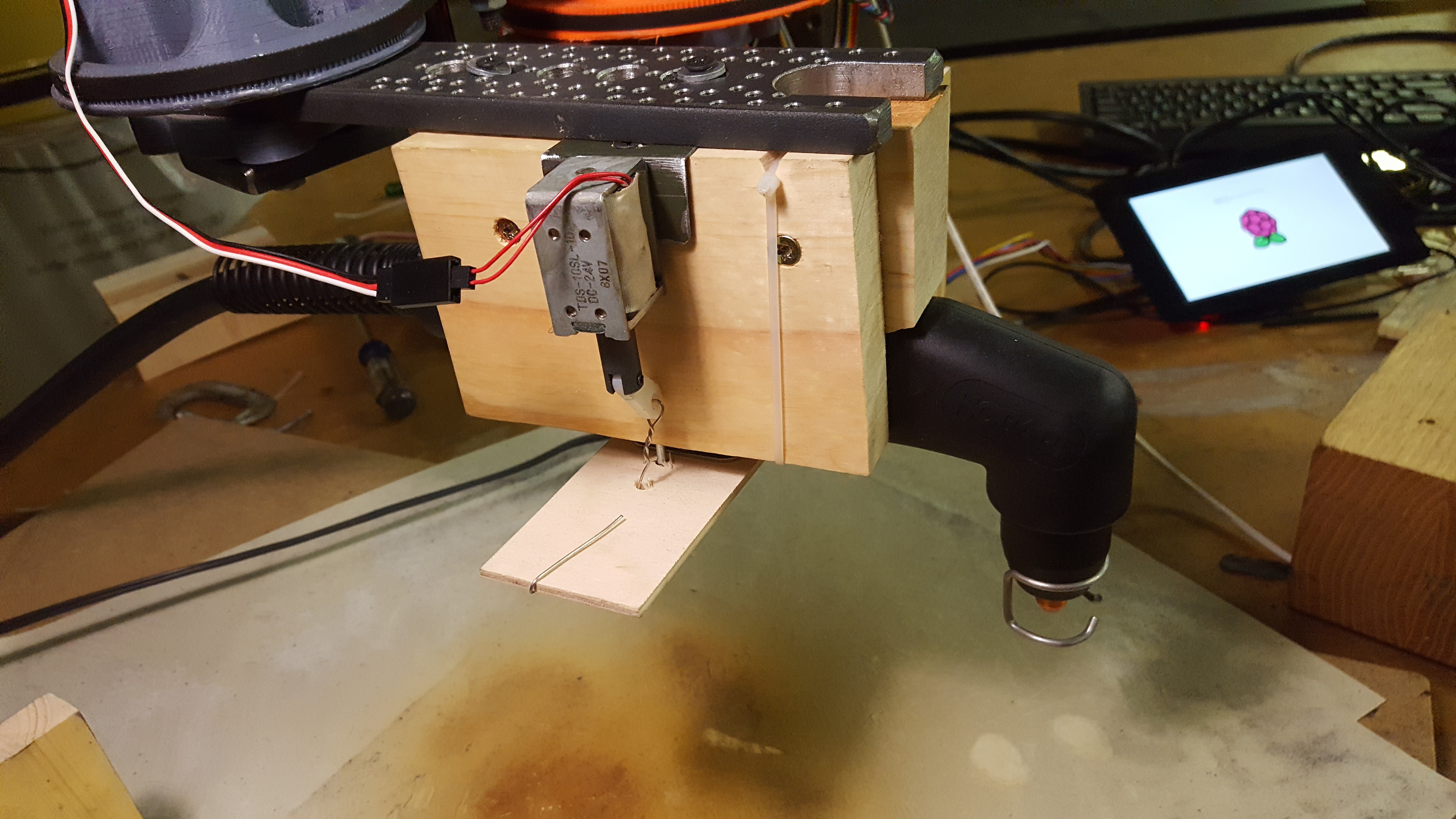

Hot Wire Foam Cutting

03/22/2017 at 05:21 • 0 commentsToday we made the letter ‘S’ in foam.The general frame was constructed with 2X2 and 2X3 wood pieces and a 6″ 1/2-13 bolt up the spine.

I used stainless steel wire for the element, but nichrome wire would have been a better choice.Links to the .svg and .stl files can be found on this project’s thingiverse page

Tomorrow we will do some glass etching

-

Let's Start With Some Speed Tests

03/21/2017 at 01:09 • 0 commentsI was just running some speed tests and tuning in some of the accelerations. It seems I've hit the max step rate of Marlin as increasing feedrates had no effect.

Banana for scale.

-

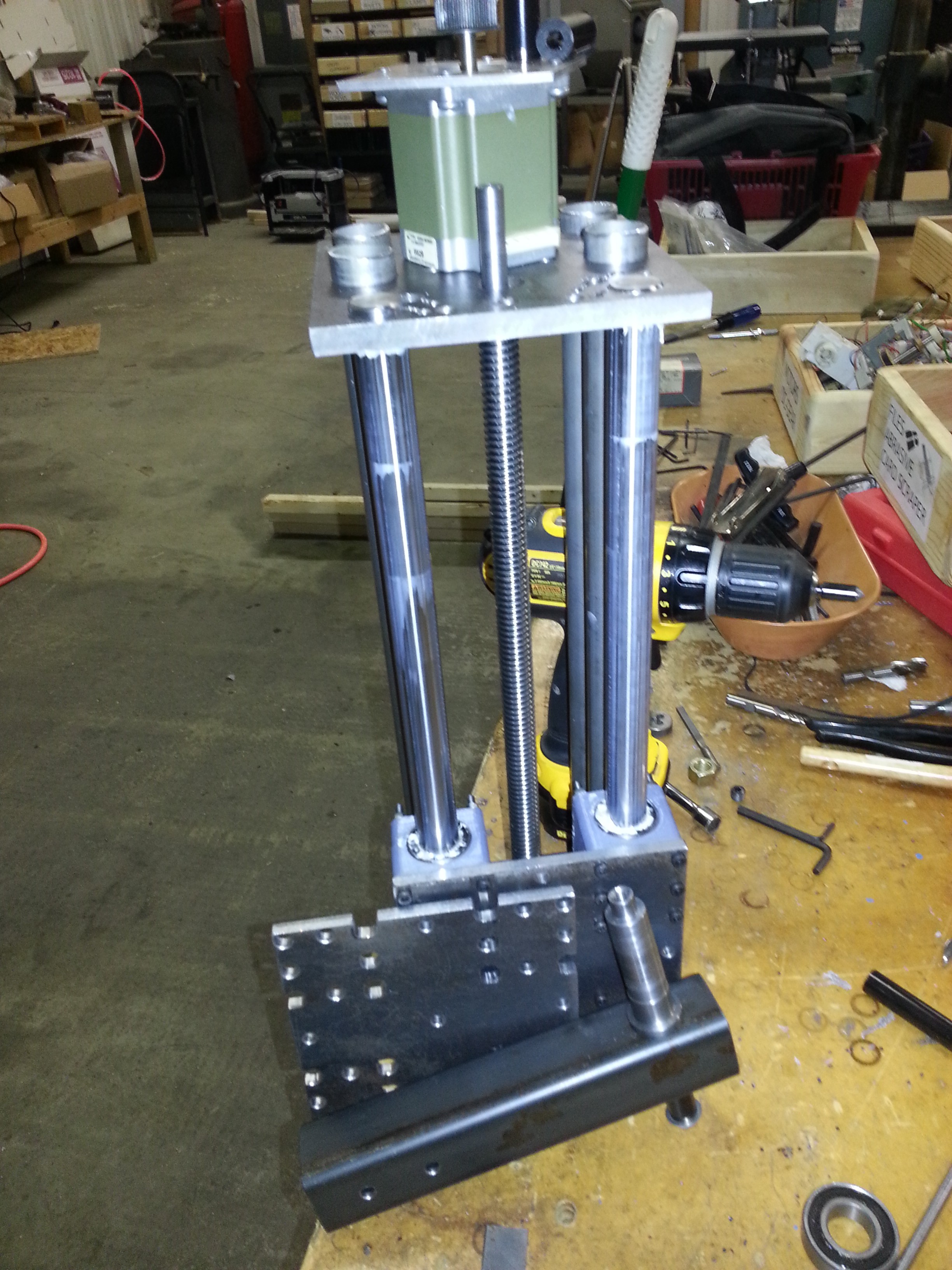

So It Begins

03/20/2017 at 09:06 • 0 commentsI don't have a lot of photos of the original machine building, but here's a few

![]()

![]()

The larger grey wheel was an early prototype. After some initial testing I realized that I would need to have much larger shafts for this to be as stable as I would like.

Here's the first set of GCODE I ran.

G1 X0 Y0 G1 X50 G1 Y50 G1 X0 G1 Y100 G1 X50

More to come tomorrow.

Evezor Robotics and Automation Platform

A Networked set Robotic Arms, Motion platforms, sensors and more. Easily programmed with a drag and drop interface.

anfroholic

anfroholic