The goal is to create a device that has over/under voltage, reverse polarity, reverse current and short circuit protection in the most power-efficient way for a reasonable price.

The Protect series addresses the areas of improvement as follows:

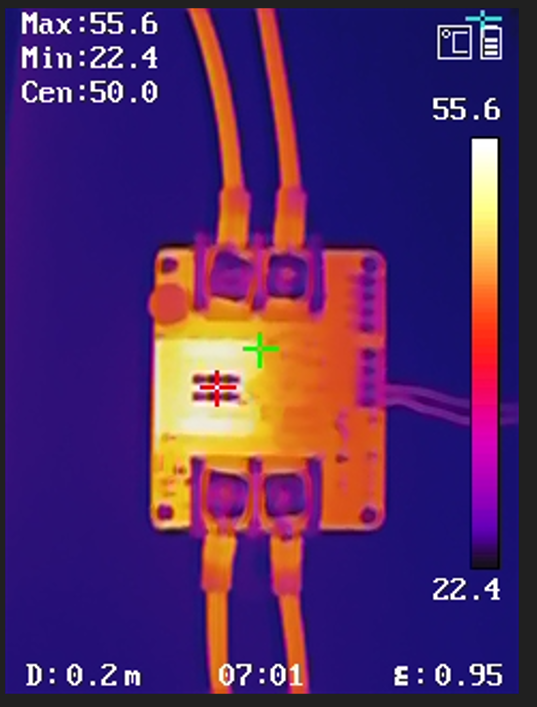

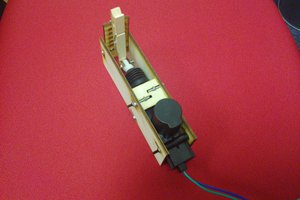

Efficiency: A lot of designs use P-channel MOSFETs, usually for achieving reverse polarity, but these are inherently inferior to N-channel MOSFETs due to the higher carrier mobility of n-type silicon. Even if an efficiency loss of a few percent is tolerable, it drastically increases the thermal load on the PCB which reduces the overall current capability of the board. We used low-Rds N-channel FETs to achieve efficiencies >98% (typ.) on the Protect, and we will do it again on the Protect+.

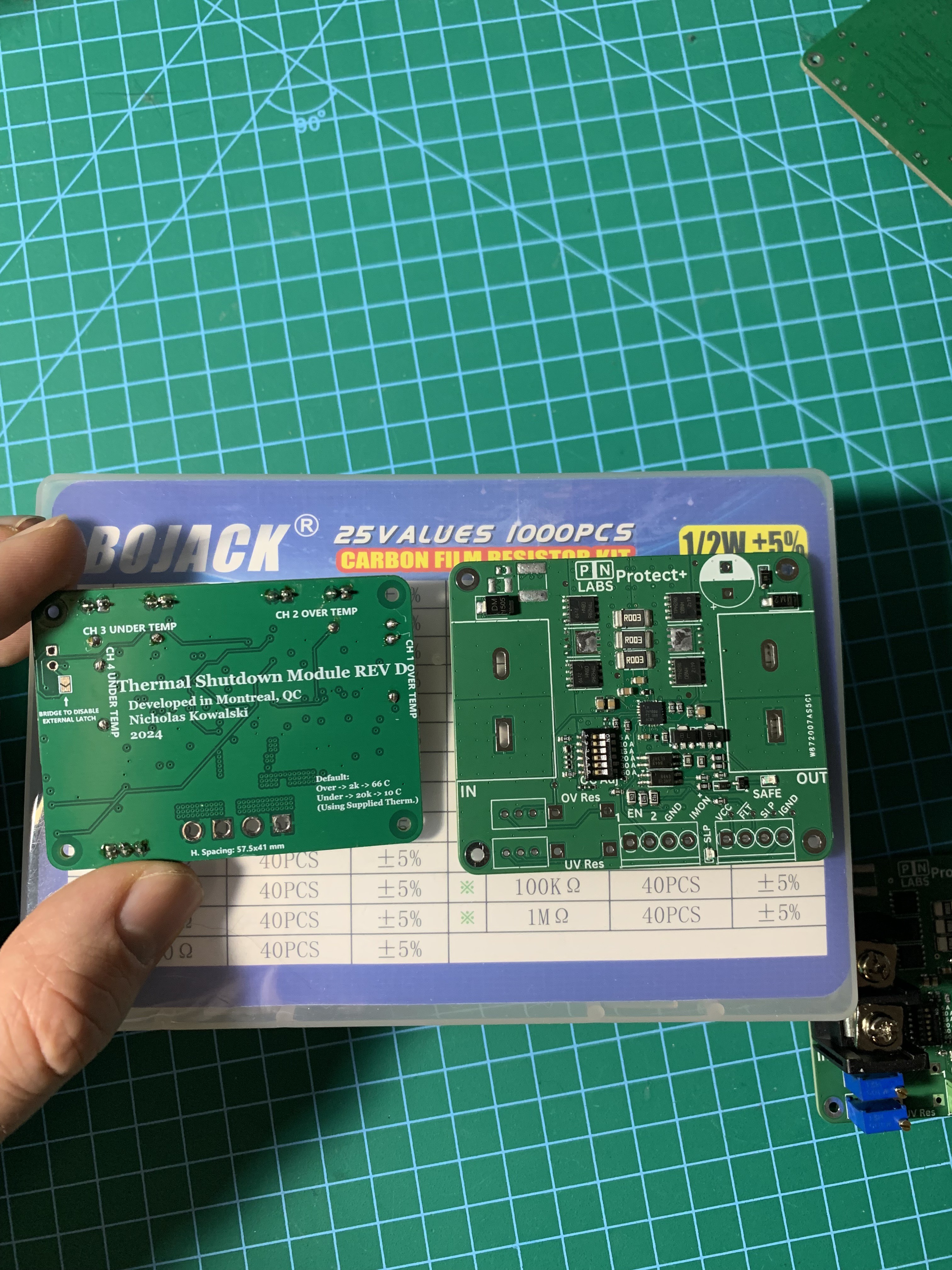

Adjustability: Most DIY and commercial designs are purpose-built for a specific unit. Since the Protect+ is intended to be reusable between multiple projects, it will be built with potentiometers to adjust the voltage cutoffs, while also making provisions to be easily replaceable with a fixed resistor. The appropriate resistor will be able to be calculated by entering the desired cutoff values in a calculator, or with simple equations.

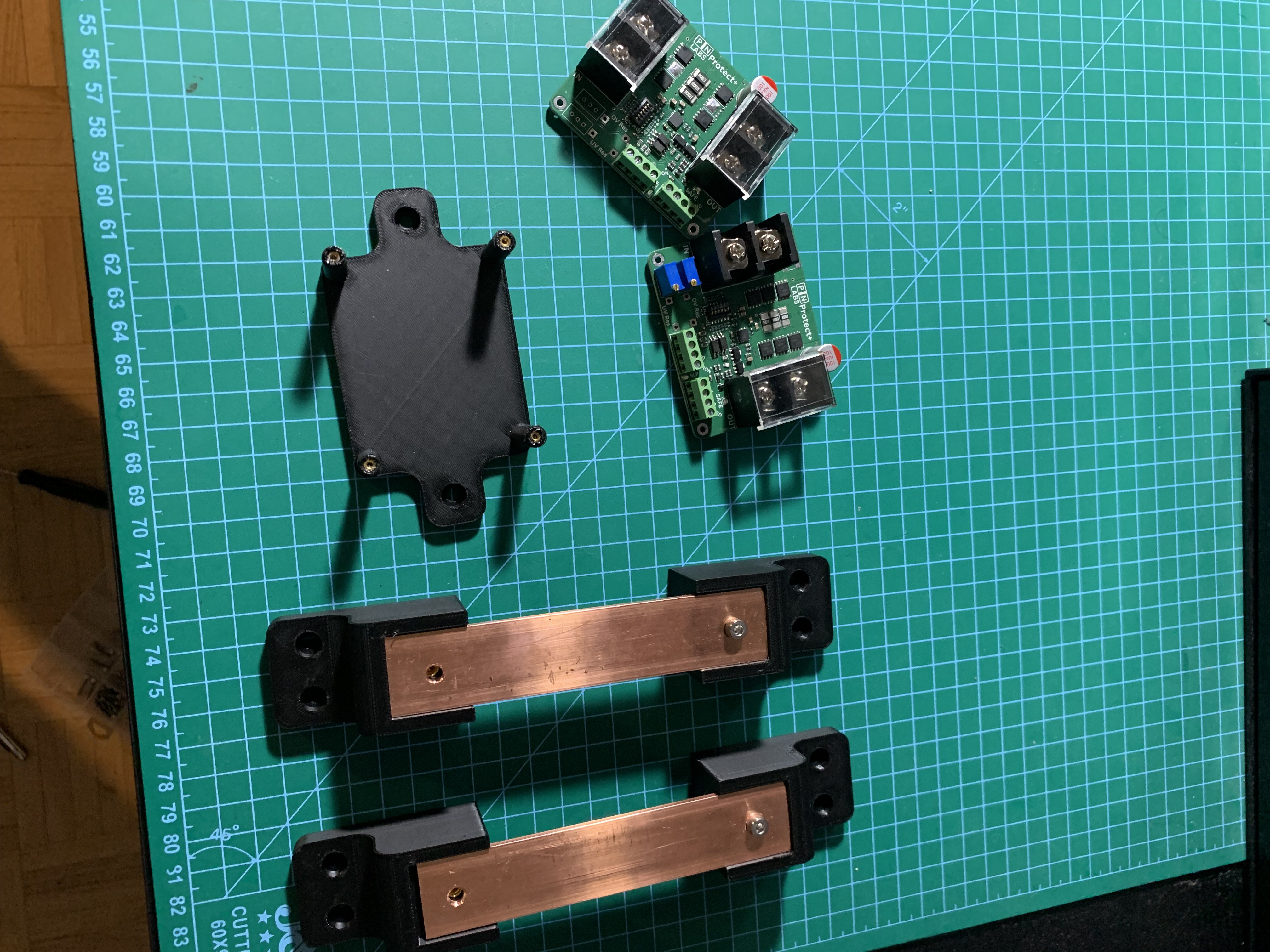

Scalability: By adding an ideal diode input stage, current from the module is prevented from flowing backward into the supply, effectively isolating individual supplies from each other when their outputs are connected in parallel. When combined with some enable or reset functionality for power path control, this provides the foundation for building larger, more complex systems that utilize multiple power supplies.

Proposed features:

- 4-60 V operating voltage range

- XT60 PW Male and Female connectors

- Up to 30 A of continuous current capability, 45 A burst current rating

- Latch-off short circuit protection, resettable via switch or opto-isolated signal

- Non-isolated current monitor with programmable gain (via resistor jumper)

- Blocking voltages of up to 75 V

- SAFE LEDs with opto-isolated fault and reset signals

- Optional jumper for disabling all onboard LEDs/optoisolators so upon entering a FAULT condition, the board enters an ultra-low current mode that wastes very little battery power.

Roadmap:

1. Collect feedback from the community on overall design.

2. Design the prototype product and perform testing to validate the core functionalities.

3. Crowdfund on Kickstarter or Crowd Supply for the first batch and develop Quality Control jigs

PN Labs

PN Labs

John Loeffler

John Loeffler

Brian Lough

Brian Lough

adria.junyent-ferre

adria.junyent-ferre

Bud Bennett

Bud Bennett