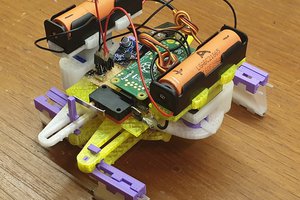

This is my DIY dog made only from parts you can simply buy, no custom PCB, nothing exotic or too over-engineered. The idea was to have a 3D printed quadruped that actually walks, does not immediately disintegrate, and stays around 100€ in parts. The brain is a Raspberry Pi Zero 2 W running Python. Power comes from two 18650 cells, each with its own step-up converter: one for the Pi, one for the PCA9685 and all the servos. Grounds are connected, but power is split so the Pi does not collapse into some catastrophic brownout every time the dog moves.

The dog has 14 DOF: 3 joints per leg and 2 for the camera head. Most joints use MG90S metal gear servos, with a few TS90MD mixed in, and small 9g Miuzei servos for the camera. For vision there is a Freenove 120° 8 MP camera, so later I can play with ArUco markers and other slightly more sophisticated experiments.

All parts I modeled in FreeCAD and printed on an Anycubic Kobra 3. Right now the dog can walk in any direction, rotate in place, and the speed is adjustable. The code is still messy and a bit chaotic, but good enough to share and use as a small experimental platform. The code itself will be published a bit later, after I clean it up at least a little, remove redundant stuff and make sure there is no data I would prefer not to expose.

Stanislav Britanishskii

Stanislav Britanishskii

Rudolph

Rudolph

James P.

James P.

François Ubald Brien

François Ubald Brien