-

Update: 30 April 2017

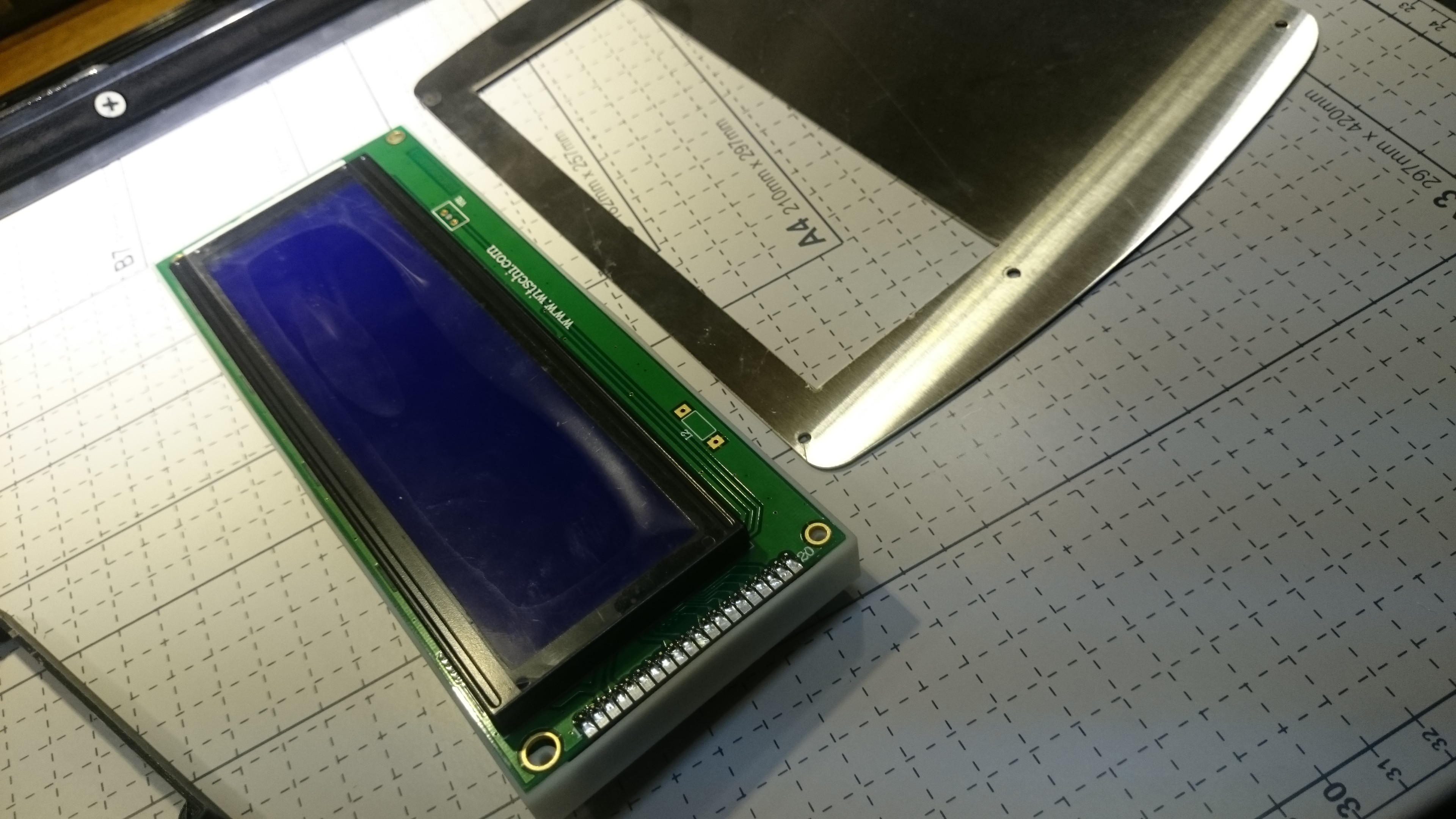

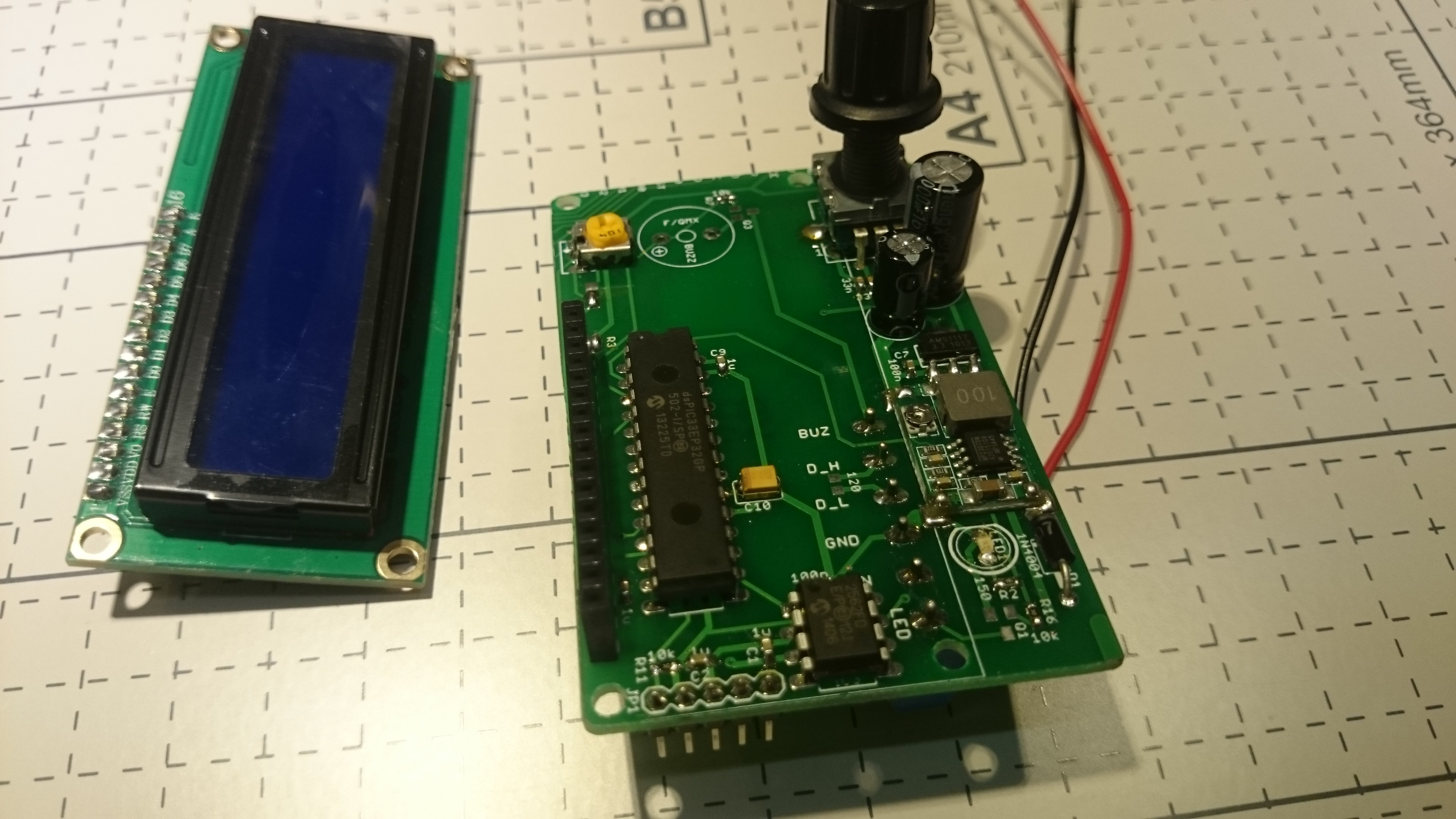

04/30/2017 at 20:25 • 0 commentsCurrent hardware status: all peripherals have been tested and work as expected. The following LCD modules have been tested and work:

- ERM25664 256x64 monochrome (White on Blue)

- Nelytech NT-G128641A 128x64 monochrome (Black on White)

- Generic QC12864B 128x64 monochrome (White on Blue)

- Generic 1602A 2x16 character monochrome (White on Blue)

Current firmware status: about 40% complete. So far only the functionality for listing attached modules and their parameters as well as accessing any of the remote console menus has been implemented on the Nelytech LCD. The identical code should be re-usable for the other graphic LCD modules, by simply replacing the glcd.c/h files with the appropriate driver. Widgets and their configuration menus still need to be implemented.

-

First Batch: Assembled Modules

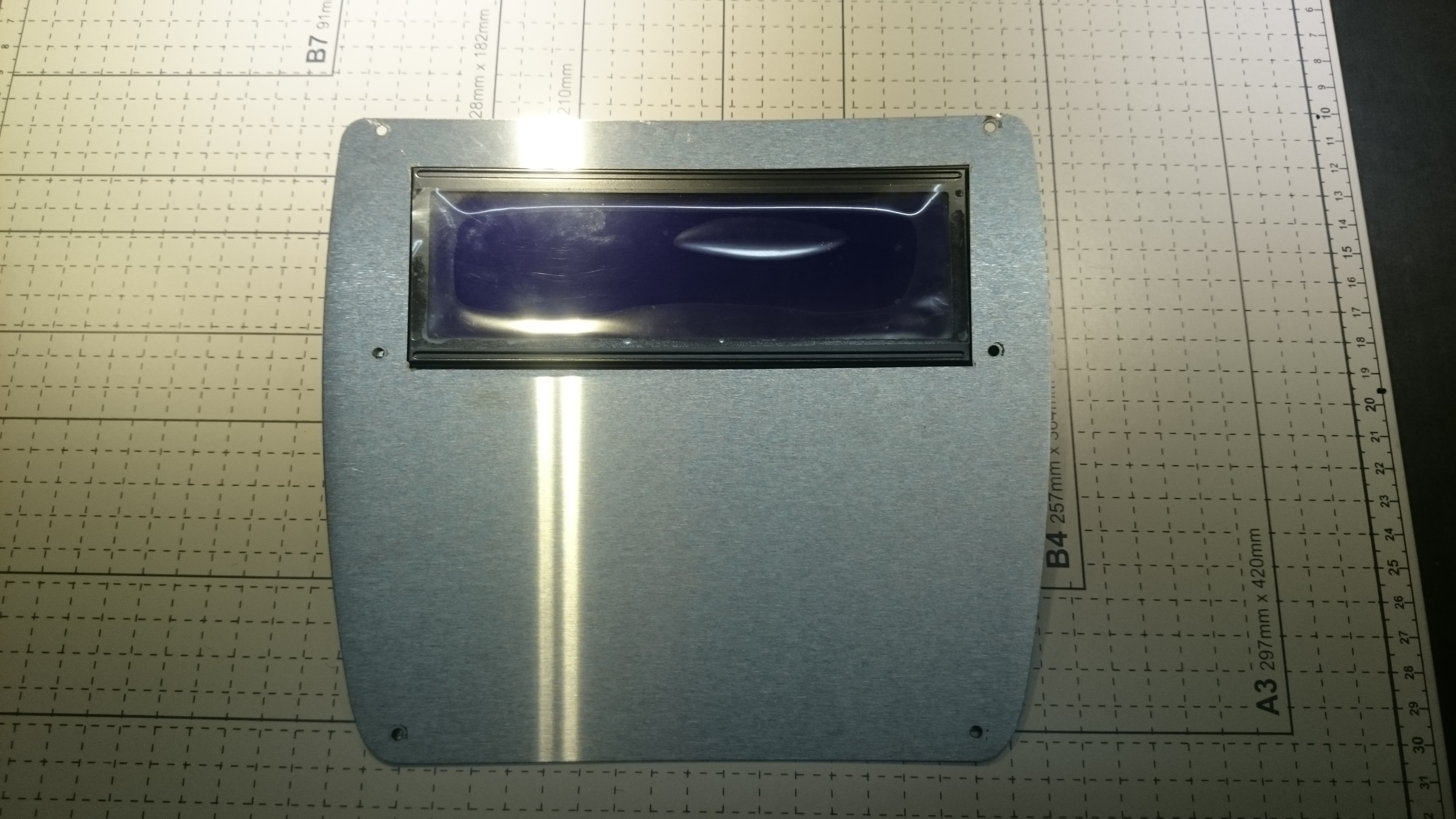

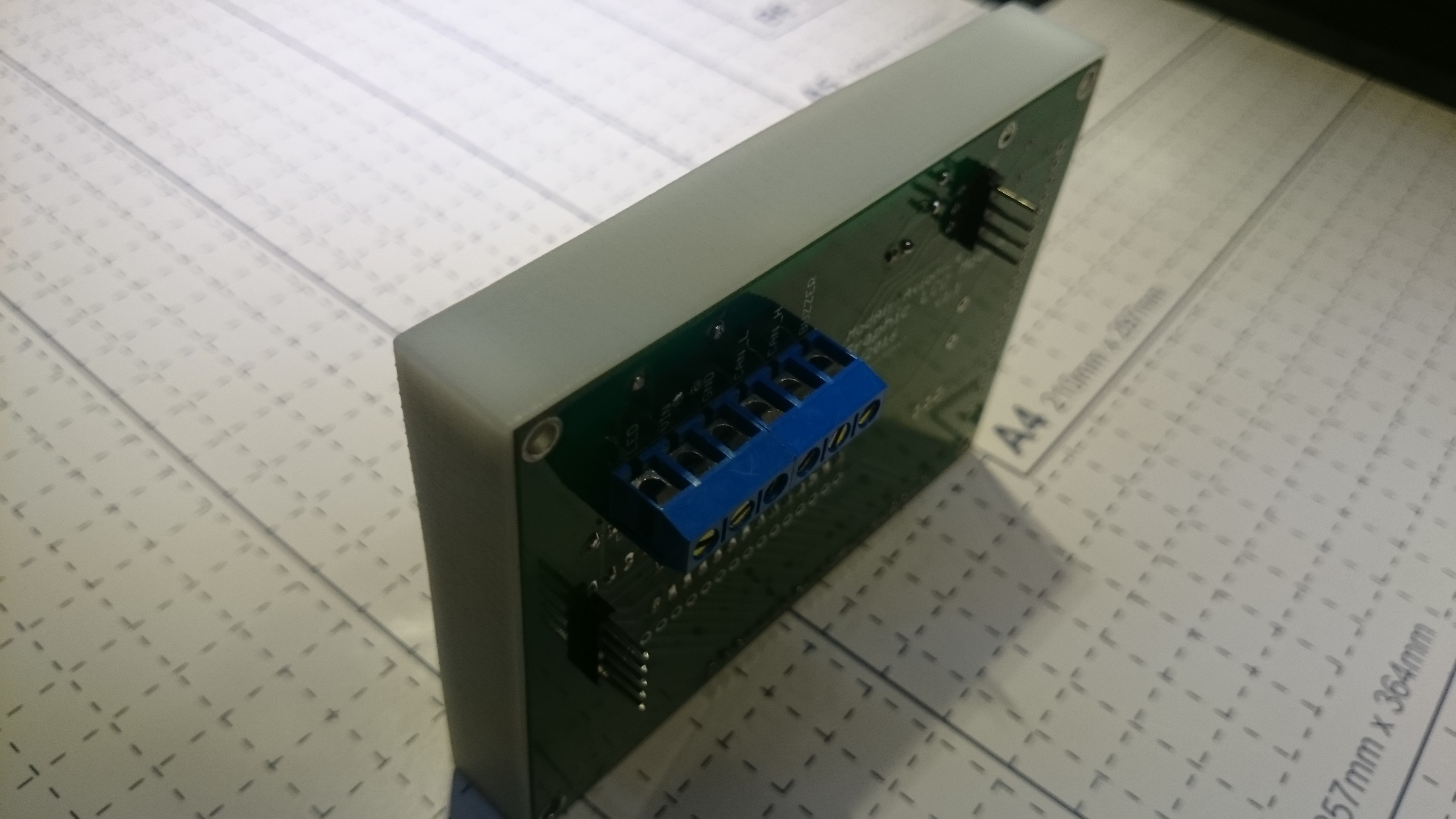

04/20/2017 at 13:26 • 0 commentsThe idea with the controller and LCD sandwiches is to mount them directly behind a front panel. I had a front panel cut from 0.9 mm brushed stainless steel (about $10 from a local metal manufacturing company), but unfortunately I only discovered the scratches underneath the protective plastic when I got back home.

The 3D printed brackets worked perfectly, and aligns nicely with the PCBs on both sides. In the design files I added 0.2 mm on all sides.

For the 1602 LCD, the PCB is cut smaller with a hacksaw. For this module, the rotary encoder is mounted on the base PCB (rather than being attached with a ribbon cable).

-

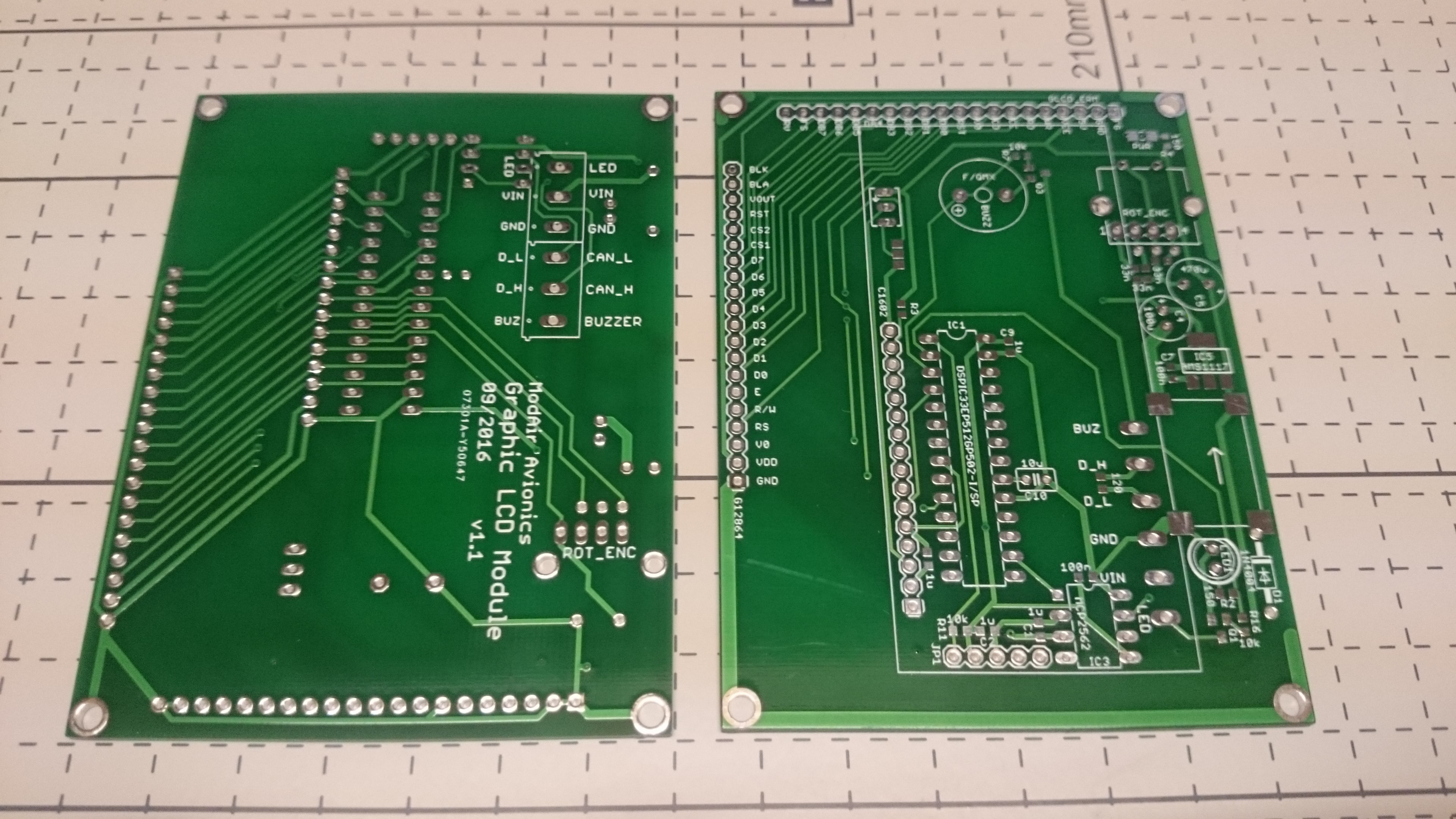

First Batch: PCBs

04/20/2017 at 12:45 • 0 comments -

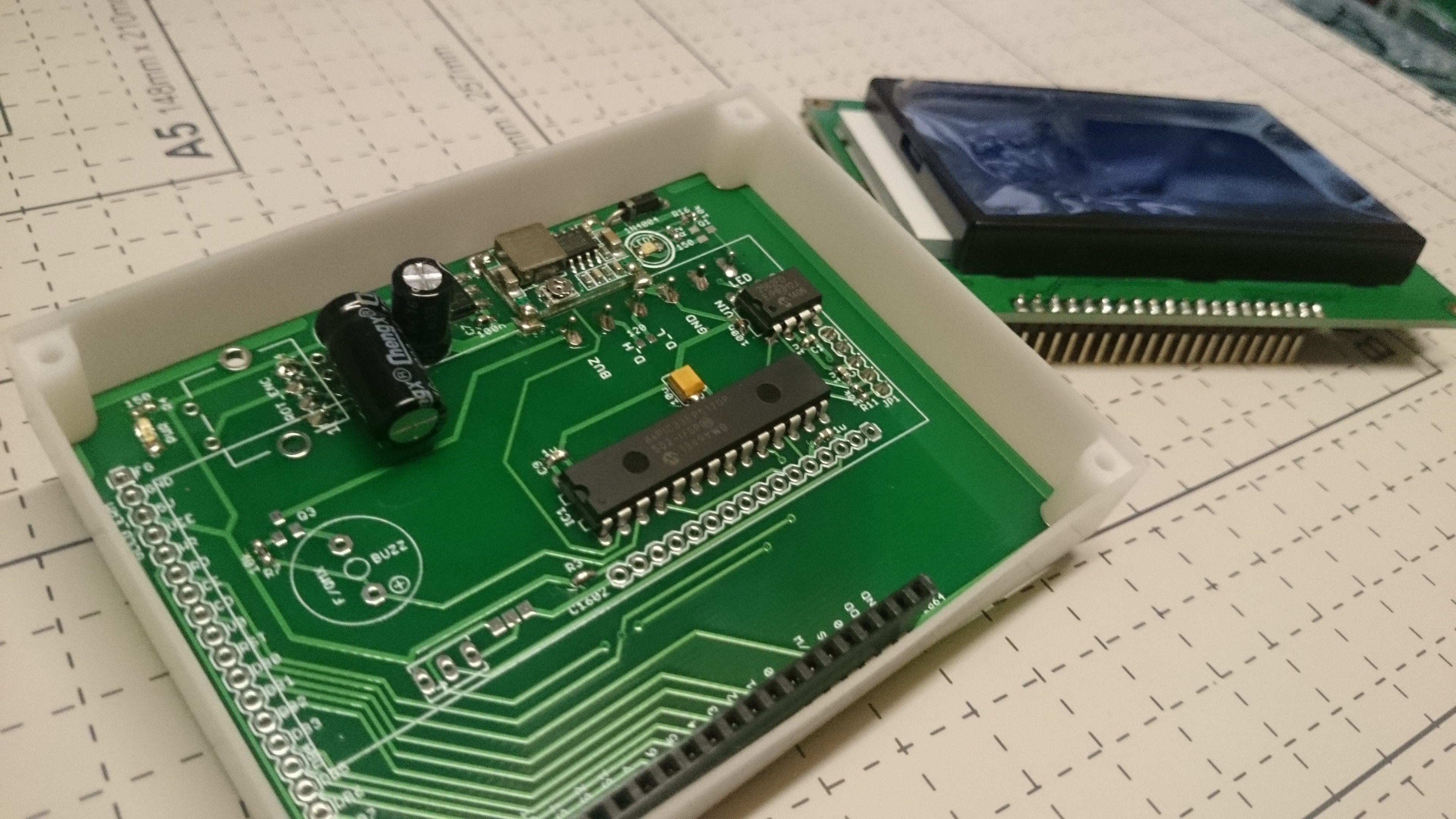

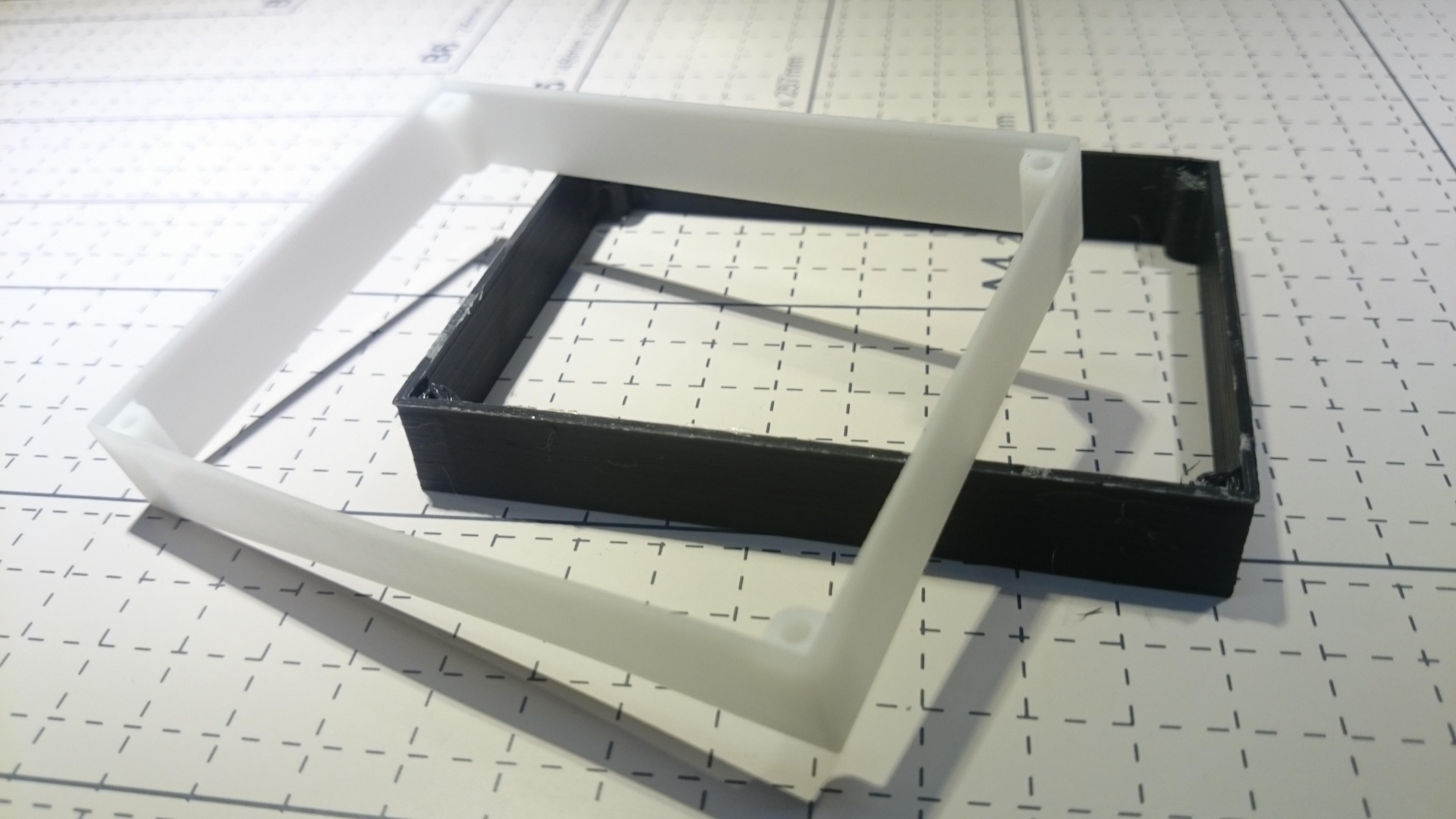

3D printed brackets

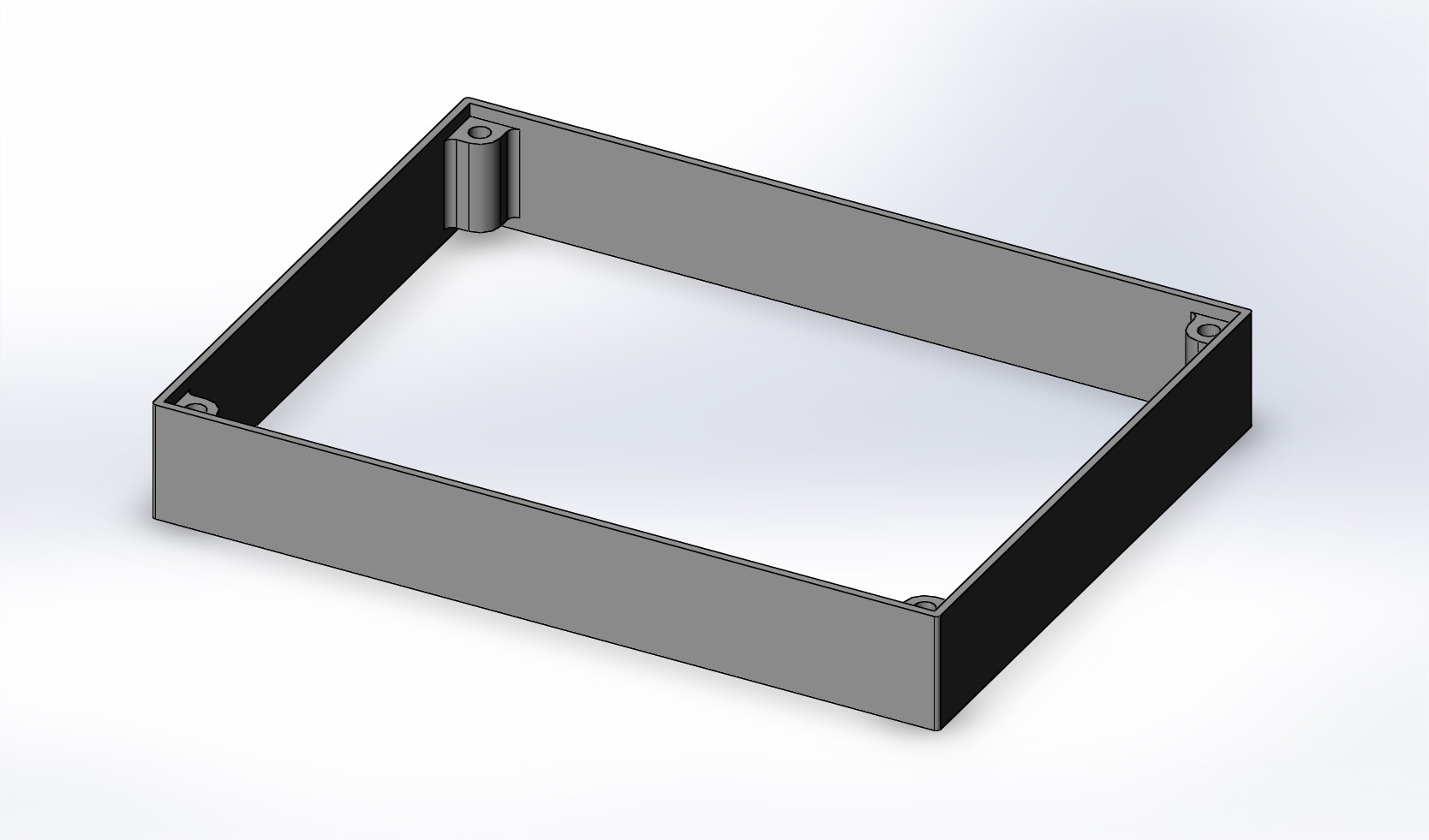

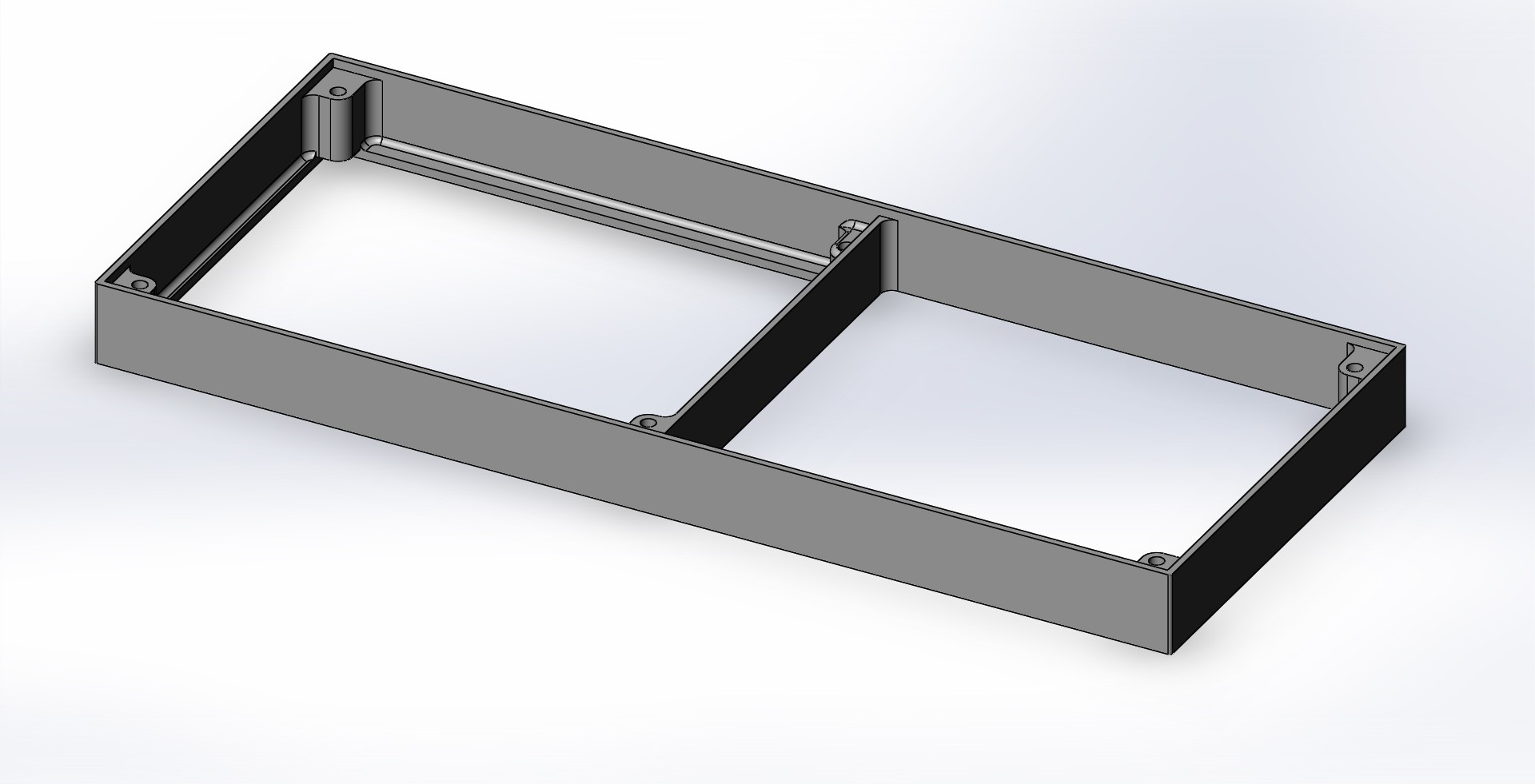

04/20/2017 at 07:31 • 0 commentsI designed some supporting brackets to sandwich the LCD Module to the PCB. Standard 0.1" female header pins were used on the PCB side, with the male header pins on the LCD side. This brings the PCB separation to 11.0 mm. With 1.6 mm PCB thickness on both sides, the resulting stack is 14.2 mm thick.

For the 93 x 70 mm LCDs:

For the 184 x 75 mm LCD module:I am quite impressed with the ITEAD SLA 3D printed parts (white parts in the pictures). There is a huge difference in quality between the SLA and the standard additive manufacturing (black ABS parts) prints.

Even though both prints used the same design files, the black brackets seemed to have shrunk and will need some filing to fit the PCBs and LCDs...

[ModAir] Monochrome LCD Modules

A LCD graphic / character display module for the ModAir project

Rene

Rene