This project focuses on creation of a 3DP (binder jetting powder bed printer) which can print with hydroxyapatite (material that makes up to 70% bone weight). Beside the printer I will be making the needed material to print out of. I will also try printing with some other materials that are more commonly available (maybe even metal powders). When I will be discusing results of material testing I will also write a bit about the usage of other materials (eg. ceramics)

The idea of this project came from realization that 3D printing is a method, that has a lot of potential in biotechnology and medicine. By saying this i'm not just saying that we can print organs, but we can use this method to make parts used in very expensive equipment. For example we could use this method to make porous elements used as bioreactors, biofilters etc. I started with bone printing as it seemed as the simplest.

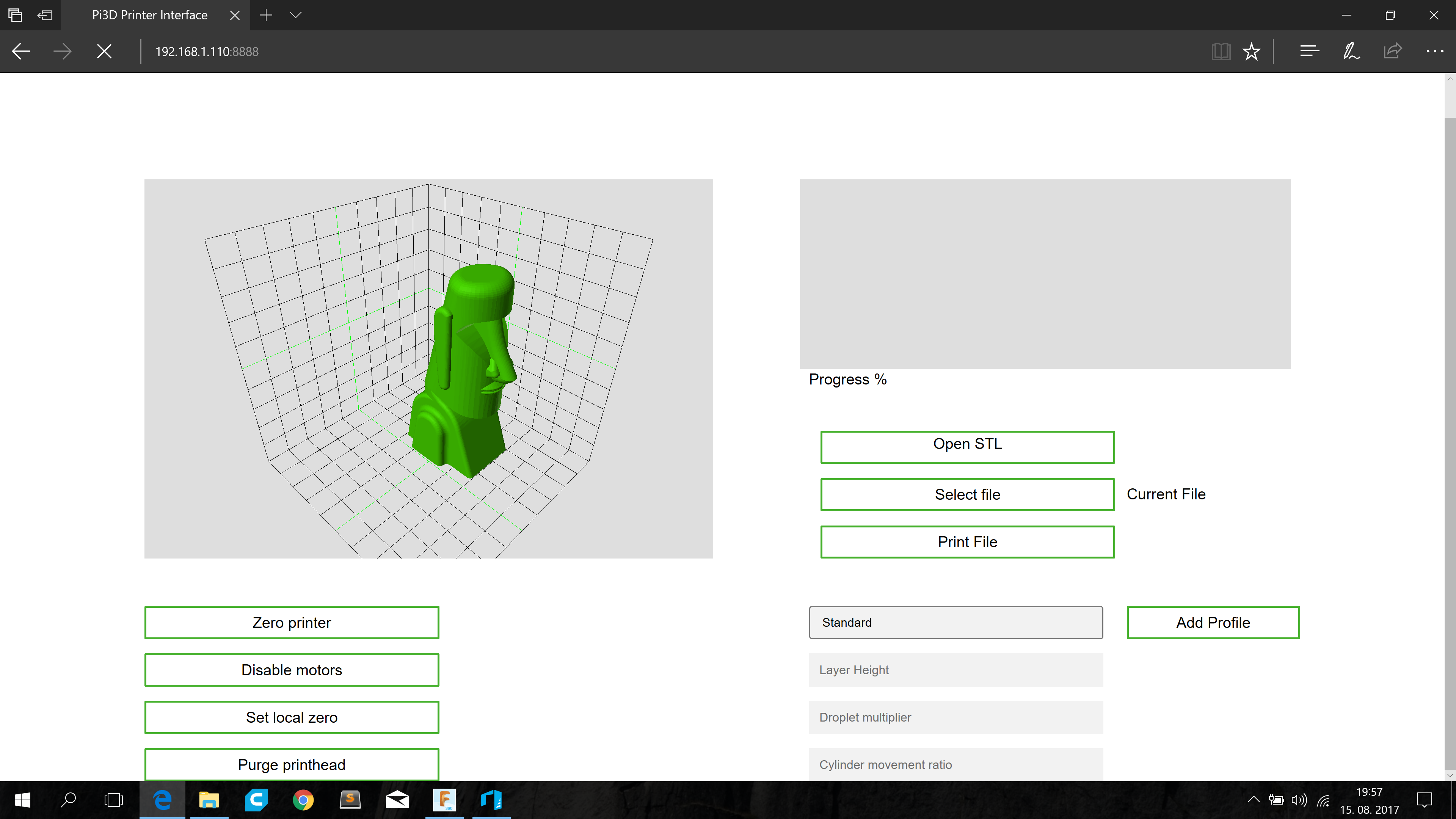

I designed the printer so it can be CNC milled. Most of the parts can be salvaged. I also tried to design the printer so it is cheap to build. I will also try to replace all expensive parts with cheaper ones that don't impact the performance too much.

Note that I am just a young enthusiast, so there is going to be plenty of things to improve. By saying this I am asking everyone who is thinking of building this printer to use their own minds and be ready to fix some of my mistakes.

I will be posting project logs everyday (at least I hope so) where I will be talking about material development and printer creation. I will alternate between these two topics so one day I will talk about printer and the next day about materials.

You can acces my GitHub repository for this project here

One thing you might like to consider is adding a proportion of fine silica powder either to the dry powder (best I expect) or the binder. Silica/quartz is just silicon dioxide (essentially pure glass) and is very well tolerated in the body. It also sinters at below 1300'C so it should act to bind your other components (esp the hydroxyapatite) together. It's essentially like clay setting in a kiln. It would not matter if the binder burned out providing the silica sets the mixture when it cools.

Keep up the great work!

Ugi