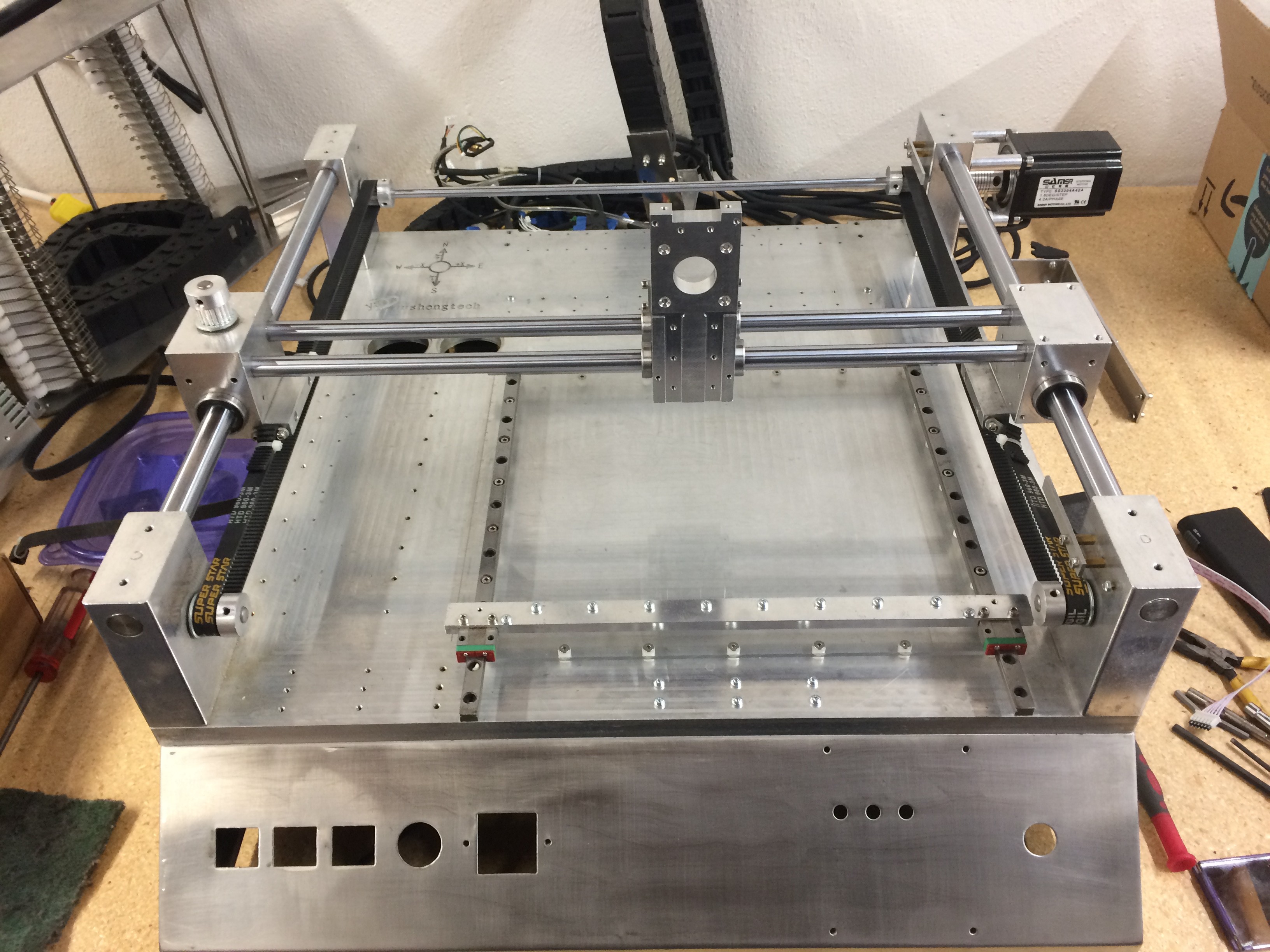

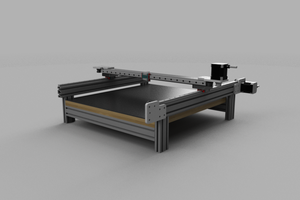

The SMT50 Machine

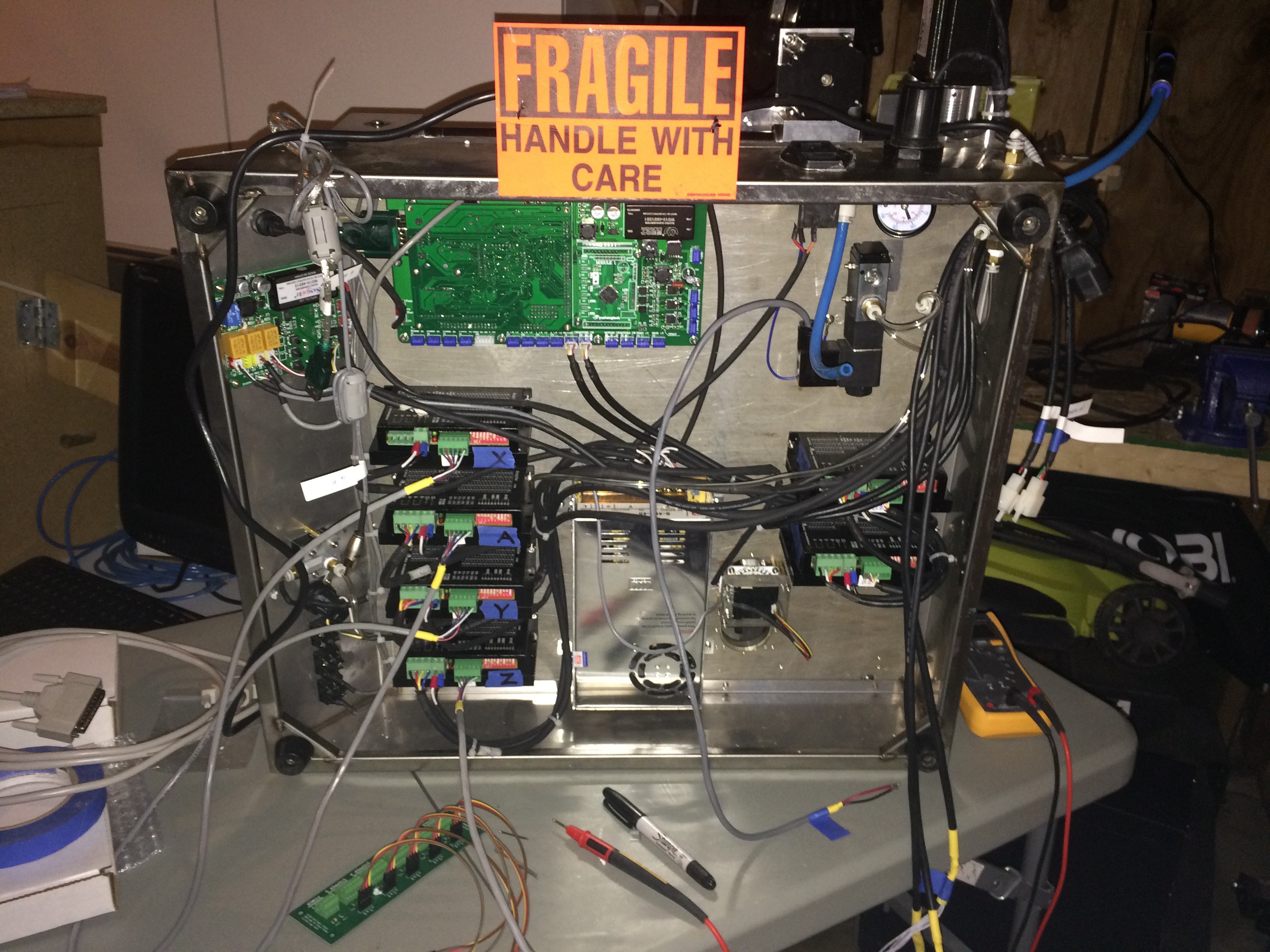

The guy that sold me the machine agreed to build a suitable shipping crate around it. Normally one would anchor an 80 lb machine to the bottom of the crate with bolts going through the crate frame and the base of the unit. Nope. It was just floating around in a sea of loose styrofoam blocks, which were pretty much disintegrated on arrival. Normally one would construct such a crate using 2x4s and 3" wood screws, or at least heavy duty long staples. Nope. He used 1x2, 1/4" OSB, and finishing nails. At least the feeders were wrapped in bubble pack.

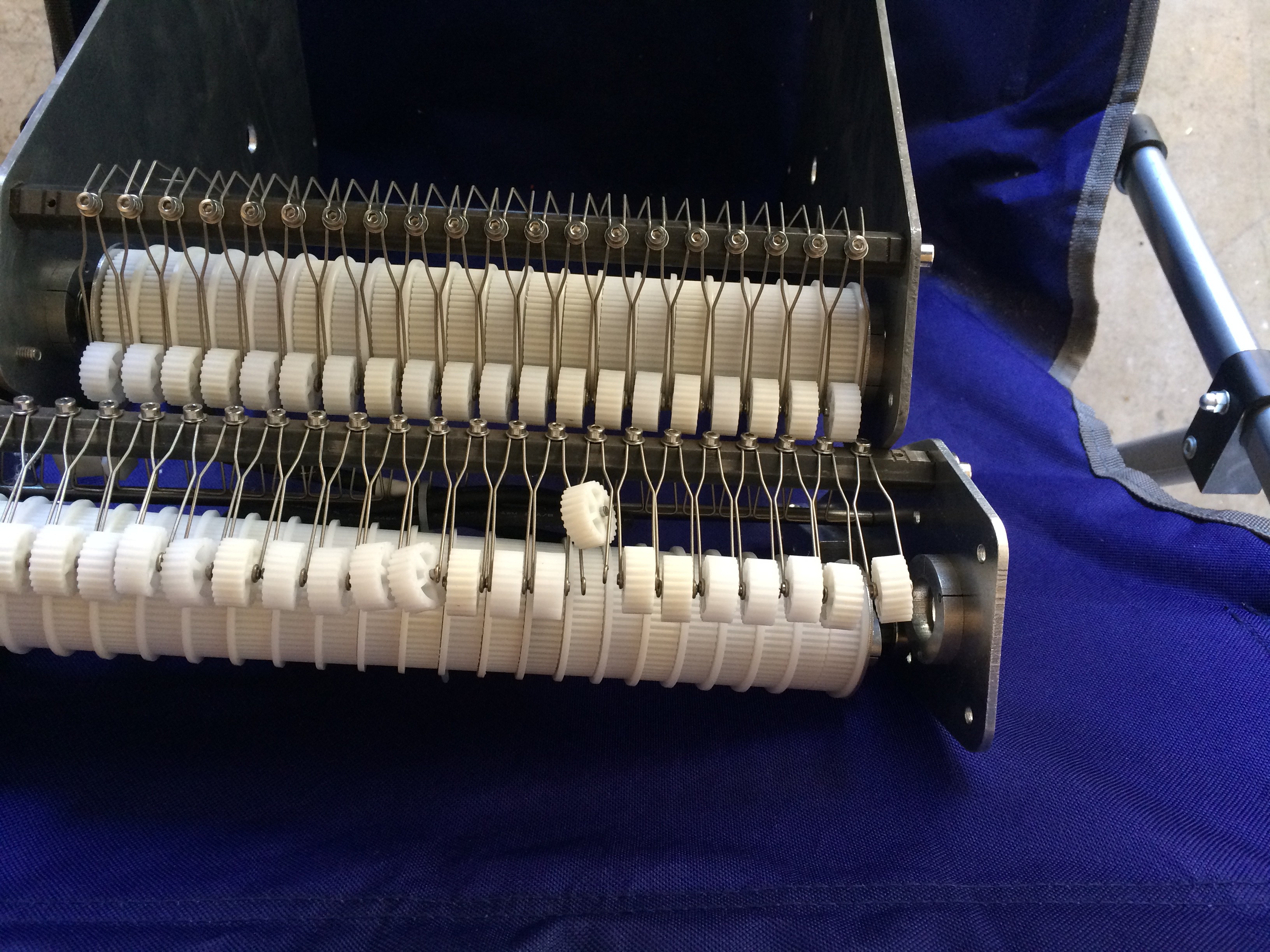

The lid came off during shipping, and I suppose everything tumbled out on to the loading dock or wherever. FedEx repacked and screwed the lid back on with drywall screws. Damage noted on Fedex release : hole punched in 1/4" OSB by the hard rubber foot on the unit (WHAM!!!) and a broken cable drag chain. That wasn't so bad. However, I found more serious damage after unpacking the feeders. One of the feeders was beat up pretty bad. The side plate was bent, the shaft bearing was popped out, and the pull tape tension springs were bent. It was repairable with vise grips and a little muscle, and carefully tweaking the tension springs back into shape.

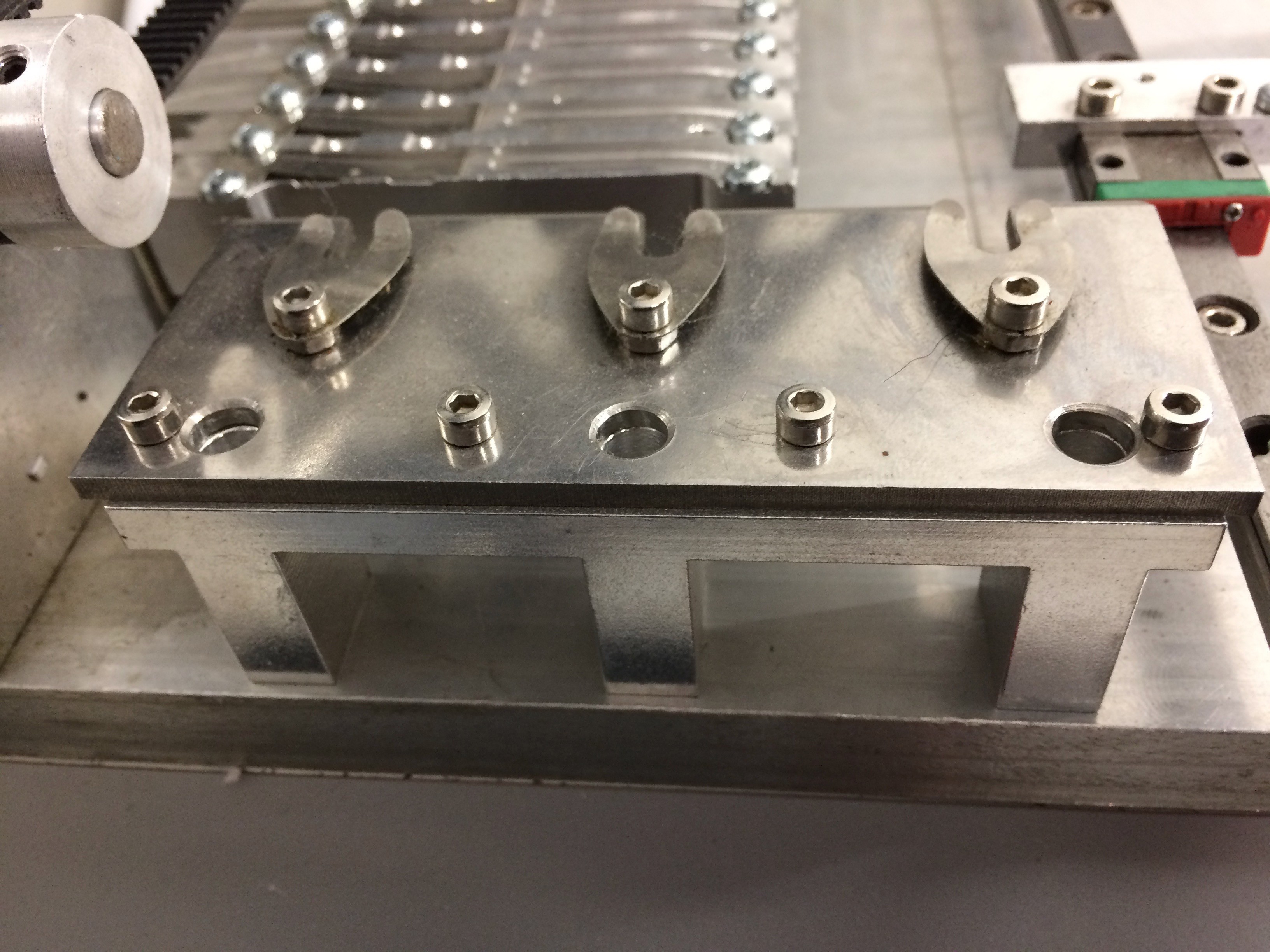

Slide Bearing Replacement

Much later, I discovered that one of the slide bearings was "sticking", presumably due to a damaged ball or race. I ordered a couple of new 16mm slide bearings from http://cncsuperstore.com/.

Bearing removal began with a bench vise and a ridiculous amount of upper body force. It chattered as it gave way, but then I ran out of room on the vise, so I finished using a spark plug socket and 3 lb sledge hammer. I also used a propane torch to gently heat the block, but I'm not sure whether that actually helped or not. It was a VERY tight interference fit. There are also set screws on the block, but clearly they weren't necessary. I'm going to ream the hole slightly to ease installation.

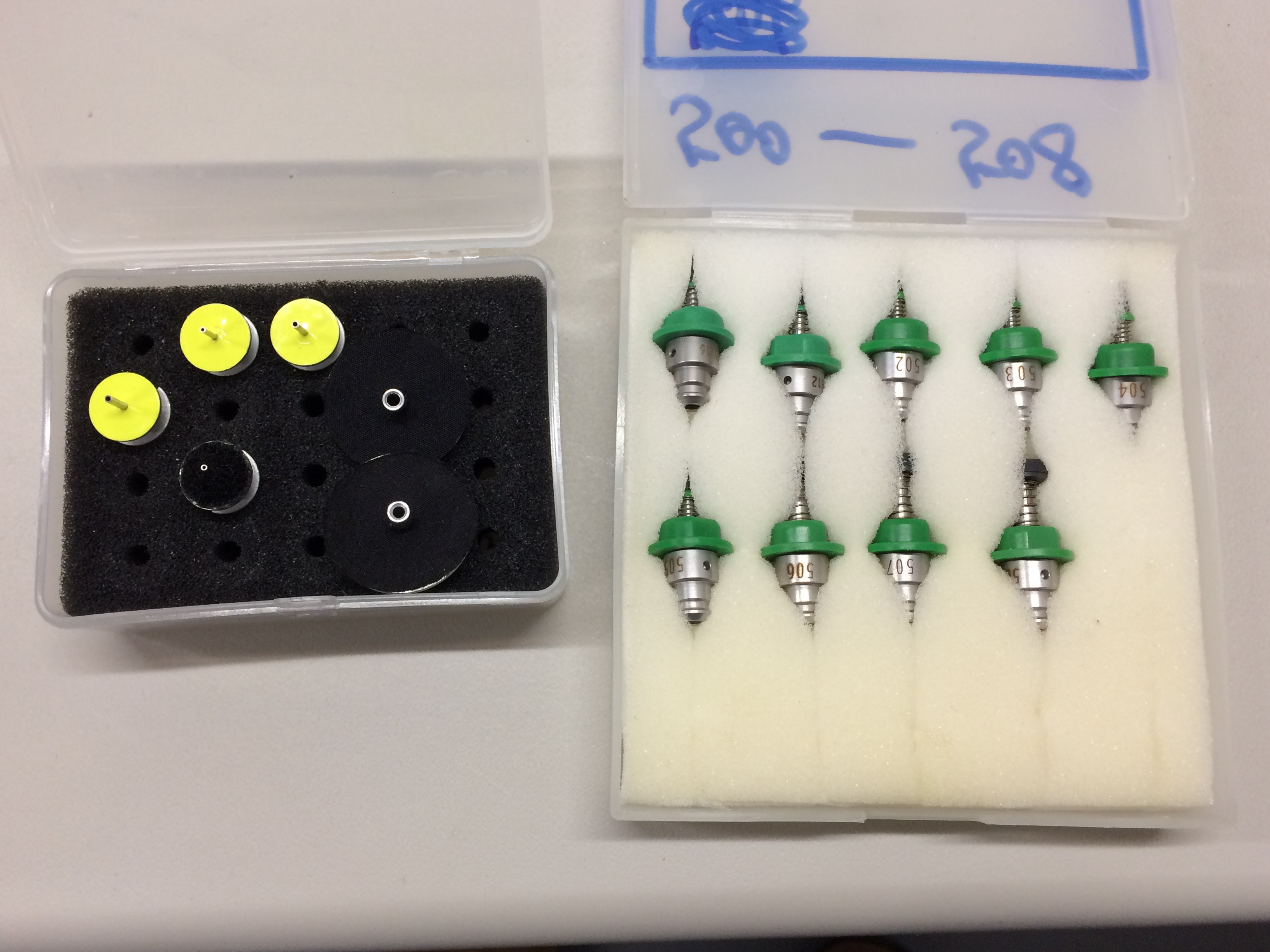

Juki Nozzles

Ordered a set of 9 Juki nozzles (500-508) from RobotDigg, $133, or roughly $15 a piece. OEM nozzles are on the left in the pic.

Modify Head Assembly to accept Juki Changer

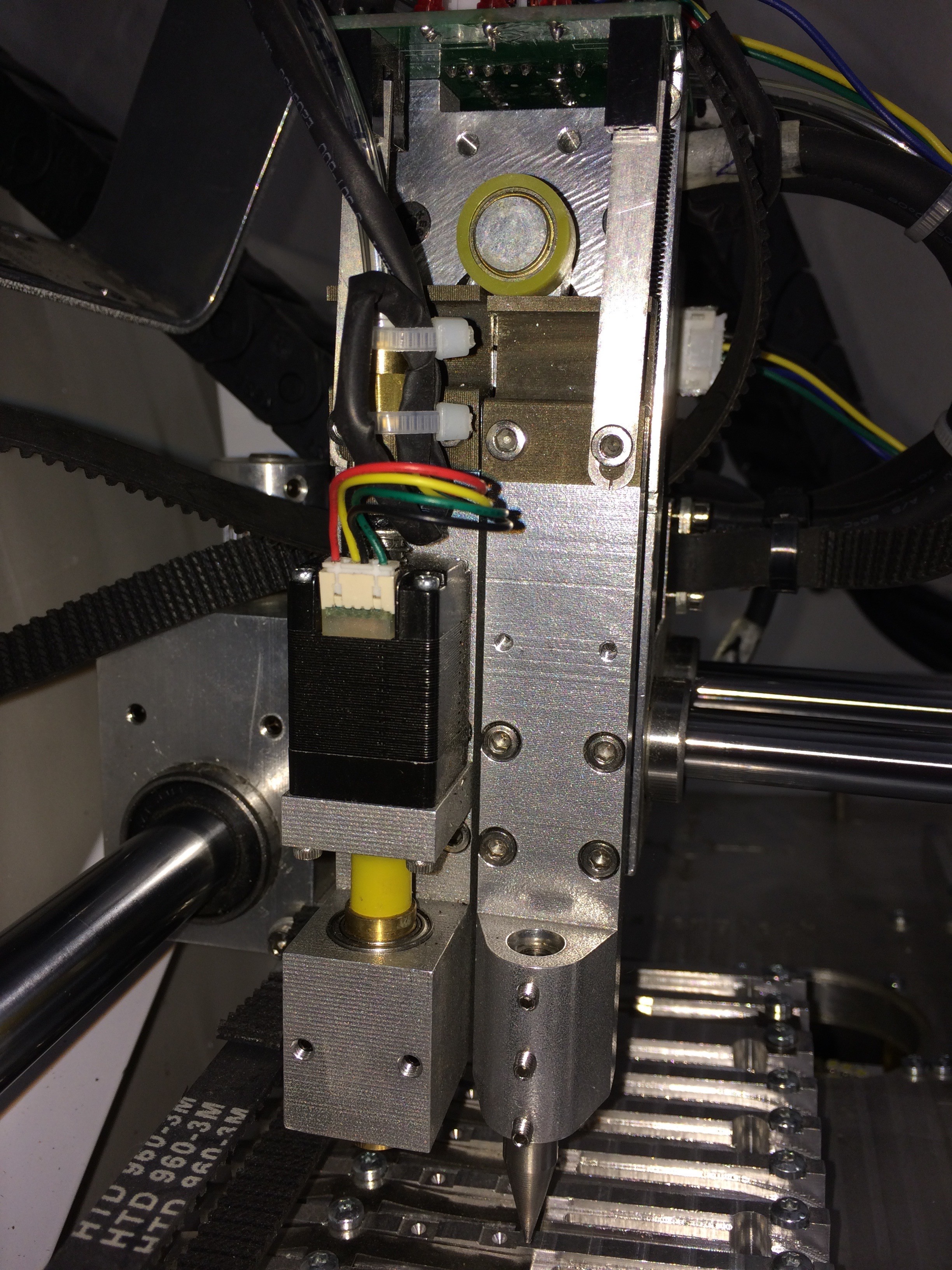

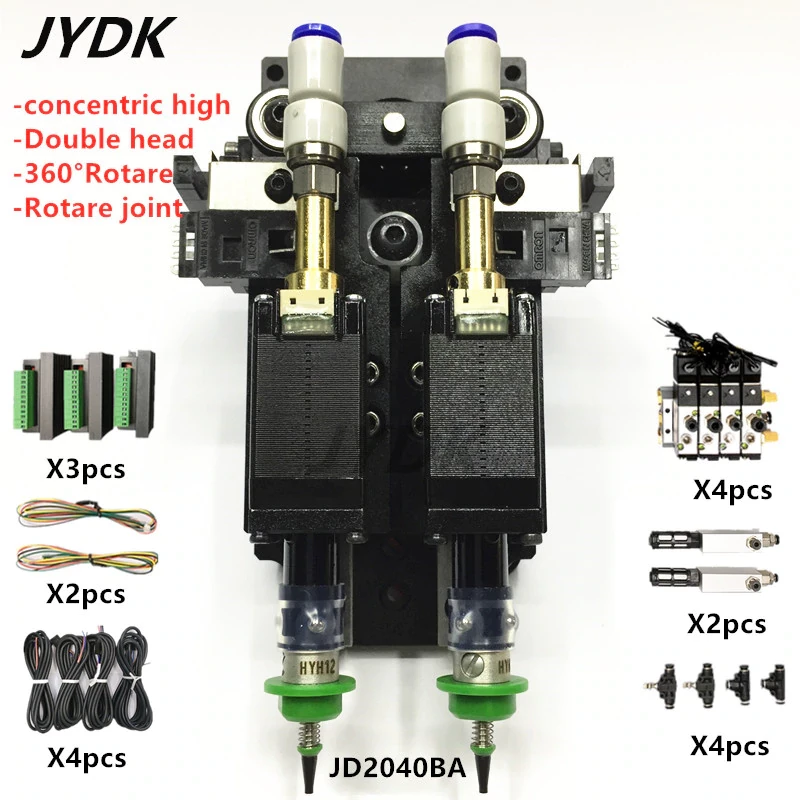

The lower part of the head assembly (below the yellow tubing in the picture) has a block containing a brass tube mounted in a pair of bearings, which extends the NEMA 8 stepper hollow shaft.

The bottom of the brass tube accepts the OEM nozzles, and incorporates an internal friction grip of some sort. I have ordered the Juki changer from:

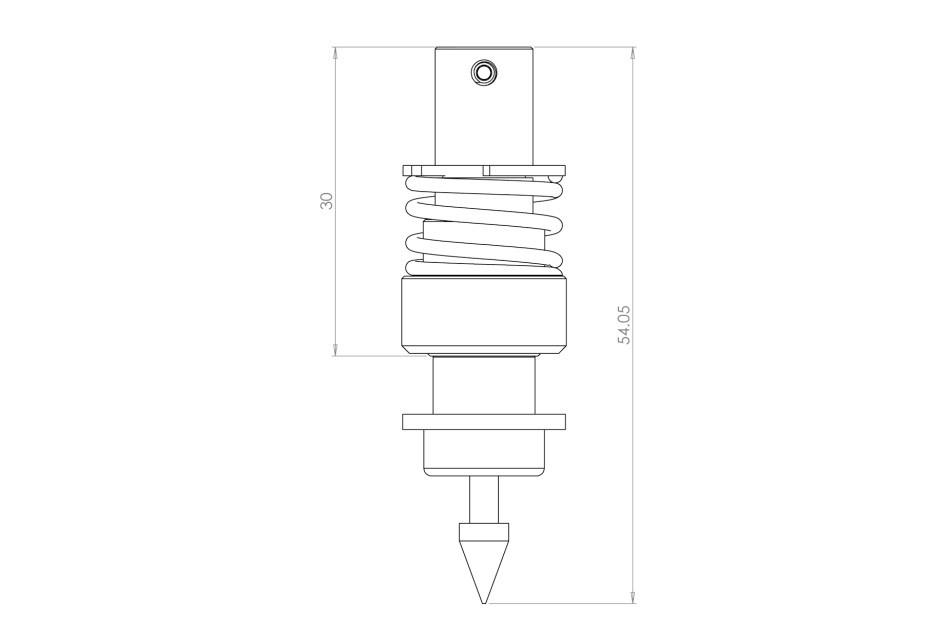

for $49.99 + $13 shipping (wtf, ouch) and will modify or eliminate the bearing block to accomodate it. Original setup is 57mm overall from bottom of the stepper body to nozzle tip (best I can measure with a cheapo 6" digital caliper). The Juki setup will be about 54mm, per the drawing. So it's a good fit, and in fact I might actually gain a couple of mm on max component height.

Nozzle Rack

Existing OEM nozzle rack:

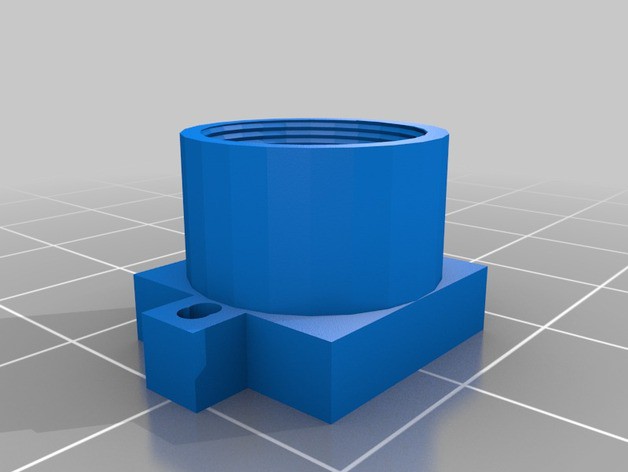

geniekobayashi 3d printed nozzle rack:

https://github.com/geniekobayashi/juki_nozzle_changer

0603 is the smallest technology I plan to use, so I'll use the 503-505 nozzles to support 0603 through 2512, that leaves 506-508, so 6 positions should be sufficient. Hopefully that will fit across the front without cramping the board area.

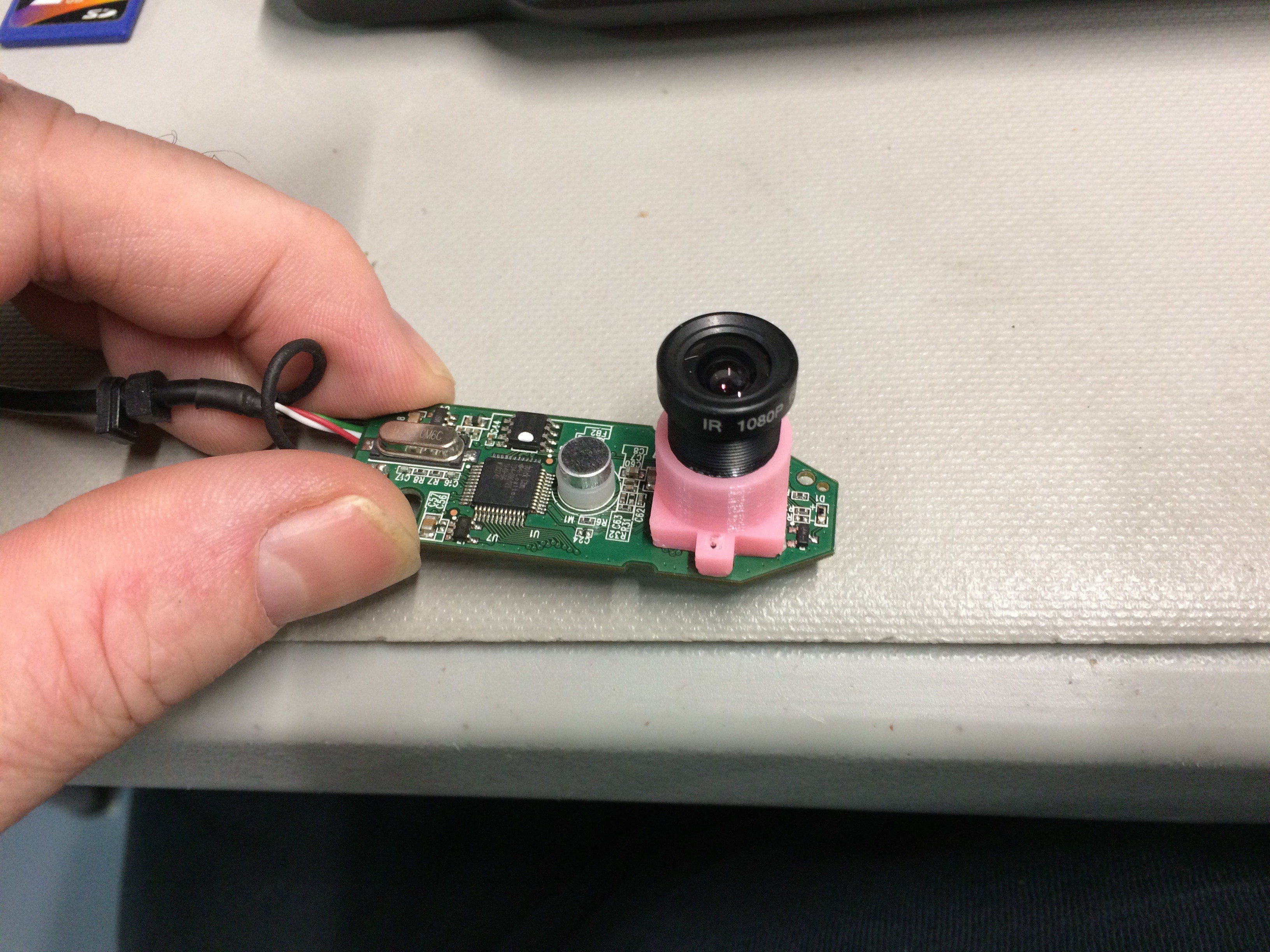

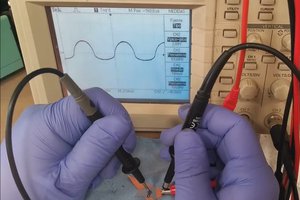

Vision Subsystem - New Cameras

The existing cameras were both analog. The video signals were routed to a small board where relays connected one of the signals to the external RCA connector under PC control. This, in turn, fed into a no-name video capture dongle, then on to the host PC USB port. Geez, what a pile of crap.

ELP-USB100W04H-L36, $43

H.264, 720P, 30 fps, M12 (S-mount) lens

Logitech C270, $21

720p

The PCB will be removed from the plastic enclosure, and a 3d printed adapter will allow use of an M12 (S-mount) lens. https://www.thingiverse.com/thing:1376200

Hizek Inspection Camera, $9.99

640x480, built-in LED illumination.

This could make a nice top camera, but would...

Read more » Darryl.N

Darryl.N

anthony.webb

anthony.webb

MasterOfNull

MasterOfNull

Nixie

Nixie

Alastair Young

Alastair Young