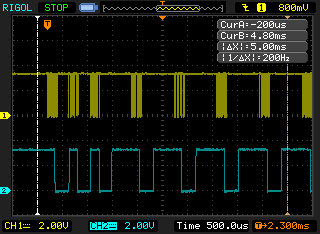

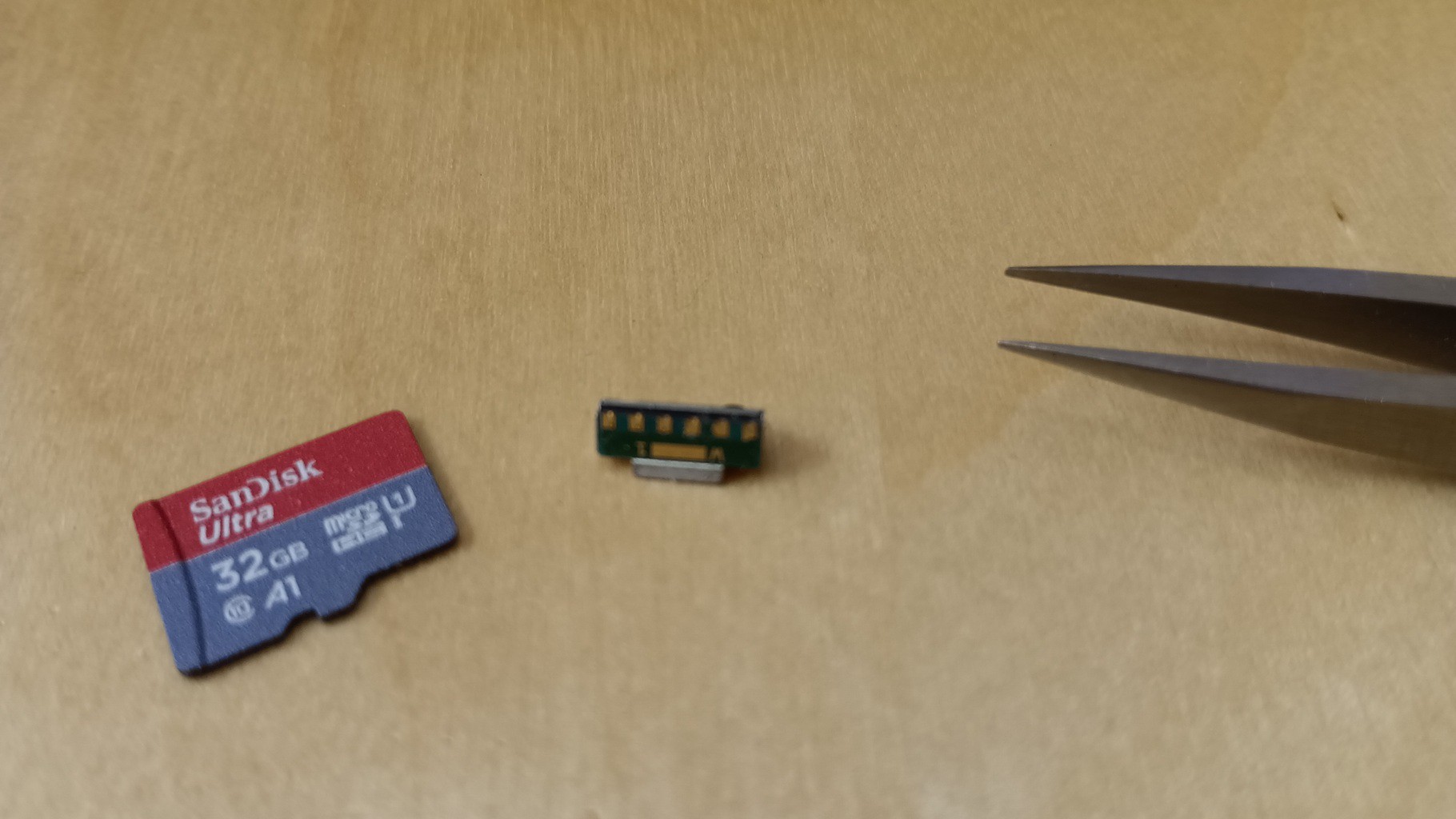

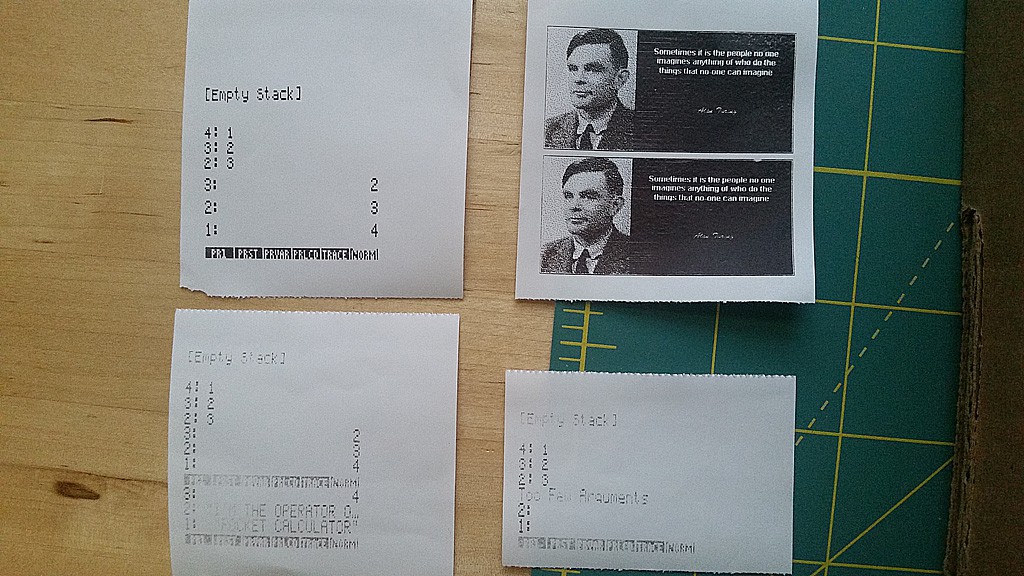

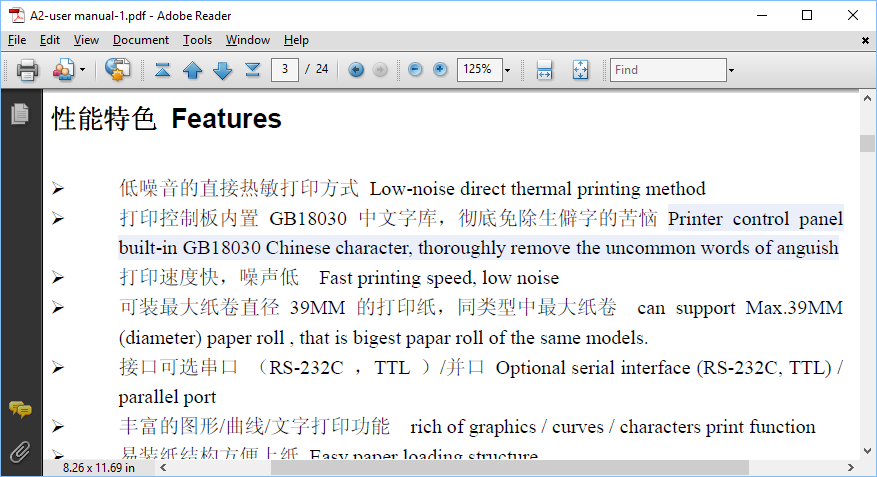

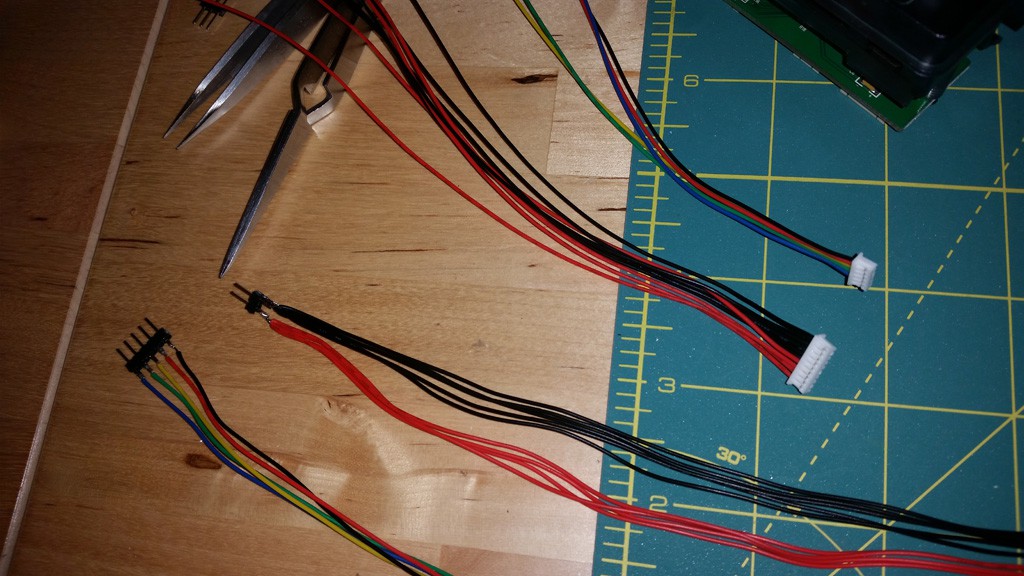

Many folks that use HP calculators of yore like to be able to use the infrared printer. These printers are really expensive given what they are, and some folks in a separate forum wondered if a workalike could be crafted from cheap printer cores from China. I thought they could be created from a POS printer core and using the famous 'Blue Pill' development board as the interface. Since I had coincidentally just implemented the generation of the related IR protocol, I was freshly familiar with how it works, so on a lark I am now attempting this interface.

It's all in the name of fun, really. I'm expecting that the total cost of this printer knockoff will be about usd$30 as described here (e.g. there is no case to speak of, just rubber band the board to the printer!) The printer new (NOS) costs a ruinous $200 or so, but you can typically find them on eBay used for about $50, so I don't know that this will be particularly cost effective relative to a polished commercial production, but who knows, it might be of interest to someone. And the infrared-to-serial/usb part could be interesting in some as-yet unimagined way.

ziggurat29

ziggurat29

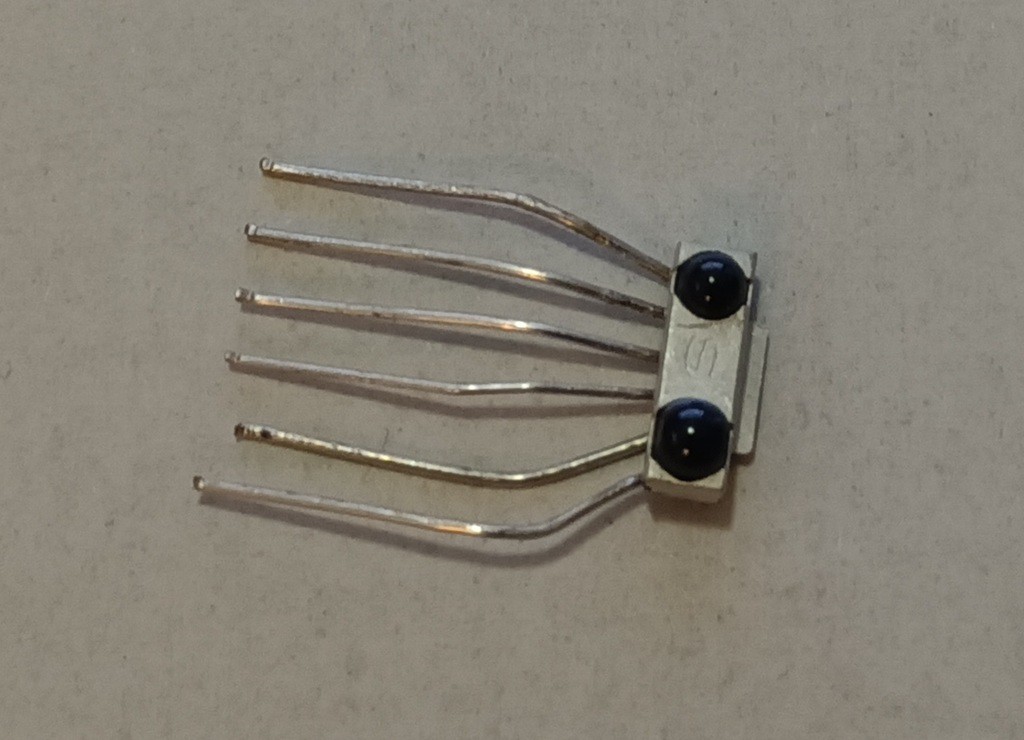

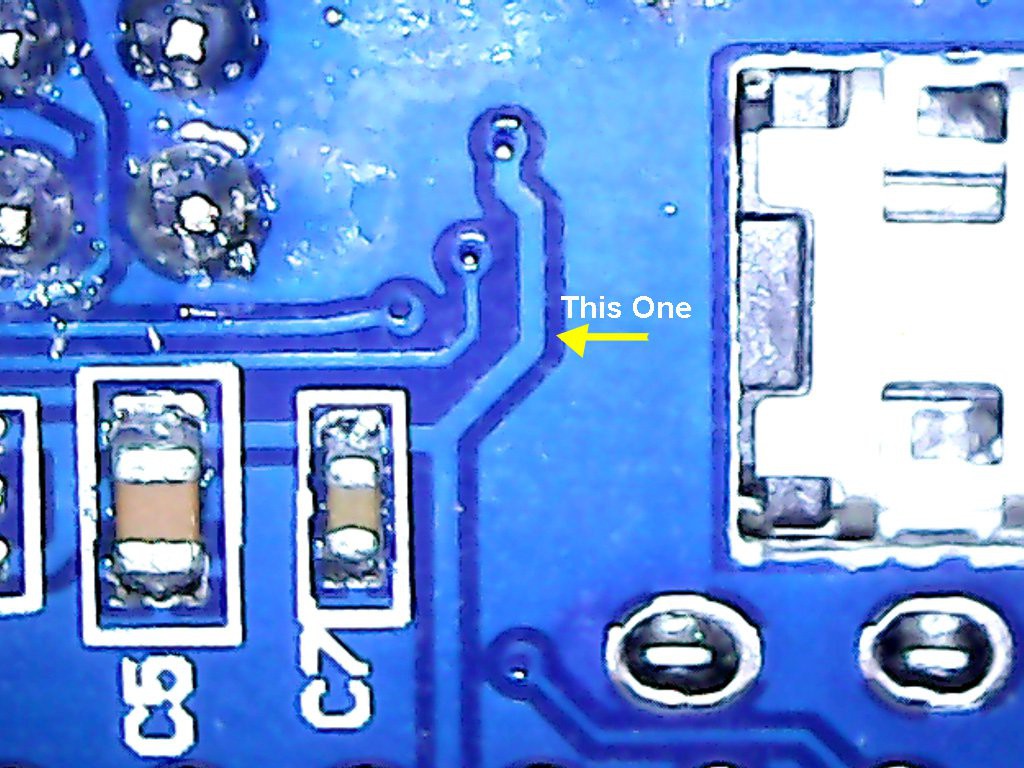

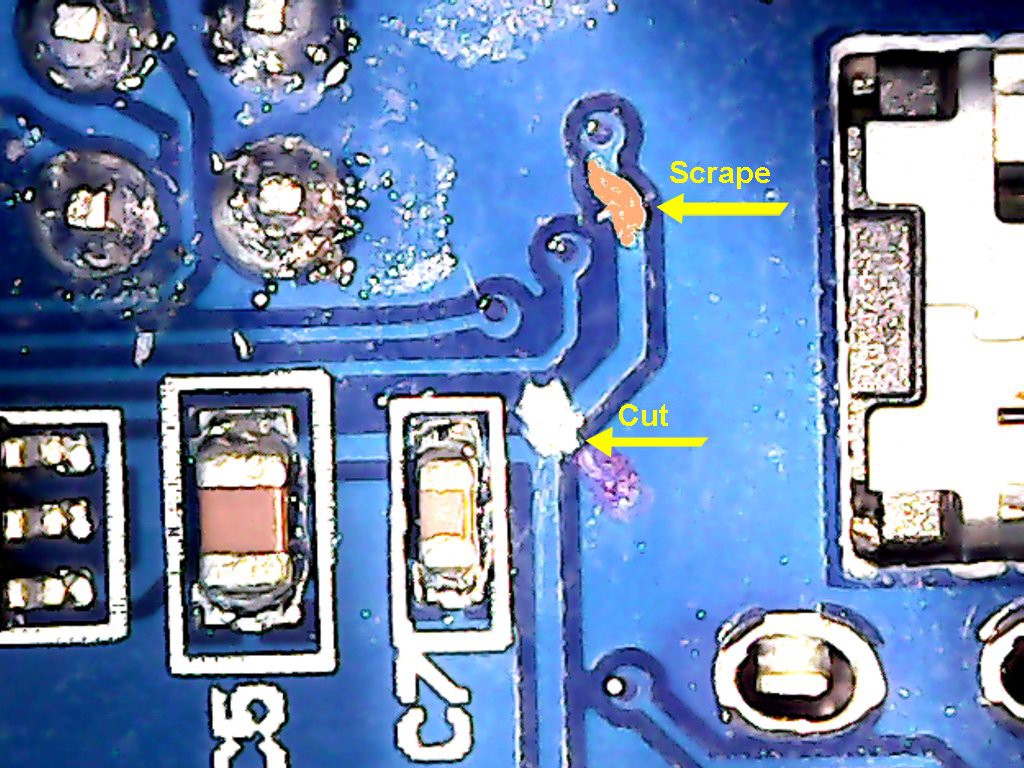

Excellent work! The description of how you overcame the faulty demodulated output of the IR receiver was stupendous. Especially since I'd just been reading on HP forums that the TSOP4133 "won't work" due a lengthy minimum post-burst period. Your writing is fun too!