PROBLEM :

Many industrial applications involve checking for flaws in places where worker cannot act due to immense heat, toxic gases & limited space. Hence it is essential to monitor such parameters in high value engineering sectors such as electrical substations and chemical sectors such as oil and gas power plant in order to protect human health and environment, and in certain cases preventing accidents.

Even though tools exists they at bulky, heavy and highly unyielding which consumes a lot of time and energy during an emergency. Also, there is a lack of thermal camera in our country and the existing ones are a bit costly (1000$).

In case, a fire accident occurs it would be very difficult for the fire fighters to locate the injured people in the plant.

EXISTING SYSTEM :

1. DAQRI Smart Helmet

Pro's :

- Augmented Reality based Thermal Vision

- Provides guided work information

- Wearable

Con's :

- Expensive in comparison to other solutions

- Difficult to reach critical areas

2. Electrical Substation Inspection Robot

Pro's :

- 360° pan-and-tilt positioner

- Autonomous Vehicle Control System

Con's :

- Detection of gas is not possible ( Requires additional system )

- Large size ( 54''x32''x62'' )

Background:

I, Varun, a final year engineering student from Chennai, India. I've always been into Robotics and combining electronics and Product Design.

Inspired after watching the movie ' The 33 ', I realized the hurdles and challenges faced by Industrial Workers in critical areas. Speaking to a Miner personally, I realized that they mostly require an assistive device to help them if the situation goes critical. Hence, I build up an AR based helmet for Miners to record the site Temperature and Gas content. While presenting this idea to Mr. Kshir Sagar, a Senior Manager in Fire & Safety Department at CPCL ( Chennai Petroleum Corporation Limited ), he gave a positive feedback and few ideas for making this better.

After seeing the unbelievable progress in Machine Learning for the past few years, empowering Industrial Workers with Machine Learning for fault detection and testing is my current goal. Along the way I've read statistics on number of fire accidents that occur in chemical power plants and hence I wanted to do my path. I've also been seeking help from industries to make this dream, a reality.

OUR SOLUTION :

SafeRanger

We propose a novel solution that could possibly enhance the current industrial safety protocol.

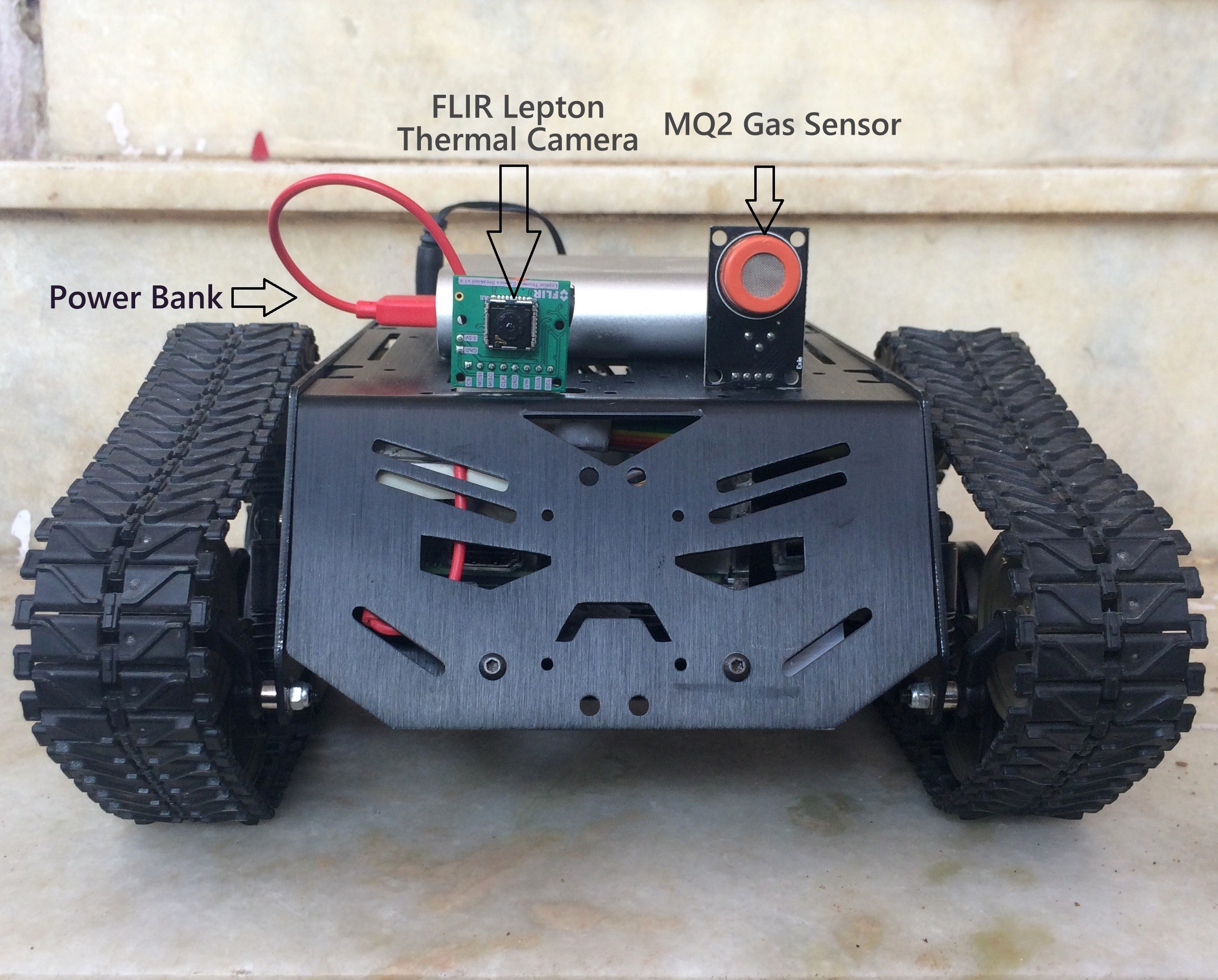

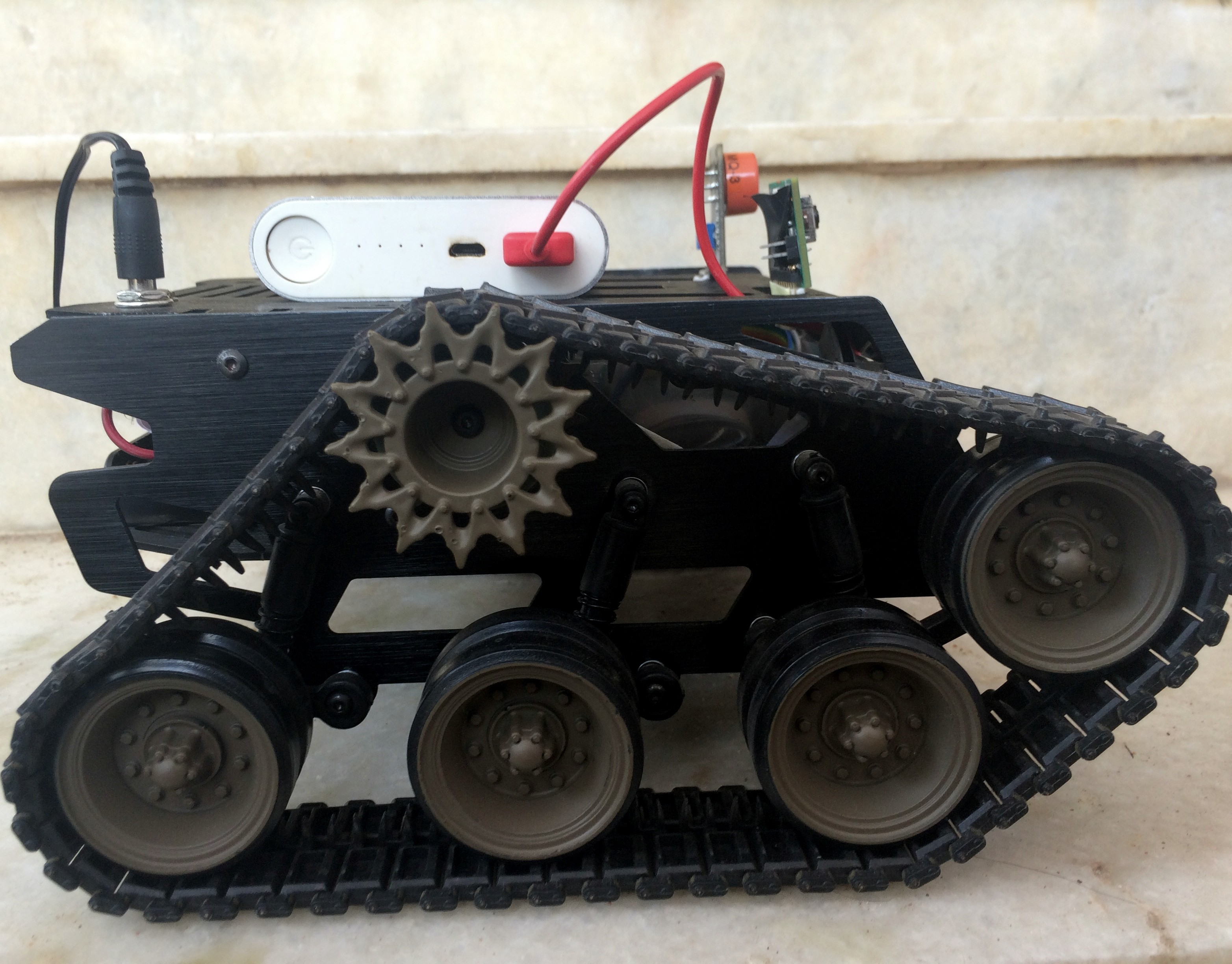

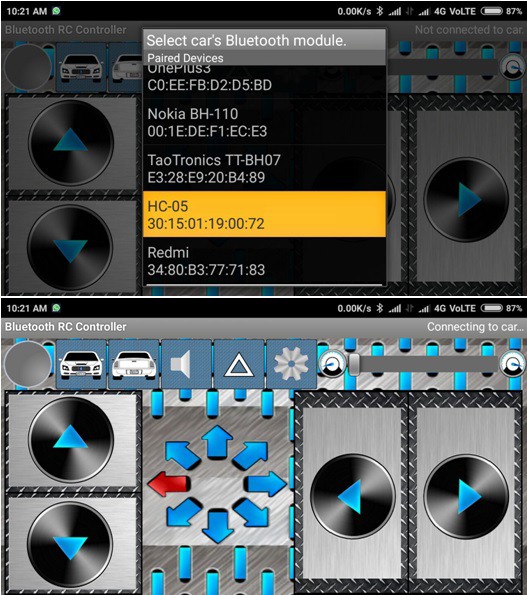

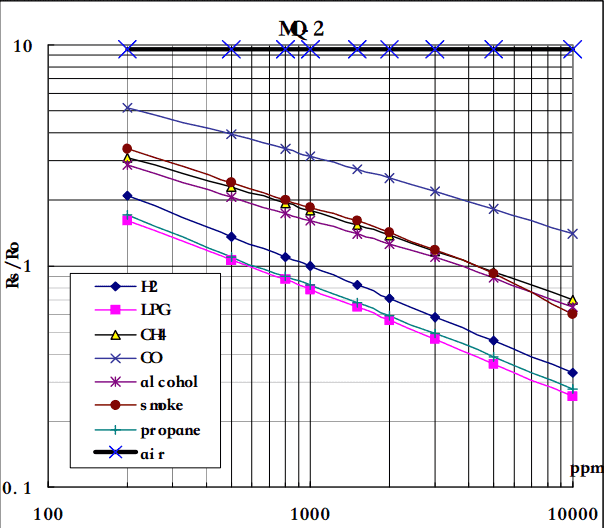

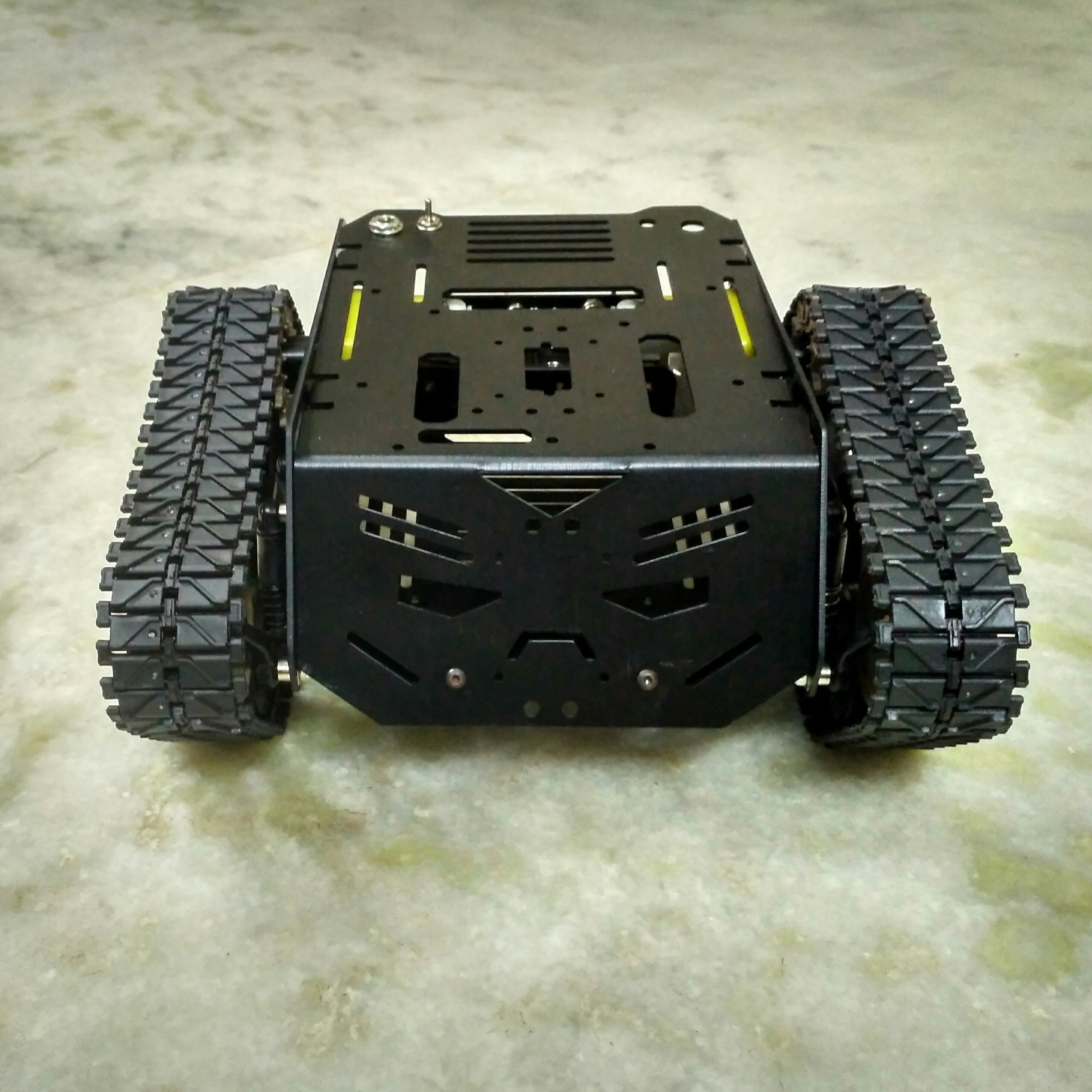

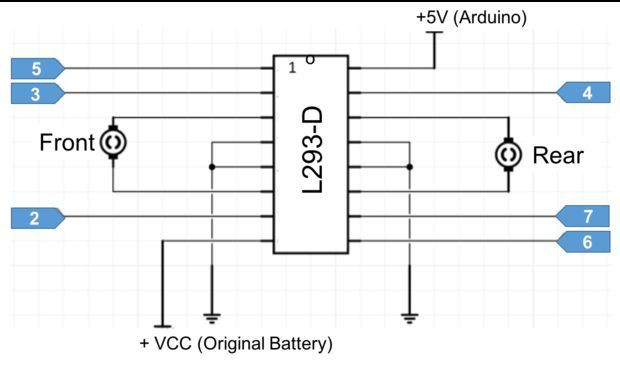

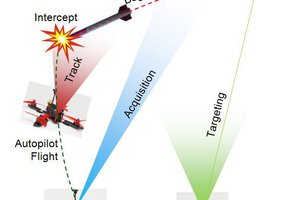

A semi-autonomous miniature multi-spectral diagnostic wireless controlled tank based rover which can monitor thermal characteristics of valves using Thermal Camera and monitor gas leaks in oil and gas power plants.

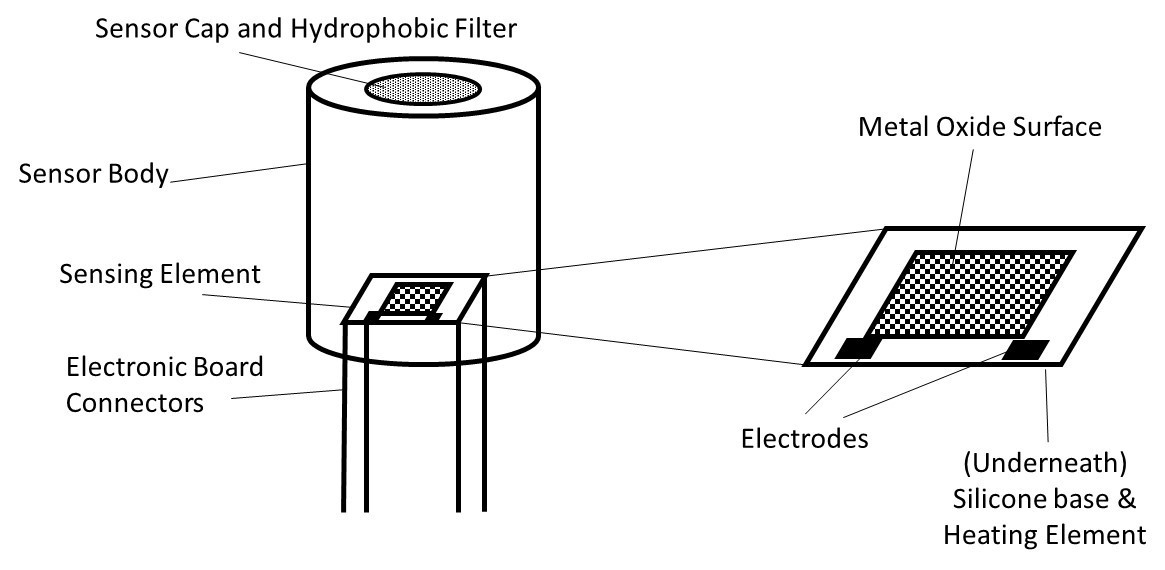

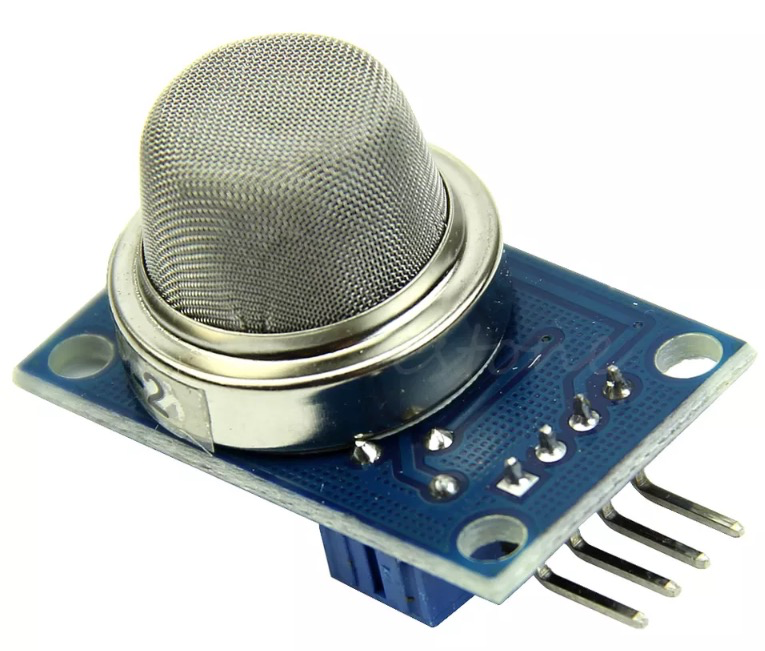

It is designed to be modular to add custom sensors with it. Currently, it houses a thermal, visual camera along with a gas sensors.

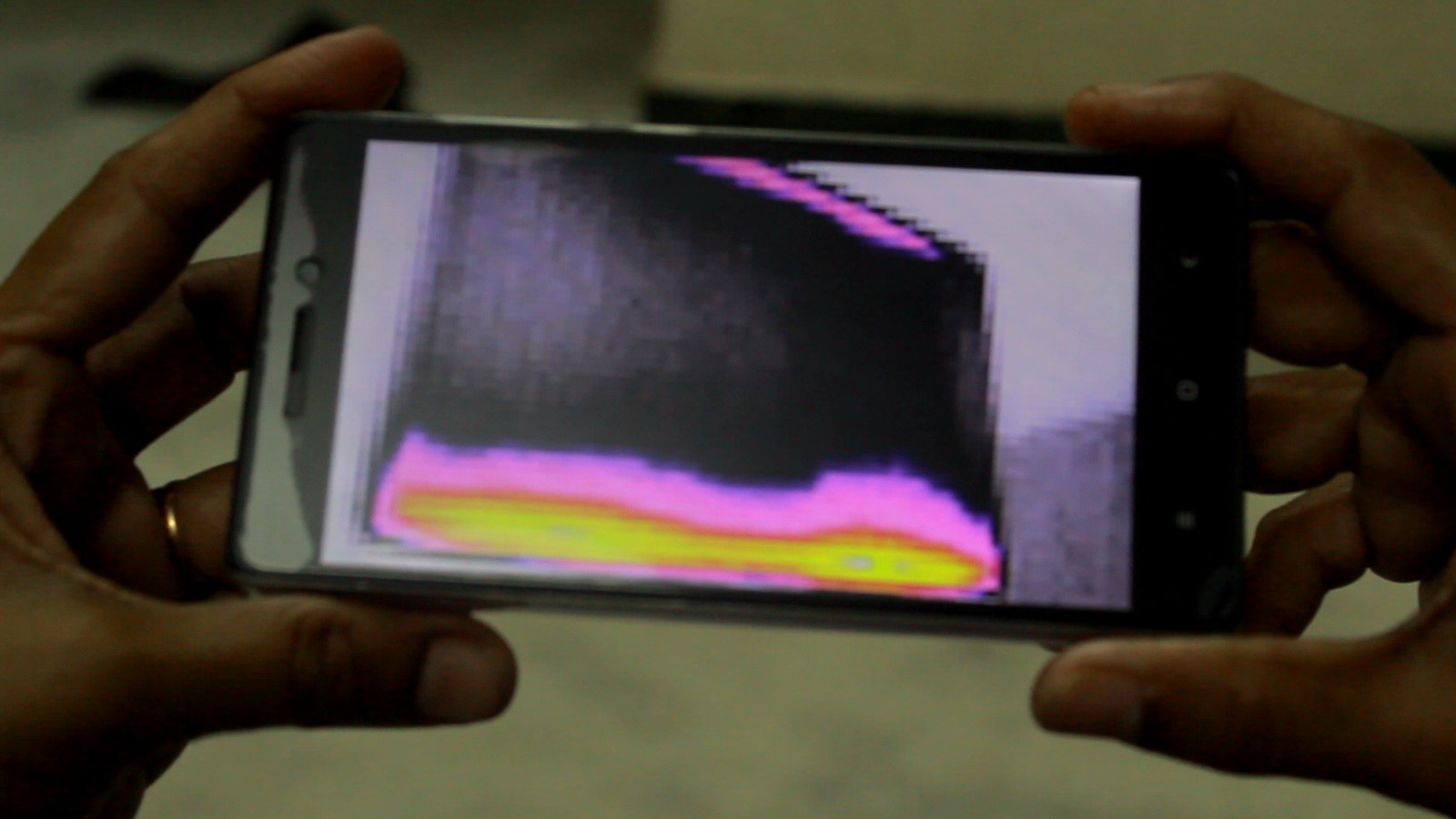

If an abnormal temperature is detected, the IR Image Processing system identifies an inappropriate heat which in turn sends the thermal data to the control centre through VNC, a Wi-Fi server with which alerts or guidance can be in turn provided to the technician, so that necessary steps can be taken.

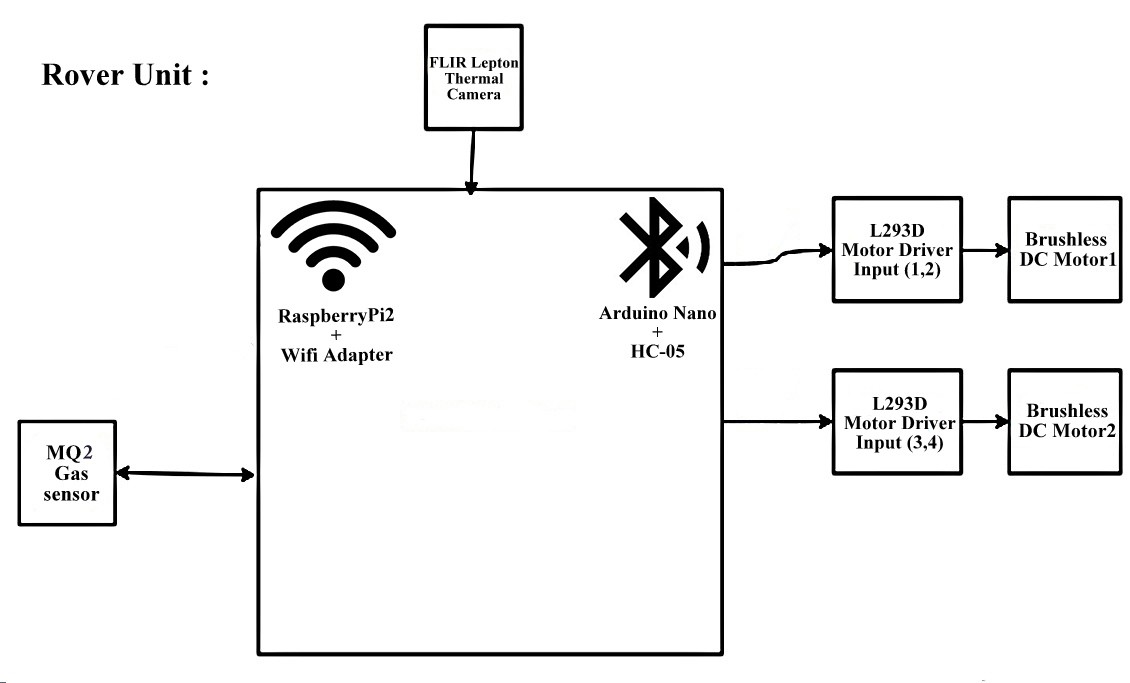

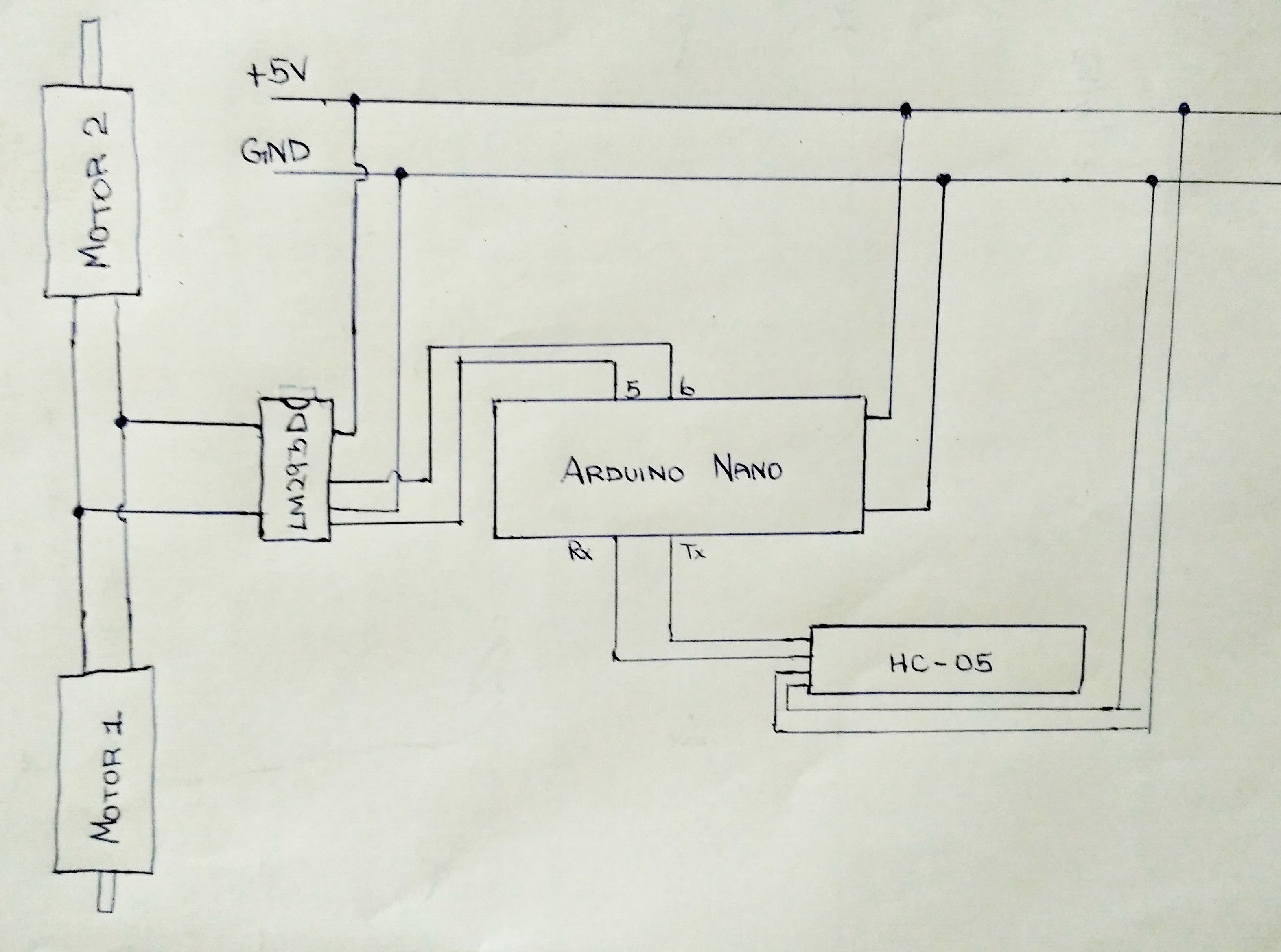

Block Diagram :

System Design :

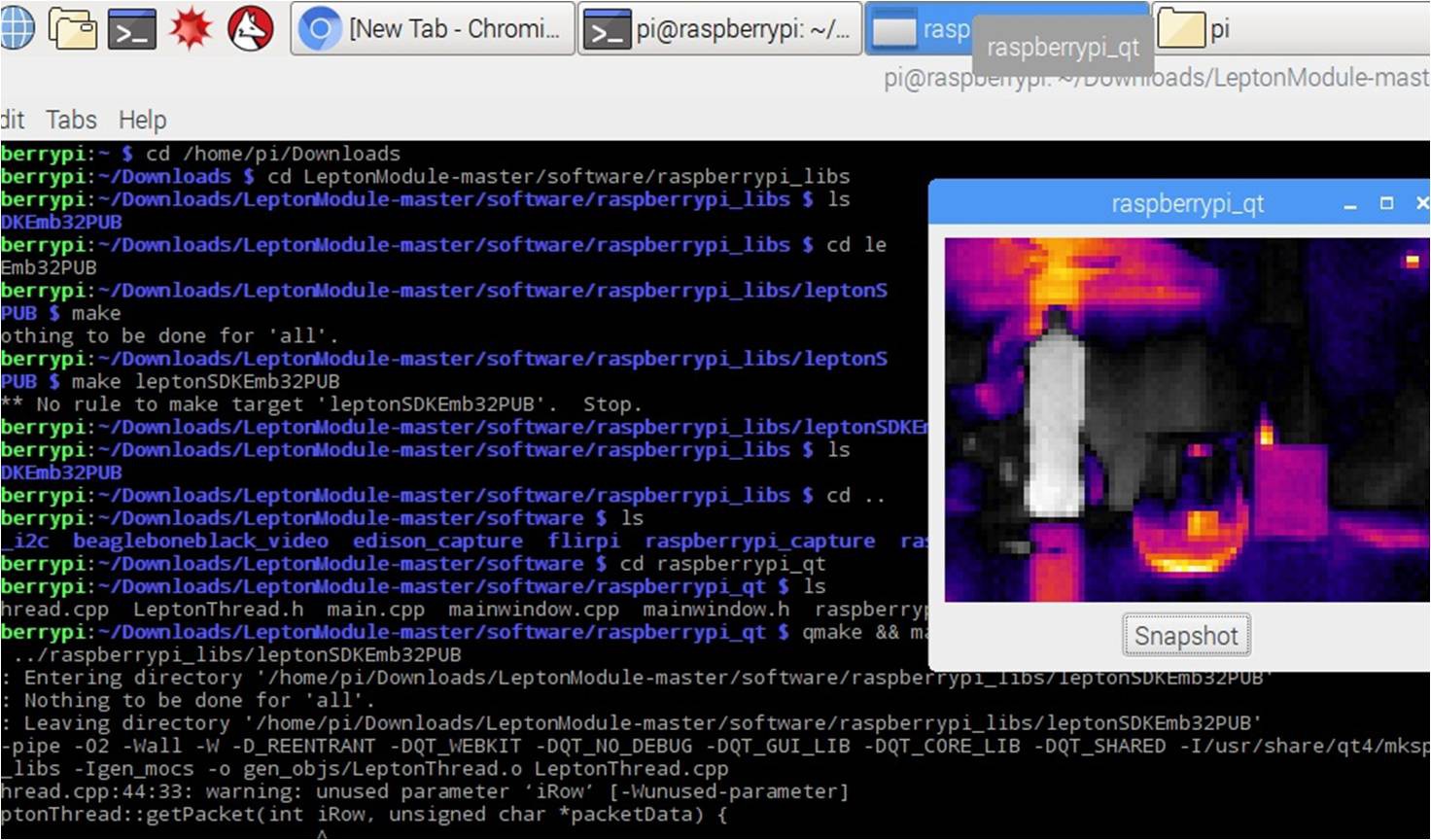

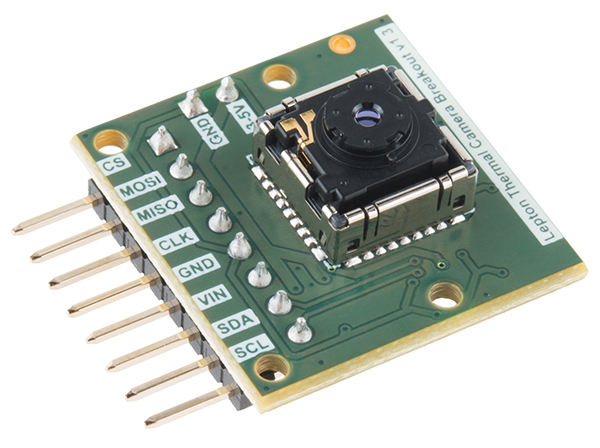

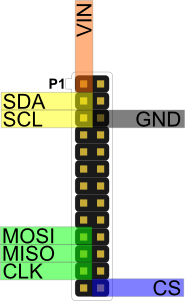

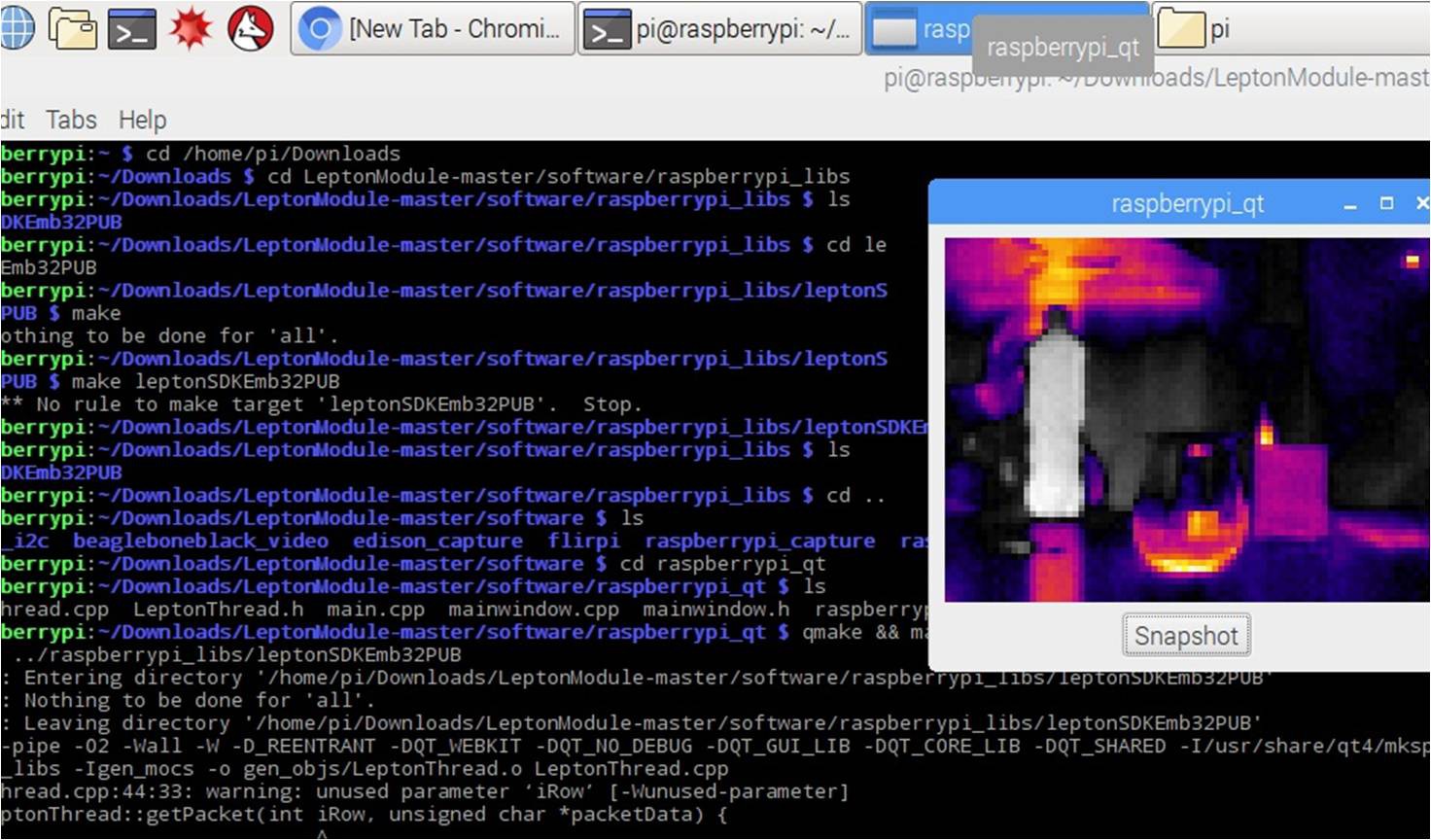

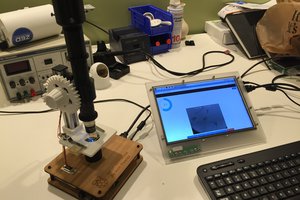

Setting up FLIR Lepton with Raspberry Pi

Once the connections are done, move to the software part :

- Install Raspbian OS from NOOBS on your Raspberry Pi

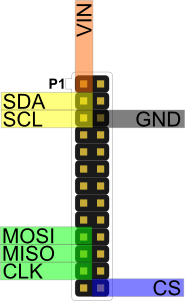

- Enable SPI and I2C interfaces

- Download and Install QT4 Dev Tools

- Go to the Pure Engineering and retrieve the raspberrypi_video directory

- Unzip the Raspberry Pi video directory ( LeptonModule-master ) and raspberrypi_video

- "make" Lepton SDK, so into the “LeptonSDKEmb32PUB” directory and run cd "make”

- Get back out to the “raspberrypi_video” directory and run "qmake && make"

- Type sudo ./raspberrypi_video in your command line

And, Voila :) Thermal images will start pouring out.

Setting up VNC with Raspberry Pi

Now, that's not over. In order to visualize the thermal data remotely, it is necessary to install VNC Server ( Virtual Networking...

Read more » Varun Suresh

Varun Suresh

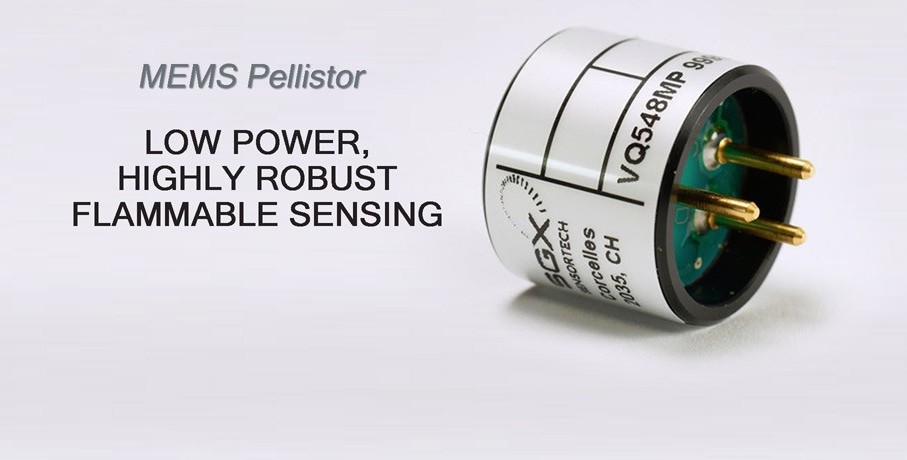

In future, I plan to work on detecting more specific gases using MEMS based Pellistor sensors which are more specifically used for industrial grade sensing.

In future, I plan to work on detecting more specific gases using MEMS based Pellistor sensors which are more specifically used for industrial grade sensing.

Raspberry Pi is a core component of our system. I wanted to use the Raspberry Pi in this project because it is a miniature computer, designed for education which has more functions for a very reasonable price. I used Raspberry Pi micro-controller to program Thermal camera and Gas Sensor. FLIR Lepton Thermal Camera is connected to Raspberry Pi using I2C interface.

Raspberry Pi is a core component of our system. I wanted to use the Raspberry Pi in this project because it is a miniature computer, designed for education which has more functions for a very reasonable price. I used Raspberry Pi micro-controller to program Thermal camera and Gas Sensor. FLIR Lepton Thermal Camera is connected to Raspberry Pi using I2C interface.

VNC :

VNC :

Ray

Ray

Curt White

Curt White

eelco.rouw

eelco.rouw

Hi there Perry here.

I have been working in the Industrial sector for over 25 year.

And I have been working on the same type of robot in my head for many years.

On of the main problems has always been communication to the robot.

I have found out over the years if that the radio does not work very good at all.

If you want a goof robot you are going to have to use multiple communication systems.

Start with the fastest then you are going to have to drop down till you even lose the picture.

Ive been looking at starting the easiest Witch I think is WIFI down to 433 mhz.

with everything else you can think of.

For video I've tried WIFI in construction sites to find out the range is line of site. so you lose site you lose video.

Then I tryed 2.4ghz and 5.8ghz. The 2.4 did work better but not buy much..

Good luck on everything. My fleet of robots will be starting shortly. I,m retired now not by choice. But I am trying to make the best of it.