-

1Laser cutting

The chassis can be laser cut from 3 materials each with their own pro's and con's:

- Acrylic - Looks good and is affordable but extremely brittle and easy to break.

- Plywood - Cheap, strong and can easily be modified but some people think it looks less attractive.

- Polycarbonate - More expensive than acrylic but not brittle.

I personally would recommend using plywood as it is more robust and can easily be hacked by students wanting to modify their robots.

If you do not have access to a laser cutter there are several companies who offer laser cutting services for very reasonable prices online. I have included a ready made file for Razorlab. The design fits onto their P1 size sheets and will set you back ~£11.50 for a plywood E.R.N.I.E, although I am sure in bulk the price would decrease. Be sure to use 3mm thick material

-

2PCB Manufacture

I highly recommend getting professionally manufactured PCBs from one of the many Chinese PCB fab houses. I used Elecrow and got 50 boards produced for £22.57 (45p a board!). If you would like to recreate the exact boards I got made you can simply visit this page and enter the following settings:

- Layer - 2

- PCB Thickness - 1.6mm

- Copper Weight - 1oz 35um

- PCB Size - 10cm Max * 10cm Max

- PCB Color - Black

- Suface Finish - Hasl (lead free)

- PCB Stencil - NO Stencil

- Panelizing - 2-5 copies

- Lead time - Shipped in 4 to 7 days

The zip file you need to attach can be found here

-

3Wheel Prep

Each kit needs 3 wheels, two of which need to have their hub enlarged to 5mm. This can be done very easily on a drill press running on a slow speed or by hand with a drill bit.

-

4Assembly Step 1

Solder stranded wire onto the motors. The wires should be around 20cm long. If in doubt, cut the wire longer, you can always cut it down later.

-

5Assembly Step 2

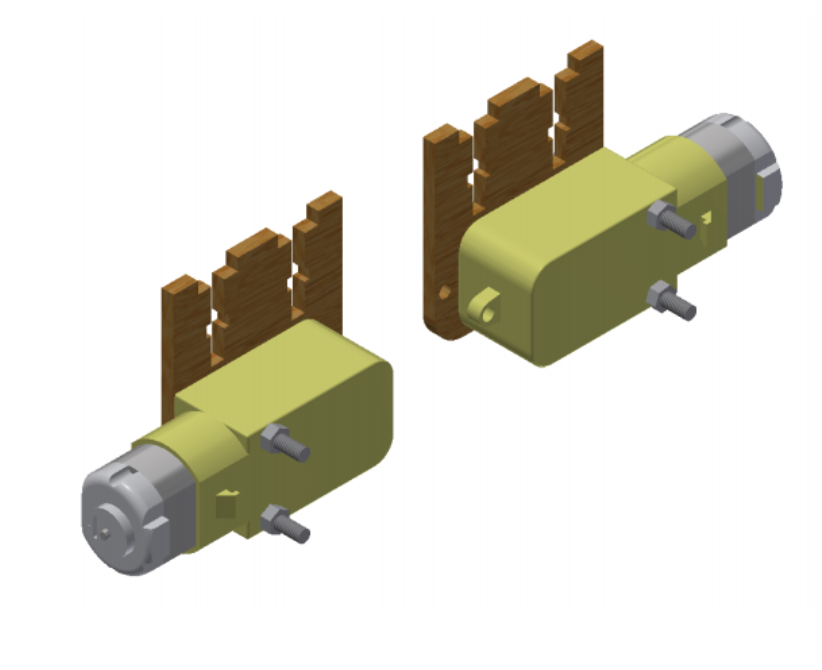

Attach the motor to the mount using the (longer) 30mm screws:

![]()

Repeat this for the second motor but this time mirrored. The end result should look like this:

![]()

-

6Assembly Step 3

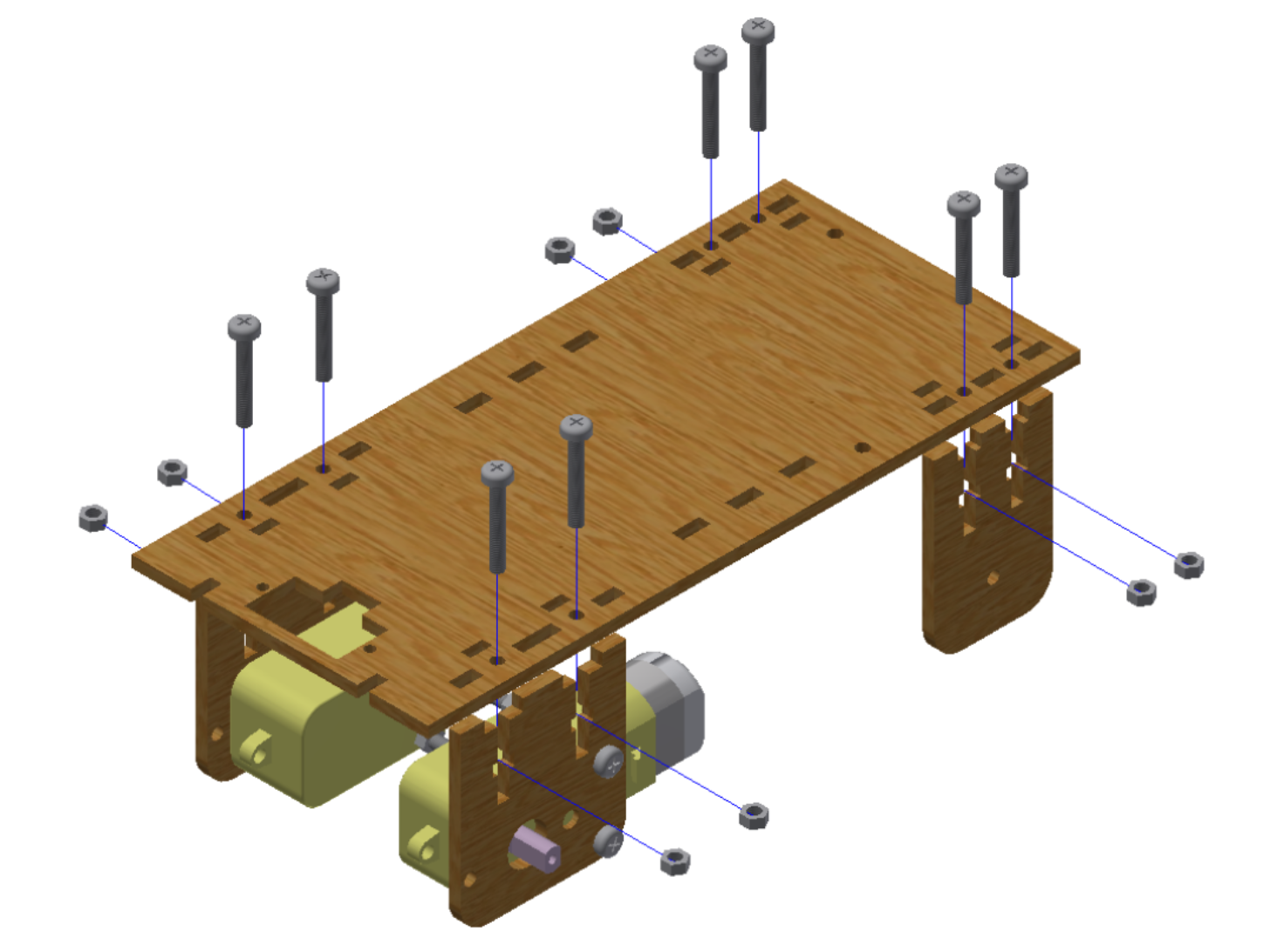

Attach the motor and axle mounts to the base plate using the 20mm screws:

![]()

NOTE: Do not over tighten the screws if using acrylic. Acrylic is a very brittle plastic and will crack easily if too much force is applied. Do not worry if the mounts have a little bit of movement in them, this will not affect the robot’s functionality.

-

7Assembly Step 4

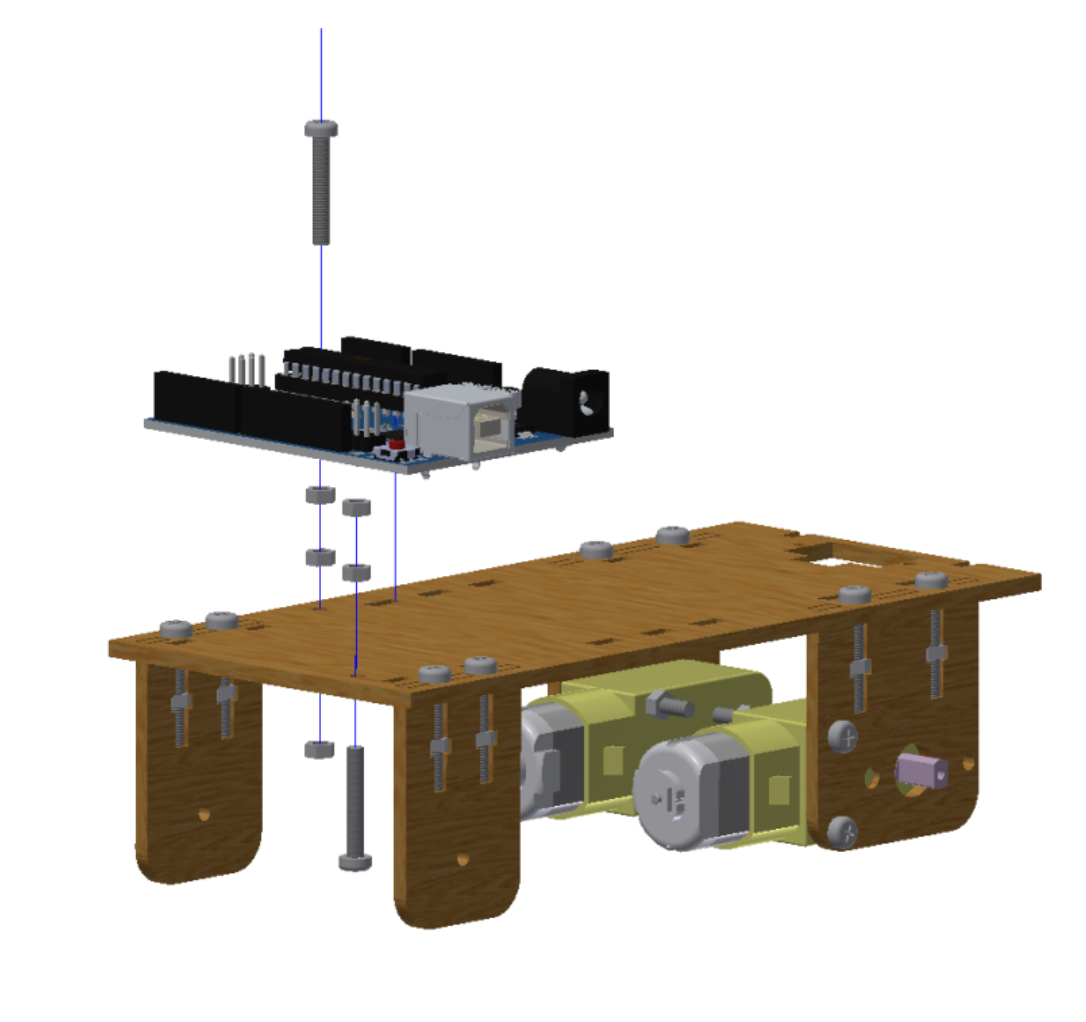

Mount the Arduino to the base plate using 2 nuts as a spacer. Note that the front screw goes from the bottom and the back screw from the top:

![]()

-

8Assembly Step 5

Apply electrical tape around the rear wheel (the one with the smaller hole). This is so that the back wheel can easily slide around when the robot turns.

-

9Assembly Step 6

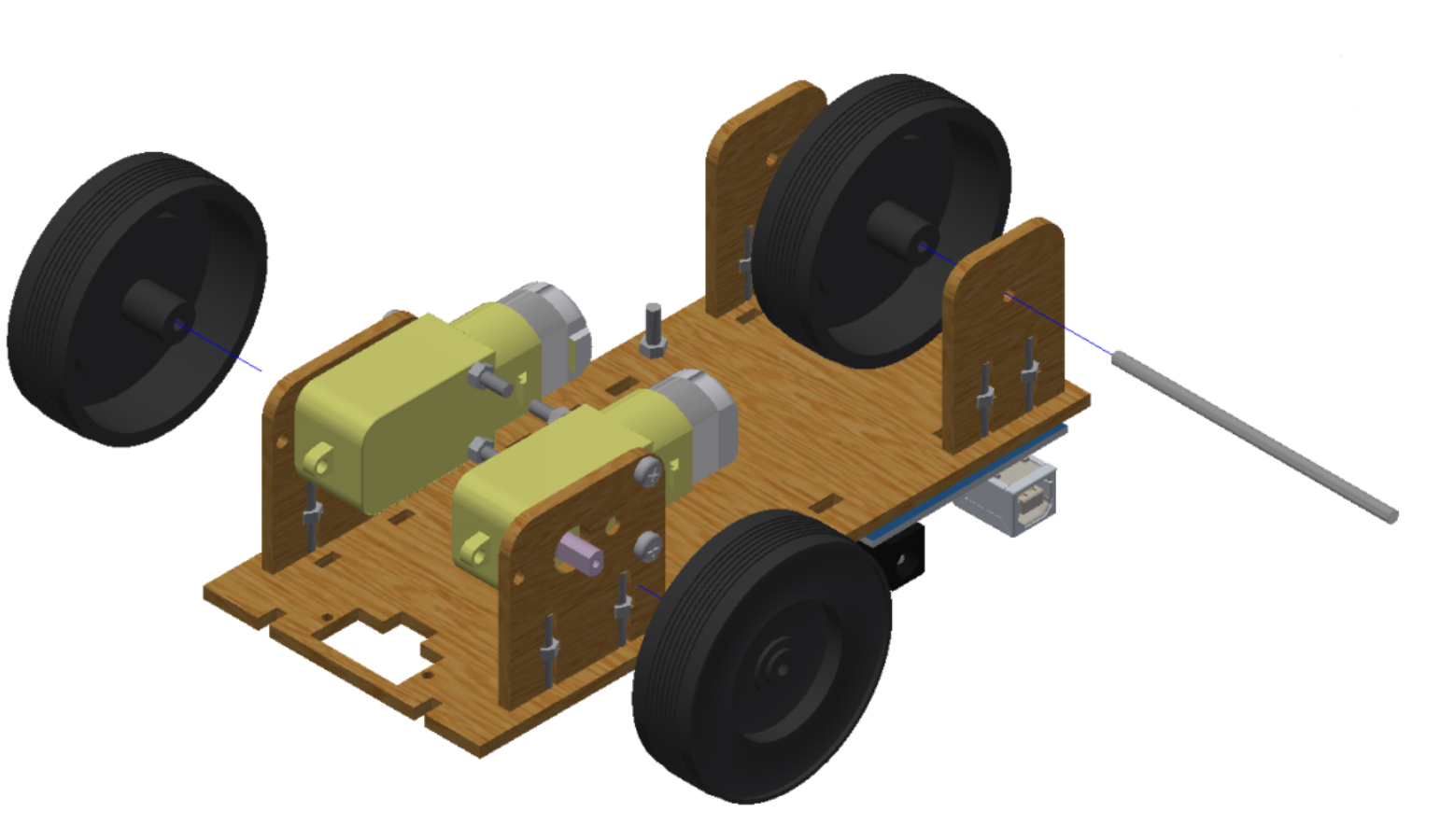

Attach the wheels to the robot:

![]()

-

10Assembly Step 7

You will find that the rear axle easily slips out of its mounts. To fix this simply wrap a little bit of electrical tape around the axle so it cannot slide around.

Sebastian Goscik

Sebastian Goscik

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.