-

Great review from EEVBlog!!!

08/04/2015 at 16:25 • 2 commentsJust got a great review from Dave over at EEVBlog! Starts at 19:41

https://youtu.be/bOE89yPxmGs?t=19m41s

I sent Stickvise in for his mailbag segment like 3-4 months ago, he has quite a backlog of packages!

One of the things I did was mill out a custom PCB with the EEVBlog logo on it to show him that his review really means a lot to me, I think he liked it. He gave a nice thorough overview of how it works and why it is useful, even went as far as to say that he thinks everyone should have something like this! What a complement!

Thanks again for taking the time Dave!

-

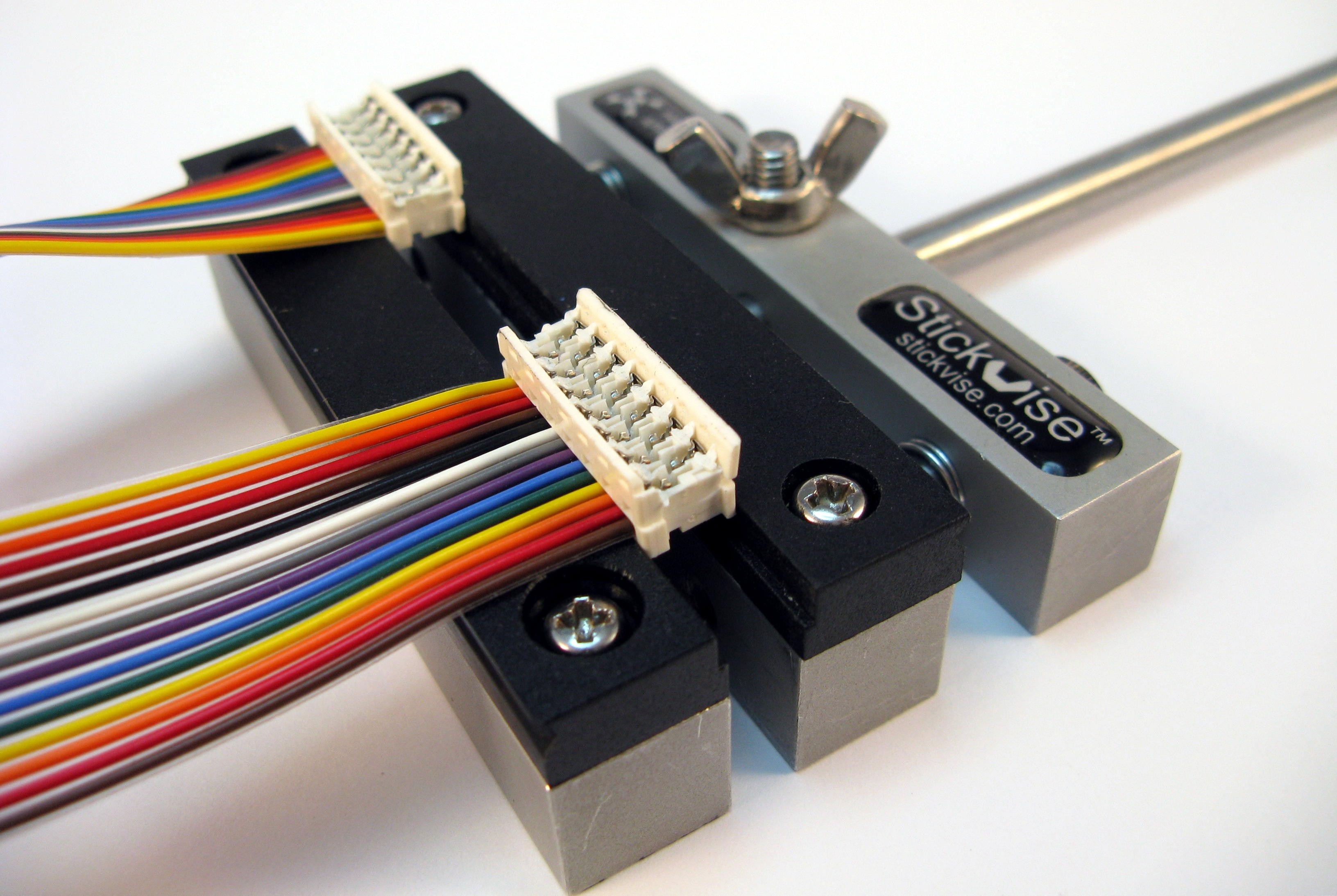

Testing cables

07/15/2015 at 18:55 • 0 commentsToday I made a ribbon cable and wanted to test continuity between the two connectors using a multimeter. When holding multimeter probes in each hand it is nearly impossible to keep the cable still for testing. That's when I realized I could hold the connectors side by side in a Stickvise and the rest was a snap!

Check it out below.

![]()

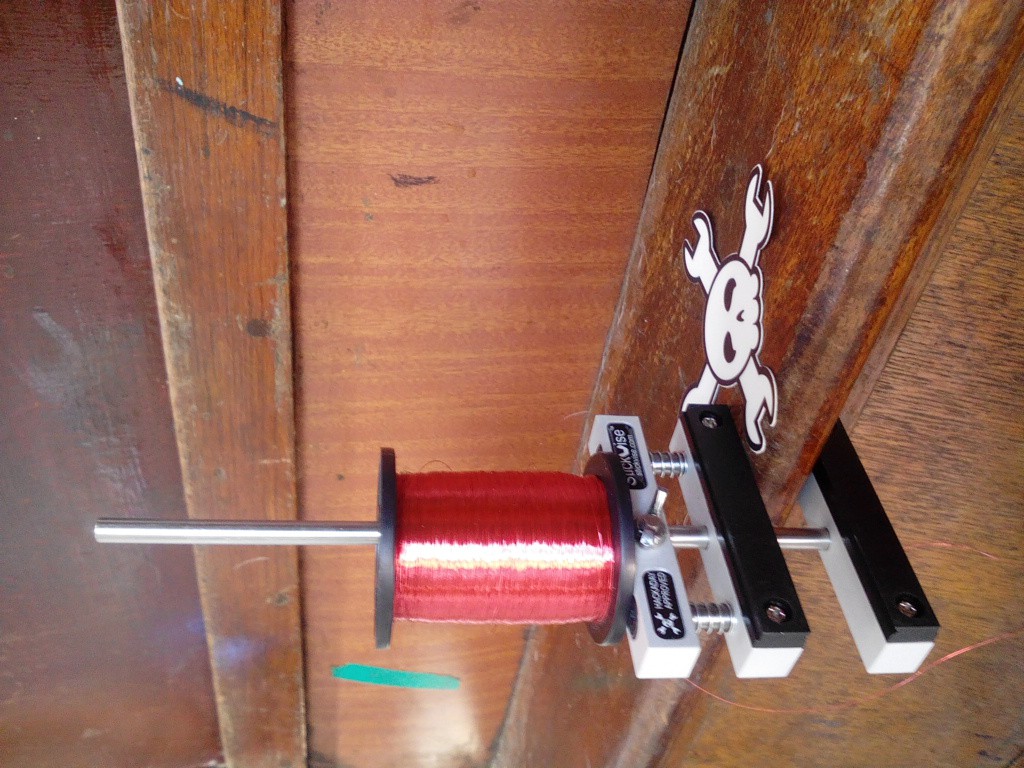

A few weeks ago @haydn jones sent me a picture of his Stickvise clamped to a table edge as a quick wire spool holder - great idea! If you have used Stickvise for anything unusual, leave a comment - I would love to see more pictures!

![]()

-

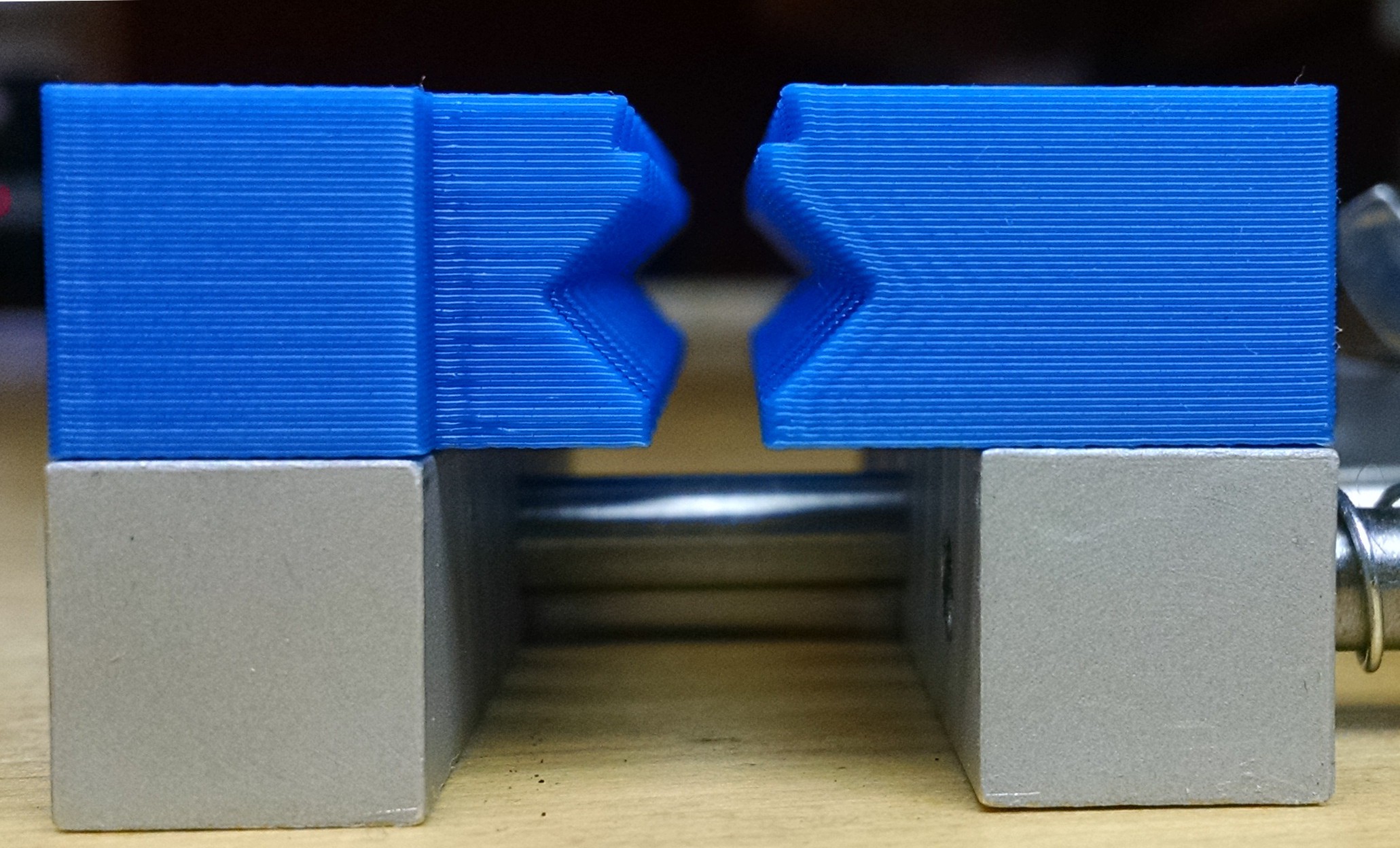

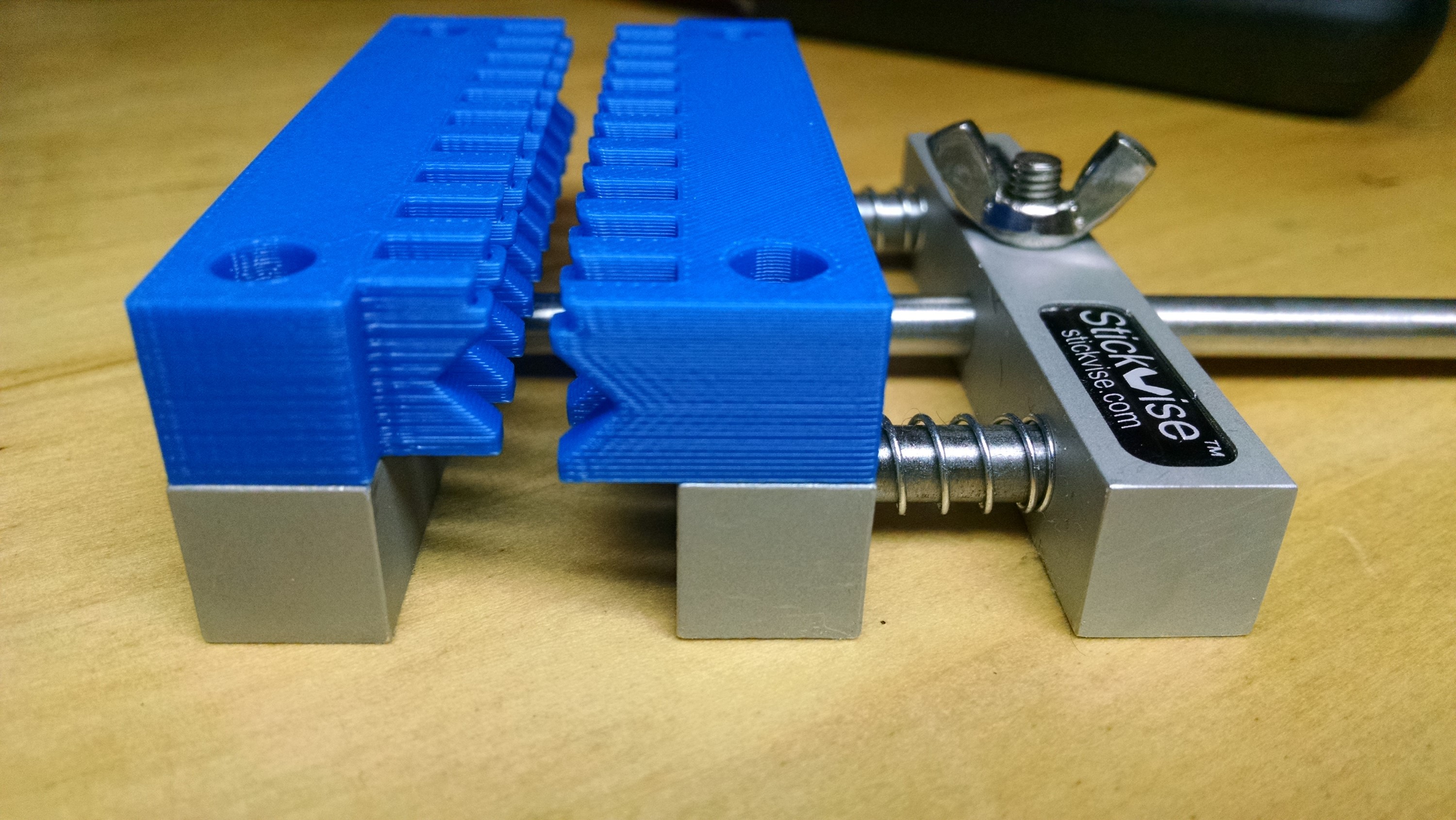

versatile new jaw design

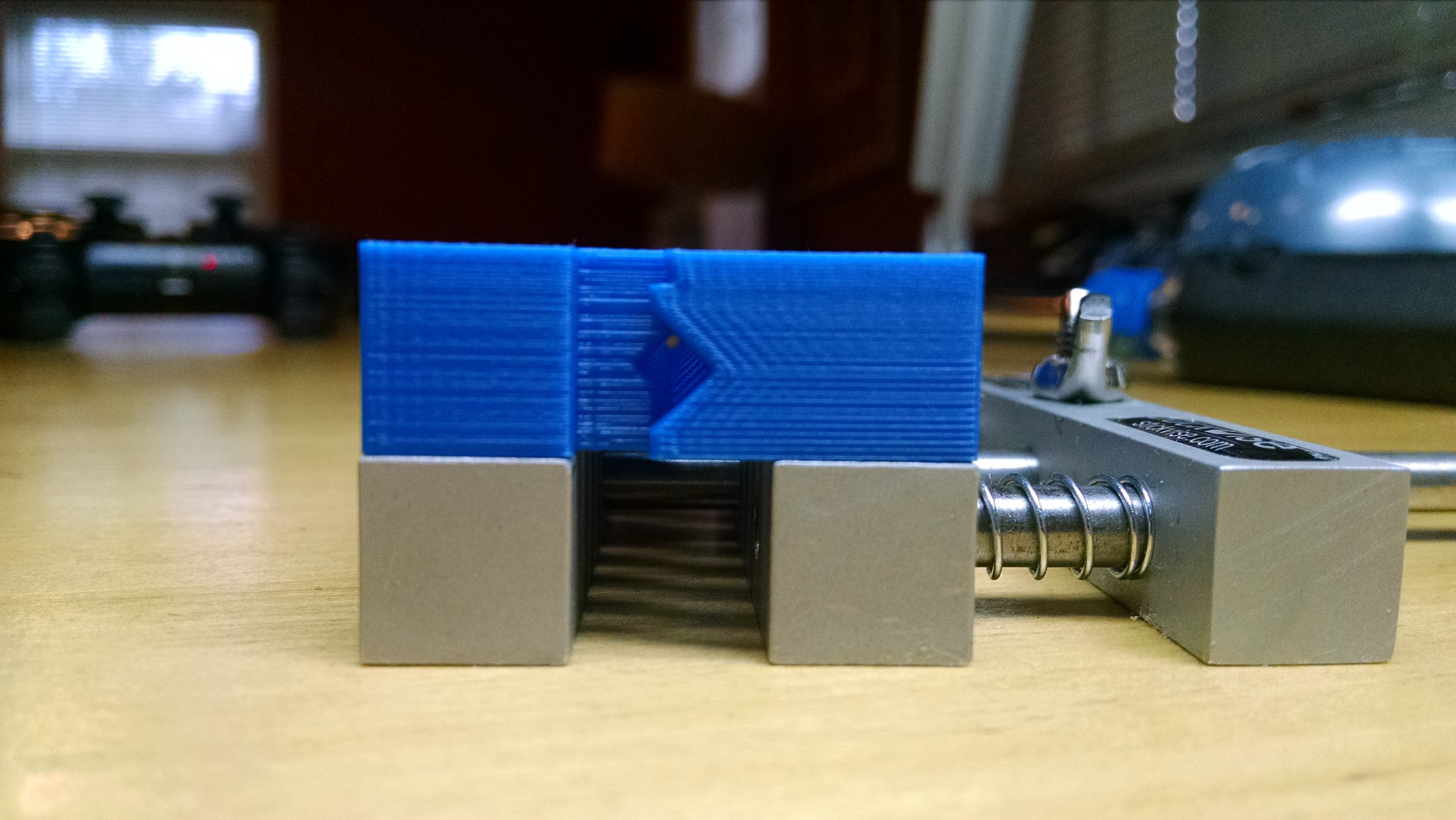

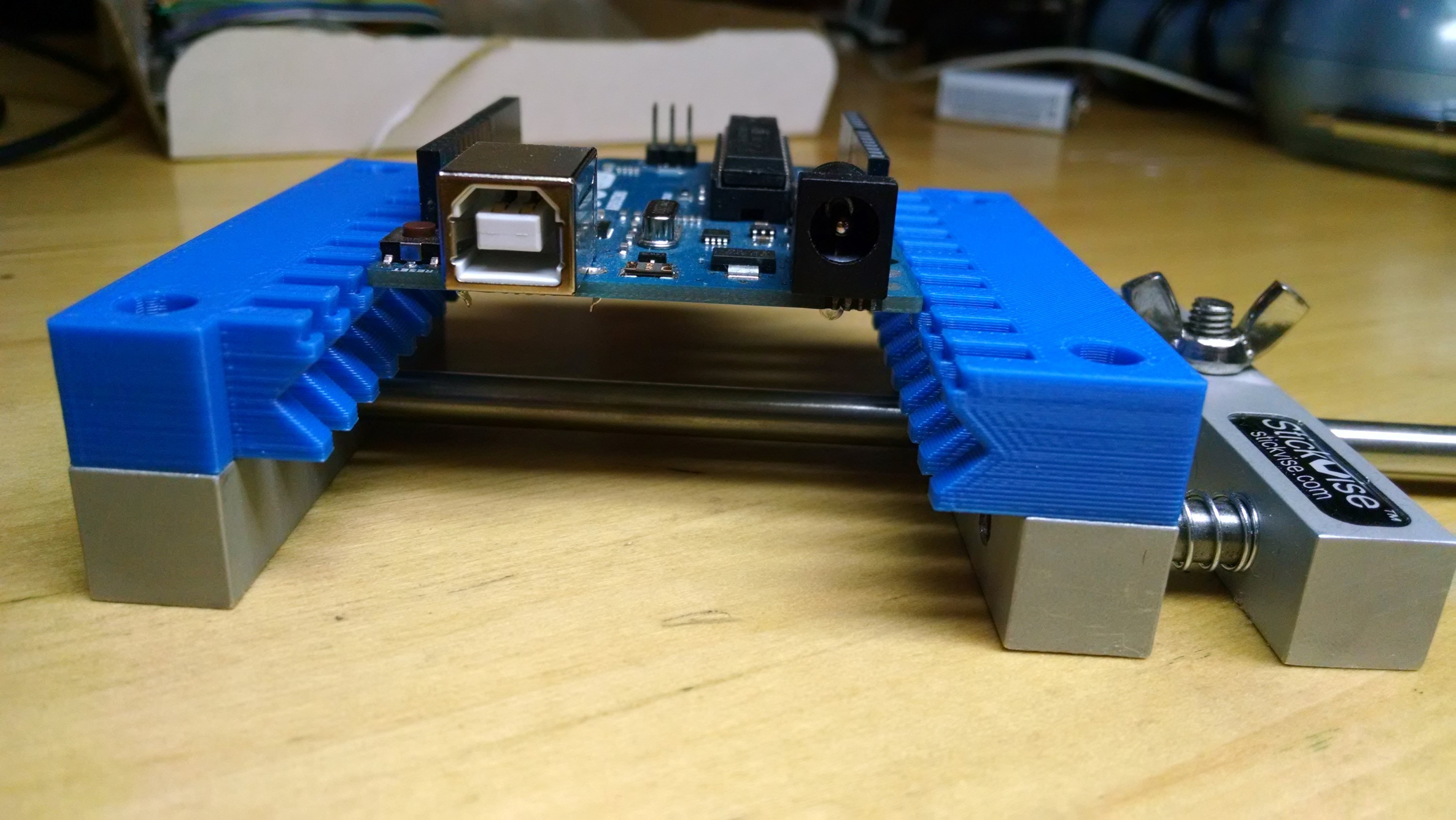

06/06/2015 at 01:24 • 2 commentsThis is probably the most versatile jaw design I have come up with so far. There is more than meets the eye in this shot.... scroll down to see how this works!

![]()

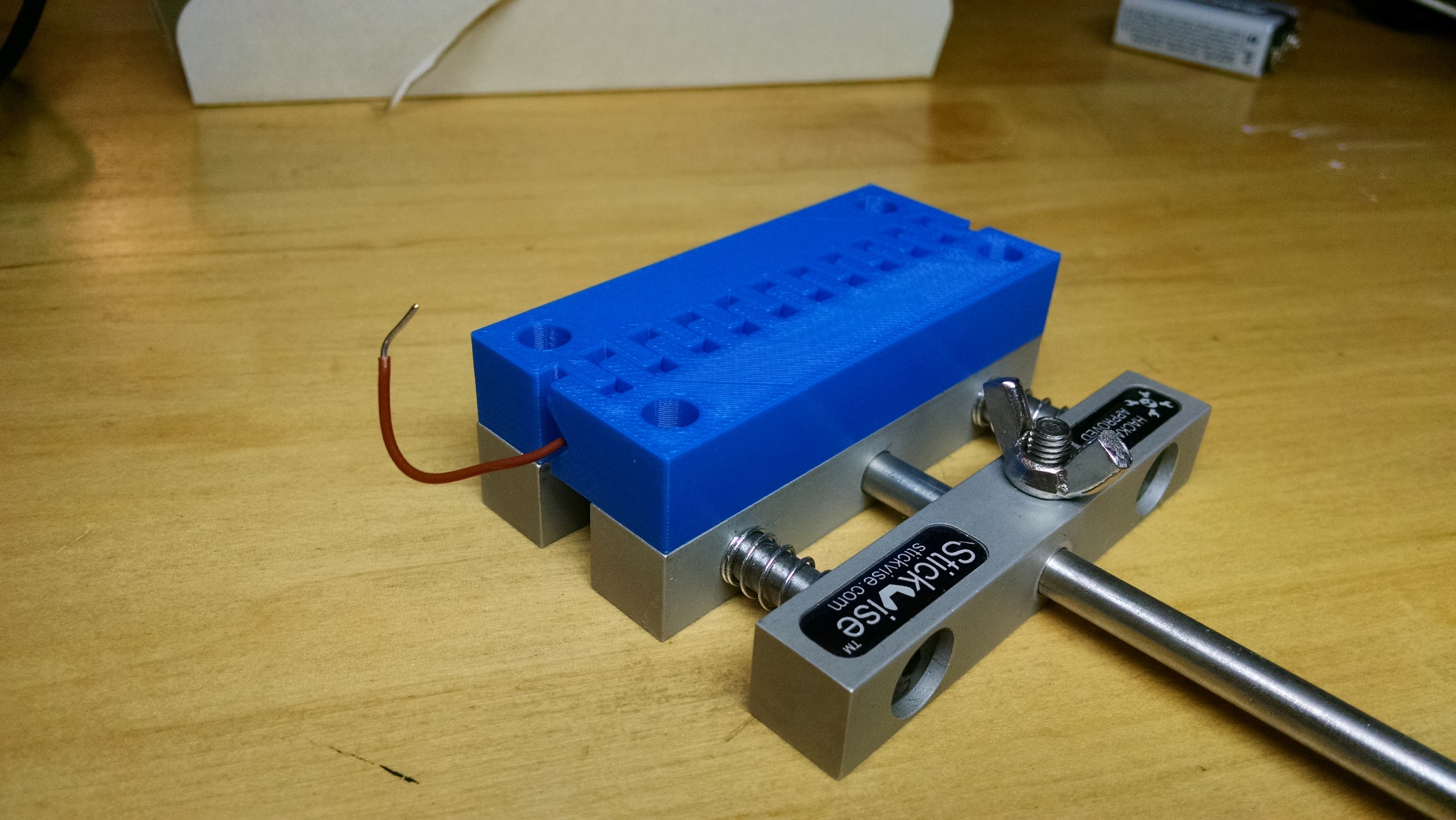

The jaws are made up of a row of alternating fingers:

![]()

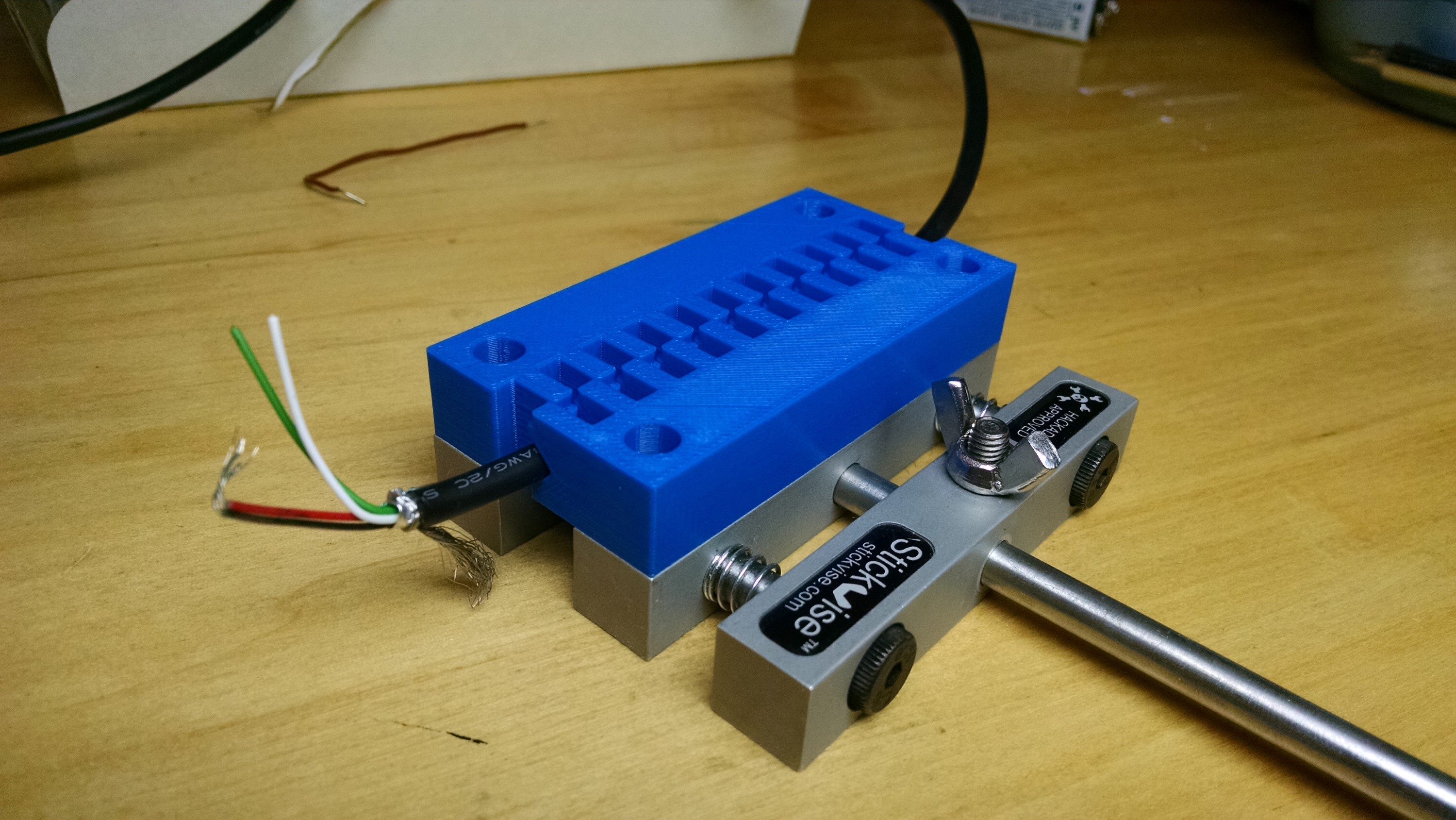

The fingers are interlocking so the jaws can close past one another:

![]()

Letting you hold small stuff...

![]()

Medium stuff...

![]()

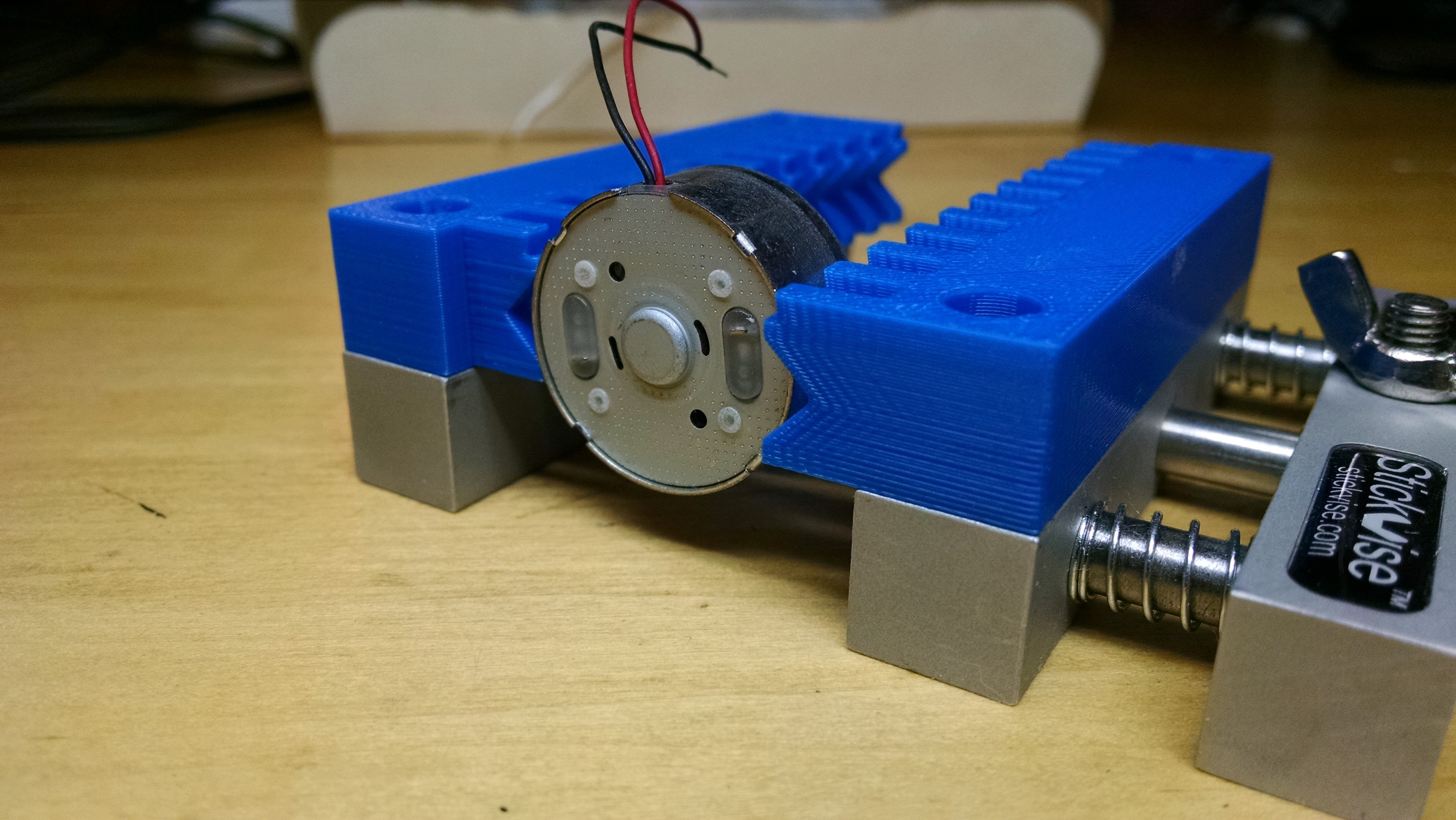

and Large stuff, this motor is about 1" in diameter:

![]()

The best part is, you can still hold a PCB:

![]()

These will be available to download for 3d printing at http://www.stickvise.com/hacks/stl-downloads

-

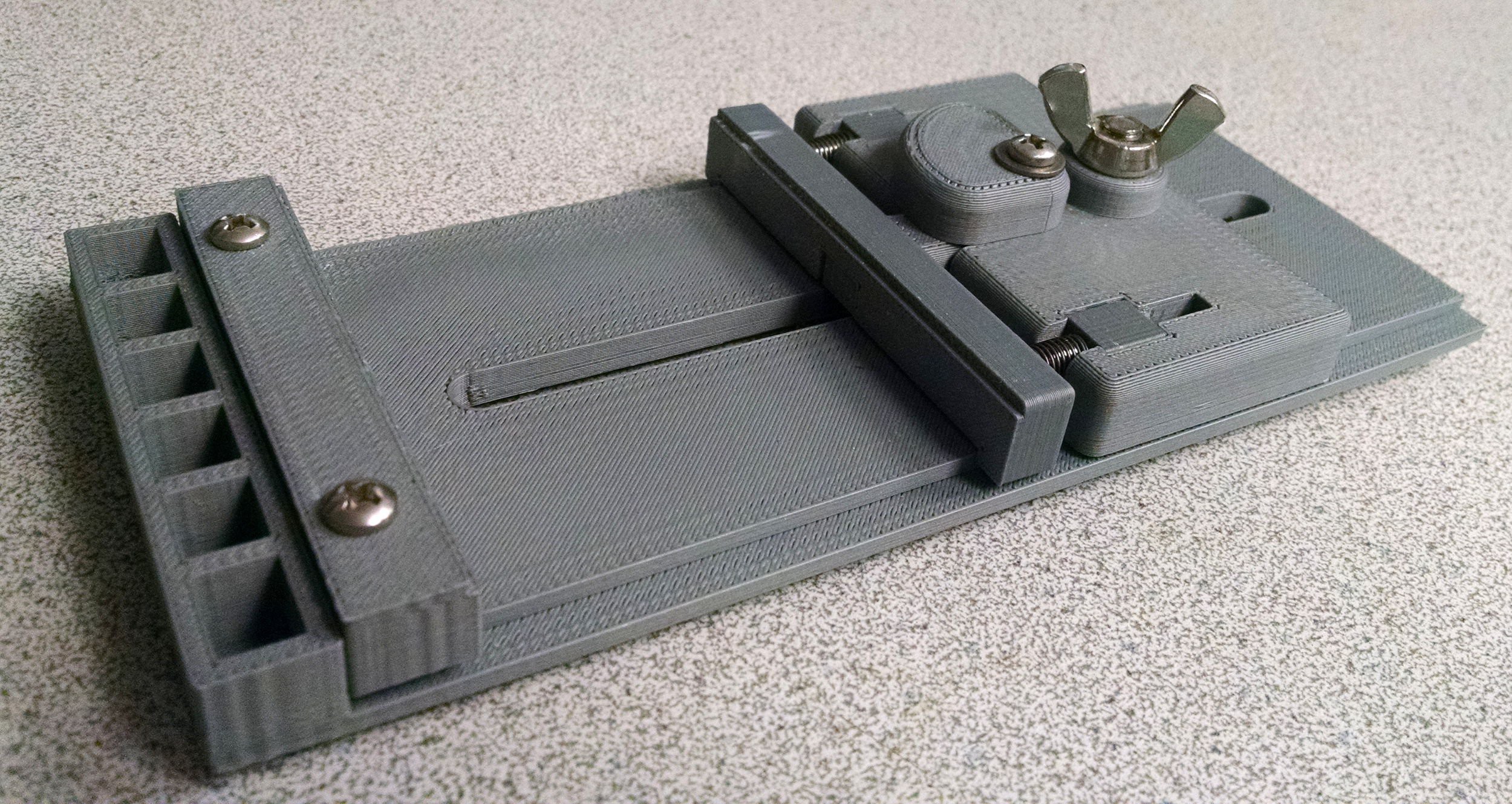

prototype zero

06/05/2015 at 14:05 • 0 commentsfound this today and had a chuckle, the design has come a long way from this first hack design I made last year!

![]()

-

Hot air test 1

06/03/2015 at 21:25 • 2 commentsThere have been questions about how the nylon Stickvise jaws will hold up to hot air rework. I did a quick test today and found they hold up fairly well. I set my hot air station to 800 F and installed a neck-down attachment. I clamped in a PCB that was lying around and attempted to desolder a crystal right next to one of the jaws. I held heat on the part for about 10-20 seconds and could clearly see the solder liquefy. I picked the part up with tweezers, turned off the heat gun and...

...the jaws were perfectly fine. See the desoldered crystal on the top right of the board.

![]()

close up shot of the jaws with PCB removed, I circled the affected area. Not too bad. I ran out of time today but may try to remove some of the bigger ICs next and see if I damage the jaws.

![]()

-

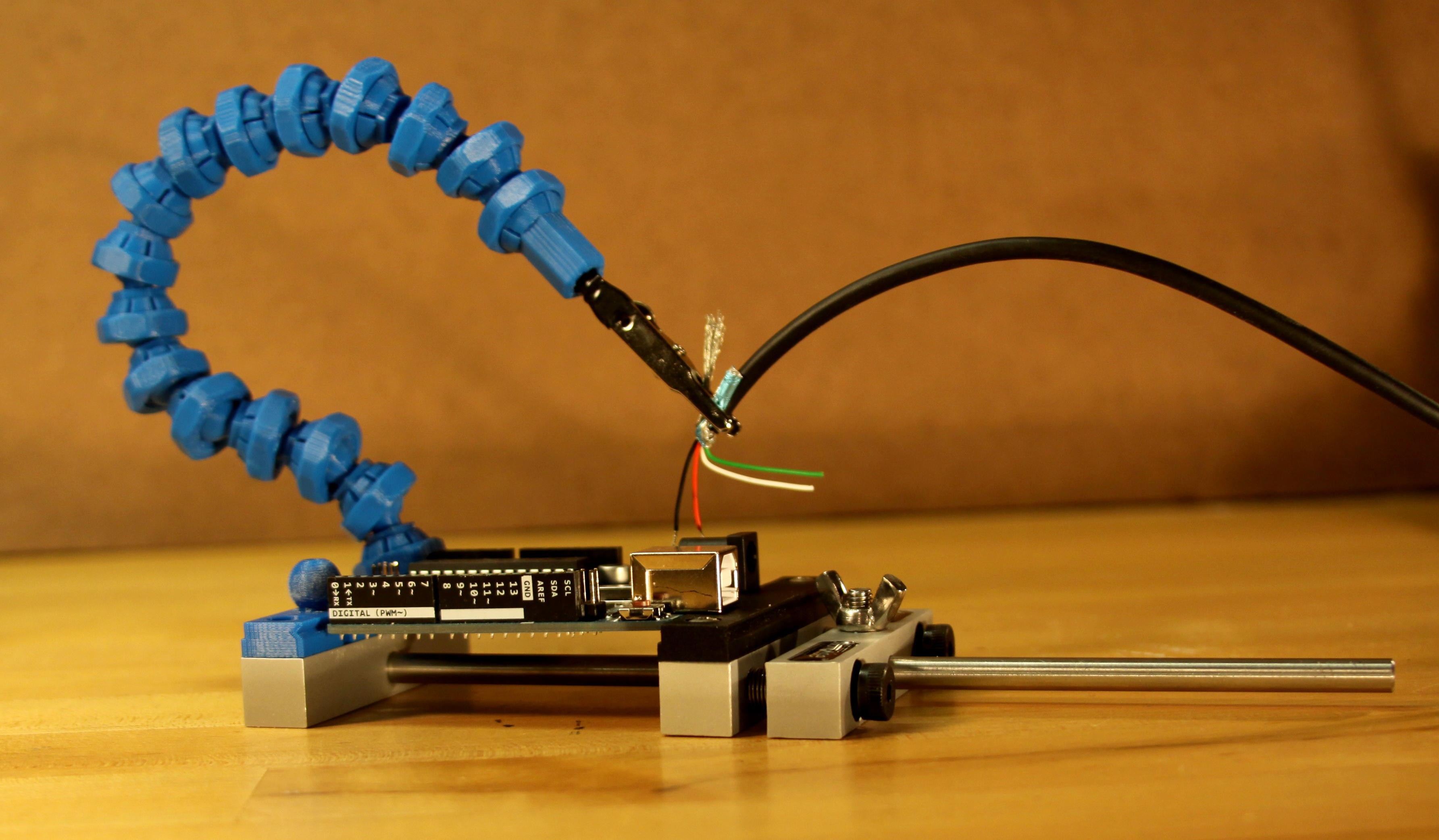

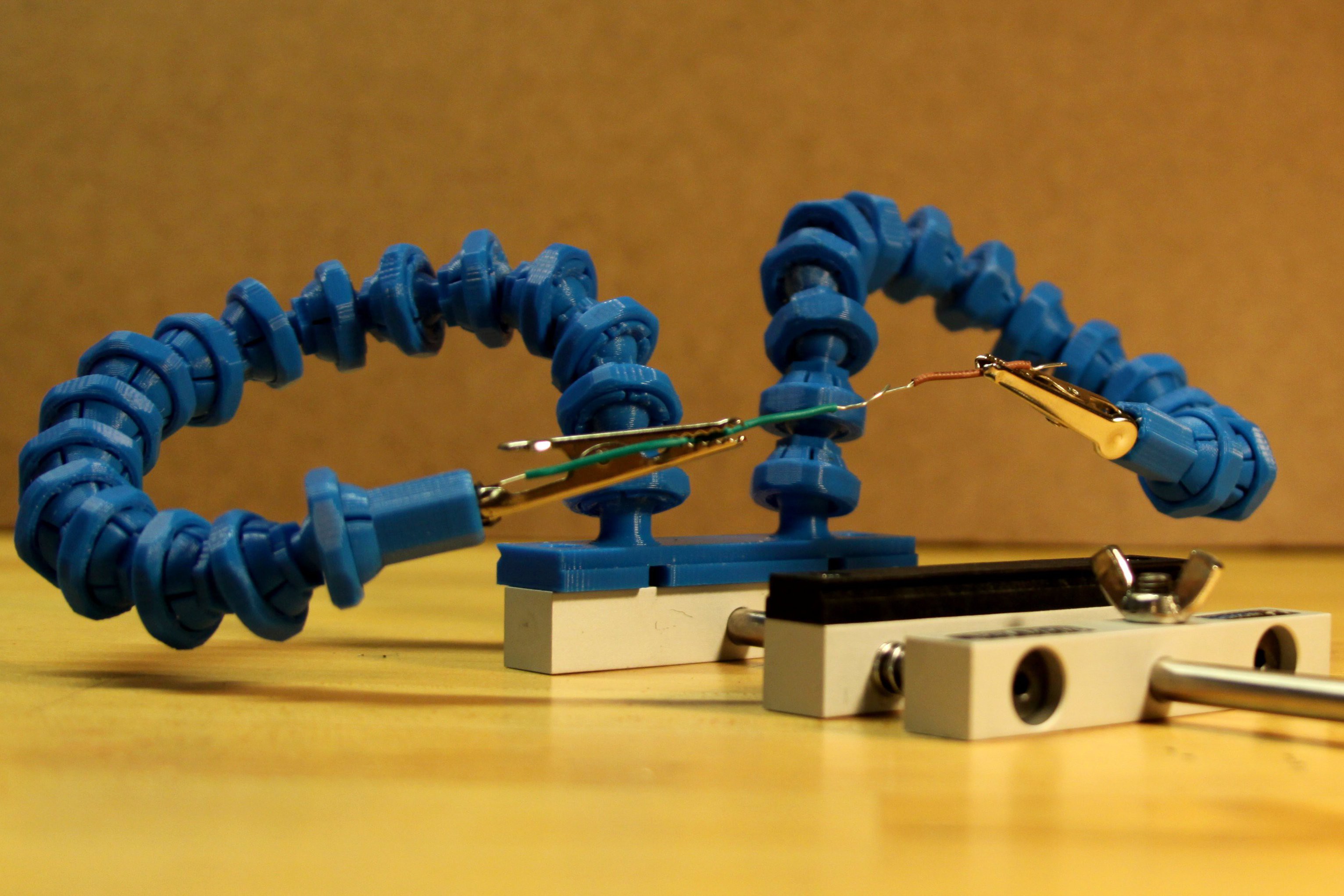

Helping hand jaws available to download

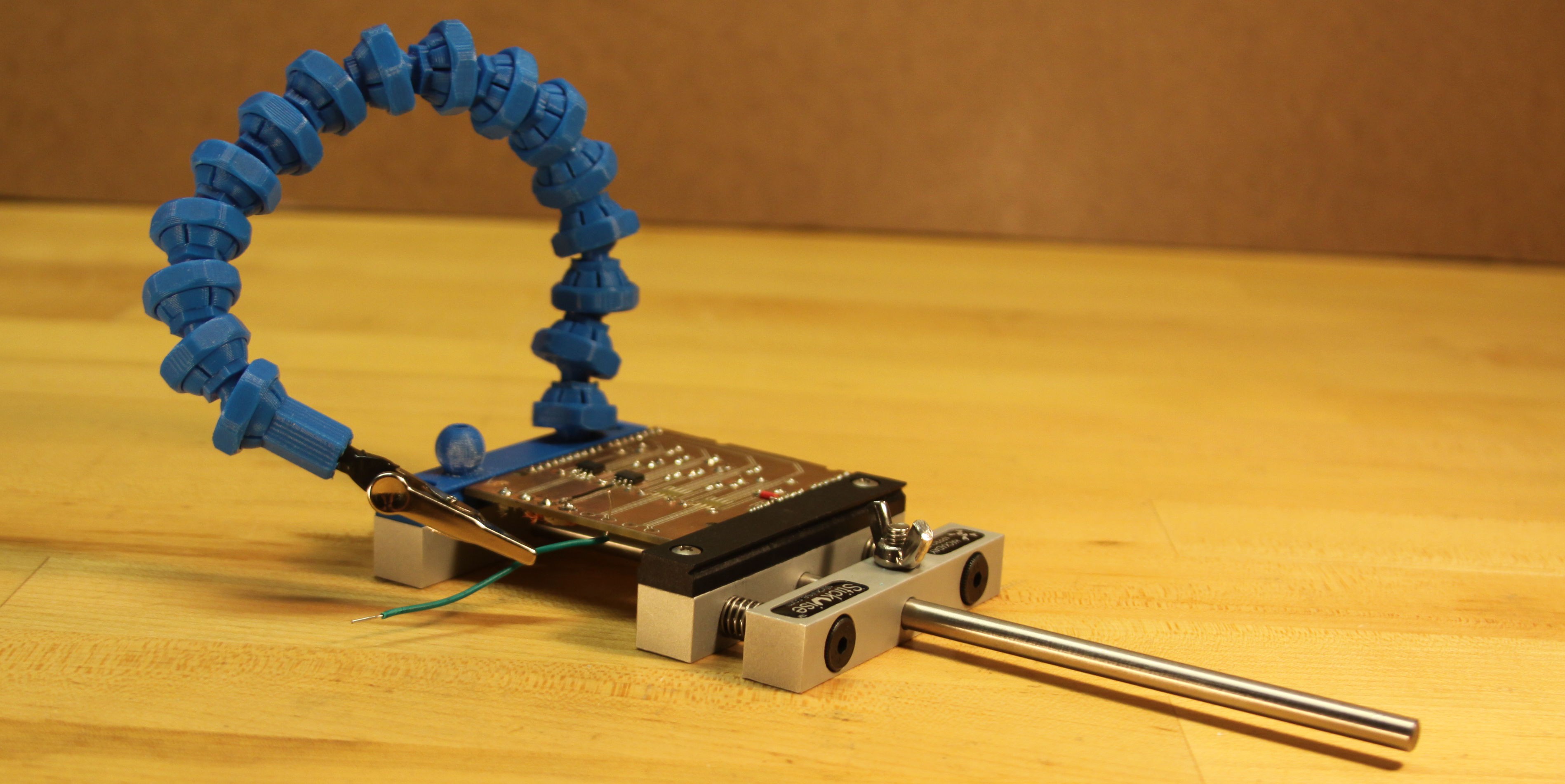

05/25/2015 at 19:29 • 0 commentsMy 3D printable helping hand system is tested and works great for holding wires / cables when soldering. I just officially added all of the STL files to the Stickvise website. Here are a couple pictures of the fully assembled system.

![]()

![]()

This is a worthwhile upgrade even if you already have a third hand or helping hand setup because these stay with the vise, making it easier to move your project around.

Head over to http://stickvise.com/hacks/stl-downloads for more instructions and to download the STL files!

-

Stickvise gooseneck helping hands

05/16/2015 at 01:54 • 0 comments***Edit: I have the kinks worked out, the ball and socket system works great now***

I have been hard at work on what I think is a killer accessory for Stickvise, a 3d printable gooseneck helping hand arm. The design is not 100% ready for public consumption, more in beta test phase. Currently the ball and socket fit together flawlessly, but the locking nut on each joint is a bit difficult to turn. This is the piece that prevents the joint from pulling apart. The fit is something I should be able to sort out in the next week, just need some time to iterate the design a few times. In initial testing, this gooseneck has over 5 lbs pullout strength, so it will not come apart unexpectedly. Feel free to try printing it out, STL files are available on the gooseneck project page:

https://hackaday.io/project/5739-locking-ball-and-socket-gooseneck-system

![]()

-

New Videos: Two ways to use Stickvise

05/14/2015 at 20:25 • 0 comments -

Stickvise is available for sale!

05/08/2015 at 23:11 • 0 commentsOk it's officially available on the hackaday store today, very excited! Stickvise went from random hackaday.io project to actual product with the help of the folks at Hackaday! I can't thank them enough for helping me get off the ground!

-

New website, feedback welcome

04/27/2015 at 23:43 • 2 commentsThe new Stickvise website went live last week and I thought I would post here to see if it makes sense to people other than me.

I designed the site more or less from scratch in my spare time (minus using Bootstrap to handle the basic CSS framework). I particularly tried to emphasize modifying and customizing Stickvise. I have a tutorial for designing vise jaws using OpenSCAD and a bunch of other ideas to get the thought process going on how the vise can be used. Please leave a comment if you think anything needs clarification or improvement.

P.S. Production had a few hiccups but should be complete this week, Stickvise will be available within a month!

Stickvise - low profile soldering vise

Stickvise is a low profile vise designed for PCB soldering. This product was born on Hackaday.io.

Alex Rich

Alex Rich