--

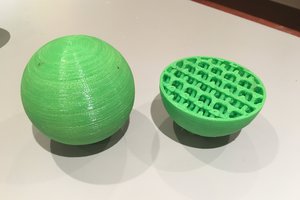

3D scanner

Takes 3D surface scans at close range. It is simple to construct as it uses off the shelf hardware and software.

Takes 3D surface scans at close range. It is simple to construct as it uses off the shelf hardware and software.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

--

Update:

I've made a "Mark 2" of this scanner which is way more accuracy, and it has a 2 axis turntable so you can scan objects from all sides easily. I'm really proud of it now, its on a new project page...

https://hackaday.io/project/181346-3d-scanner-mk2

And I've launched it on Kickstarter, it has 2 days left to run (correct at 28th Sept 2021):

https://www.kickstarter.com/projects/jontupel/tupel3d-desktop-3d-scanner

Thank you all for showing such an interest.

Create an account to leave a comment. Already have an account? Log In.

@Jolar, we'd all like the build details for this project. Would you please add them? Thanks!

>4 Raspberry Pi Zero's perform synchronised capture

Do you have any details on this?

A good source of scatted random dot pattern is a laser bounced off a dull white slightly curved surface. We used an Aspirin for a similar project in the 90's. very efficient, cheap.

great work. I always wondered why structured light scanning could not be done with a rudimentary laser with a projection pattern. The pattern can be a rotating disk with cutouts or something like that. I can wait to see the scripts published.

Actually, David Laser Scanners does it. Structural images they chose are mainly horizontal & vertical stripes. https://www.youtube.com/watch?v=1ptq9I-DT3I

The question I have, Is that mesh straight from scanner or it was post-processed? I had similar results with one camera and Agisoft but with A LOT of pictures and some post.

I'm not too familiar with Agisoft but in my experience the pattern projection helps more than the number of images. In the example image the only post processing was to crop the 3D model to show the central region where the hand is.

I can't wait to see more details on the project. You're getting a really great outcome with clever use of rather rudimentary hardware, impressive!

I am really looking forward for more details too about this. Perhaps I'll even build one if details arrived.

I love it.

If you projected 3 patterns (say random Red, Green and Blue patterns) from different projectors at different angles would that help with the creation of the 3D image?

By 'projectors' I'm thinking something simple like:

http://www.kmhpromo.com/custom_projector_pen/projector_keychain.html

you're thinking of structured light scanning, this is photogrammetry.

Also i have my doubts with the claim that this is fully automated. VisualSFM outputs point clouds , and surface reconstruction on meshlab usually requires a lot of manual cleaning before a decent mesh can be obtained.

No, the thinking behind it was that with a single projector you're only going to be able to add features to a single "face".

With multiple projectors (so long as they don't wash-out areas that are already lit - hence the three colours) you would be able to give features to surfaces which multiple cameras could see, but a single projector could not reach.

Regarding "fully automated" what I meant by this is that from a click of the button a 3D mesh arrives on the laptop screen. In the example image I did crop the scan to make it a nice rectangle but there was no manual processing or tidying of the 3D hand.

I like those ideas. I used a digital projector so I could experiment easily with different pattern projections - its a major factor in the accuracy.

Become a member to follow this project and never miss any updates

Greg Zumwalt

Greg Zumwalt

mariusstrom

mariusstrom

Aidan Leitch

Aidan Leitch

I don’t suppose there is a similar way to digitize buildings, without needing the random dot patterns?

Also, why does the data from the Pi Zeros have to go to the “cloud”? Surely any recent PC can handle the work.