The finished project should mill PCB's and laser etch materials like leather. The goal for the workingarea is 400 mm * 400 mm at least.

Homemade PCB-Mill / Laseretcher

Homemade X/Y-Table to mill PCBs and etch materials like leather with a Laser

Homemade X/Y-Table to mill PCBs and etch materials like leather with a Laser

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

The finished project should mill PCB's and laser etch materials like leather. The goal for the workingarea is 400 mm * 400 mm at least.

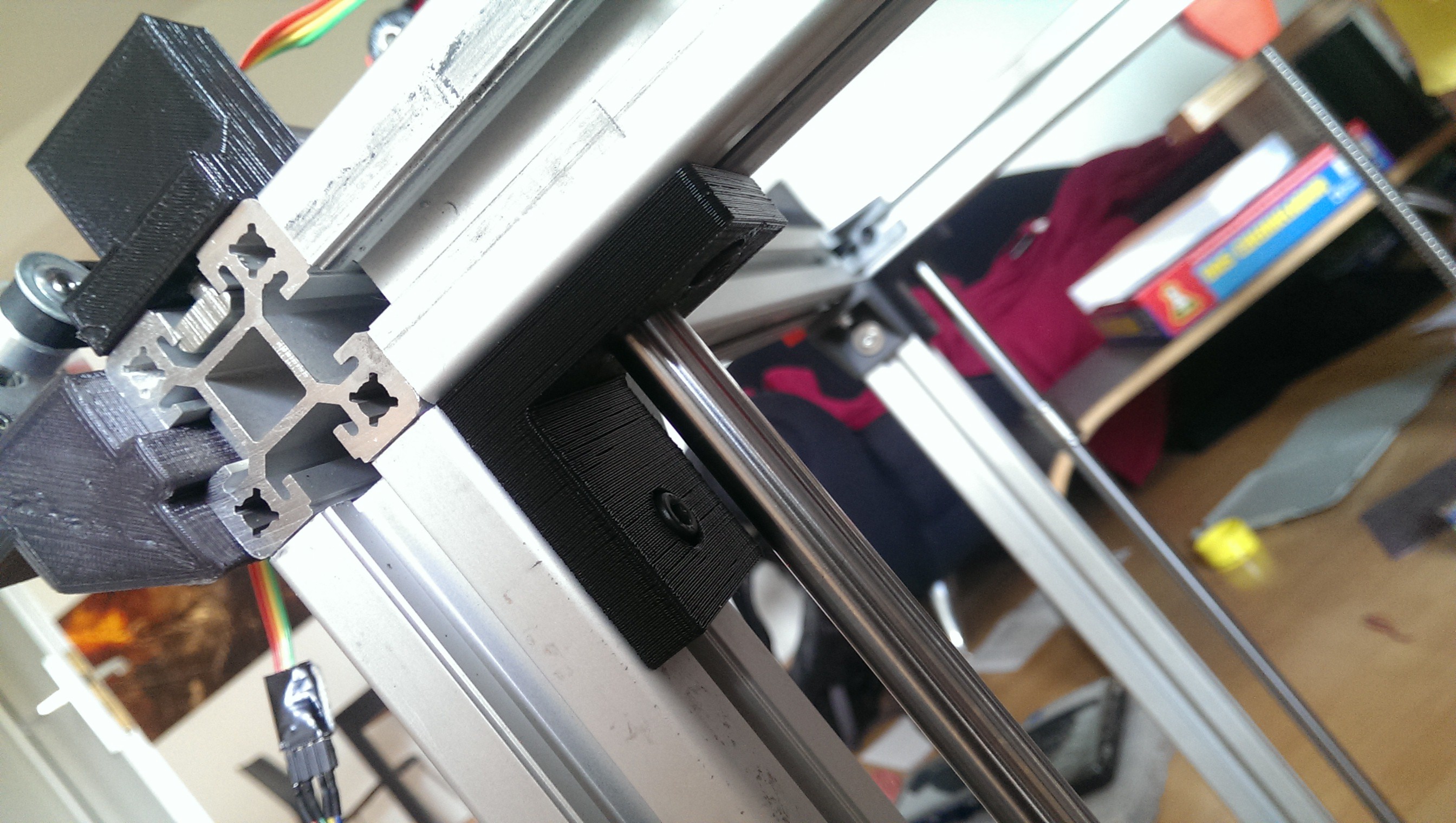

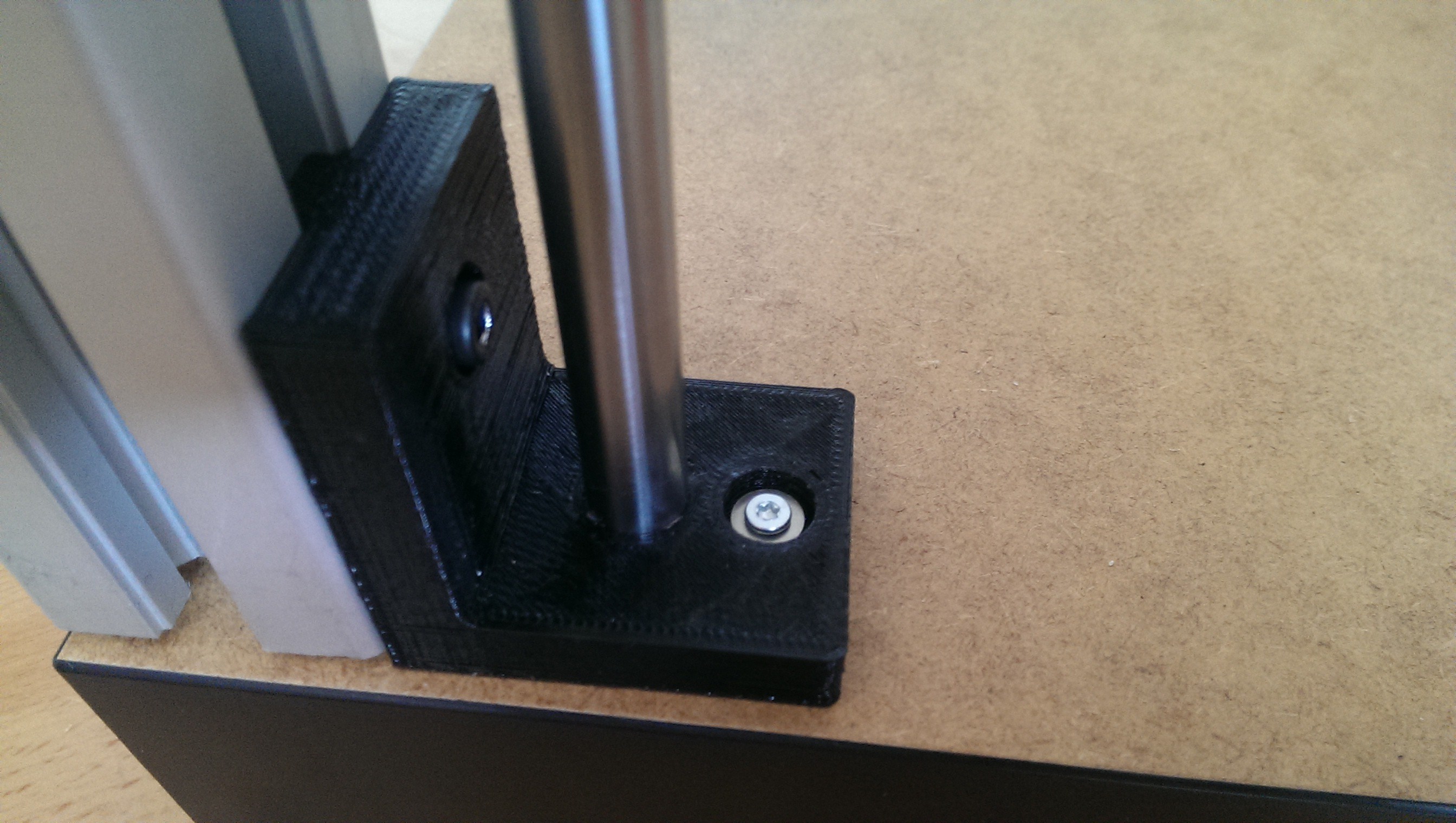

Mounted the linear rails for the Z-axis:

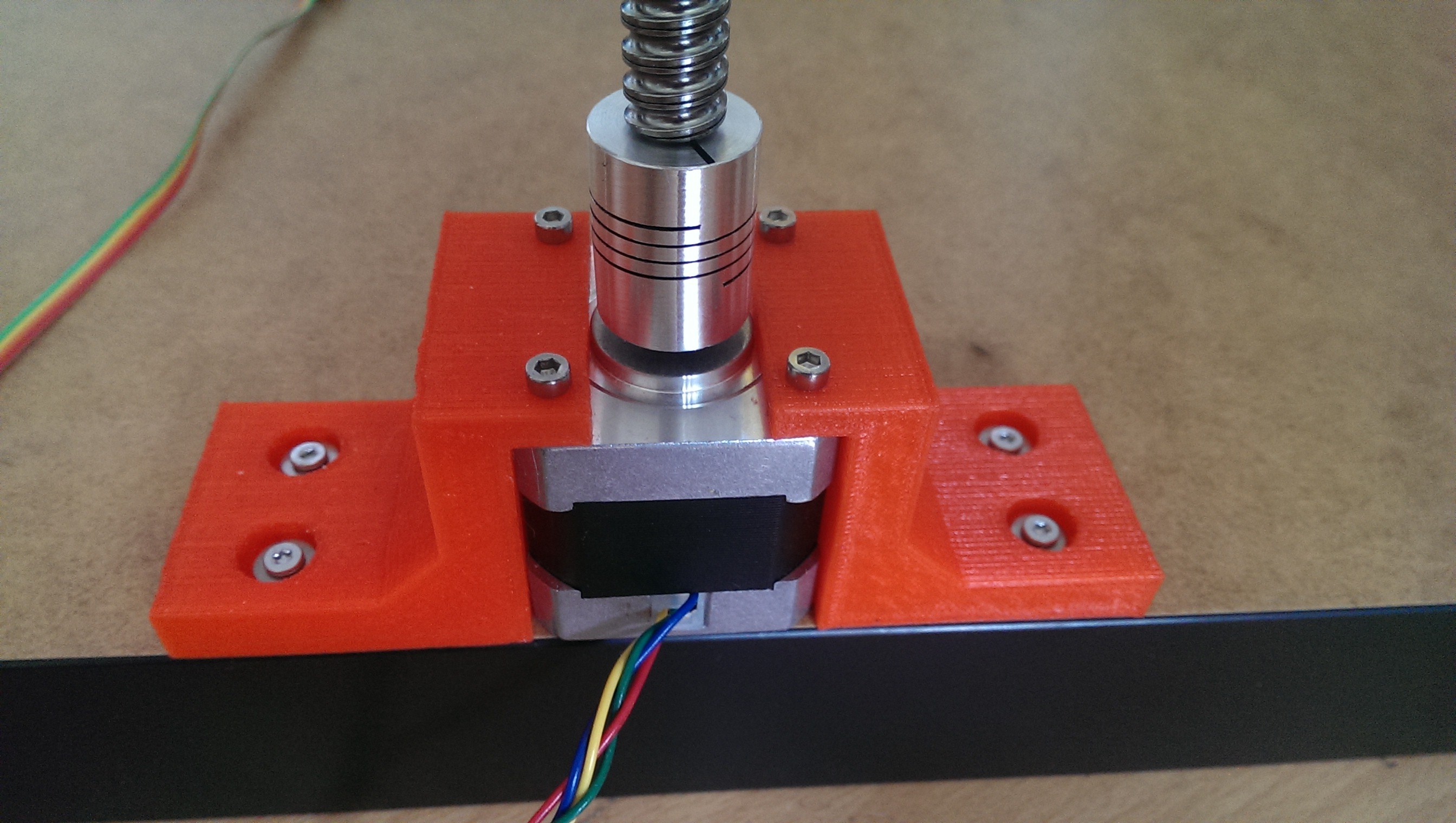

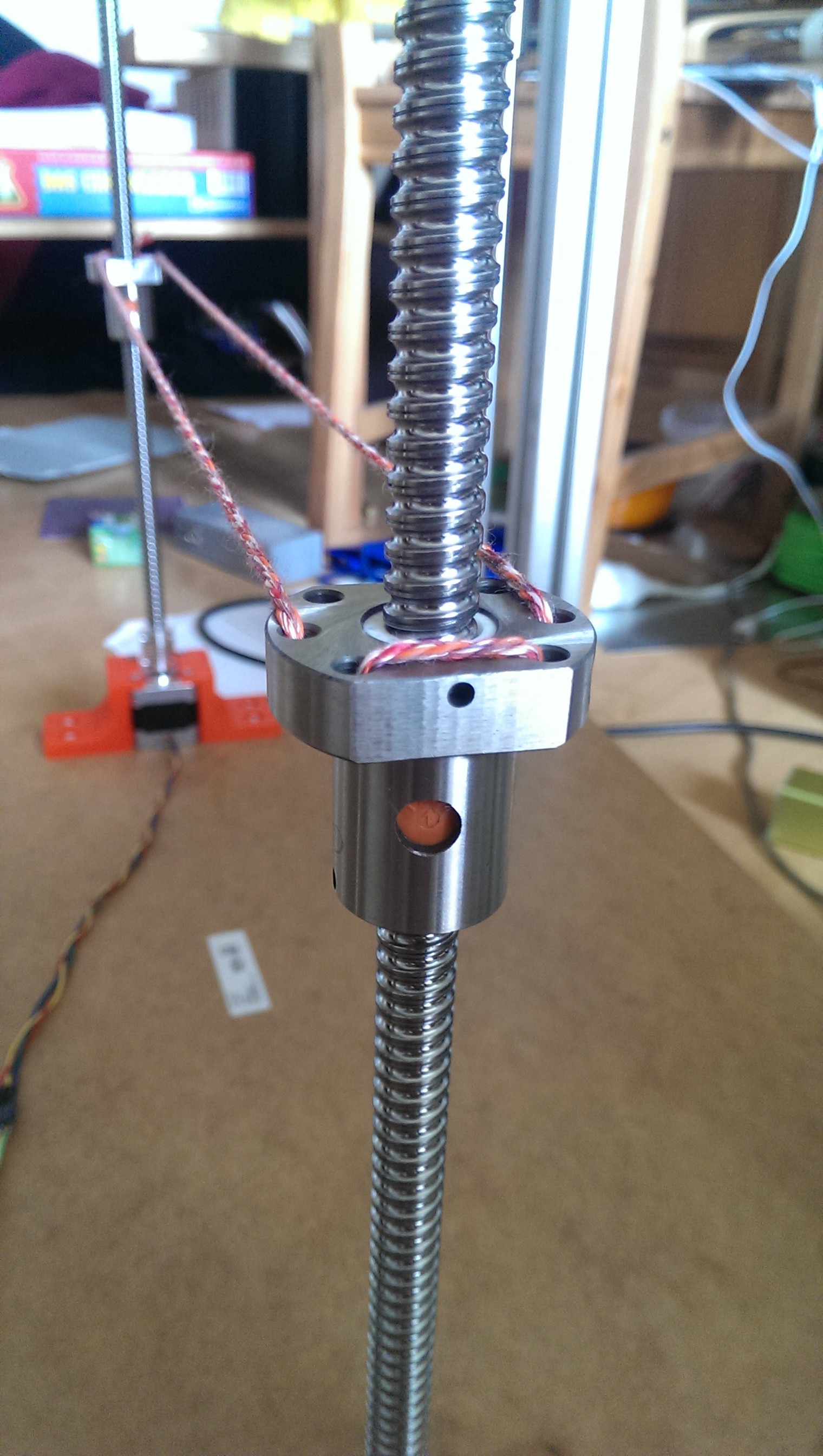

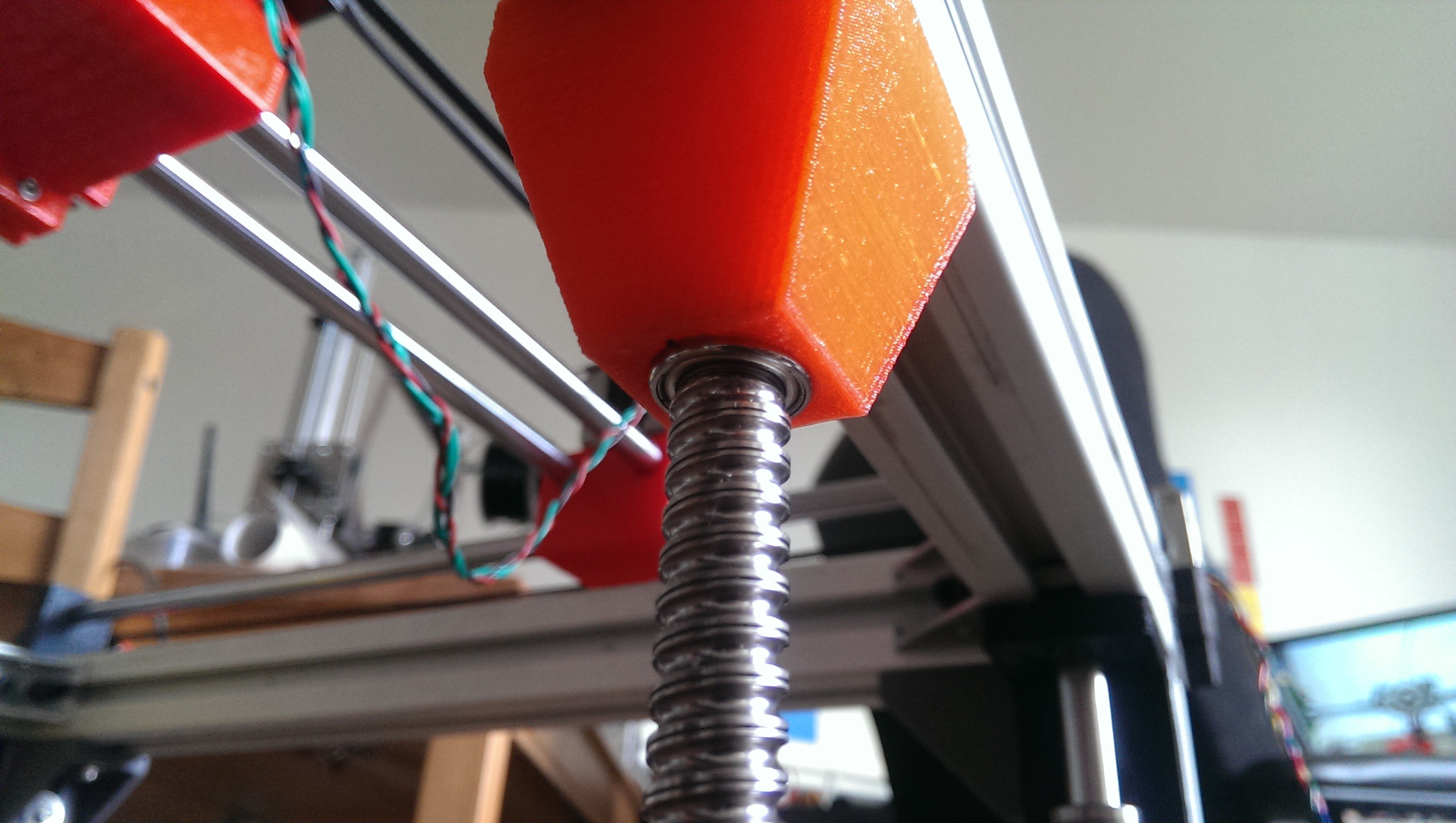

Mounted the Z-axis ballscrews:

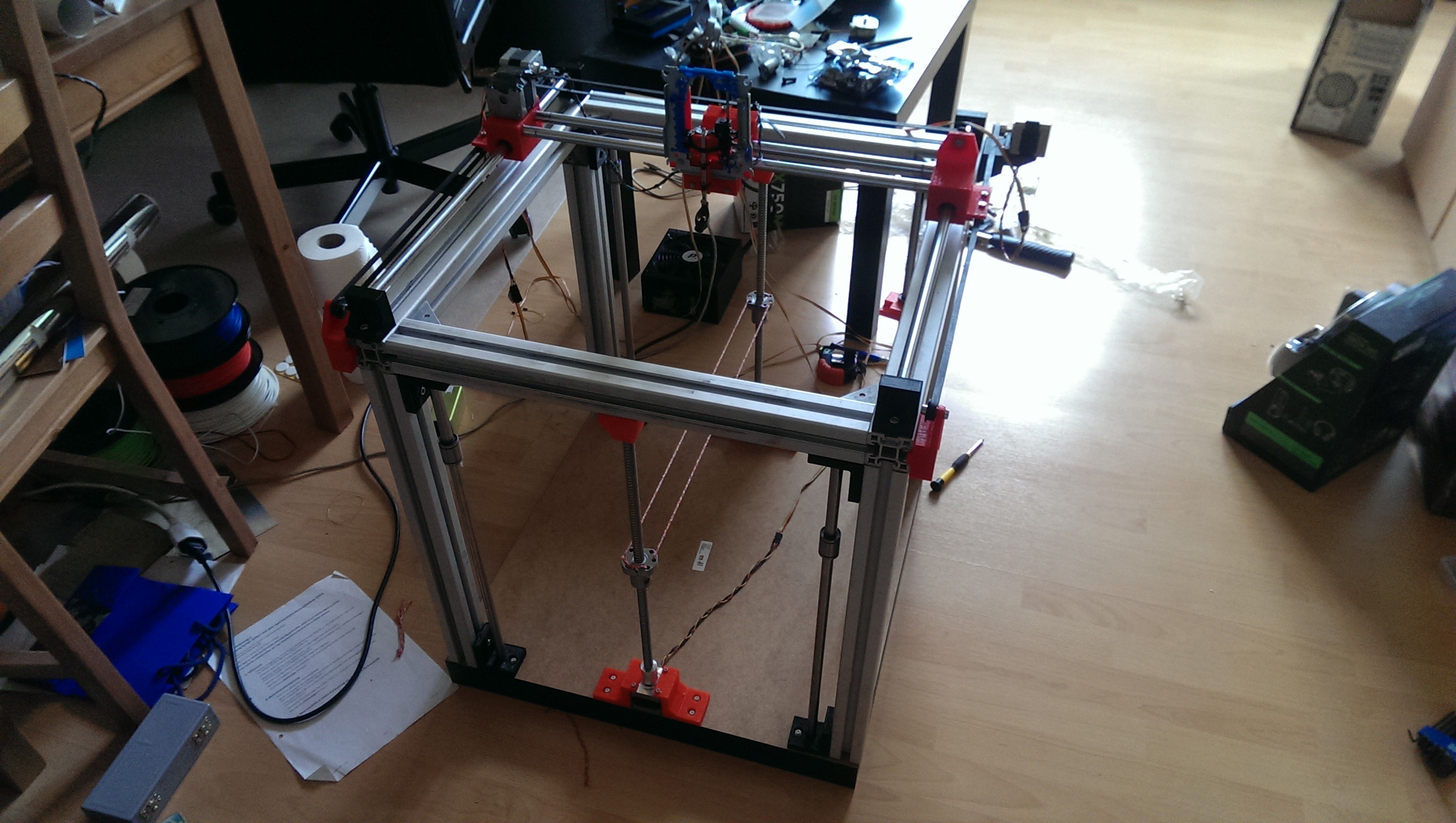

The entire system:

The next step is to mount a big plate on the ballscrews and the linear shafts.

The next step is to mount a big plate on the ballscrews and the linear shafts.

Now the Motors for the X-Axis are mounted outside, so the Working-Area gets bigger.

I've added a small Z-axis out of an old DVD-Drive and hoocked it uf to my CNC. At the z-axis i mounted a pen, so now my machine can plot pictures on a Paper or flat surfaces like my "Sprit" or alcohol bottle.

Here is the first test-video of my CNC, in this Video, i couln't controll the laser, but at the moment it works. This is a normal violet laser who writes on a glow in the dark surface.

Here is the Video: http://youtu.be/Xan15t2EbFY

Now the Y-axis is added to my PCB-Mill and the belts arrived so i dont't have to use those

First Test of the X-axis was succesfull. The axis don't have a belt at the moment, because they didn't arrived at time, but a sholace will works fine ; ). Next step is to Design the new holder for the y-axis linear shafts, with a included beltholder.

Create an account to leave a comment. Already have an account? Log In.

hi everyone who is following this project.

If one of you would like 2.1W, 3.5W and 5.6W lasers EnduranceLasers.com would be happy to give you 10% off for them, just give us a promo code "Hackaday"

Become a member to follow this project and never miss any updates

phil

phil

joekutz

joekutz

please add a tutorial on how to make it.