-

11Attaching Ampflow A28-400-F48 main drive motors to NMRV 050 gearboxes

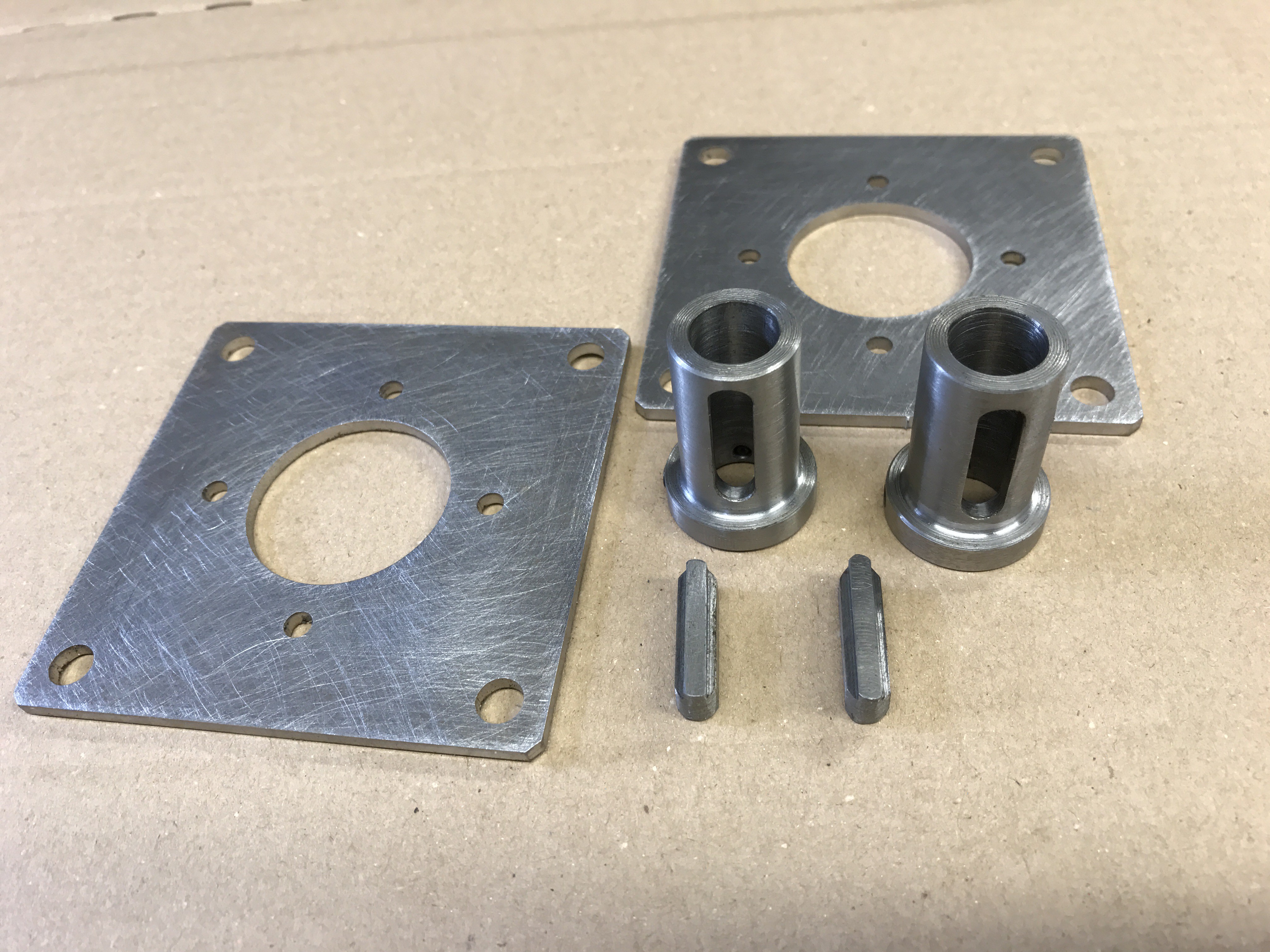

Download the adapter plate drawing and have 2 of them laser cut. The outside holes need to be countersunk to accept 6mm countersunk machine screws (not shown).

I took one of the gearboxes and one of the motors to my local machinist and asked him to make adapter collars for them to fit together. I could have made a drawing for the collars, but this was easier and enabled the machinist to come up with his own design, with the slot going all the way through the collar and the keyway having different sizes on top and bottom. Very clever solution!

The machine screws holding the motors looked a bit small so I queried Carlos at Ampflow about opening them up but he advised against removing the front motor plate due to possibility of changing the motor timings.

-

12Building the Rotating Claw Mechanism

The rotating claw mechanism can be easily bolted on/off the Z saddle plate for performing weeding tasks. There's also the option (recommended) to add a planetary gearbox to reduce the speed of the 400W ACM servo motor by 10:1. The servo motor needs to be specially tuned with the Leadshine protuner software as the inertia on the motor is quite high and it will otherwise wobble quite badly. Download the tuning file HERE. The other thing to remember with these motors is that they are 8 pole and all the other motor drivers in the CNC mechanism will also need to be tuned with this file HERE. The ACM motors need driver modules (ACS806) which can be tuned using a special cable from Leadshine and a Prolific USB to serial convertor cable.

![]() The gearbox above is 100% compatible with the motor and no adapter plates or collars are required.

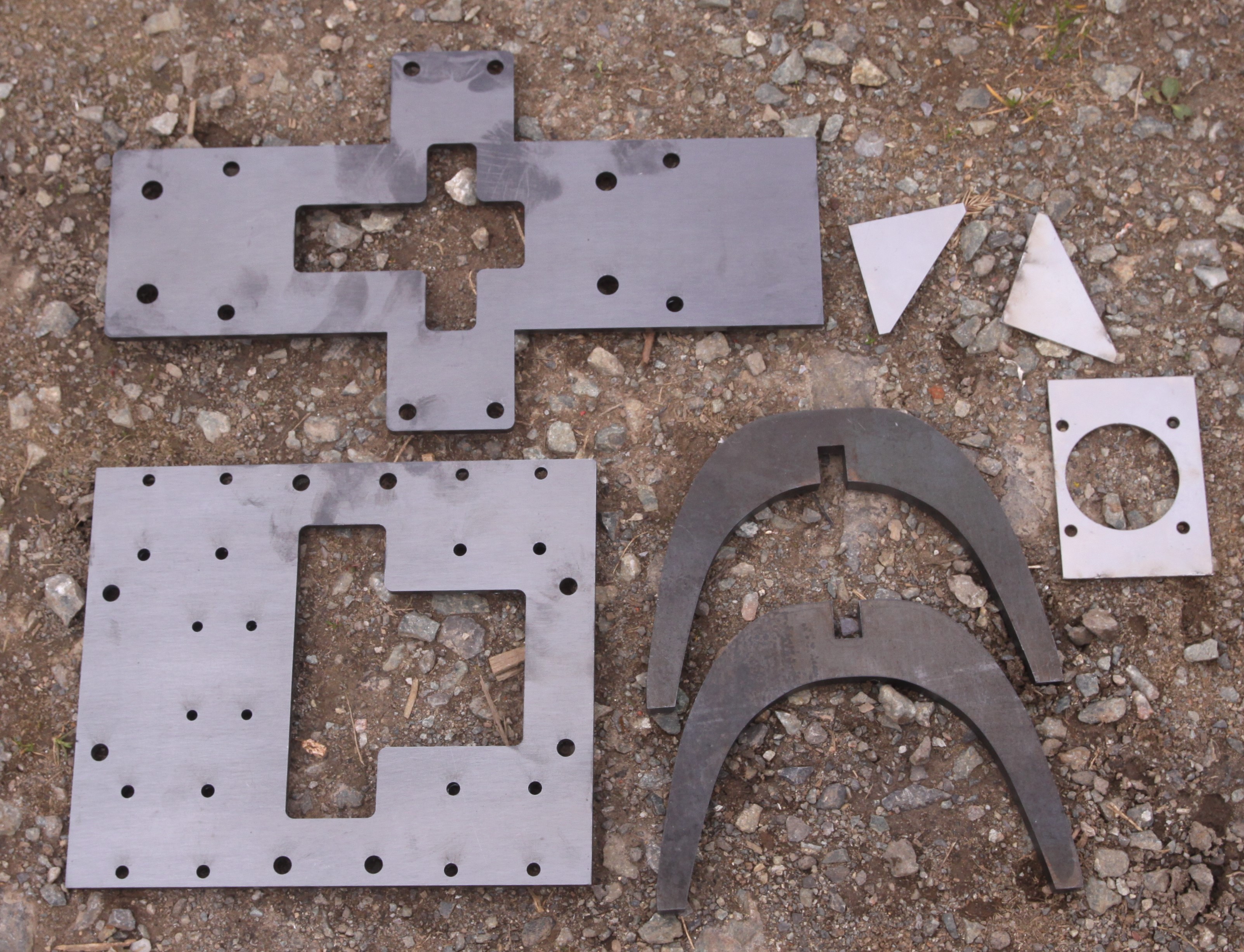

The gearbox above is 100% compatible with the motor and no adapter plates or collars are required.Download the claw mechanism drawings and get the claws, main plate, motor plate and gussets laser cut.

The bottom left plate is the Z axis saddle plate, upgraded from the previous version.

-

13Step 13

WEEDINATOR 2019

The WEEDINATOR project continues .... The inevitability of robots working on farms draws ever nearer ....

Capt. Flatus O'Flaherty ☠

Capt. Flatus O'Flaherty ☠

The gearbox above is 100% compatible with the motor and no adapter plates or collars are required.

The gearbox above is 100% compatible with the motor and no adapter plates or collars are required.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.