-

Muffsy has a Home (page)

07/14/2015 at 14:34 • 0 commentsAfter a long time, spreading the efforts between Hackaday.io, Instructables and Tindie, Muffsy now has a home. There's still some way to go, but all the information that was spread around will become available at this new home page.

Here it is: http://muffsy.com

-

Etch Your Own PCB

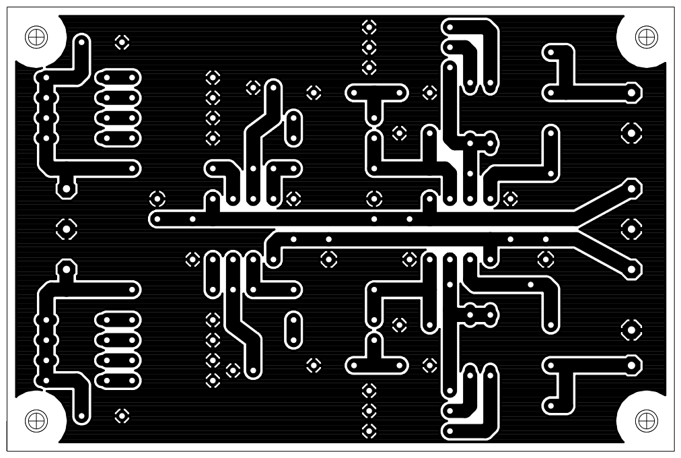

07/10/2015 at 12:51 • 0 commentsInstead of buying the PCB with the Muffsy Phono Preamp kit, you can etch your own!

This is a single layer version of the Muffsy Phono Preamp PP-3, with ground fill. It will offer proper protection against interference, and almost no copper has to be etched away.

![]()

Download the copper side and silkscreen PDFs from here:

They are in A4 format, so make sure you don't stretch them if you're using a Letter format printer.

A text file included in the zip archive will explain the orientation of the layers.

Note:

Do not use the picture above to etch the PCB, it's just for illustration.

-

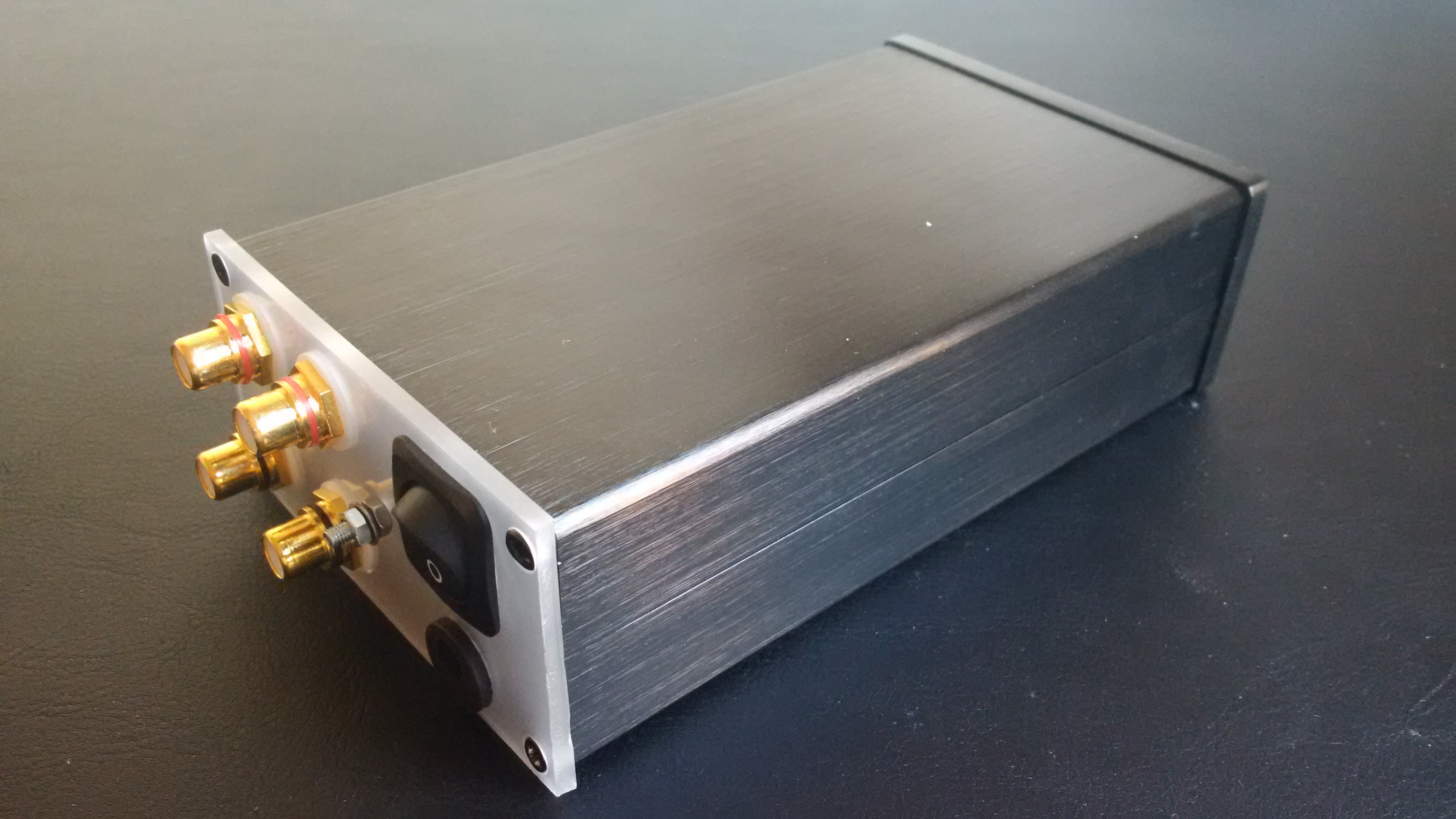

Enclosure

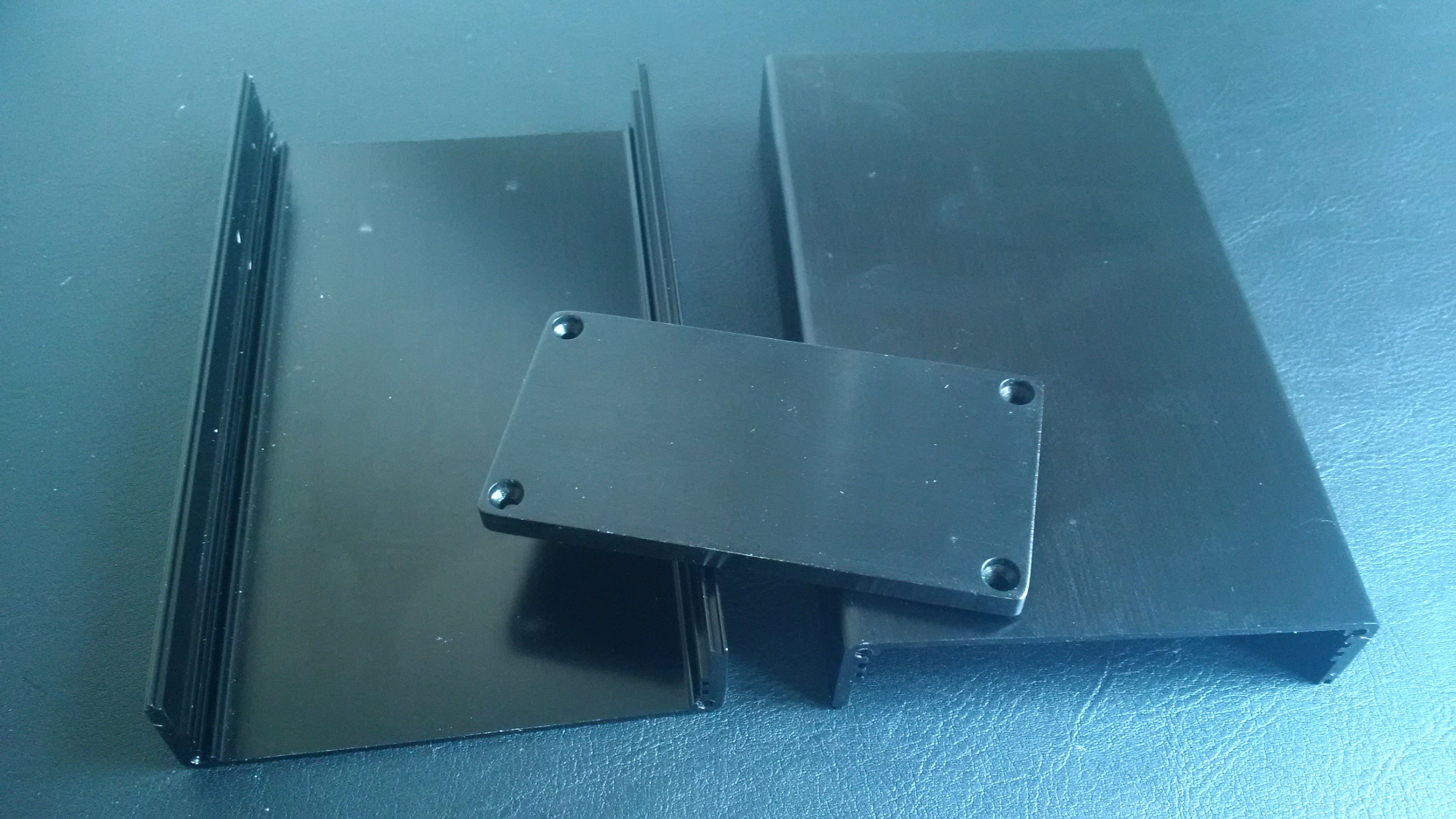

06/16/2015 at 15:49 • 0 commentsYou can pretty much build the Muffsy Phono Preamp into any enclosure you can imagine. This will not cover all possibilities, instead I'll show you how I mounted my phono stage in a B-0905 enclosure that I found on eBay.

The way I found it was simply by searching for "0905 enclosure" on eBay. A couple of weeks later, this showed up:

![]()

These are the dimensions of my enclosure:

- Width: 92 mm

- Height: 47 mm

- Depth: 158 mm

The nice thing about this enclosure is that it has grooves on each side for mounting PCBs, and both the Muffsy Phono Preamp and the Muffsy Power Supply slides right into them. No need for drilling or special mounting.

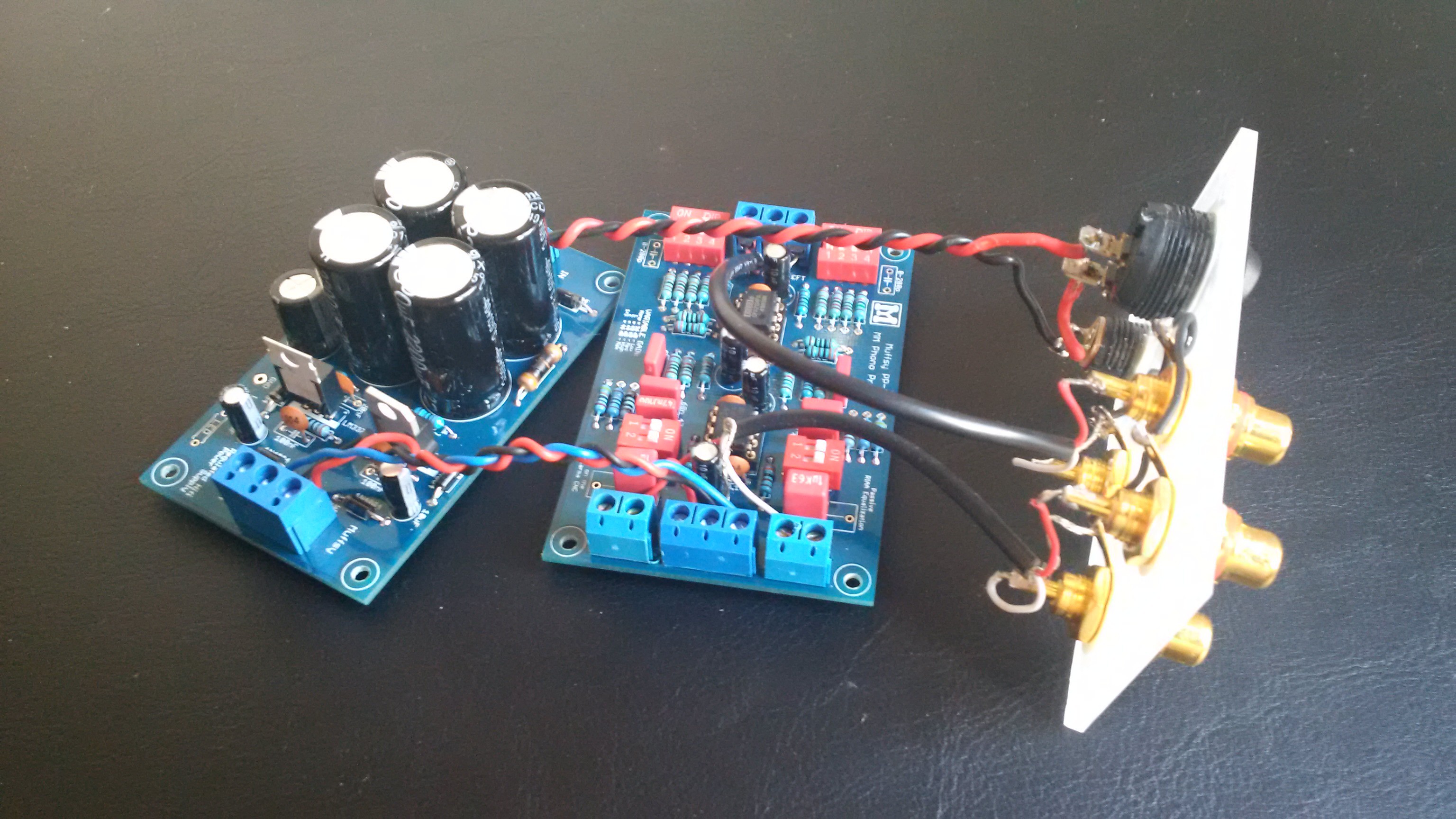

Assemble the Parts

I have prepared the phono stage, power supply and the back panel (click on the links for instructions).

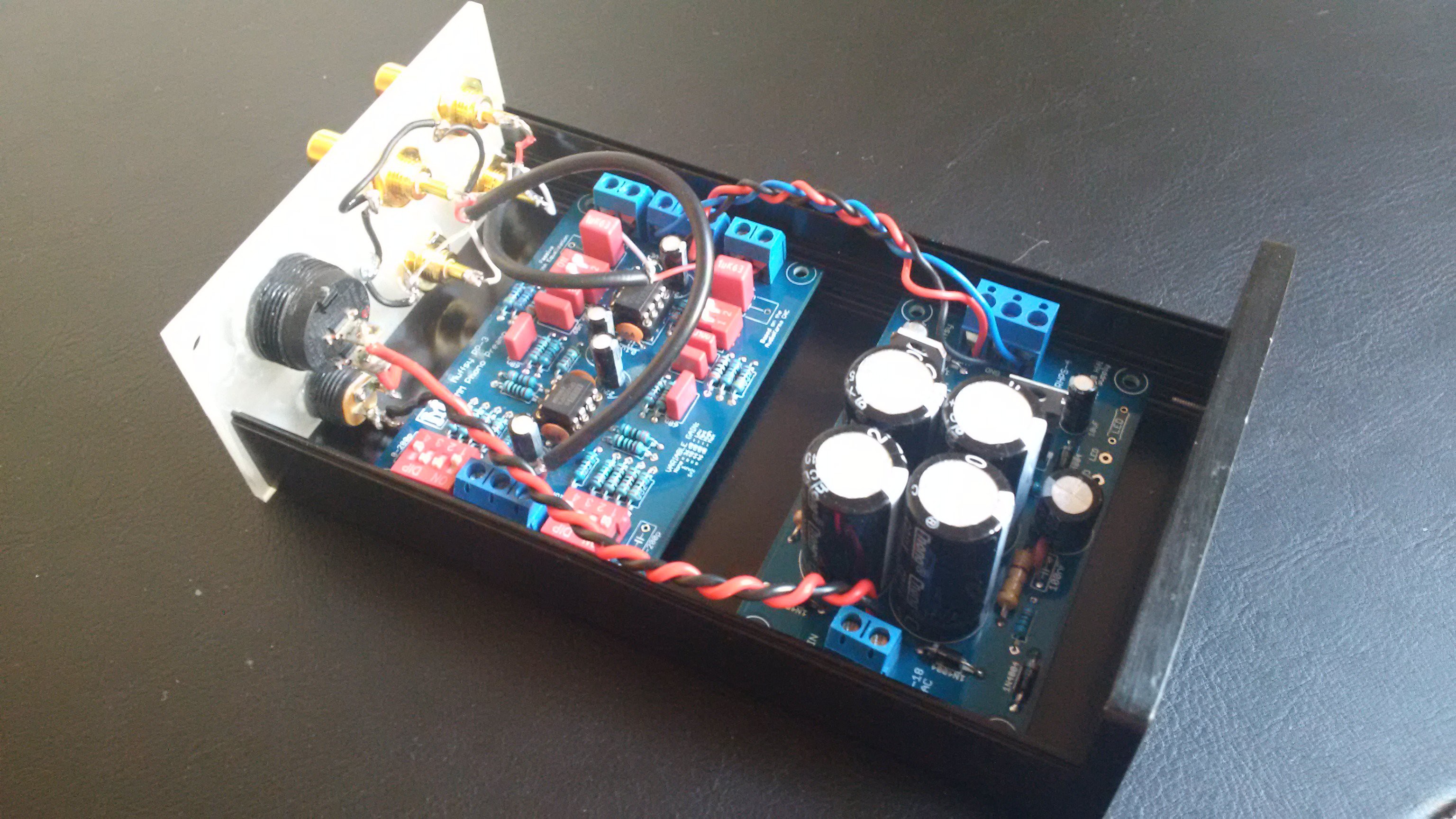

![]()

Notice that I have the holes in the screw terminals facing inwards, to make sure no cables are touching the cabinet walls:

![]()

Insert the PCBs

From here it's just a matter of sliding the PCBs in place:

![]()

Fasten the Back Panel

With the PCBs in place, just fasten the back panel:

![]()

...and We're Done!

Mount the top piece of the enclosure, and you've got yourself a phono stage:

![]()

-

What's New

06/11/2015 at 14:38 • 0 commentsThe Muffsy Phono Preamp PP-3 has been redesigned from scratch. There were a few design elements that were deemed important:

- Size: Standard width of 84 mm (same as the power supply)

- Screw terminals: Must fit within the PCB, and not cover the text

- Audio paths: Shorter and equal length

- Input capacitors on the PCB

- Gain: Both switches set to "OFF" must have a function

- Even better power filtering

- Space for larger audiophile resistors in the audio path

- Improved copper traces for variable size output capacitor

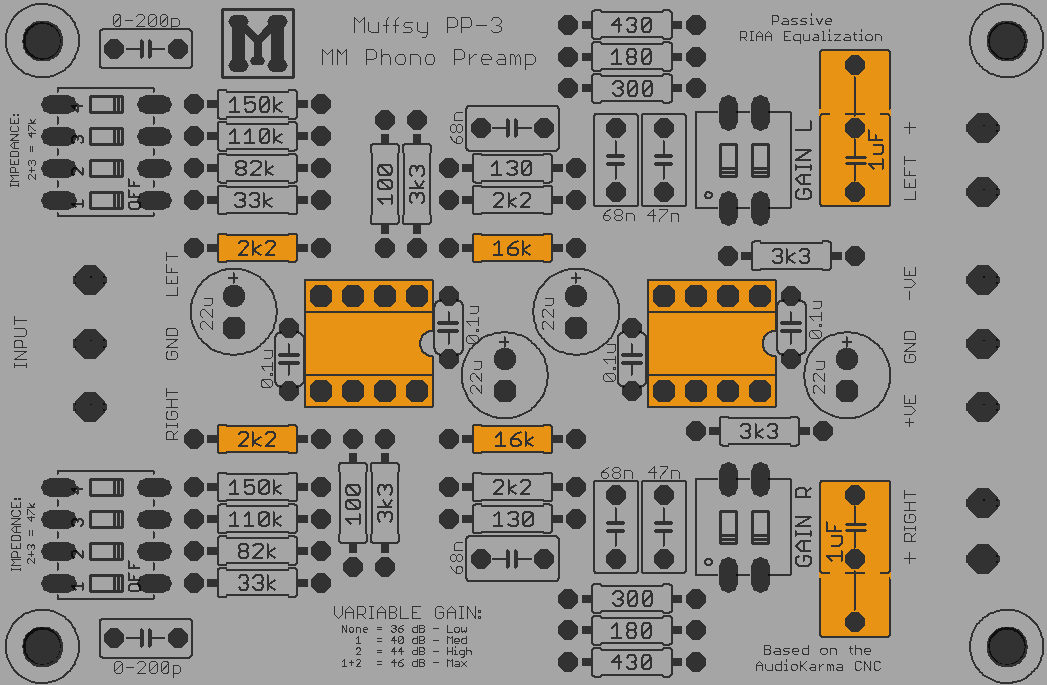

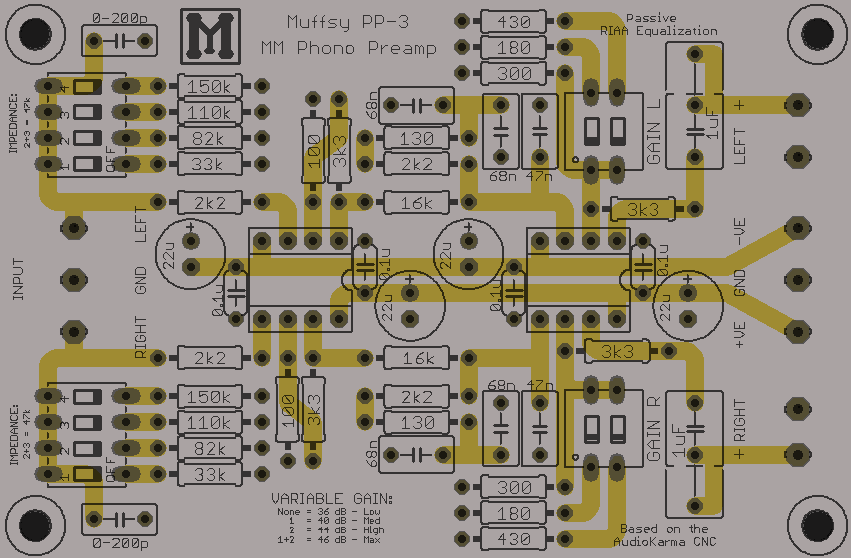

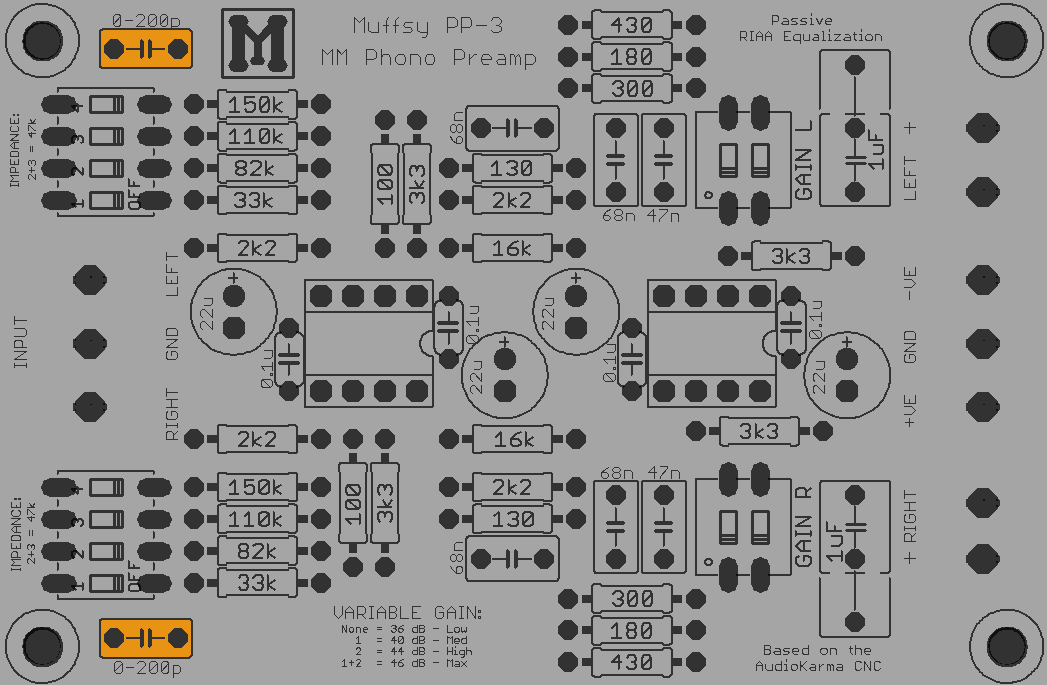

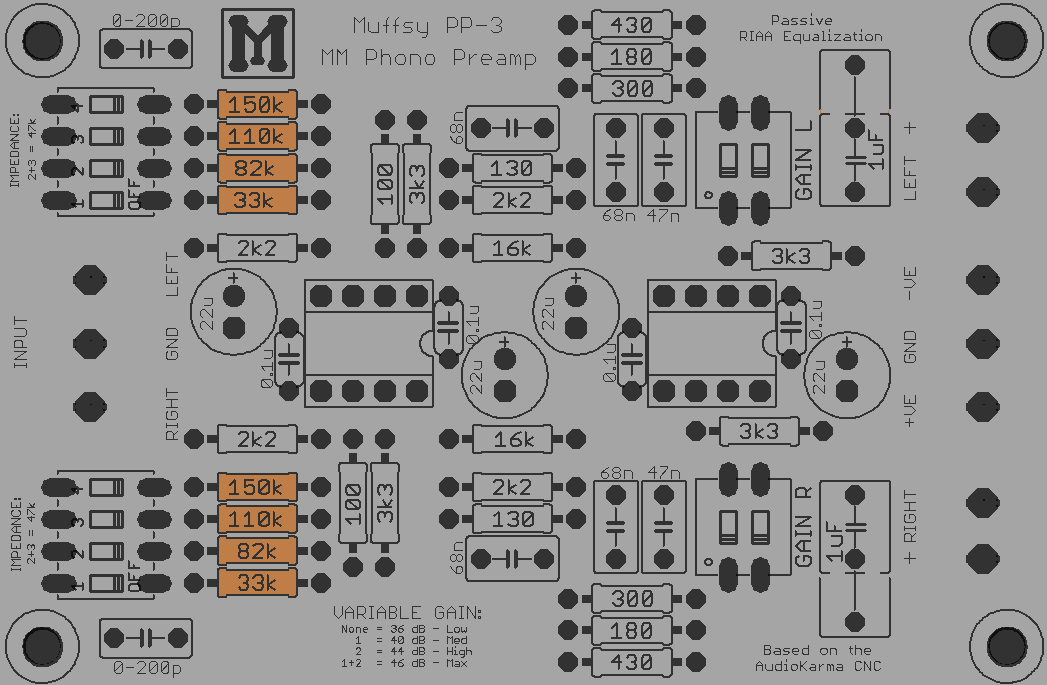

![]()

The picture above shows the top-side of the PCB, the components in the audio path are colored orange. Notice the extra space around the resistors that gives room for the larger audiophile type resistors.

Size

The size of the board is now 84x56 millimeters. This is a standard PCB width, and will make it easier to install in a variety of enclosures.

This PCB (and the power supply) will slide into the grooves of a B-0905 enclosure, as you can see in this picture:

![]()

Screw Terminals

Screw terminals now fit nicely on the board, with space left over on the outside. This can also be seen in the picture above.

Audio Paths

Because of the shorter length of the board, and the added space for screw terminals, the audio paths are abysmally small. What's more, the left and right channel audio paths are exactly the same length.

Input Capacitors

The input capacitors are back on-board. Check this project log for more information.

Gain

Another gain level was added, with both switches set to the "OFF" position. Check this project log for more information and how to modify the gain to suit your requirements.

Power Filtering

The electrolytic bypass capacitors are now 22 uF, up from 10, which will filter the power even more. The 10 uF capacitors will still fit though.

Resistors in the Audio Path

Notice that the two 2k2 and the two 16k resistors in the audio path has more space around them. That will allow the use of Vishay Dale or similar type of larger resistors. All other resistors are not in the audio path, so they won't contribute to the sound signature.

Improved Copper Traces

All traces have been shortened considerably, and both audio channels are exactly the same length. The two channels are also highly symmetrical, apart from the two gain resistors in the first gain stage.

![]()

The copper traces for the output capacitors has been re-routed to improve the connection of larger sized capacitors.

Two of the key elements to doing this was rotating the input impedance switches and changing the placement of the RIAA equalization circuit components.

-

Audio Wiring

06/11/2015 at 13:47 • 0 commentsPutting it all Together

These are the parts involved:

- The phono stage

- Shielded audio cable

- Back panel with:

- Two female RCA panel connectors for input

- Ground screw for input

- Two female RCA panel connectors for output

Back Panel - Grounding

The first thing we'll do is to make sure all the grounds are the same for every RCA connector and the ground screw. Connect them all together as shown in this picture:

Back Panel - Input and Output

These are the cables that connects the phono stage. The best choice will be to use a shielded phono cable, especially for the input.

Here's how the input cable is connected to the RCAs. Connect another cable to the output, which is the two remaining RCA connectors, and the back panel is done.

Phono Stage - Input and Output

The two audio cables, input and output, that connect to the back panel must also be connected to the phono stage.

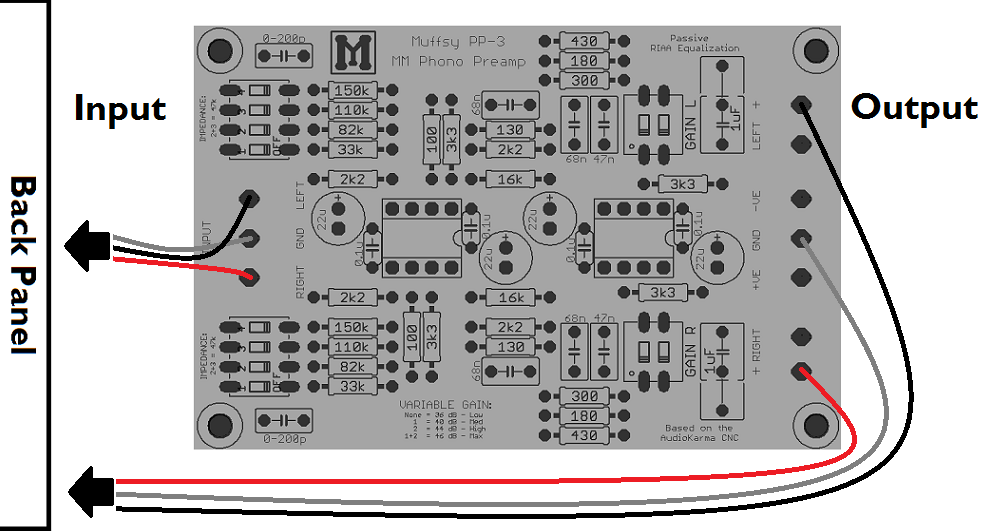

The picture below shows how to hook up the phono stage, using two-lead shielded audio cable:

![]()

The left side of the board is the input (from your turntable), the right side is the output (to your amplifier). They were connected to the back panel in the previous step, and this is where they attach to the phono stage itself.

NOTE:

Make sure that the input is closest to the back panel. You will want the input signal cable to be as short as possible. Both to keep the cabling capacitance down and to avoid unnecessary interference.

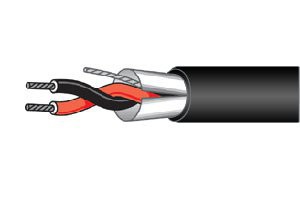

Here's a picture of a two-lead shielded audio cable:

The RED cable is always the RIGHT CHANNEL.

The GREY cable represents GROUND. It will be the shield on your shielded audio cable.

The BLACK cable is the LEFT CHANNEL. Depending on the cable, it can also be white.

Other Cabling Options

Cables can have one lead, two leads, two leads with shield, four leads (with or without shield) and many other variations. The Muffsy Phono Preamp can accomodate all these types of cables.

For the input and output, there are two connections per channel (+ and GND), with a GND connection in between. This makes it easy to find a proper way to cable your phono stage.

-

Input Capacitance

06/11/2015 at 10:50 • 0 commentsPhono cartridges need some input capacitance to function properly, and the Muffsy Phono Preamp PP-3 now lets you add capacitors to fill that need.

We're talking about small levels of capacitance, if any, from 0 and upwards to 200 pF. There is space for these capacitors on the PCB, shown in orange below:

![]()

As the capacitance of the cabling in the tone arm and your signal cables often will be enough (and in many cases too much), you are advised to not install these two capacitors. How do you do that? Just leave the spots empty.

If you don't know if you need any extra input capacitance, chances are that you don't.

There are a lot of resources on the Internet that discuss this topic in detail. That would be outside the topic of this project note, so please consult the web for more information.

-

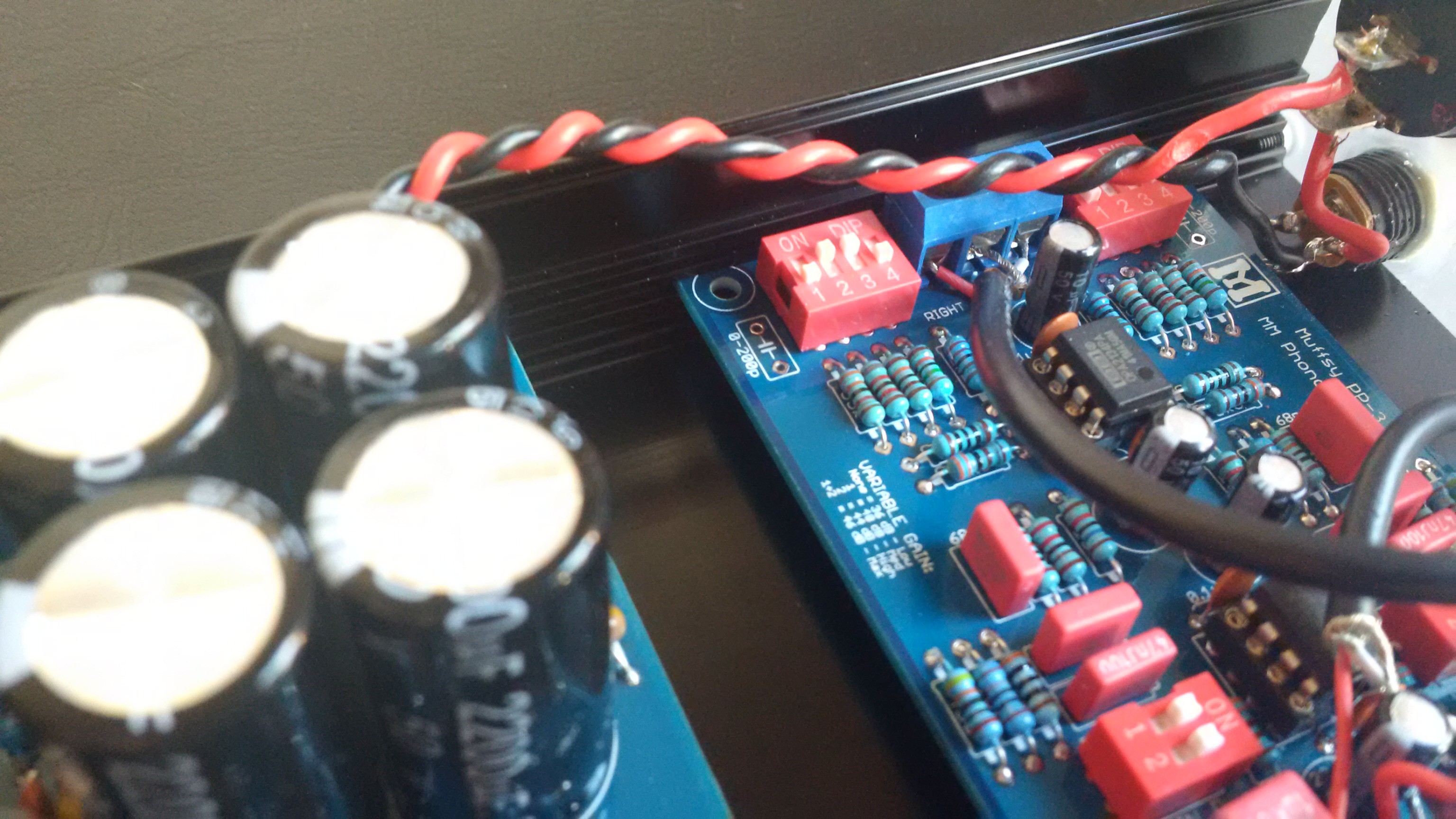

Variable Gain

06/11/2015 at 10:28 • 0 commentsThe Muffsy Phono Preamp PP-3 adds one more level of gain, compared to the PP-2.

By doing so, you get more gain levels to choose from. But perhaps more important, it's become more fail safe as you will even have a gain setting with both switches set to "OFF".

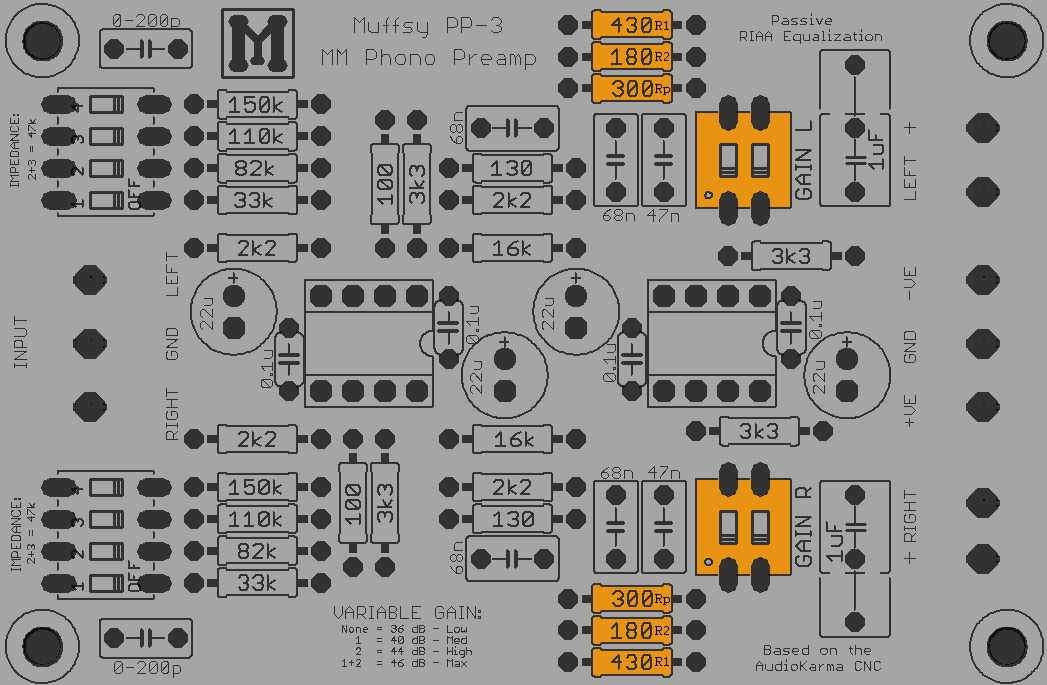

![]()

The gain is set for each channels with the two-way dip-switches and resistors marked with orange in the picture above.

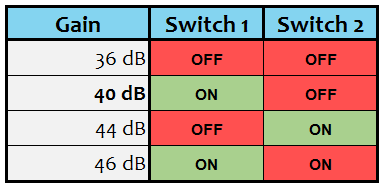

The default build will give you the following gain levels:

![]()

Modifying the Gain Levels

The usual standard amplification of a phono stage is 40 dB (switch 1 set to "ON"). The other gain levels can come in handy depending on the rest of your audio equipment.

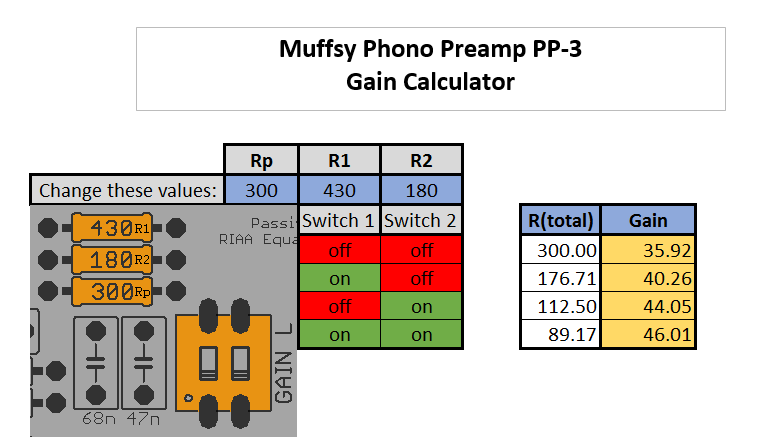

Even though the Muffsy Phono Preamp PP-3 has very usable gain levels, they may not be entirely suitable for your needs. Being DIY, everything can be changed. Here's how.

You will need to find the right resistor values, the ones labeled 430 (R1), 180 (R2) and 300 (Rp) ohms in the picture above. Click on the picture to view a high resolution version, if the text is too small to read.

![]()

This calculator made in Excel will do all the calculations for you, substitute with the ones that you choose and you're good to go. It should be noted that a gain level of much more than 46 dB can, in some cases, lead to more noise.

-

Back Panel

06/10/2015 at 14:22 • 0 commentsThere are many ways to construct the back panel, and you may very well choose a different route.

As a very minimum, you will need:

- Audio input (from your record player)

- Audio output (to your amplifier)

- A ground screw together with the audio input

You will most likely also need:

- Power input connector

- Power button

Here's how I made my back panel.

I ended up working with plexiglass for the very first time. Let me tell you, that's no walk in the park. Unless the park is full of dragons and crocodiles and other things that makes you very cross indeed.

Nonetheless, I think I got the hang of it. Here are a few pictures. This first one shows my desk with a lot of clutter and a piece of plexiglass that has a power button, a 2.1mm power connector and the first two RCA plugs:

![]()

Here's a close-up of the back panel at this stage:

![]()

As you can see between the RCAs and the power button and connector, there's a hole for the ground screw.

Now, here it is completed (yes, I know, the ground screw is still missing):

![]()

The backside looks like this, with ground screw and ground cables:

![]()

There you have it. An input, an output, power and power button, a ground screw and ground cabling.

If you should wonder about the tidying up afterwards, it was almost as bad as working with plexiglass.

-

Powering the Phono Stage

06/10/2015 at 14:13 • 0 commentsThere are a lot of ways to power the phono stage, but they might not be too obvious as it needs a dual power supply. That's positive voltage, ground and negative voltage, in the range of +/- 9 to +/- 18 volts.

I'll give you three ways of powering your phono stage, starting with the absolutely best one:

The Muffsy Hifi Regulated Dual Power Supply

+/- 15 volts is commonly used for operational amplifiers, and that's what you get here.

The quality of this power supply is exceptional, and it must make you wonder what goes into the $1.000 (or more!) power supplies that some manufacturers will be more than happy to sell you.

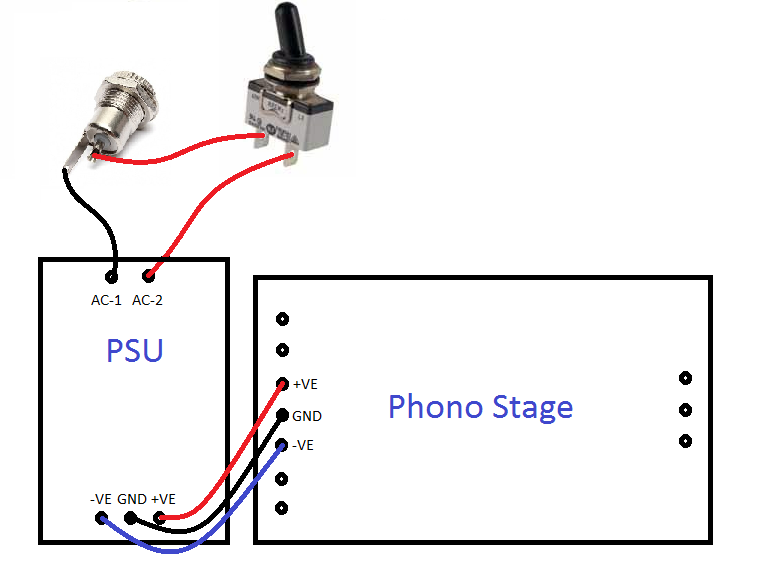

This is how you hook up the Muffsy Hifi Regulated Dual Power Supply:

![]()

The power comes from a 15-18VAC wall wart into the power connector (top left).

One of the cables go to directly the PSU, the other through a single pole single throw (SPST) power switch and then to the PSU. This is how we can turn the phono stage on and off. You don't have to worry about the orientation of these cables, as they both carry the same AC power.

NOTE:

Both power cables are live. Make sure that both the power connector and the power switch are completely isolated from the chassis/enclosure!

With power going into the power supply, you'll get +/-15VDC from it. Connect the +VE, GND and -VE on both boards, and you have power on the phono stage.

You should twist the two cables from the power connector to the PSU, and braid the three cables from the PSU to the phono stage to reduce interference.

If you want to add an LED, the Muffsy Hifi Dual Power Supply has you covered.

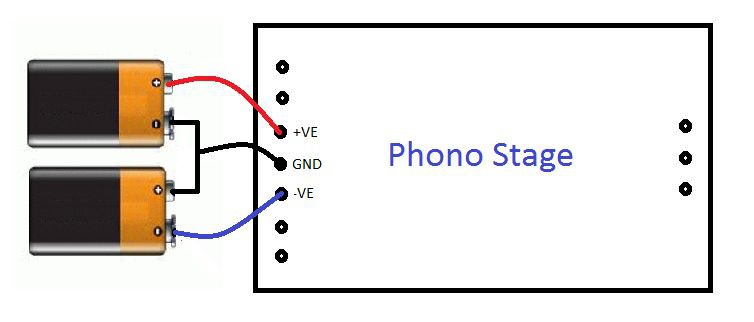

Battery Power

![]()

You can even power the phono stage with two 9 volt batteries, and it will run on them for weeks. Here's how, referring to the picture above:

- GND: Connect the positive side of one battery to the negative side on the other battery.

- +VE: The remaining positive side is your +VE.

- -VE:The remaining negative side is your -VE.

A suitable power switch would be a DPDT, since you need to break both +VE and -VE. Here's a diagram of the cabling with power switch:

![]()

LED for batteries will have to be connected between +VE and -VE. The resistor in series with the LED can be from 820 to 2k2 ohm rated at 1/2W. Lower value gives more brightness.

Just keep in mind that an LED at max brightness uses the same amount of power as the whole preamp. I would recommend using 2k2 ohm and sacrifice some brightness, just to make the batteries last longer. (If the resistor is 1k2 ohm or higher, 1/4W can be used.)

DC to DC Converter

The first two options were either an AC power that was converted to dual DC, or two separate batteries. There's another way that's quite neat as well. On paper, it should be quite a lot worse than the other two. We'll see that it might be a good option after all.

I was in the position where I powered a class D amplifier with an old 19.5 volts laptop power supply, and I wanted to add the phono stage to this setup. A voltage divider was not an option, as the virtual ground and real ground would connect. Not wanting to short-circuit everything, I had to find another solution.

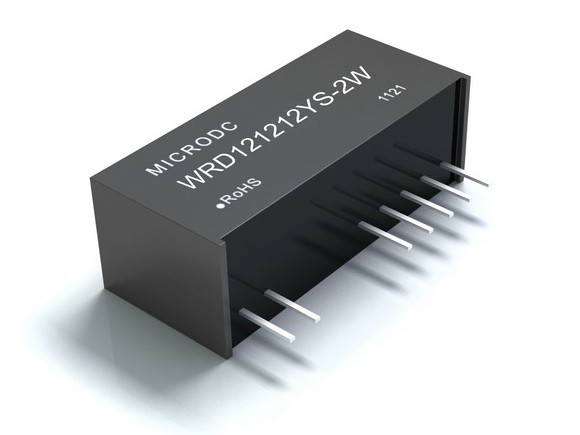

Enter the WRD isolated and regulated, twin output DC/DC converter.

![]()

It comes in different variations, and can be powered by 5, 12, 24 or 48VDC. The output will be twin 5, 9, 12 or 15VDC.

I chose the WRD241212YS-2W, because it accepted an input voltage of 18-36VDC. The output is a twin 12VDC. (The WRD121212YS-2W will accept 9-18VDC in, and will also provide 2x12V out.)

Make sure you choose the 2 watt version to get sufficient power for the CNC. The 2 watt version will power two CNC boards with power to spare, but you'll want that extra headroom.

The twin outputs are really comparable to two batteries, as they provide two independent 12 volt power supplies.

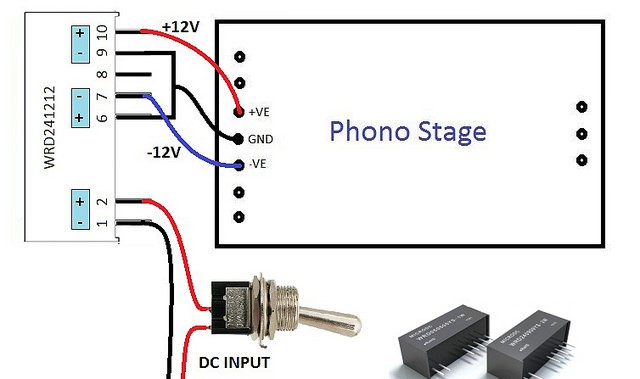

Here's how to wire the WRD, complete with (an SPST) power switch:

(The WRD PSU is much larger on this picture than it is in real life, just to make the wiring easier to see.)![]()

The output power is completely isolated from the input power. The ground connected to the CNC (which is really the positive side on one PSU connected to the negative side on the other) can be connected to the INPUT DC ground without any worries. This is really helpful if you want to trace down and get rid of any ground loops.

So why is this the worst (on paper) solution? The WRD power supply has a very high ripple. up to 50mV, which is 500 times as much as the Muffsy power supply. That is quite a bit worse, to be honest.

The phono stage's onboard bypass capacitors will filter away much of this ripple, and the ripple rejection of the operational amplifiers takes care of the rest. I have used this solution, and it is absolutely impressively silent.

If you want to add an LED, connect it between -VE and +VE. Connect a 1k5-4k7 ohm resistor, rated for 1/2W in series with the LED. Lower resistor value gives brighter light. (If the resistor is 3k9 ohm or higher, 1/4W can be used.)

-

Input Impedance

06/10/2015 at 14:02 • 0 commentsAlthough the default input impedance for most cartridges is 47k ohm, many are reporting that other input impedances are giving better results.

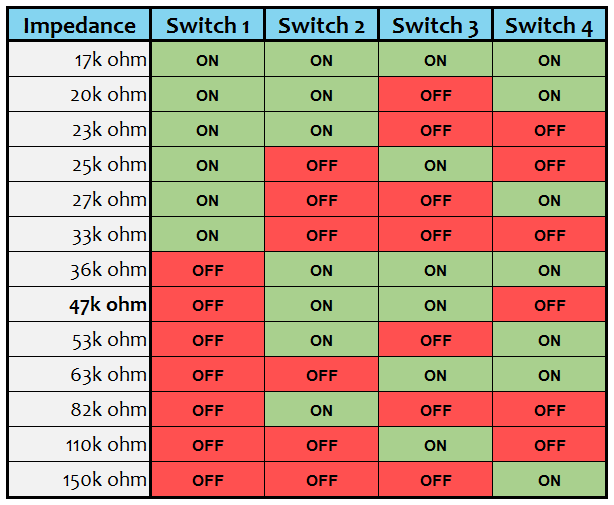

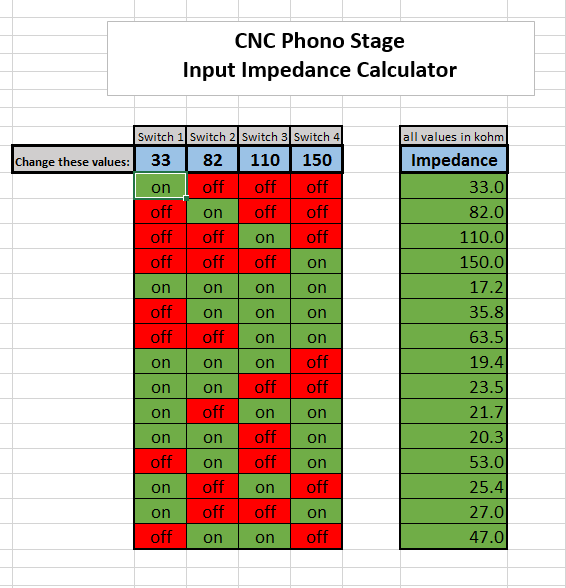

The standard CNC circuit has the following impedances, selectable with a four-way DIP-switch:

- 18k, 33k, 47k and 62k ohm

These values are quite sound when looking at them one by one. Having the possibility of paralleling up to four resistors should give a few more useful options. The four values above don't give many other options though.

How about using these values instead?

- 33k, 82k, 110k and 150k ohm

Let's see what we end up with:

![]()

(The value in bold is the industry standard impedance for MM cartridges)

There are a few options that are too close together to be useful (which I haven't listed in the table above), but we get quite a range to choose from nonetheless. Look at this next bit for a complete list of impedance choices.

Modifying the Input Impedance

Part of the fun of building something yourself is that you can adapt the project to suit your needs. Here's how you can modify the input impedance.

It's all a matter of changing the resistors shown in orange below:

![]()

These are the input impedance choices you get with the default resistors:

![]()

To help you decide the best set of resistors, use this Excel impedance calculator. Simply fill in different resistor values and see the impedances change.

NOTE: The industry standard input impedance is 47 kOhm. I would recommend that at least one of your settings matches that, or has a value that's reasonably close to 47 kOhm.

You may notice that there are a few more values in this table (which uses the default Muffsy PP-3 values) than what I have presented earlier. That's because I chose to ignore some of the impedances that are almost equal.