-

Part the Schematic

08/17/2015 at 18:36 • 0 commentsThe electronics could hardly be an simpler; I used a board from a previous project and modded it slightly as described in the earlier logs. Here is the effective schematic:

This board has two programming headers because this PCB needed to be able to be programmed from either the PICKIT3 or MELABs' own programmer. It complicates the visual of the schematic a bit, but it sure helped when initially programming the boards for the movie project that I made them for originally.

-

Part the Code

08/17/2015 at 18:31 • 0 commentsWay back on Star Trek: First Contact I started using Microengineering Labs PICBASIC PRO compiler. I used PICBASIC to write the code for the Borg suits and the spacesuit lighting in that film... That was 19 years ago, and I still use it for simple projects because it is very fast for me to develop in. Here is the very simple program to operate the lighting here:

'written for PICBASICPRO V3 'author Alan McFarland 'August 16, 2015 'simple program to operate lighting for Harlan's walker 'uses PIC12F1501 DEFINE OSC 16 'define the clock speed so PICBASIC knows OSCCON = $FF 'set speed to 16MHz '****************************************************************************** ' SETUP '****************************************************************************** ADCON1 = %00001111 'port a is all digital IO tape con 3 'output pin to LED tape relay var porta.2 'output port to control relay pwmrate con 20000 'pwm freq faderate con 10 'delay in PWM loop to control duration of rate change level var byte count0 var word begin: high relay 'as soon as the µC wakes up, turn on the relay to latch the power hpwm tape,0, pwmrate pause 250 'let settle trigger: for count0 = 0 to 255 gosub fetch 'read in the sine value from the lookup table hpwm tape,level, pwmrate 'send to hardware PWM & fade up to full pause faderate next for count0 = 1 to 50 'with a 2.3 second nap, this keeps light on for 115 sec NAP 7 ;nap for 2.3 seconds next for count0 = 0 to 255 gosub fetch 'read in the sine value from the lookup table hpwm tape, 255 - level, pwmrate 'reverse the value since we are fading down pause faderate + 20 'make it longer to provide notice that its shutting off next low relay 'this will turn off power to the board END fetch: lookup count0,[0,0,0,0,0,0,0,1,1,1,1,1,2,2,2,2,3,_ 3,3,4,4,4,5,5,6,6,7,7,8,8,9,9,10,11,11,12,13,13,14,15,16,16,_ 17,18,19,20,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,_ 42,43,44,45,46,48,49,50,51,53,54,55,56,58,59,60,62,63,64,66,67,69,70,71,73,_ 74,76,77,79,80,81,83,84,86,87,89,90,92,93,95,96,98,99,101,103,104,106,107,109,110,_ 112,113,115,117,118,120,121,123,124,126,128,_ 128,129,131,132,134,135,137,138,140,142,143,145,146,148,149,151,152,154,156,157,159,160,162,163,165,_ 166,168,169,171,172,174,175,176,178,179,181,182,184,185,186,188,189,191,192,193,195,196,197,199,200,_ 201,202,204,205,206,207,209,210,211,212,213,215,216,217,218,219,220,221,222,223,224,225,226,227,228,_ 229,230,231,232,233,234,235,235,236,237,238,239,239,240,241,242,242,243,244,244,245,246,246,247,247,_ 248,248,249,249,250,250,251,251,251,252,252,252,253,253,253,253,254,254,254,254,254,255,255,255,255,_ 255,255,255], level return -

Part the Fifth

08/17/2015 at 11:02 • 0 comments -

Part the Fourth

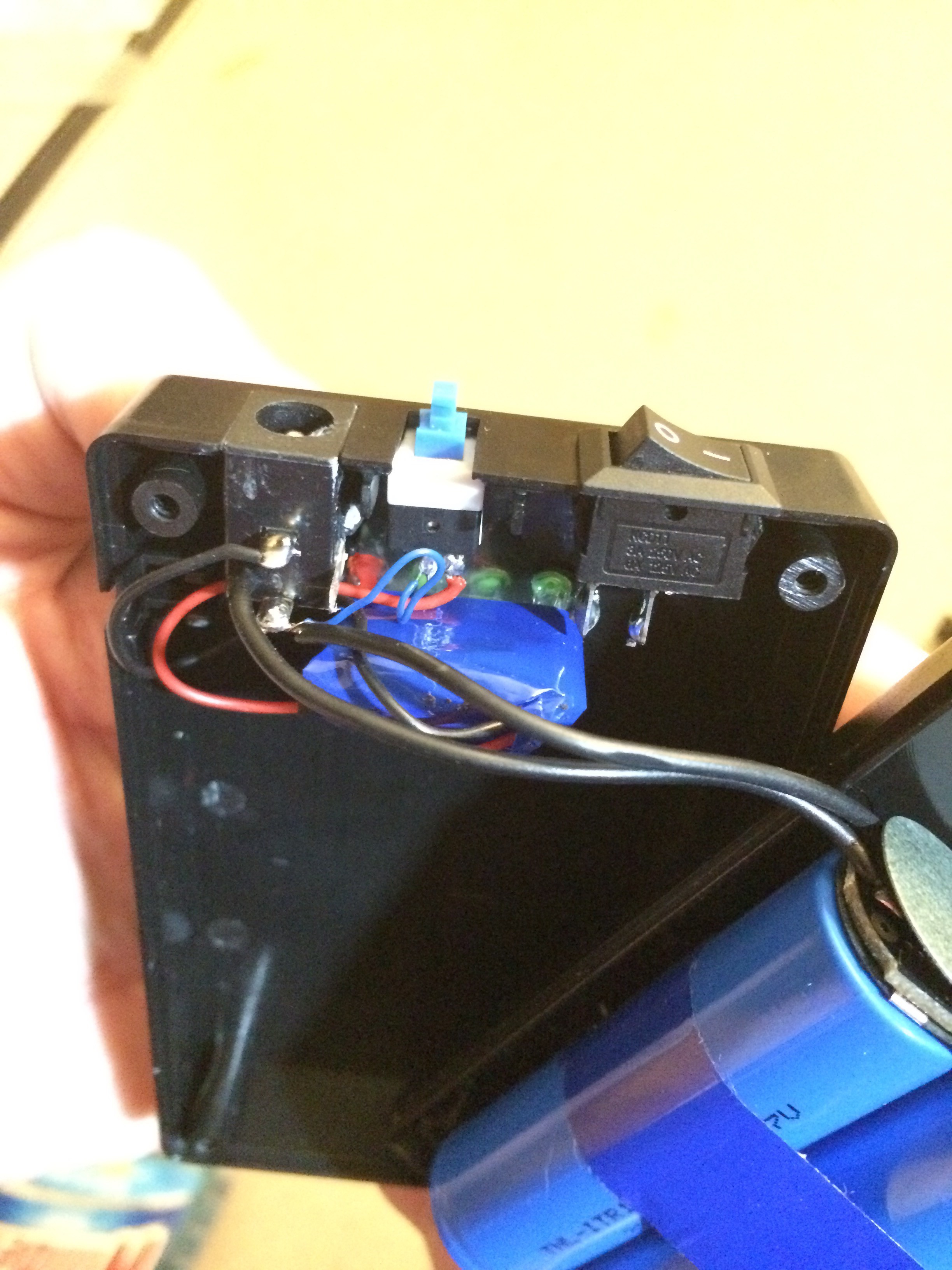

08/17/2015 at 10:56 • 0 commentsI also wanted to use jacks everywhere so it could be easily removed and serviced if necessary. I hard-wired the power plug (red/black wire with hot glue strain relief) that would connect to the battery pack, and used two jacks for the LED tape feed and the switch connection:

Although both of the jacks appear to be the same, the LED tape one is 2.5mm center and the switch is 2.1mm center, so they cannot be mistakenly interchanged.

The power pack and the project box I used were exactly the same size. Some thin Velcro holds the two boxes together.

And all the works conveniently fit inside the walker's utility pouch: battery pack, lighting controller, and battery charger:

All that was left was to make the button. Again I used some heat shrink to protect the wire & connection, and attached it up by the right side handgrip:

-

Part the Third

08/17/2015 at 10:45 • 0 commentsAmazon has a 12V lithium ion battery pack I'd used on other projects before; it comes with a charger and the price ($24) is pretty decent to get it next day. (Aliexpress has better pricing, but it can take weeks to get stuff from China).

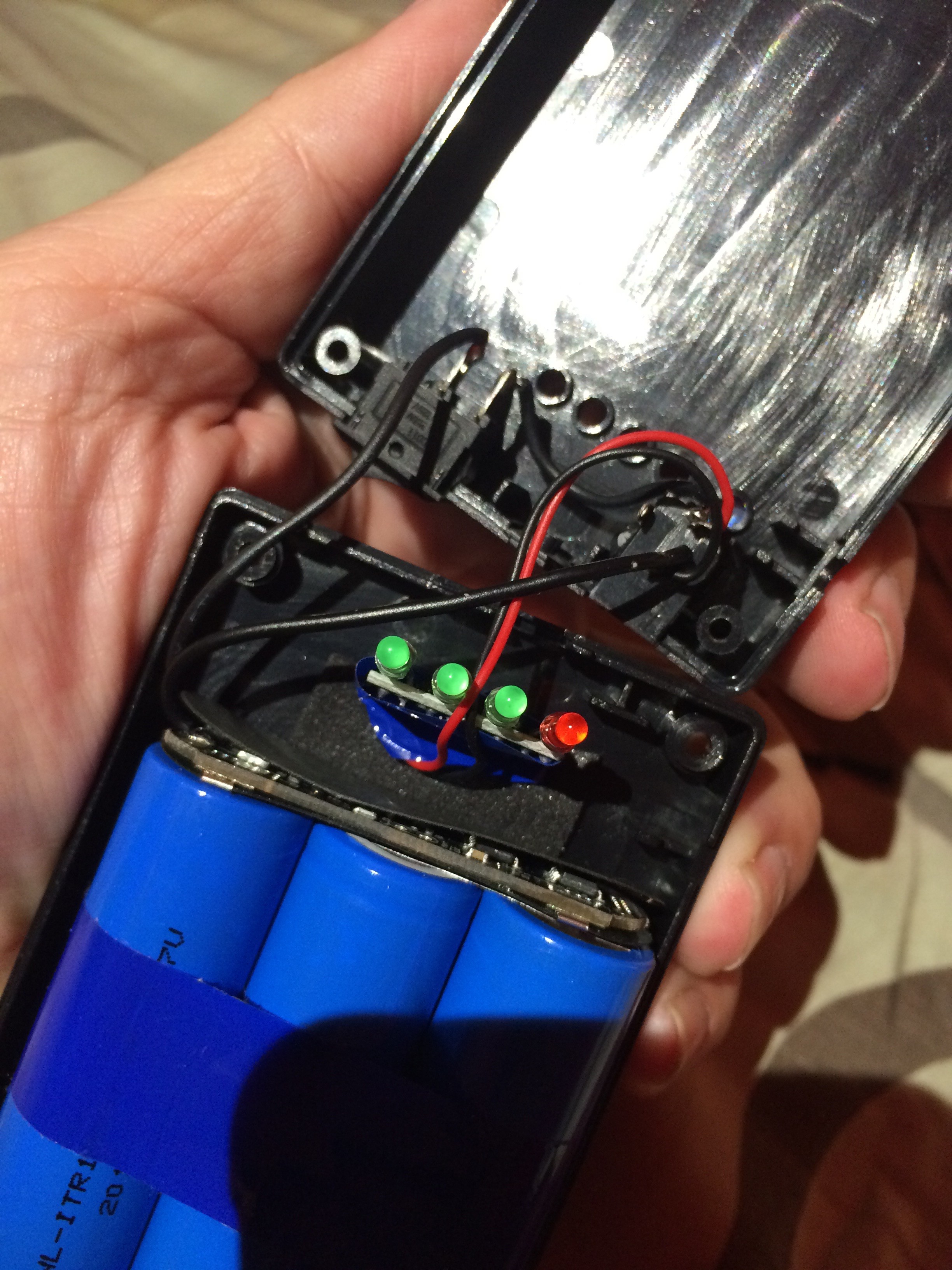

For this application though, the battery pack required a bit of hacking. First off, there's a switch on the battery pack that must be on for the unit to operate, and that switch must also be in the on position to charge it. Not intuitive, in my opinion. It also has a battery gauge that reads out the charge level.

That LED level indicator is handy, but it is on all the time the battery pack is on. That would drain the battery pretty quick. So I opened up the pack, wired the rocker switch out of the circuit, and put the charge indicator on a momentary switch so it could be used to gauge the charge only when someone is actually looking to check the level.

Switch bypassed and momentary switch installed:

Reassembled:

-

Part the Second

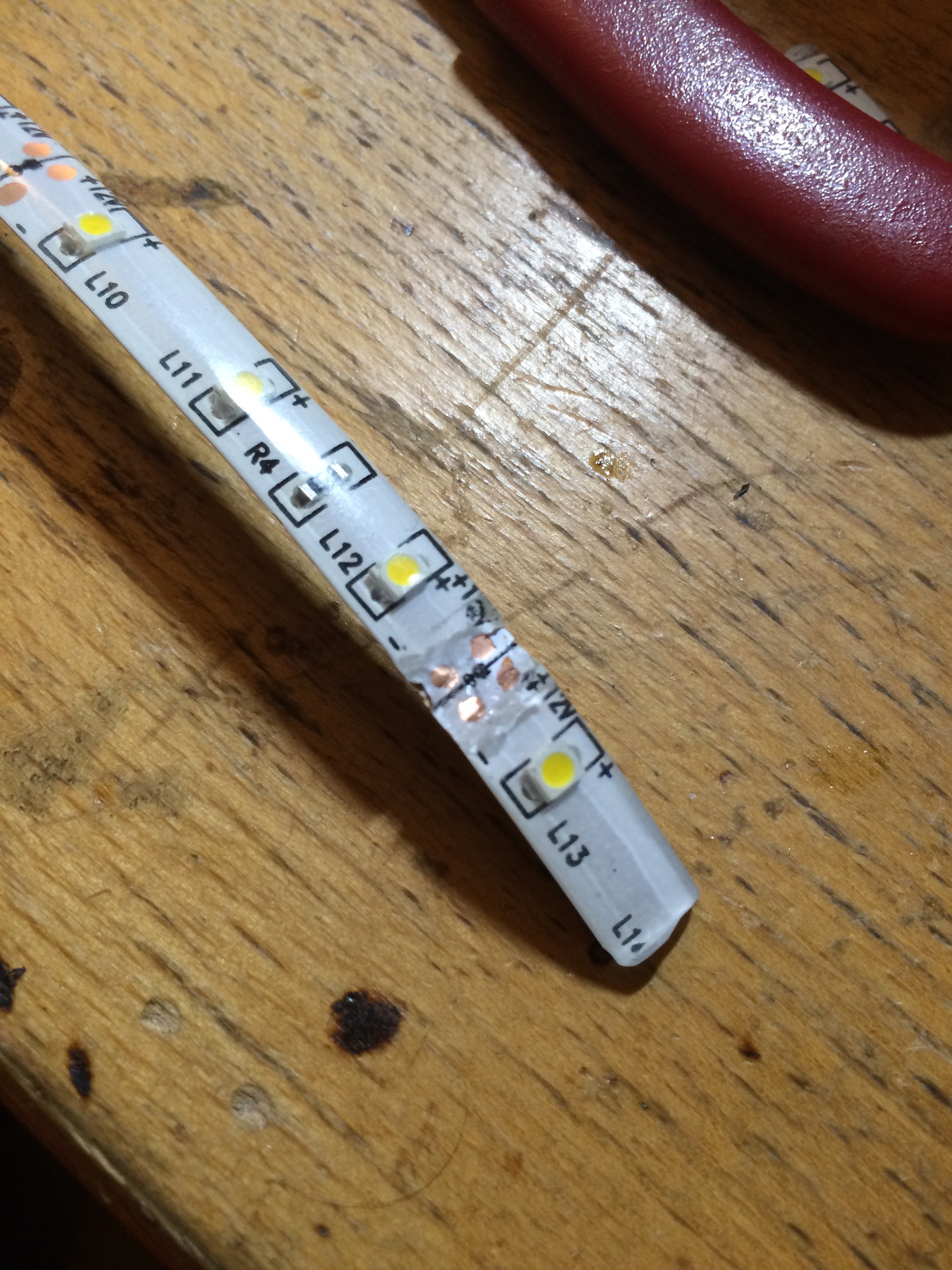

08/17/2015 at 10:31 • 0 commentsNext up was the LED tape selection. I wanted to use waterproof tape, because I learned from building the LED lightsuit for Dr Manhattan on the Watchmen movie that unprotected LED strip is easily damaged. Waterproof LED tape wasn't available back in 2007 when we did that movie (back then blue LED tape was over $100 a roll!), but silicone-sealed LED tape is easily available from Amazon, and I had a partial reel of it left over from something I did for The Magic Castle a few years ago:

I cut a piece to the proper length to fit the front bar of the walker, and then stripped away the silicone an inch in so I could solder the wires onto it (a rosin flux pen is invaluable for this!) and then heat shrink the whole thing to protect the junction.

Tape with silicone cut away:

Wires soldered:

Heat shrinked:

And installed on the walker's front bar:

-

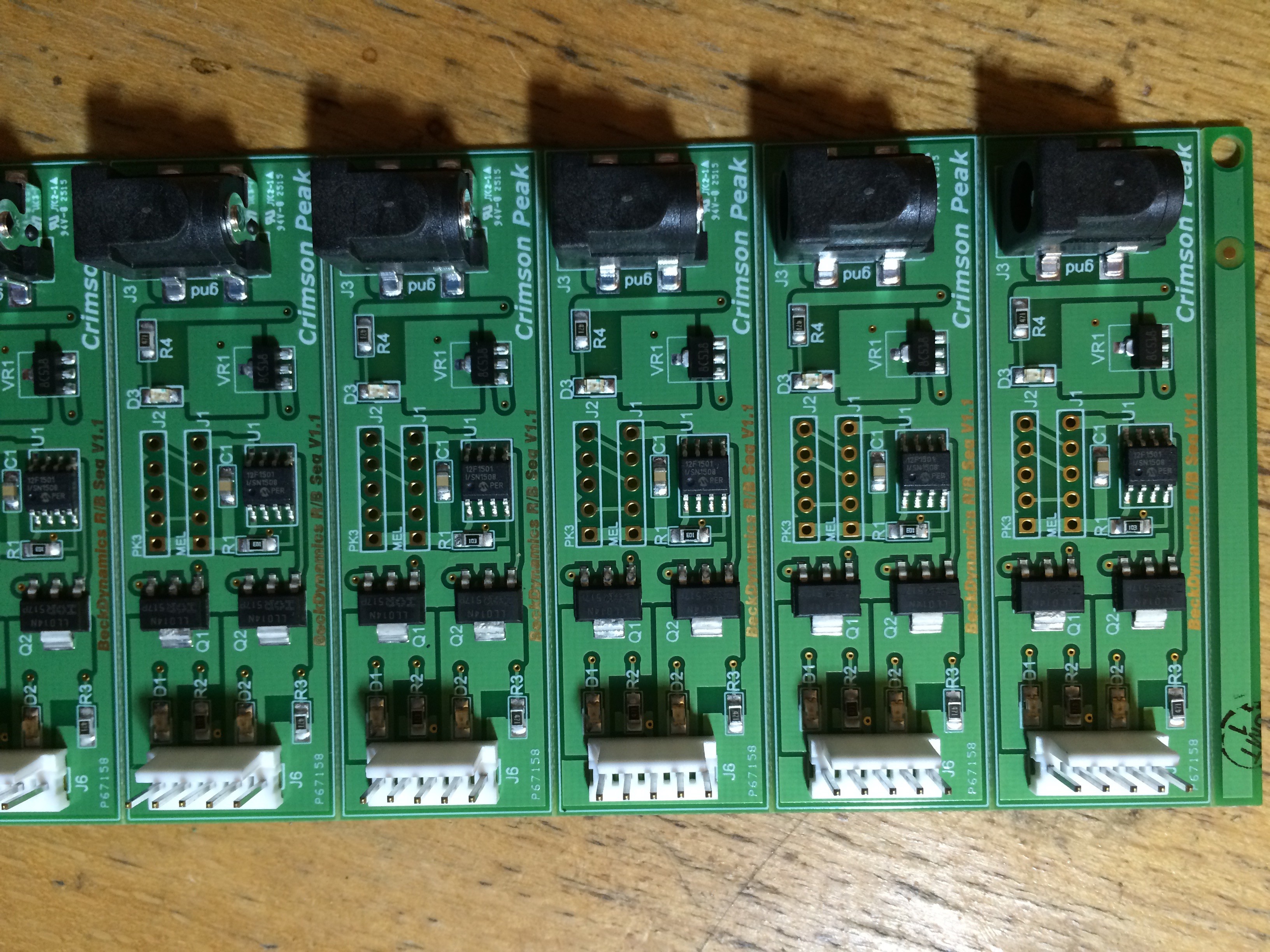

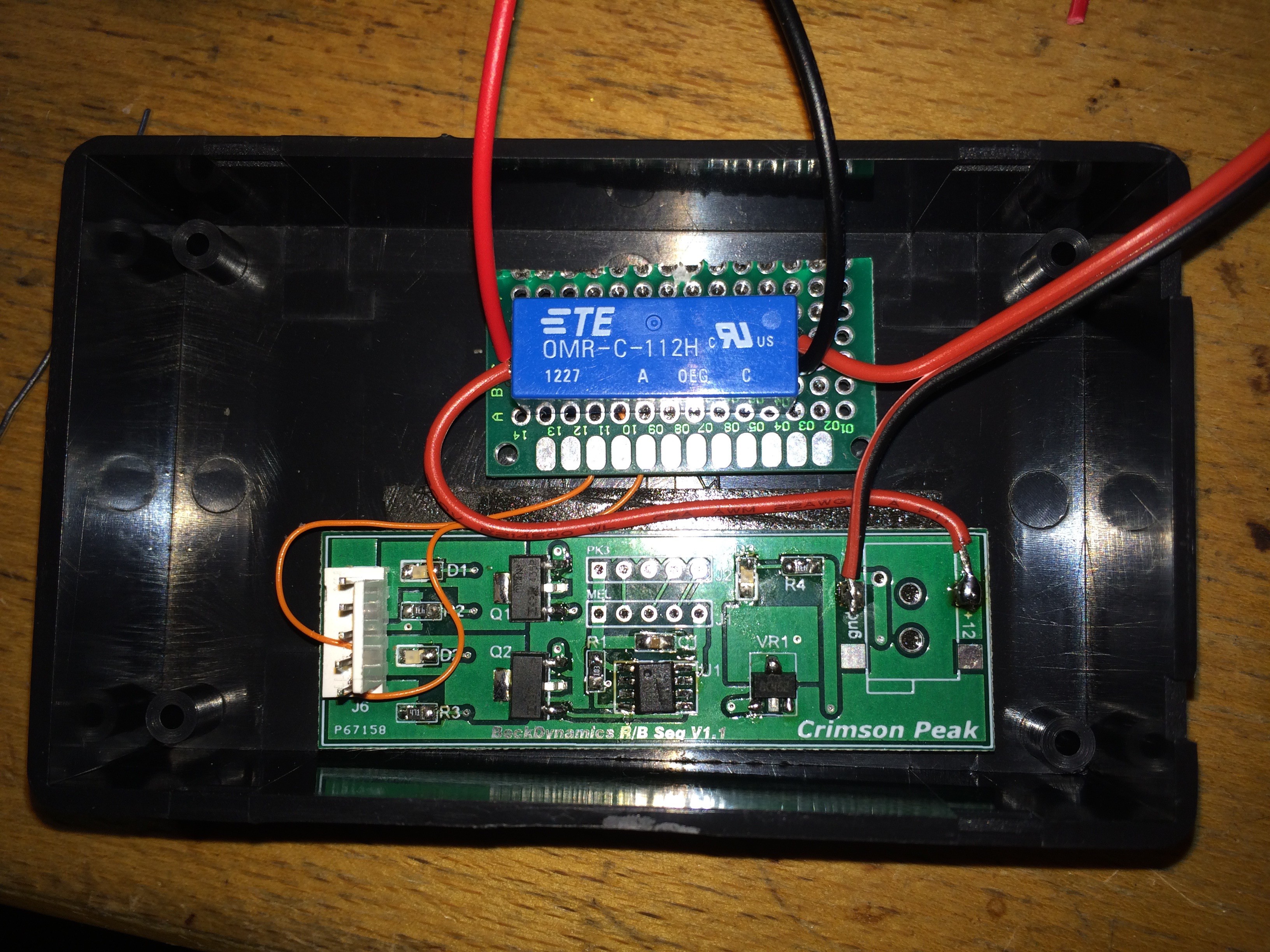

Part the First

08/17/2015 at 10:19 • 0 commentsI've made hundreds of circuit boards over the past 27 years for electronics special effects movies over the years, so I figured I probably had something that would work. I wanted essentially a timer with a MOSFET to switch 12V through PWM. I had recently finished something for a movie coming out later in 2015 and I had a bunch of PCBs left over form it, and I realized I could use one of these little boards with almost no modification.

This board has two MOSFET outputs for two different LED control channels. One of my design goals for this was to have the battery last as long as possible without recharging, but since I was using 12V LED strip and a 5V PIC processor, sleeping the processor wouldn't be good enough as the 5V regulator would always draw some current.

The solution I came up with was to use one output for the LED tape, and use the other output to switch a relay to open the circuit from the battery pack completely. Then all the pushbutton switch would have to do is close the circuit across the relay contact--the µC would activate, turn on the relay coil, and then the pushbutton switch could be released. The µC would fade up the LEDs, time their on duration, fade the LEDs off, and then turn off the relay coil to save the battery. This approach worked really well, and the reed relay coil only draws a mere 11mA.

Path Lighting for Walker

A lighting rig that attaches to walkers to assist users to see where they are going in the dark.

scubabear

scubabear