I have had a lot of requests for a how to on making the mechanical portion of the feeder. Well Here it is:

Spec's

20mm:

-federate [need to measure this]

-can handle food upto 4mm

25mm

-1L/min Federate with 50:1 ratio box

- can handle pelted food upto 6mm

What you will need:

Tools:

-Hand Drill

-Allen KEys

-Philips Screw Driver

25mm Feeder Parts

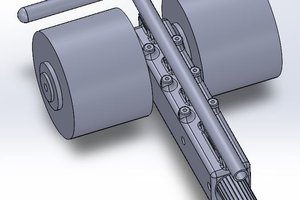

>25MM X 235MM SDS auger wood drill bit

>25mm Pvc Inspection Tee

>28mm metal saddels [28 mm MSBZP] two of these

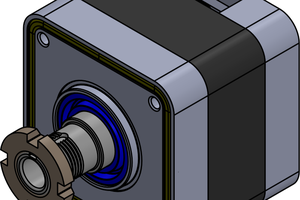

> Aluminum Flexible Shaft Coupling 6mm to 10mm [SDS is 10mm, motor 6mm]

> MFA 919D 12v dc motor, 50:1 and lower gear ratio

>8 wood screws

>2’ Length of 3x2” wood

> 5cm length of 25mm PVC piping [for fitting the hopper]

As You can see the Motor is an expensive one, I had one of these knocking about but any similar power slow rotating [120 rpm and below] 12v motor should work. It is important to get one that has a shaft height [ie the heigh of the shaft above the mounting plate] of blow 14mm. If it is lower you can always mount the motor on a shim.

20mm Feeder Parts:

>20MM X 205MM SDS auger bit

>20mm Pvc Inspection Tee

>25mm Pvc Saddels [two of these]

> Aluminum Flexible Shaft Coupling 4mm to 10mm [SDS is 10mm, motor 4mm]

>Electric 2 Pin Connector DC12V 40-50mA 10RPM DC Geared Motor

>8 wood screws

Feel Free to use this design, modify it and make it better if you can see a way to do so.

For great ideas on how to control this unit with codes, wiring diagrams and everything you need take a look at:

https://hackaday.io/project/7008-fly-wars-a-hackers-solution-to-world-hunger

[You will find them about half way down, I recommend the temperature based arduino controller]

Michael Ratcliffe

Michael Ratcliffe

Rory

Rory

f4drj

f4drj