Why mains?

There are some nice benefits of a mains voltage PCB heated bed:

- high power output

- cheap (no need for costly PSUs)

- lightweight (no aluminium plate needed like in silicone heater pad solutions)

- handy (reduces weight and size of printer due to smaller PSU)

- versatile (any printing surface my be installed on top of it)

- highly efficient (about 10 % less electricity cost over MK2+PSU with typ. eff. 90%)

Features

This implementation comes with a few more extra features:

- super fast heatup time (about 10 times faster than the common MK2)

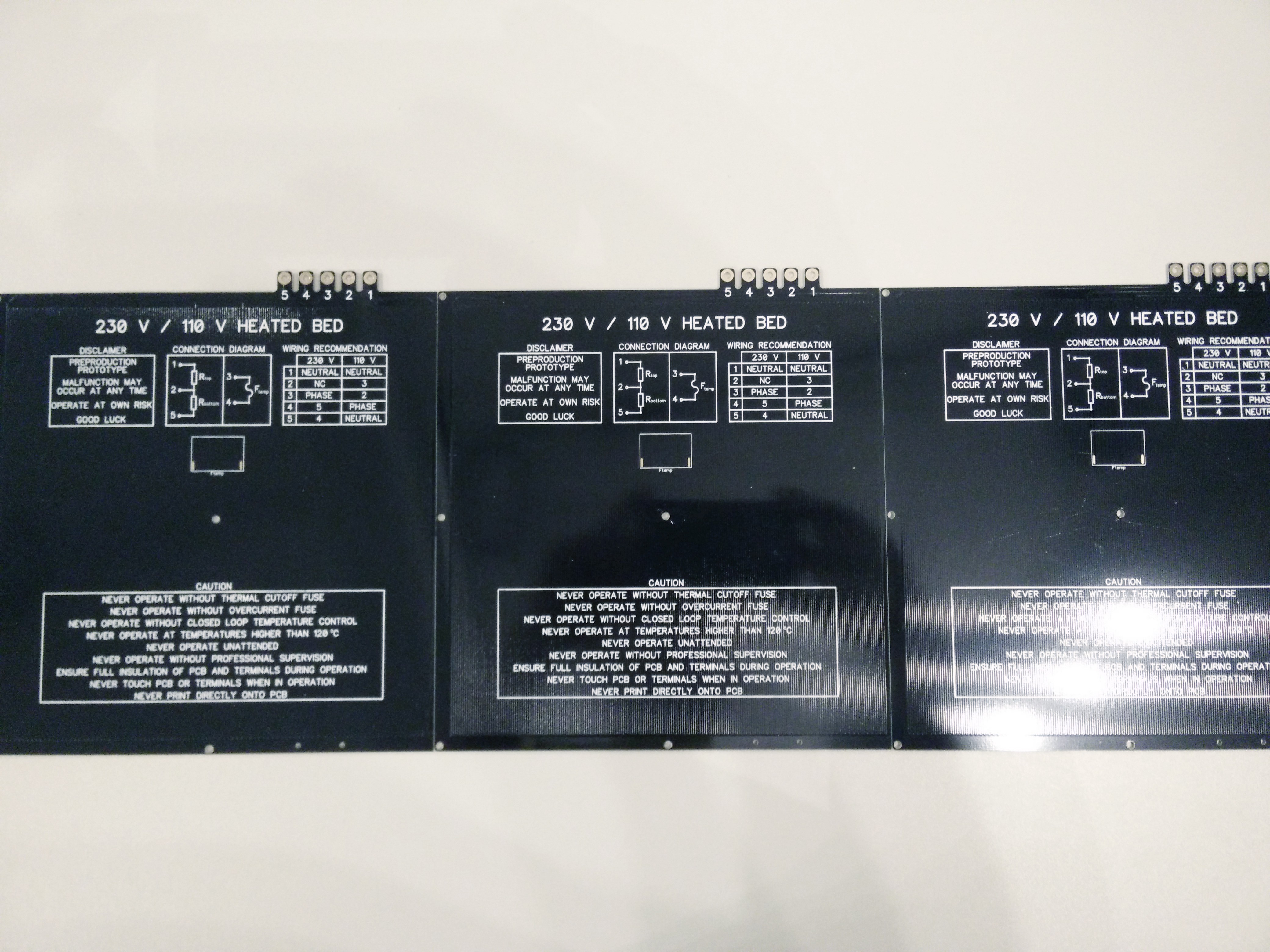

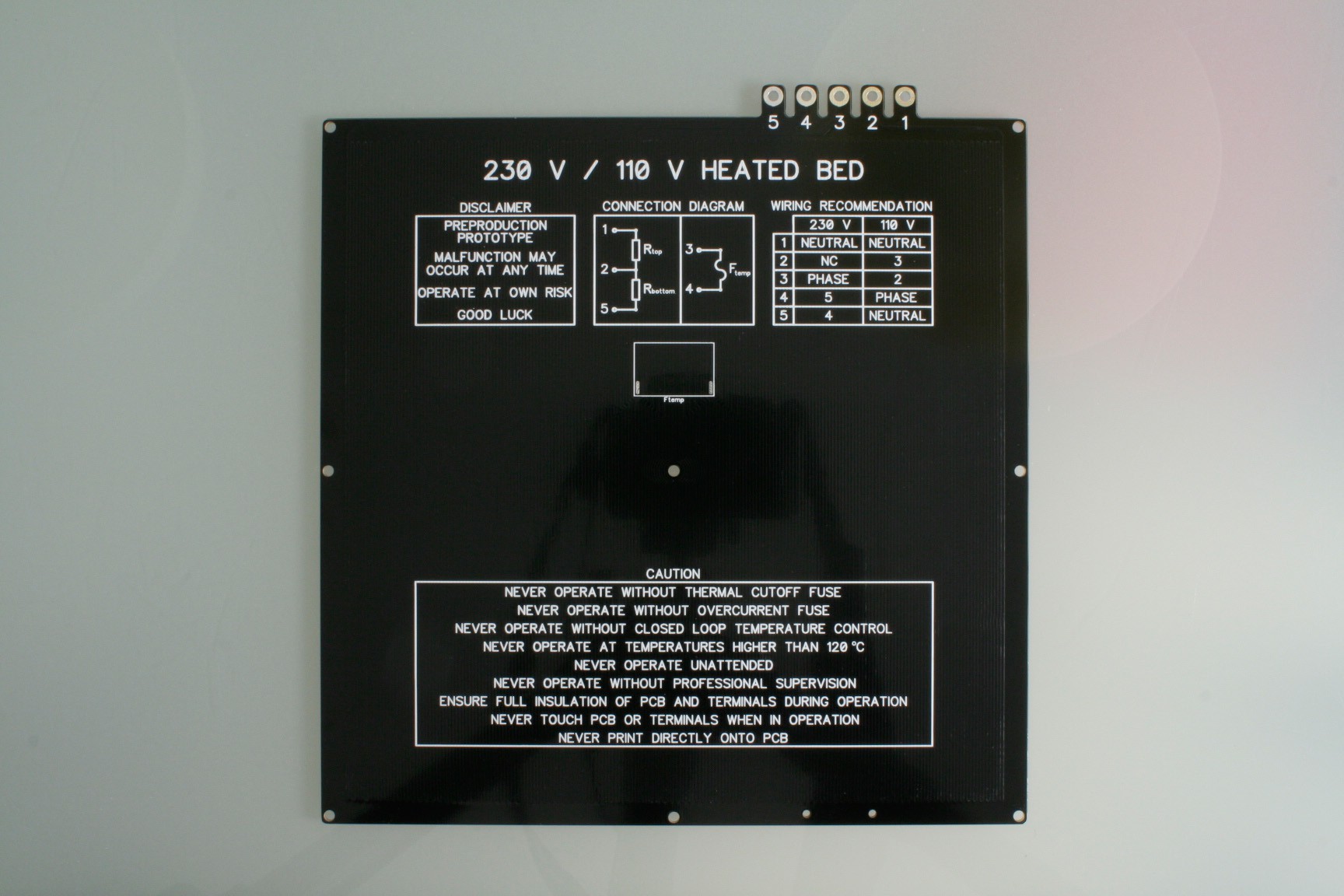

- 230 and 110 V~ support

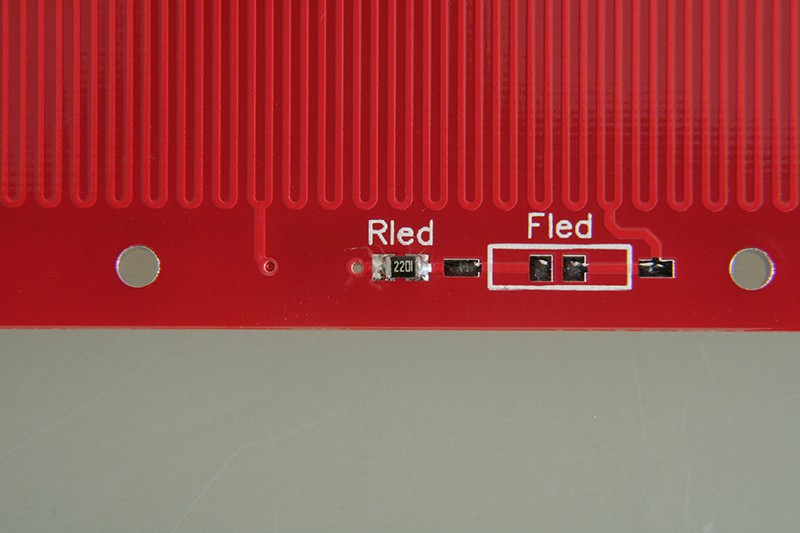

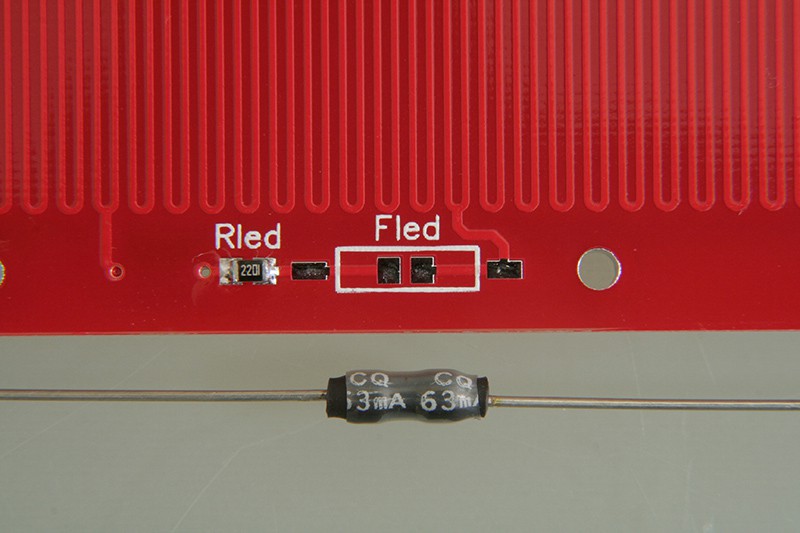

- power indicator LED covered by tough transparent polycarbonate

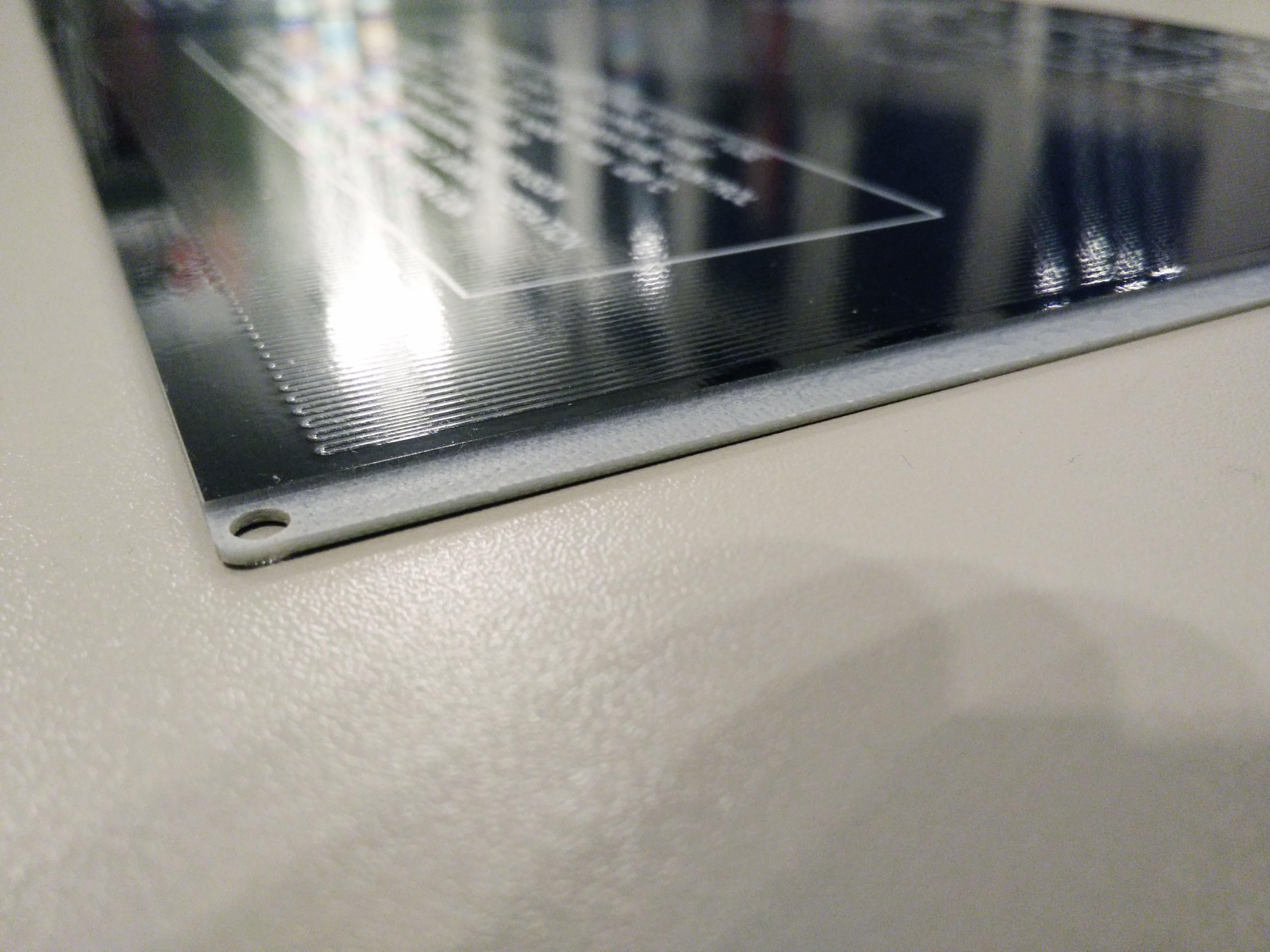

- no thermal breathing / flex due to double sided layout

- extra mounting holes for three point leveling

- compatible with RepRap MK hole spacing of 209 mm center-to-center

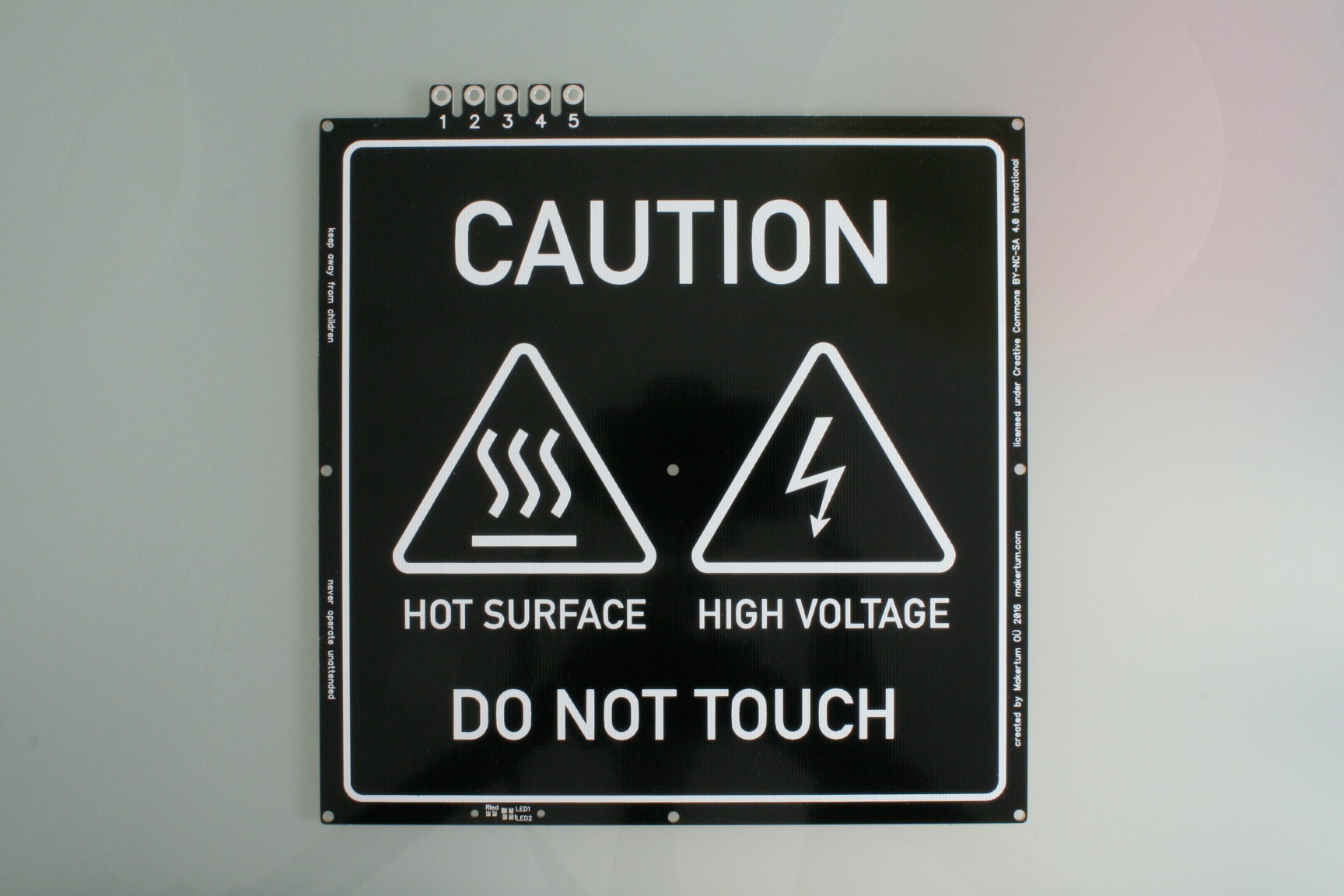

Safety

I did everything to make this the safest heated bed available:

- fully insulated screw terminals

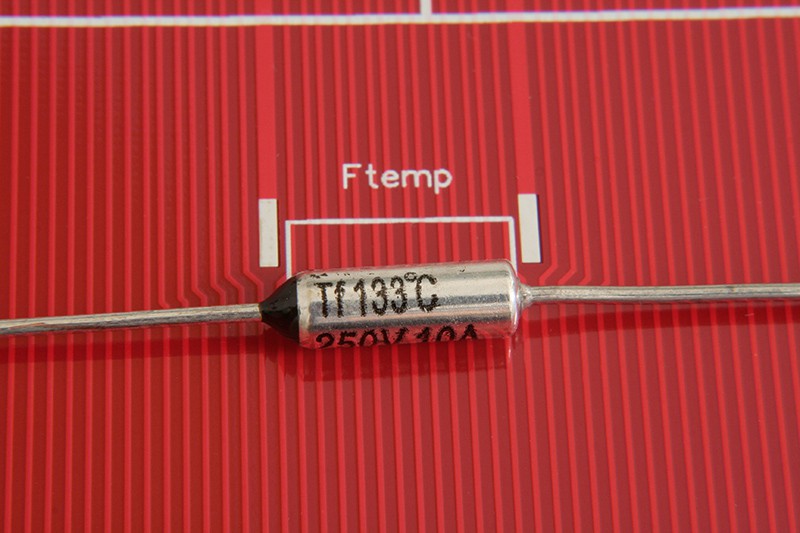

- thermal fuse prevents overheating

- current fuse prevents overcurrent

- made from temperature resistant FR4

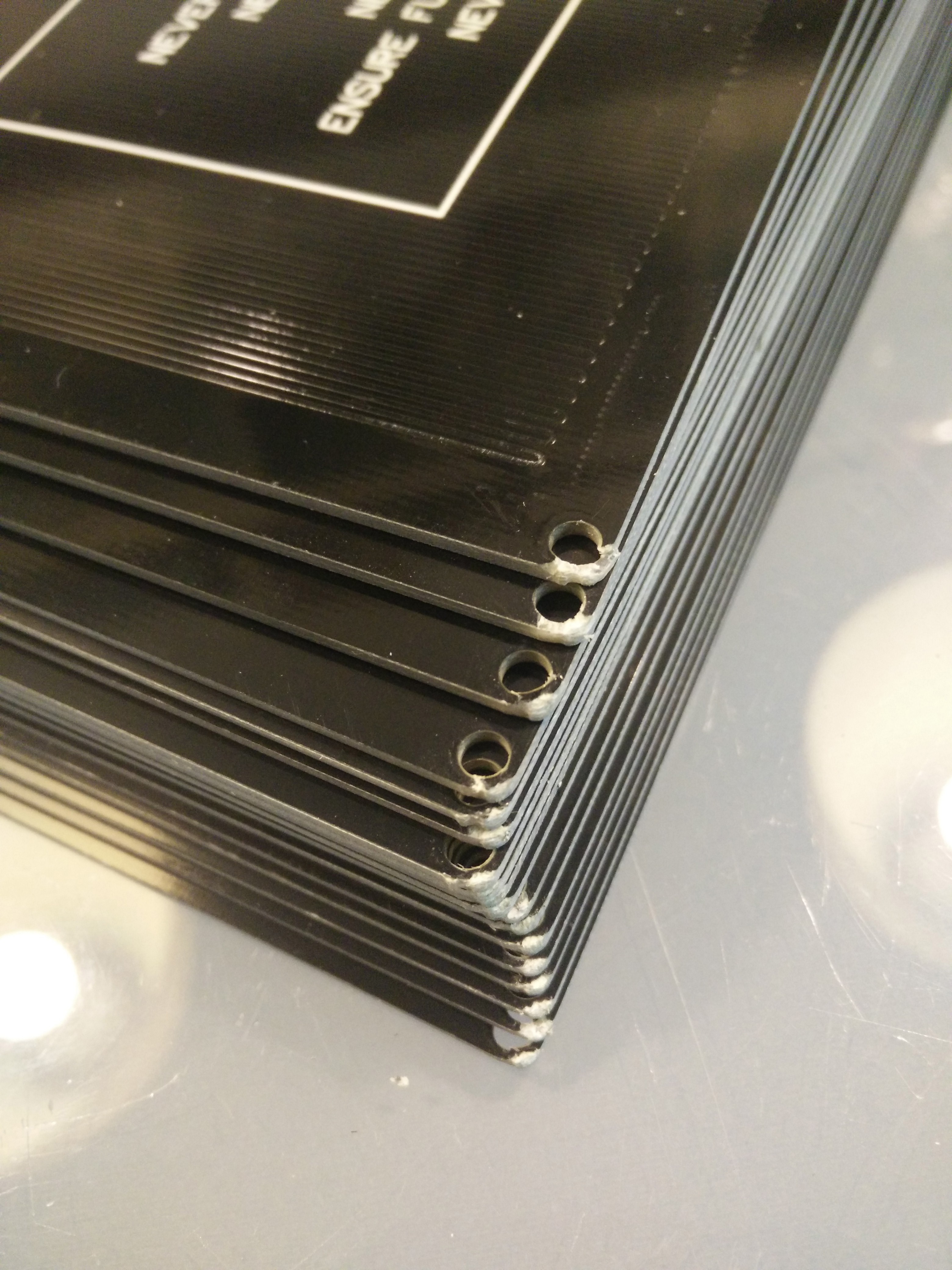

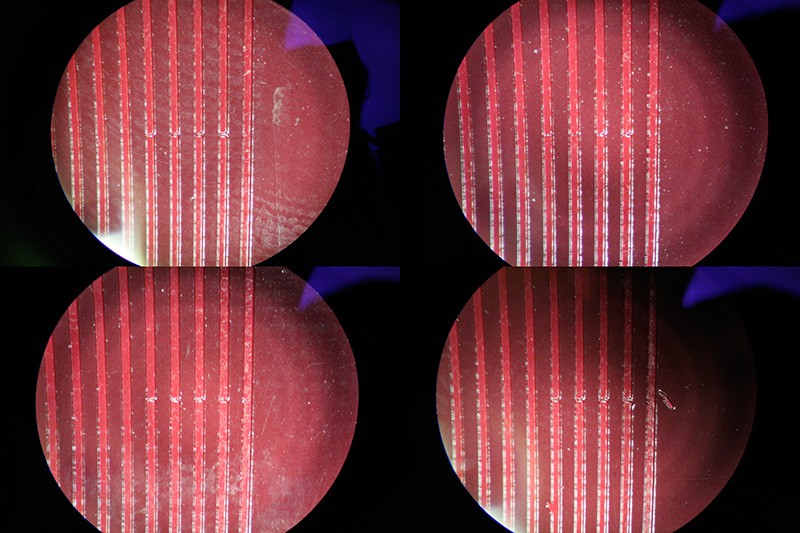

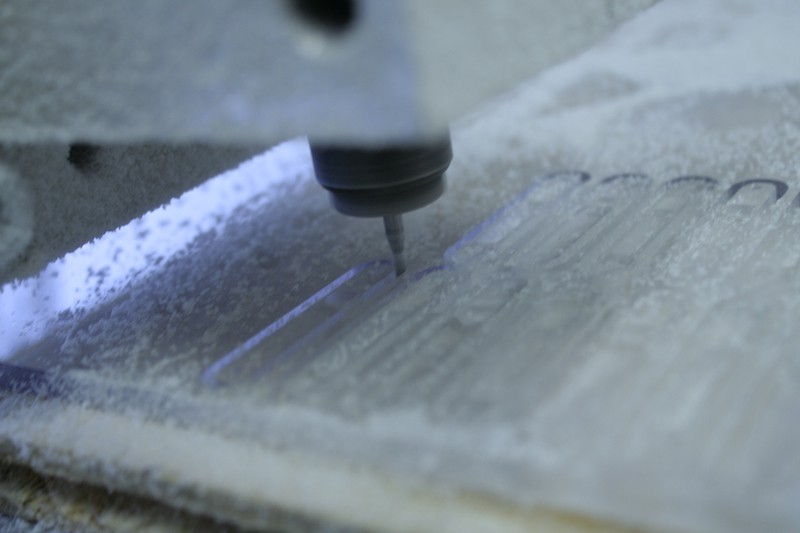

- thorough stress testing on every manufactured batch

RFC

If you have any ideas or concerns about the design, please share your ideas in the comments.

Moritz Walter

Moritz Walter

recommended for US customers

recommended for US customers

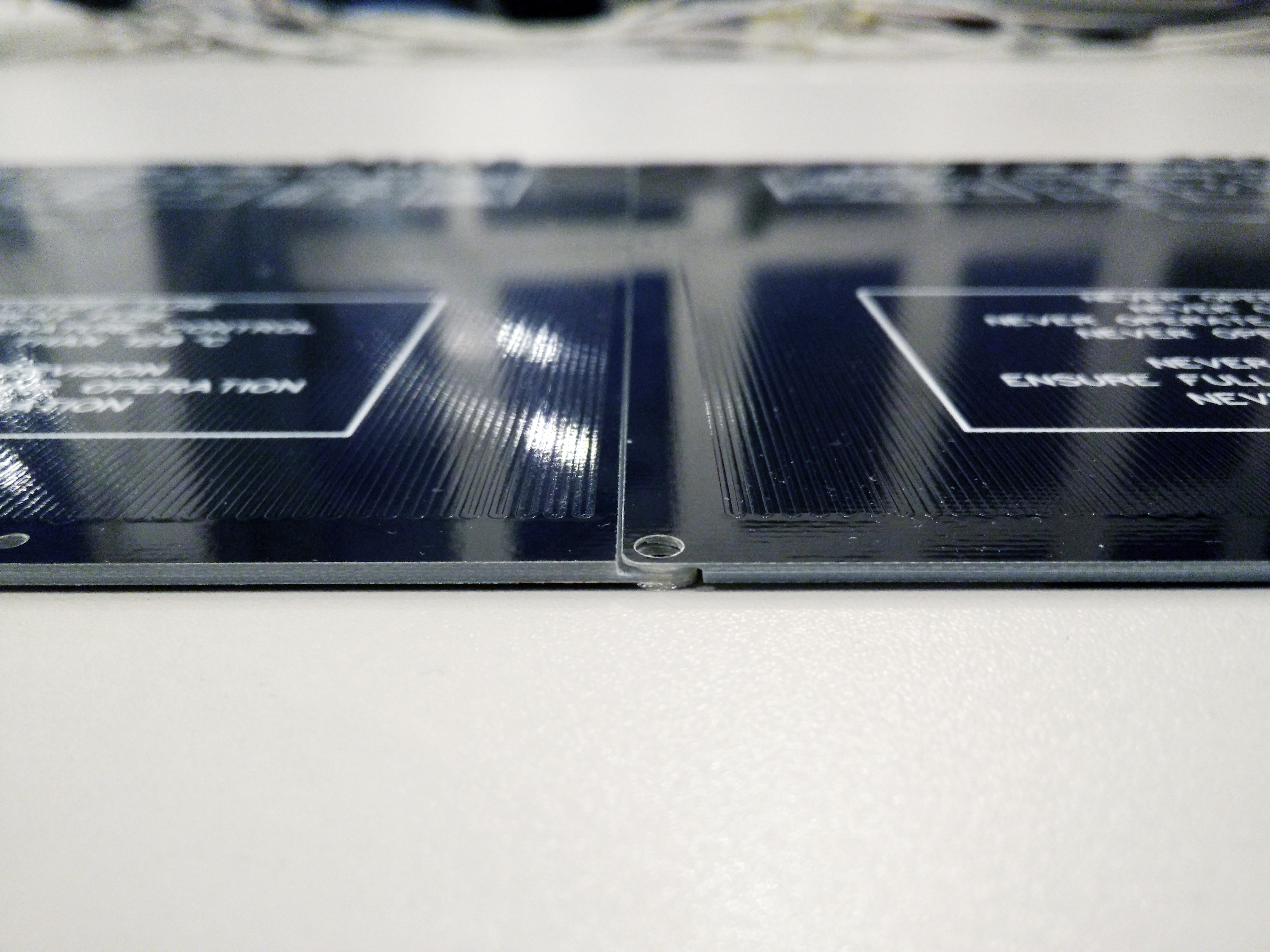

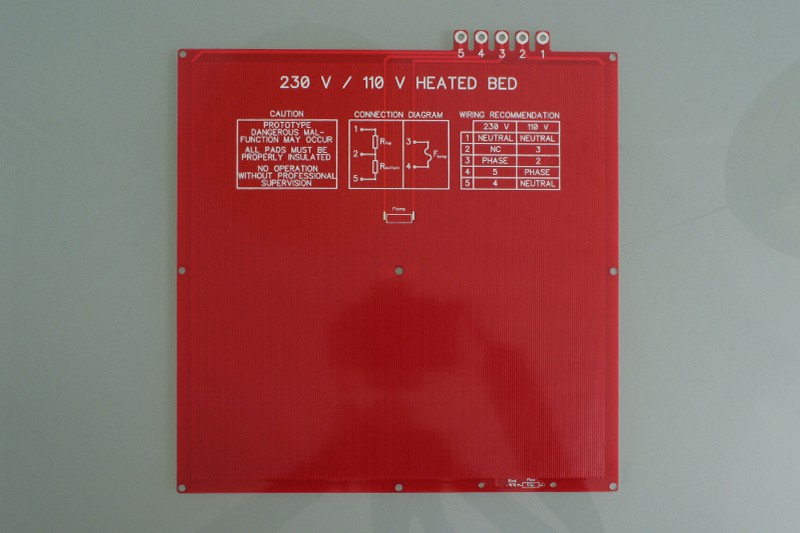

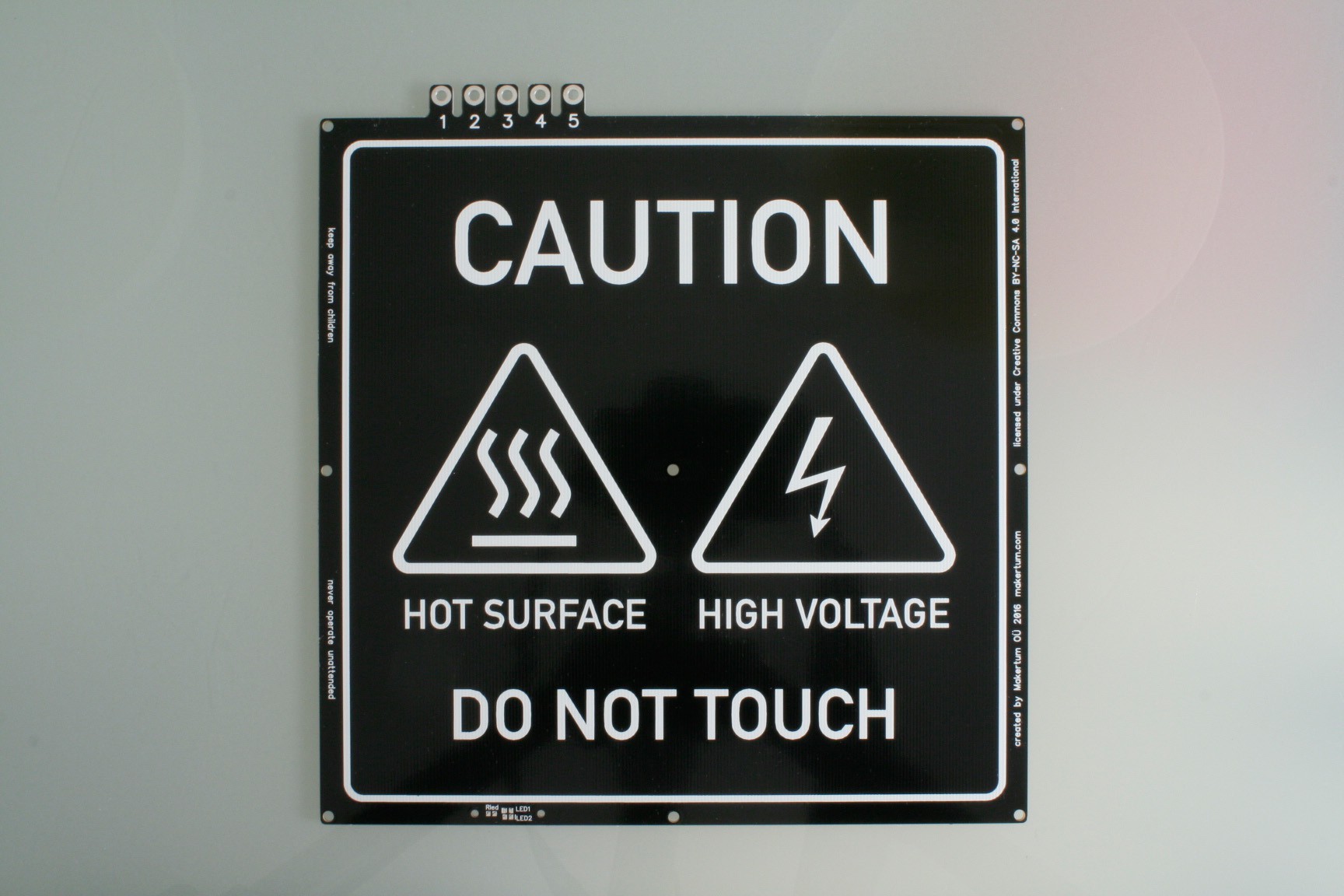

New silkscreen

New silkscreen

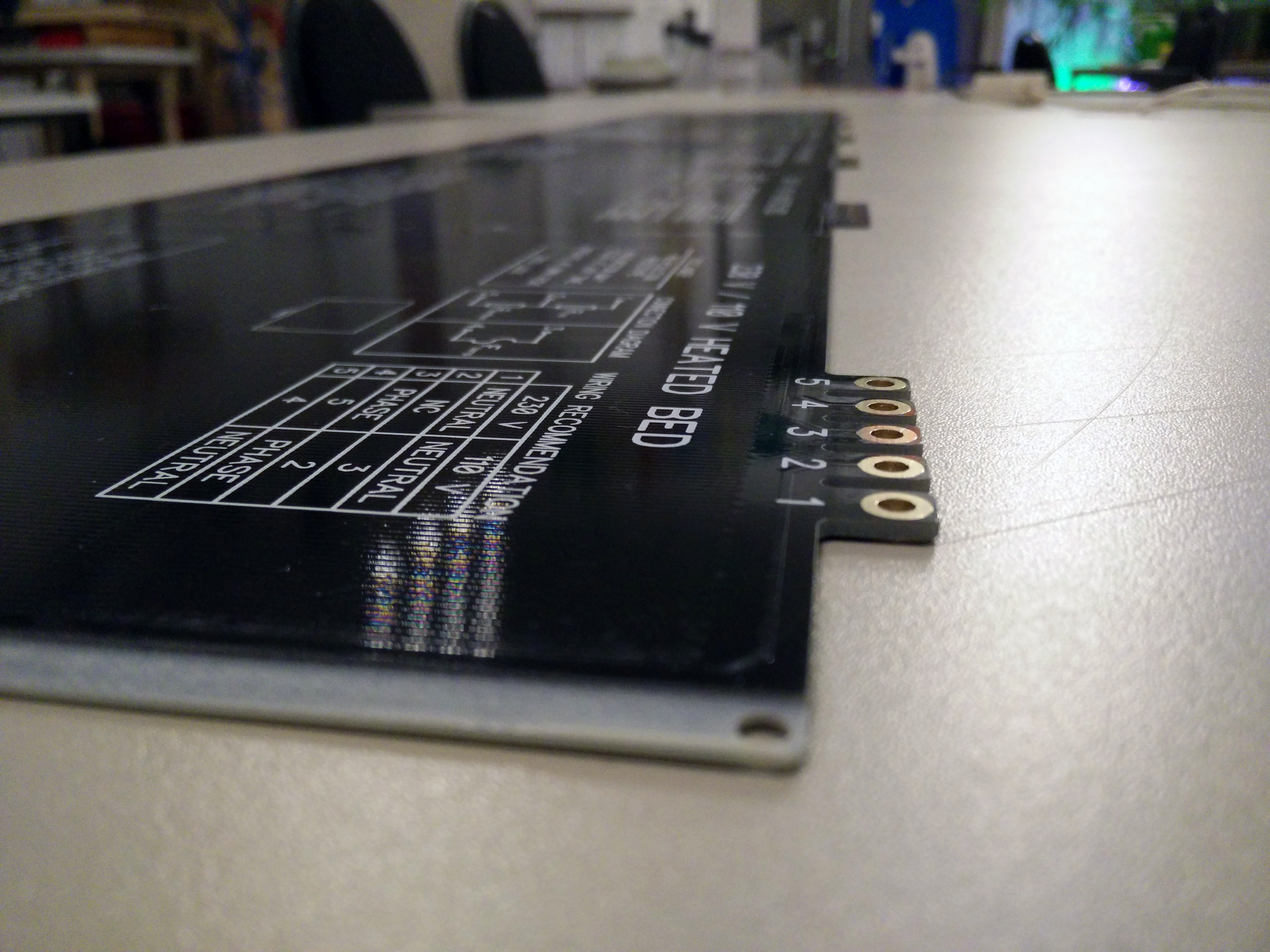

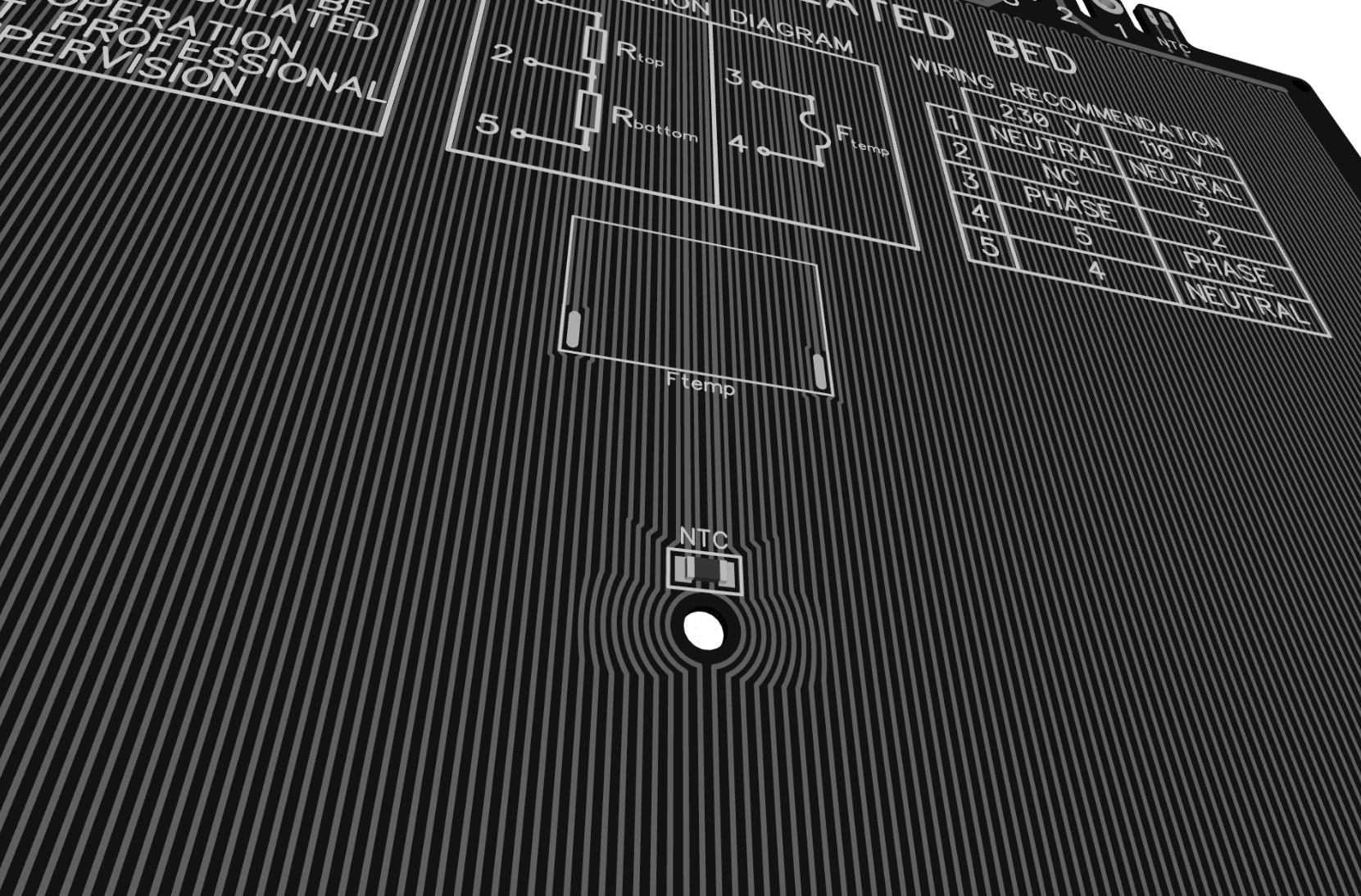

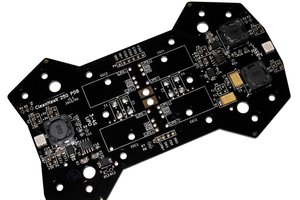

PCB (top)

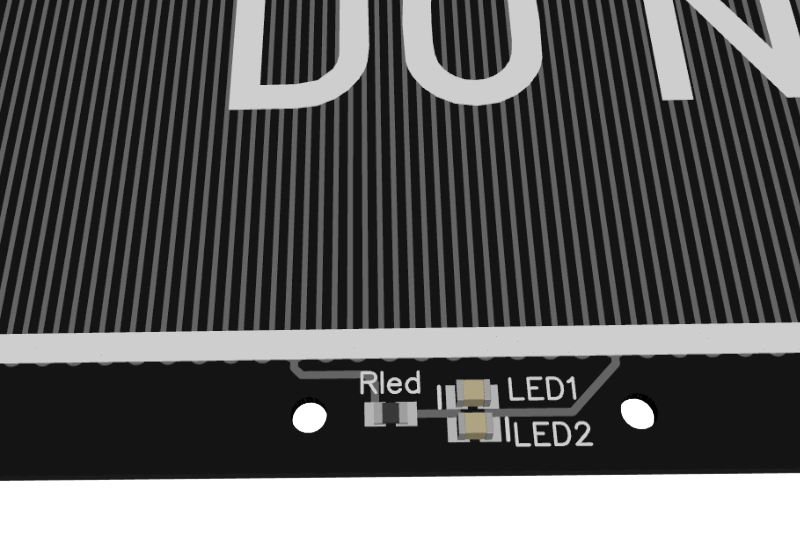

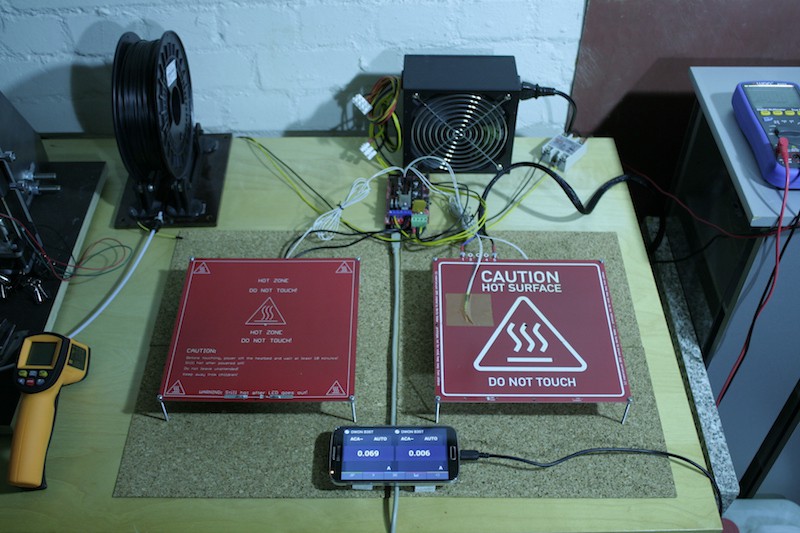

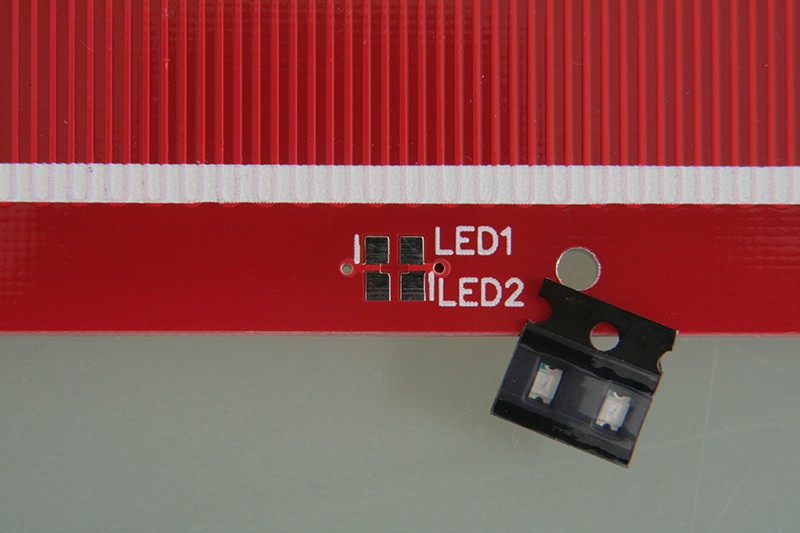

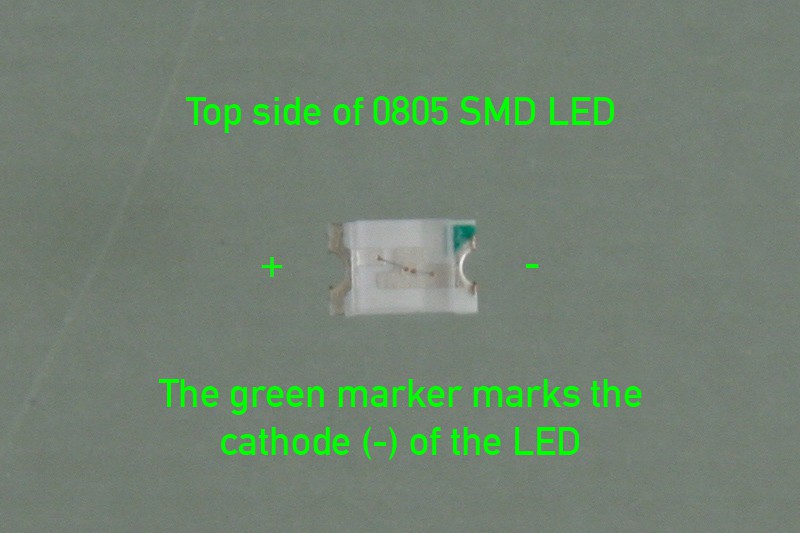

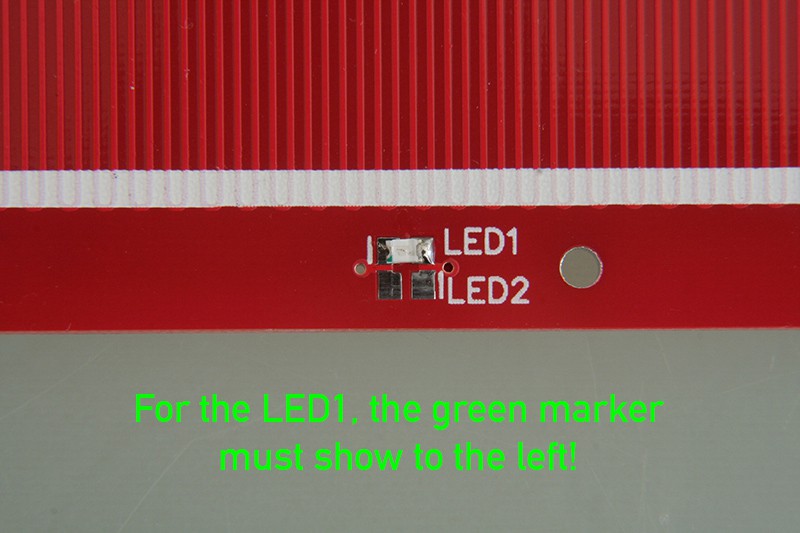

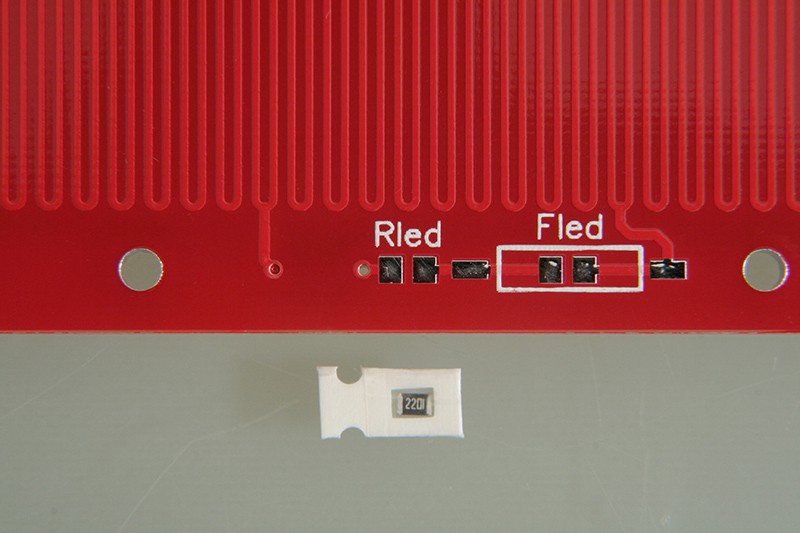

PCB (top) parts and electronics

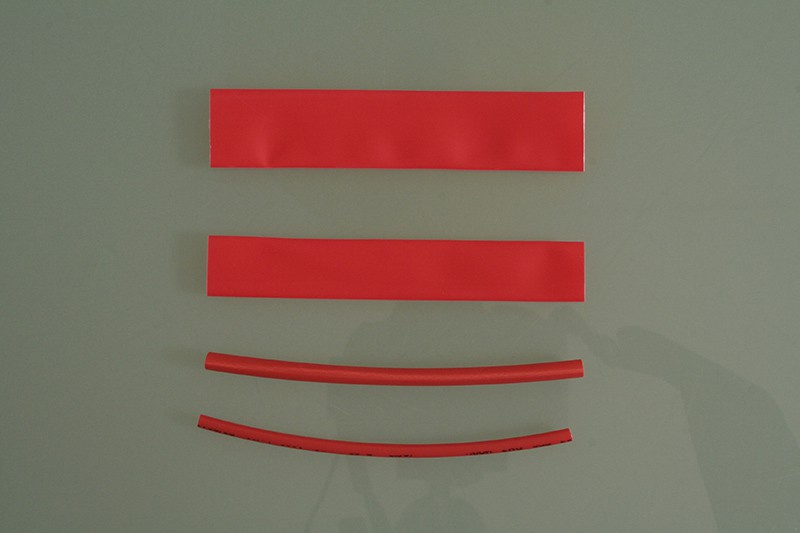

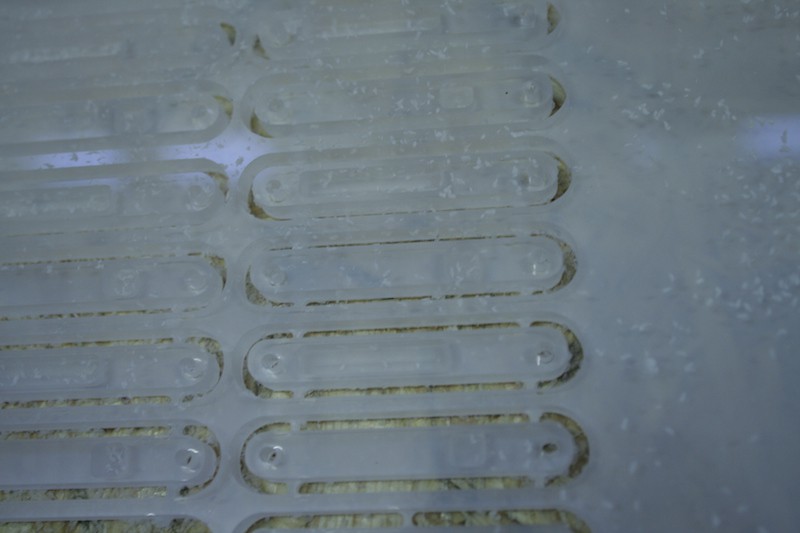

parts and electronics PCB (bottom)

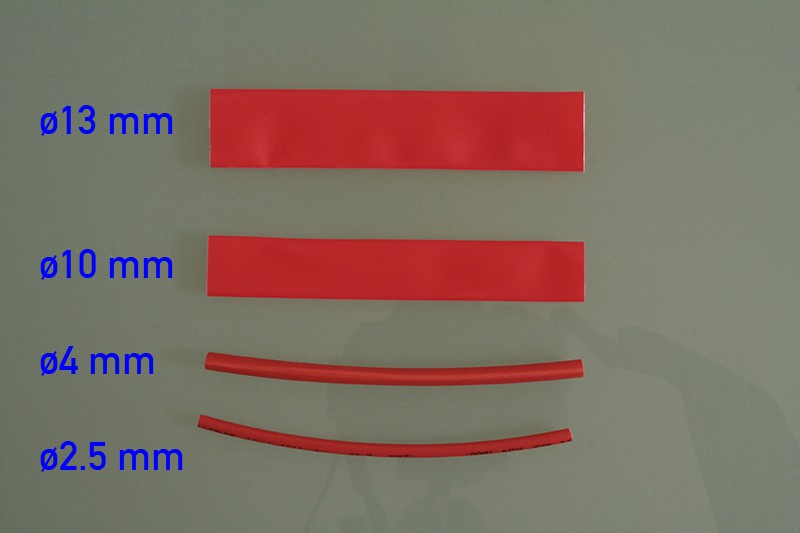

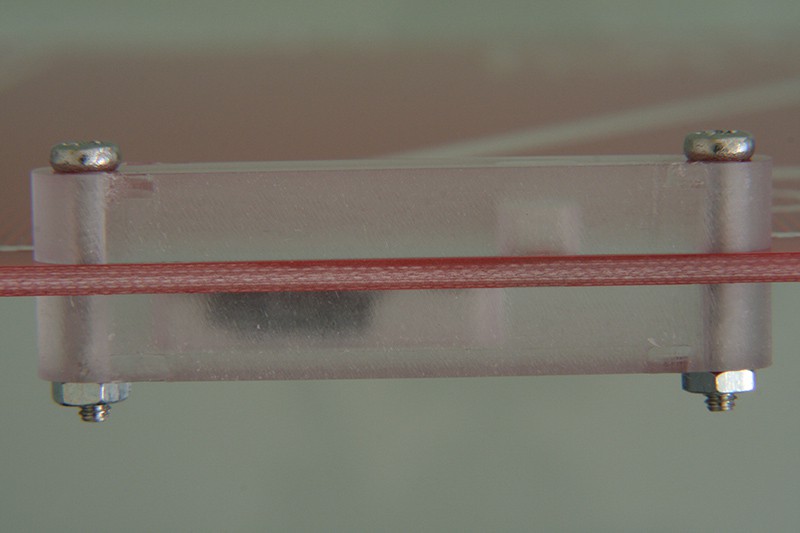

PCB (bottom) shrinking tubes

shrinking tubes

Peter Fröhlich

Peter Fröhlich

2bluesc

2bluesc

jaromir.sukuba

jaromir.sukuba

Tony

Tony

i really love this idea, but i think these should be double sided aluminum core pcb(3mm), i think its called double sided mcpcb. I would increase the size to 220mm to leave space for the screw holes, its a popular heater size these days anyway. Also, i would ground the aluminum core. In some country you need a ground for anything higher than 24v anyway. Also, i'd like 120v instead of 110v, because in my home, the main is more like 123v... i'm trying to do this with 2 kapton heaters, but i can't even find a suitable 12v one...