Hi!

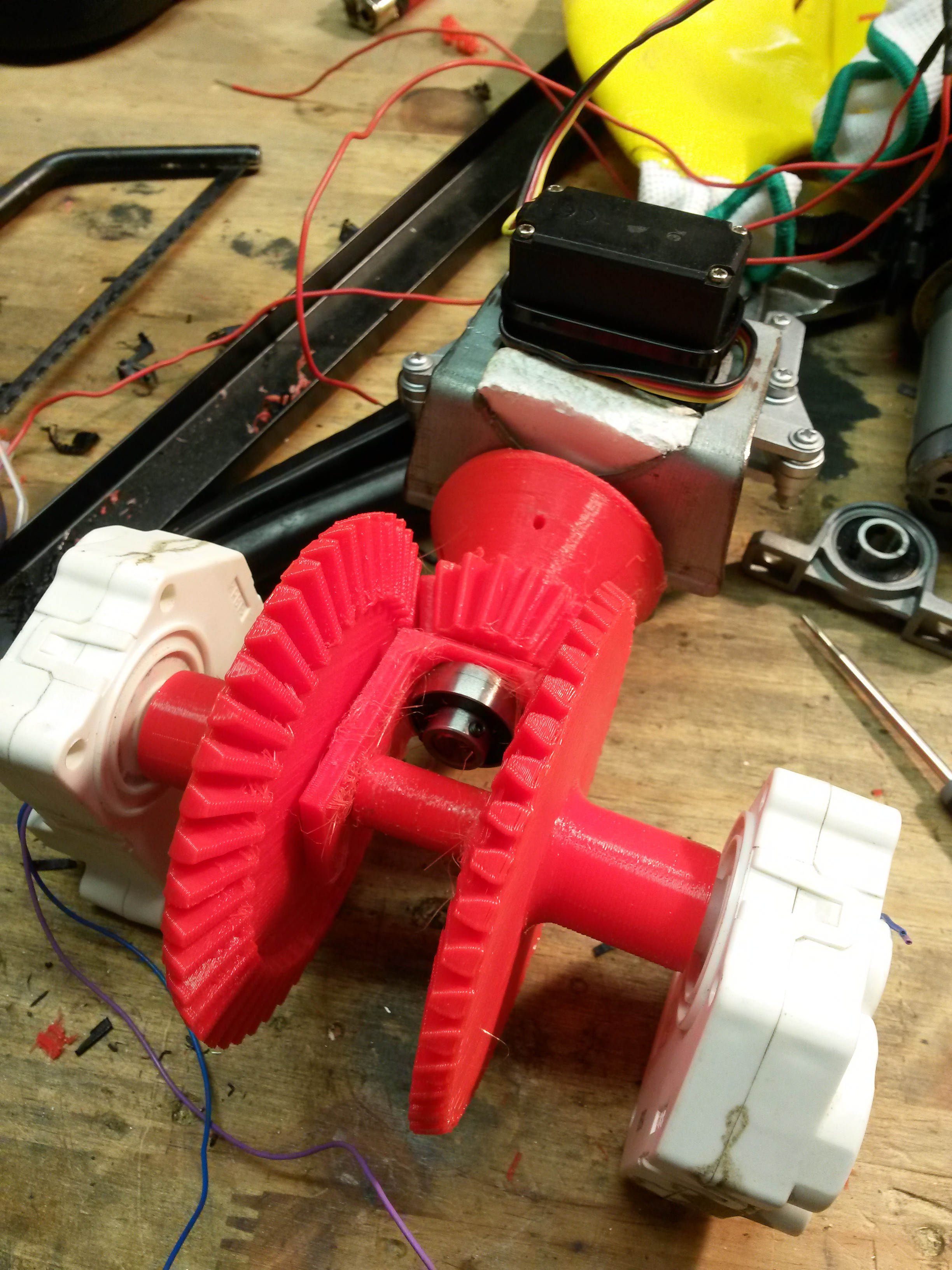

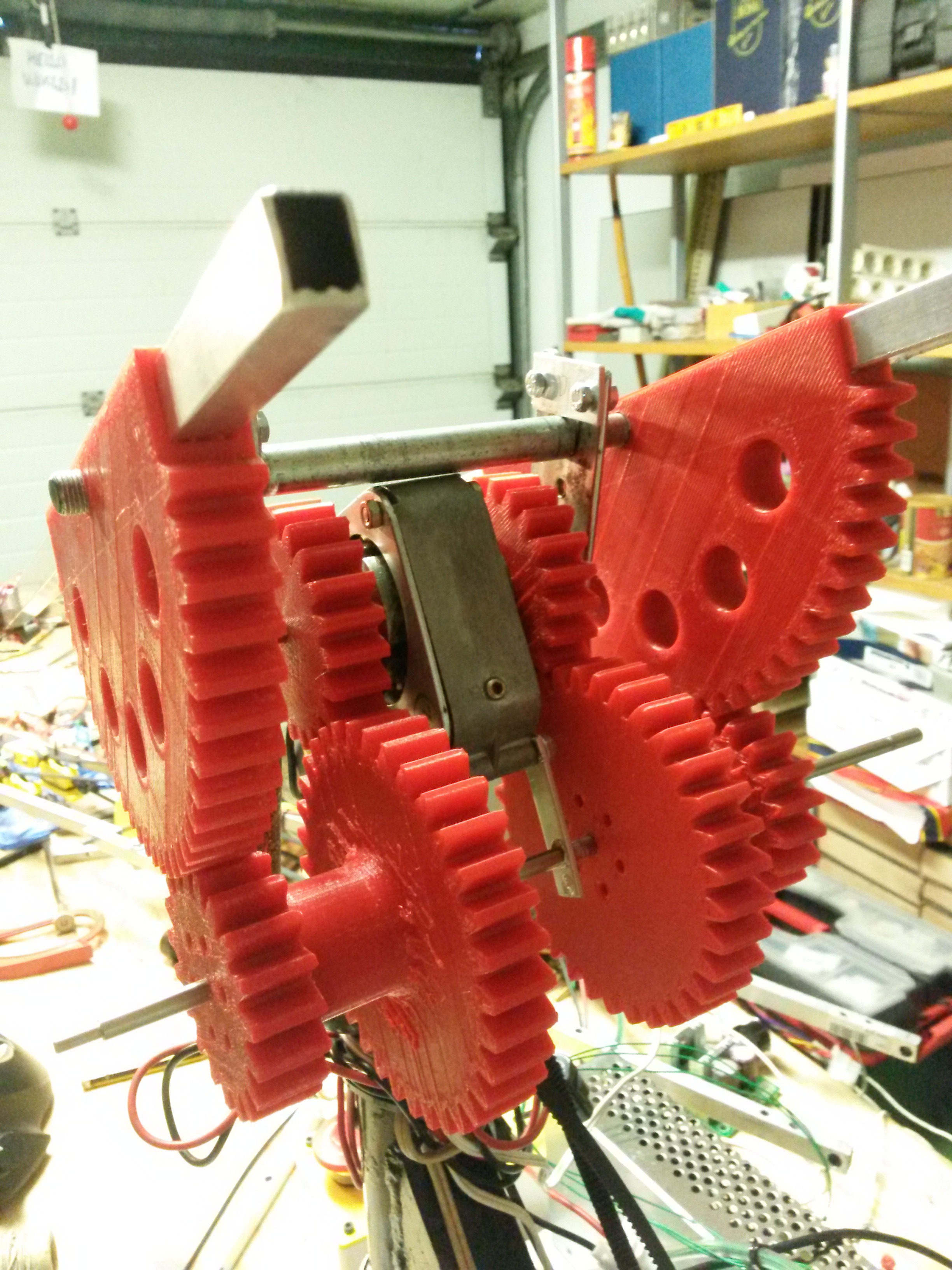

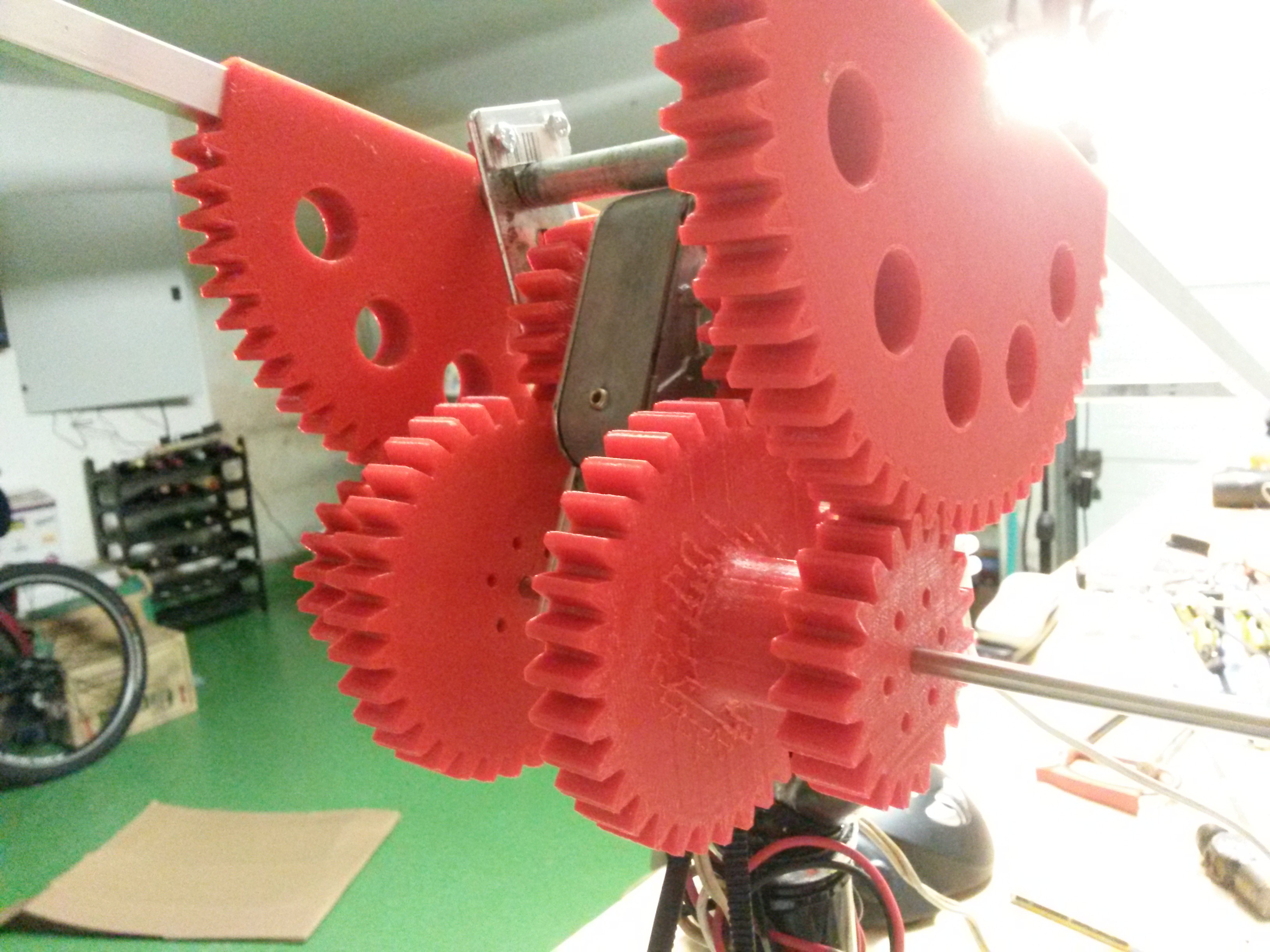

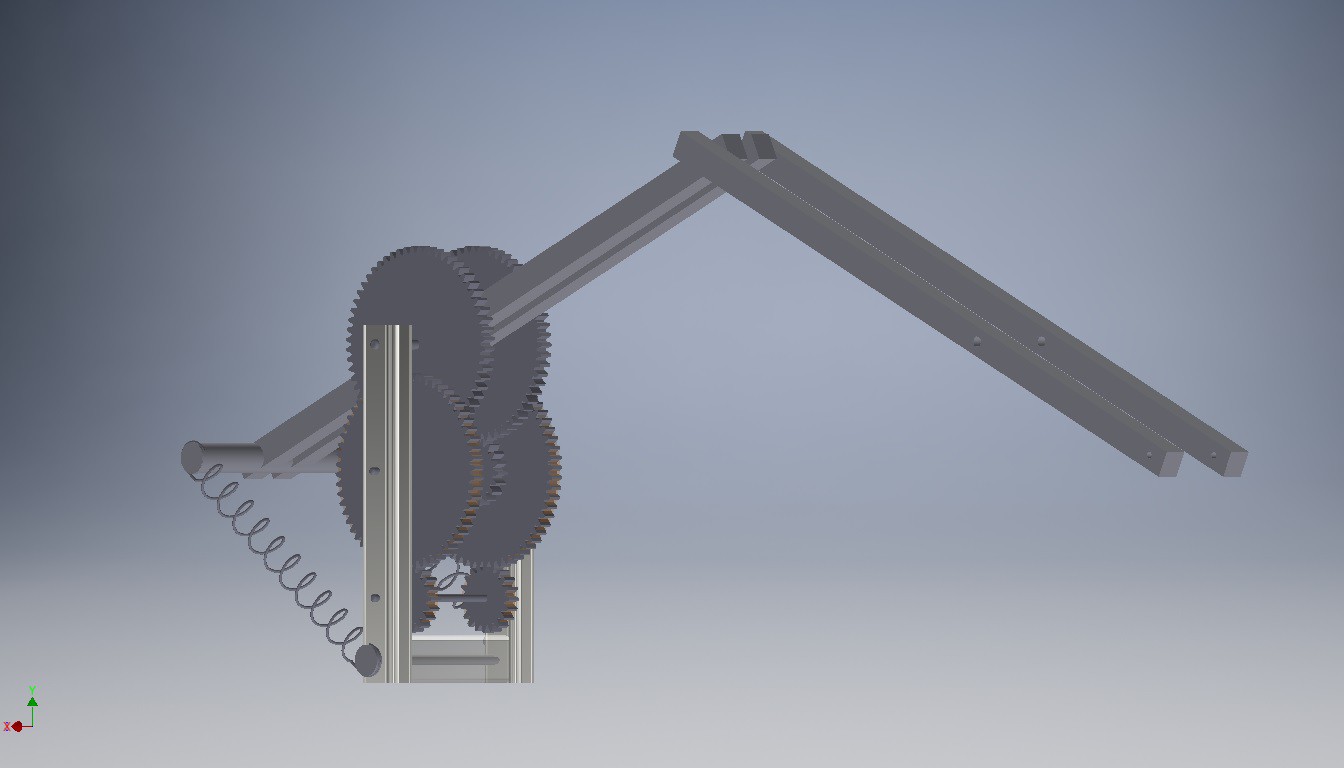

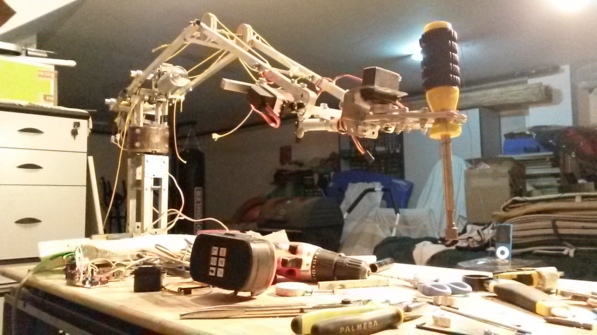

I'm developing this project as a challenge, because i saw a lot of robotic arms but with very high prices (for some applications you don't need an accuracy of 0.5mm). So i think that it could be made of recycled materials and some 3d printed parts. Now I'm testing a lot of configurations to do the best job.

My first goal is to have an accuracy of 5mm. i know that it's too much but it's only the beggining.

Second is to add another degree of freedom at the claw.

Third is to add some kind of artificial vision.

Fourth is to have a multitool system, so you can work with a screw or a soldering iron, a drill etc

Last is to standar electric windows motors so you don't need to adapt 3d printed parts to your motors. But if you want to use different motors and need help, contact me :)

Of course i'm trying to use usual things that you can find near home.

I will post any changes, i hope you like it and, of course, if you need more information, don't hesitate of asking me by mail, twitter or my website.

See you soon!!

Here's the last video i did. (11-12-2016)

Antonio Regueira

Antonio Regueira

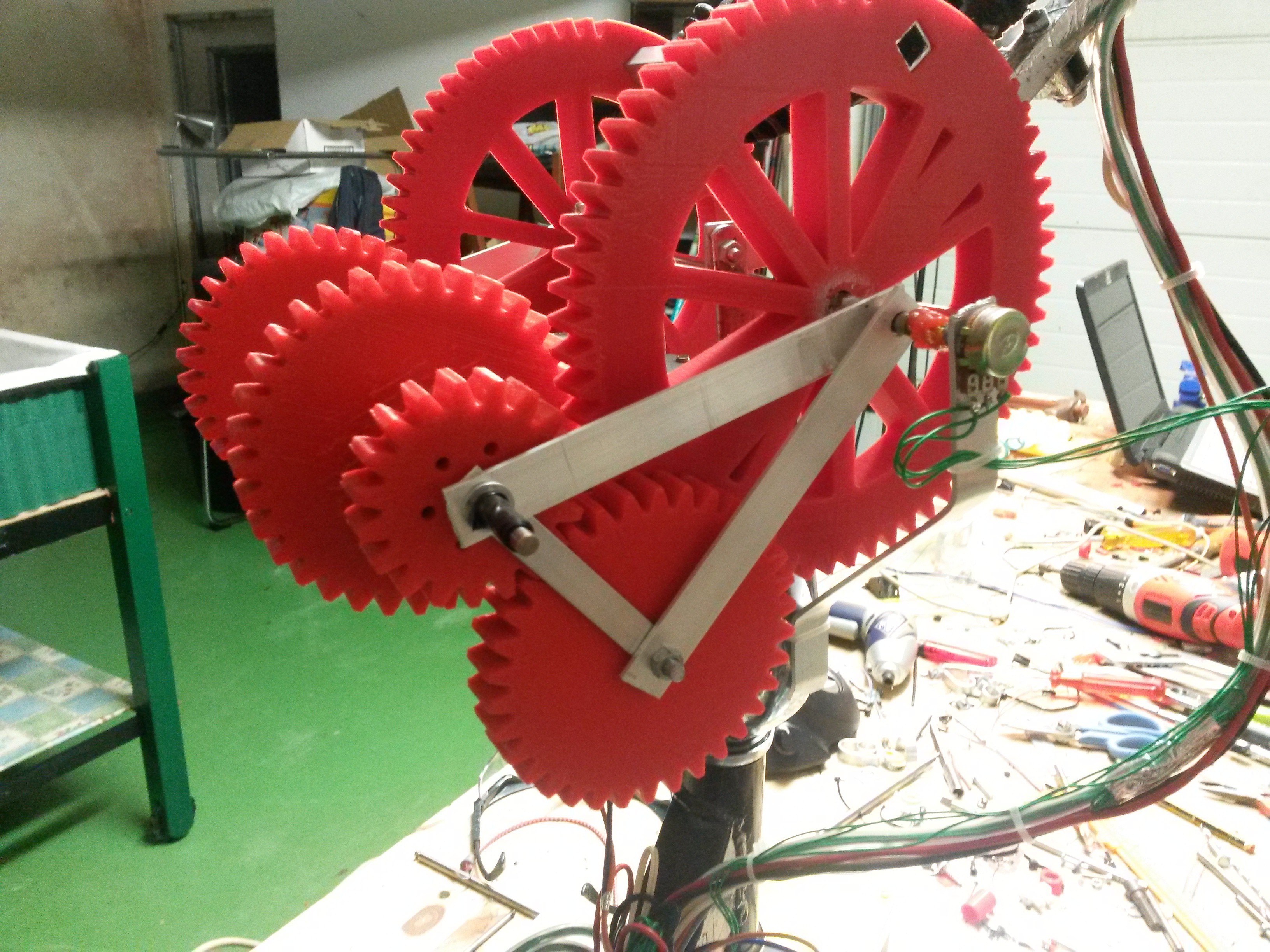

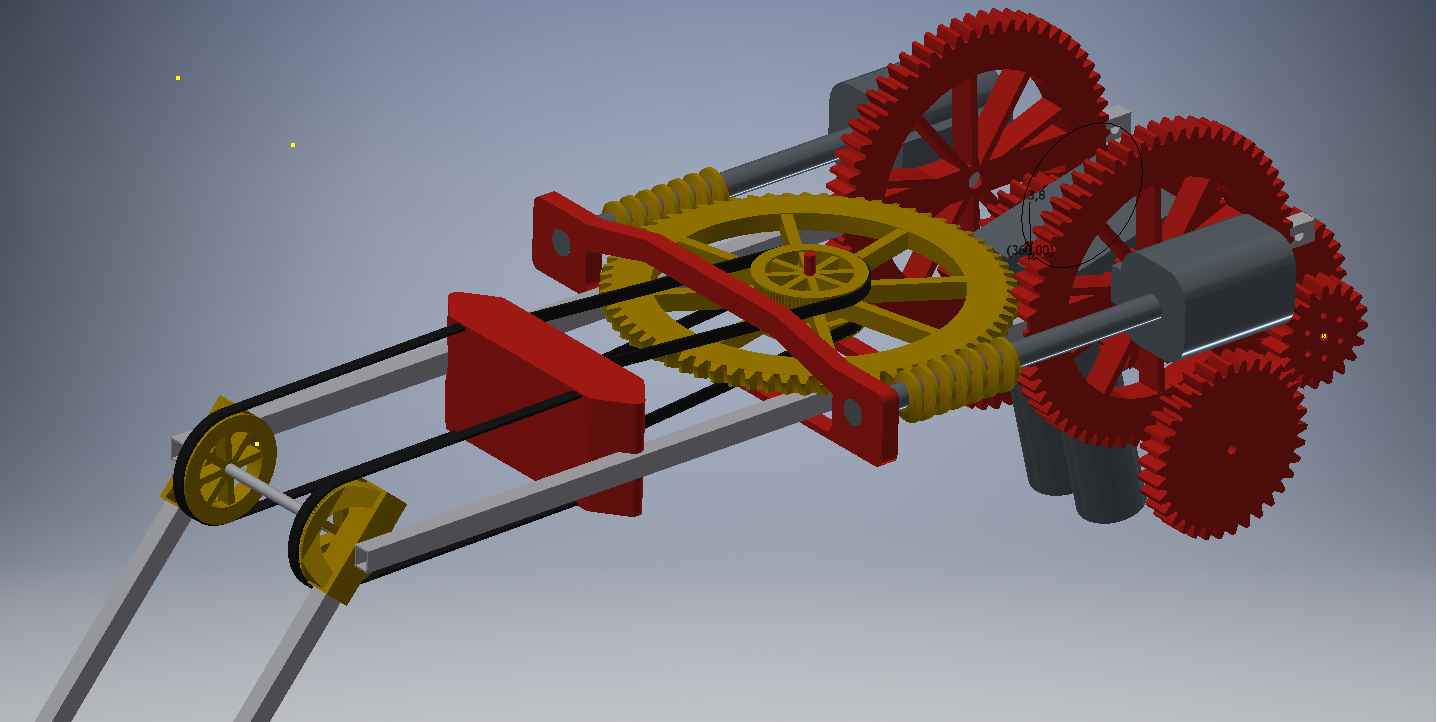

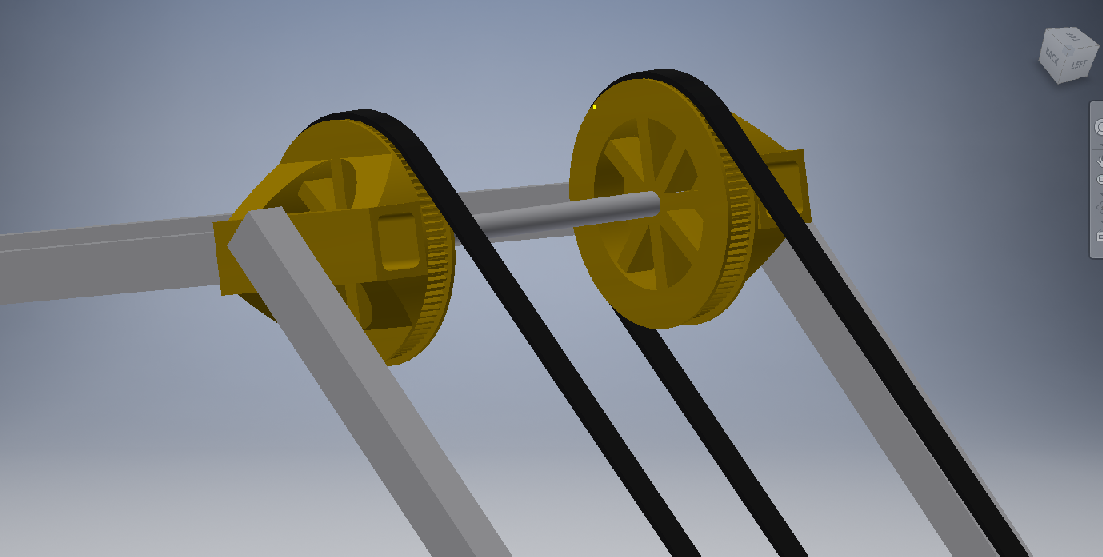

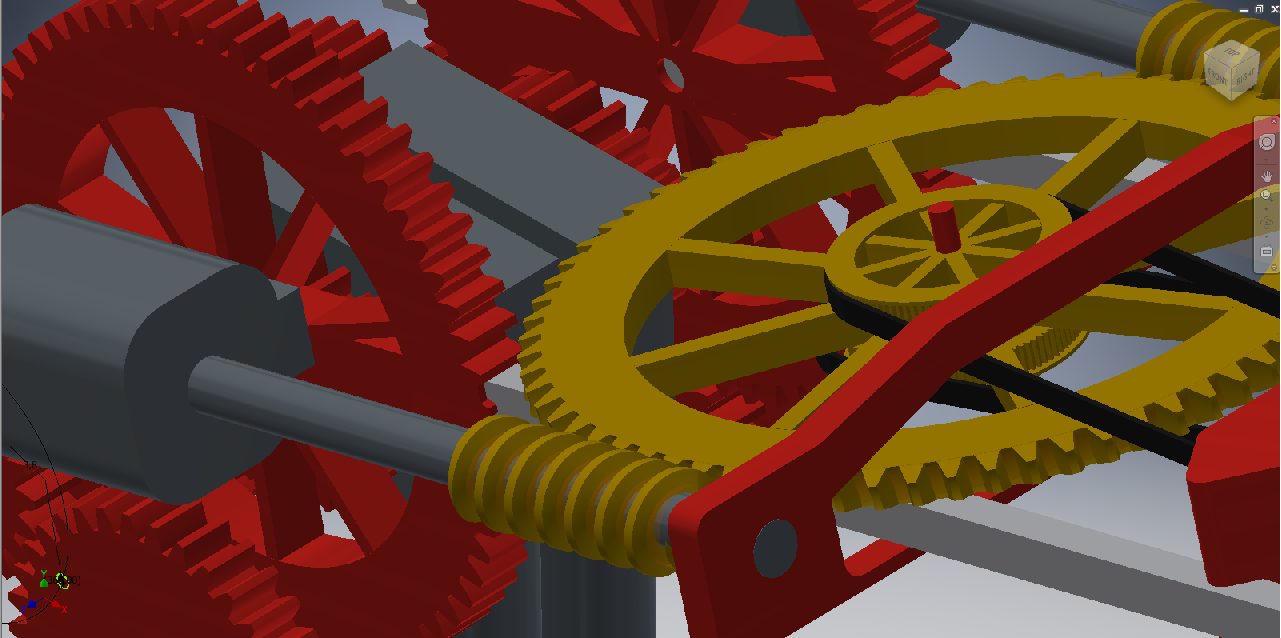

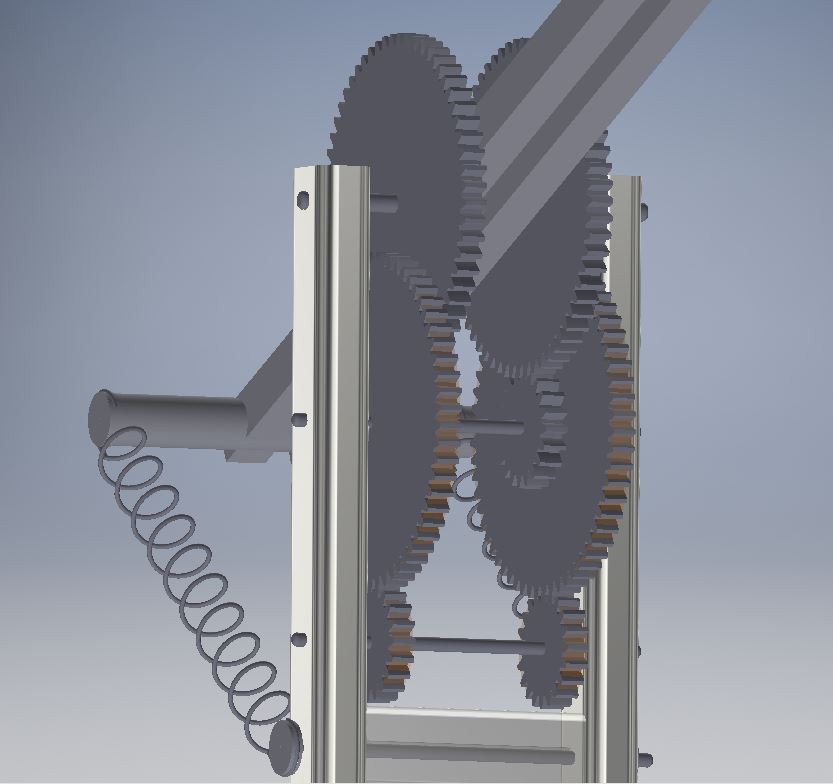

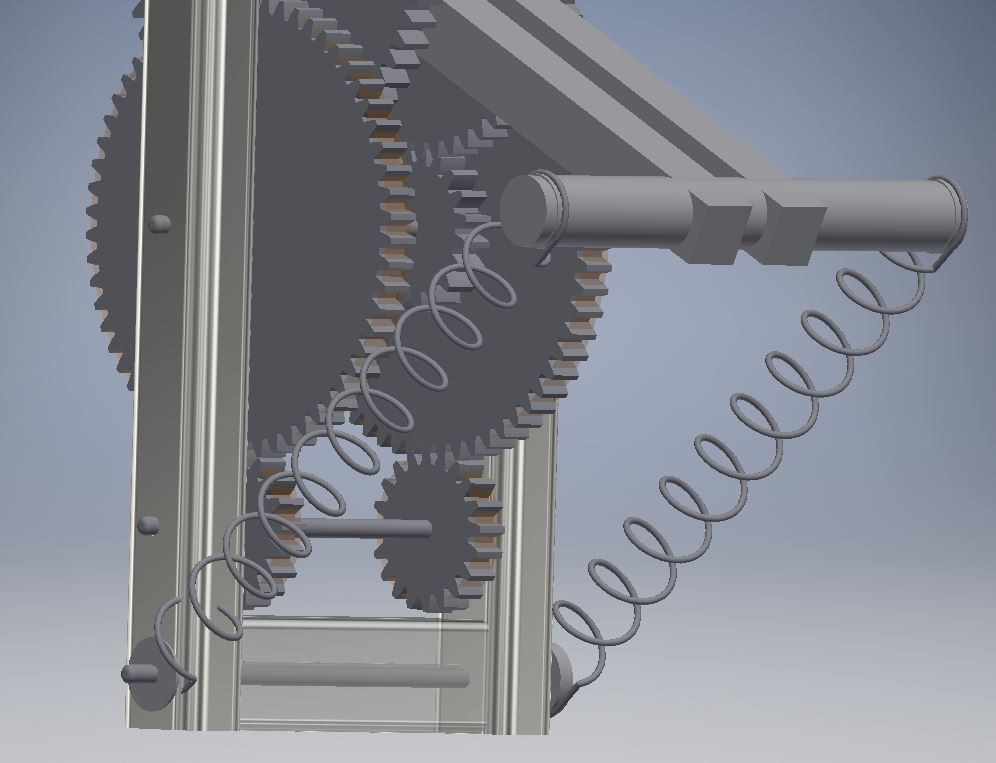

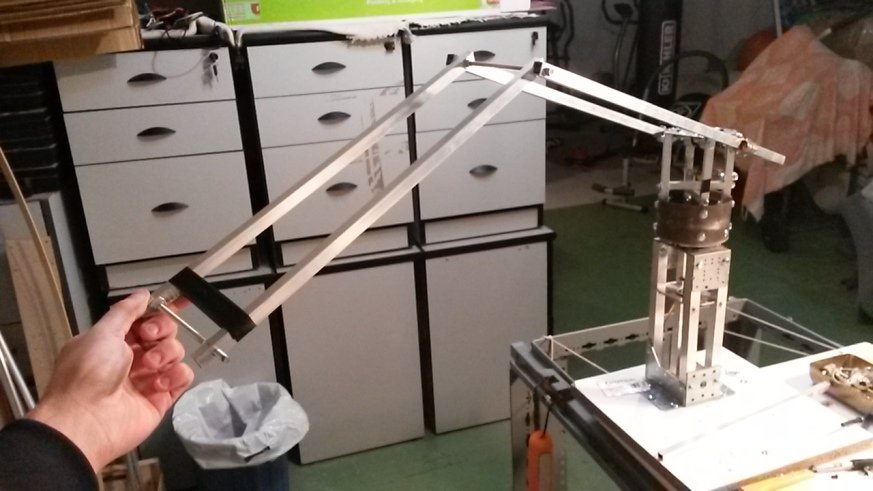

ng a belt to the shoulder and it worked fine, but this way I couldn't apply force to both direcctions, so I decided to make a printed gears.

ng a belt to the shoulder and it worked fine, but this way I couldn't apply force to both direcctions, so I decided to make a printed gears.

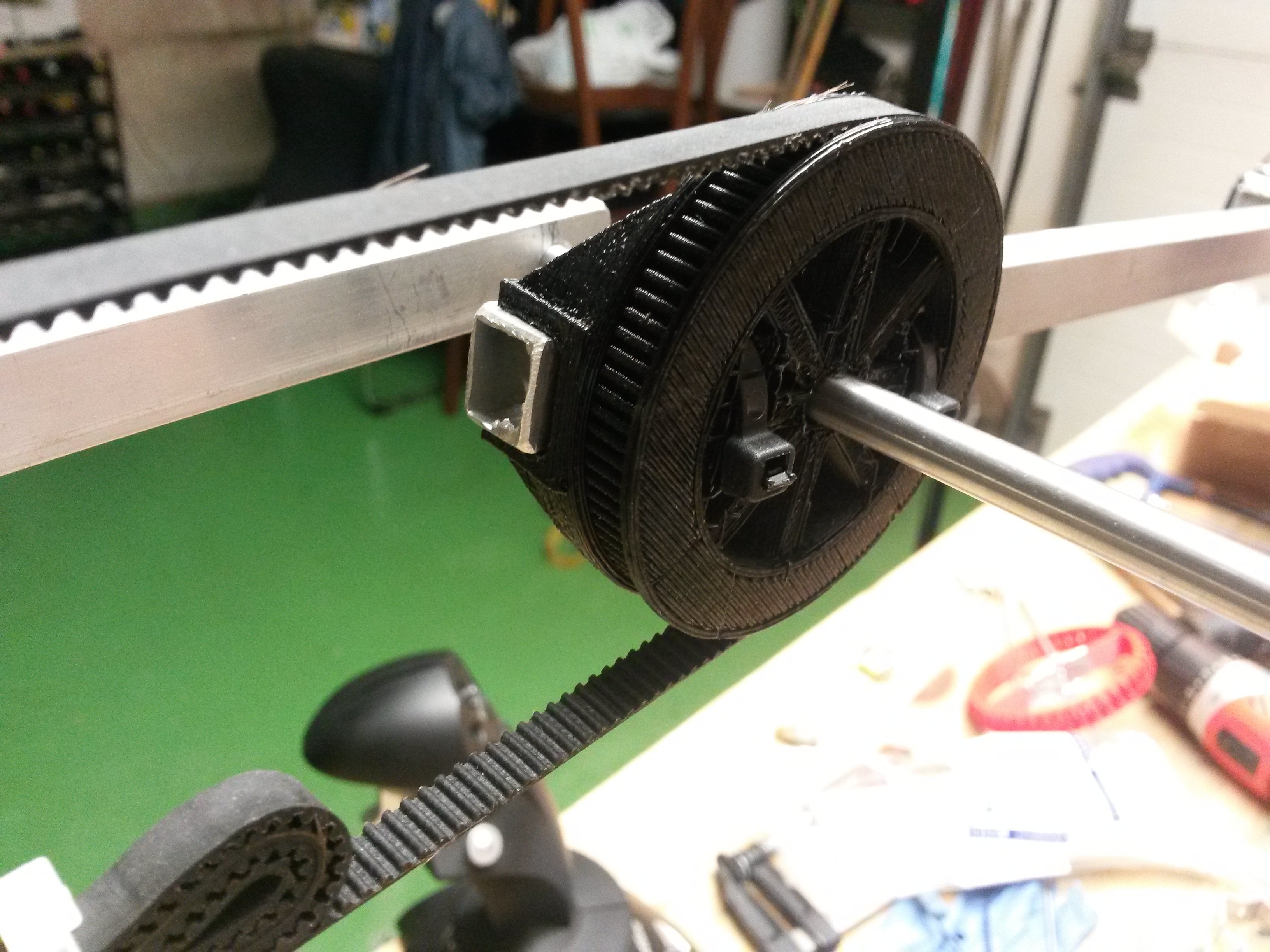

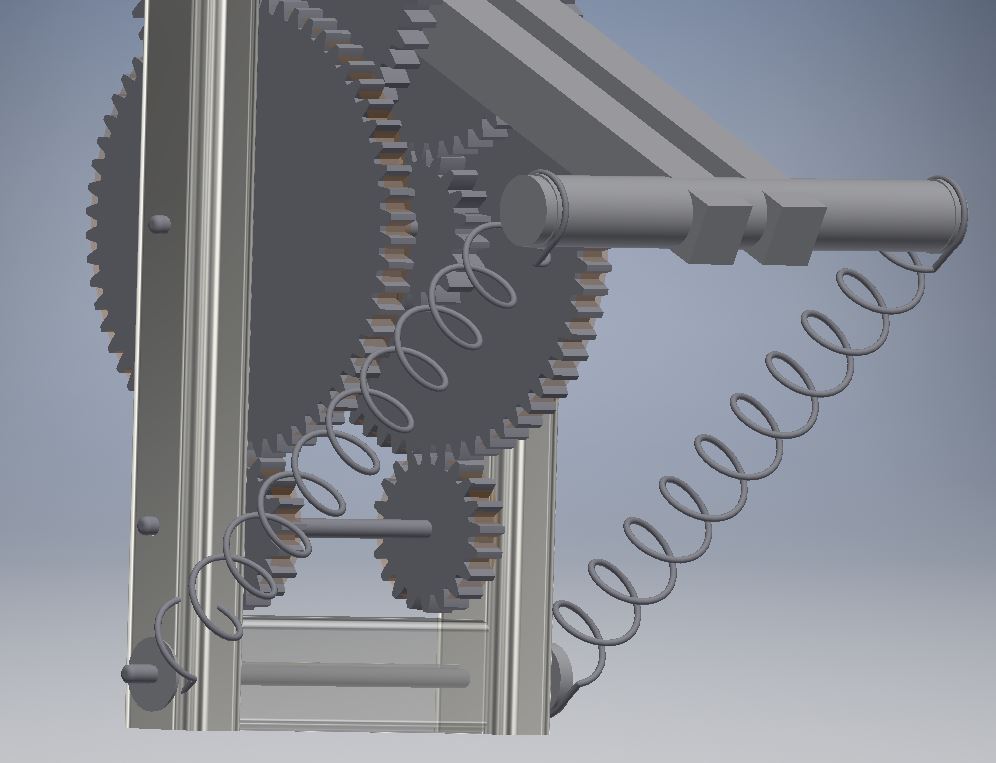

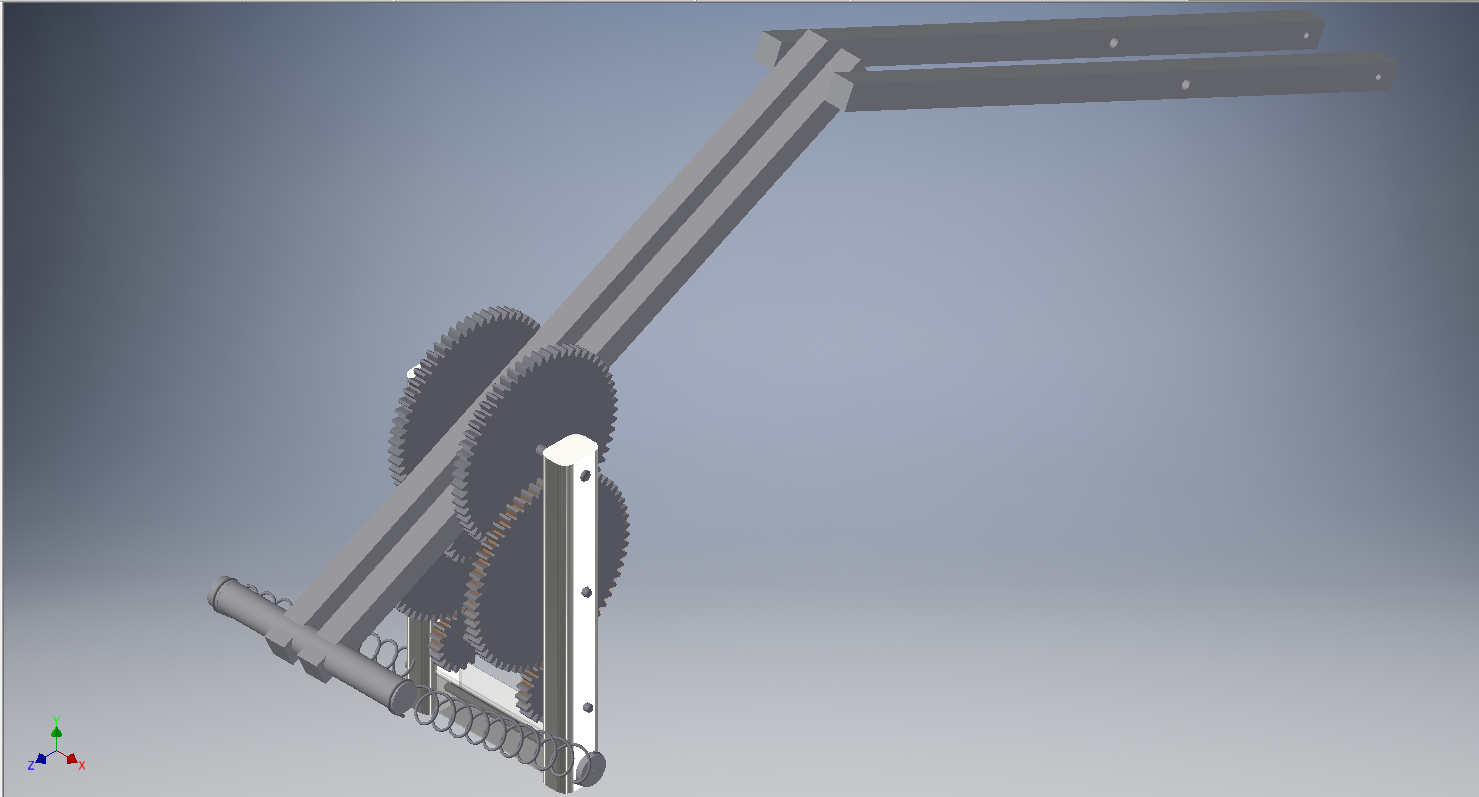

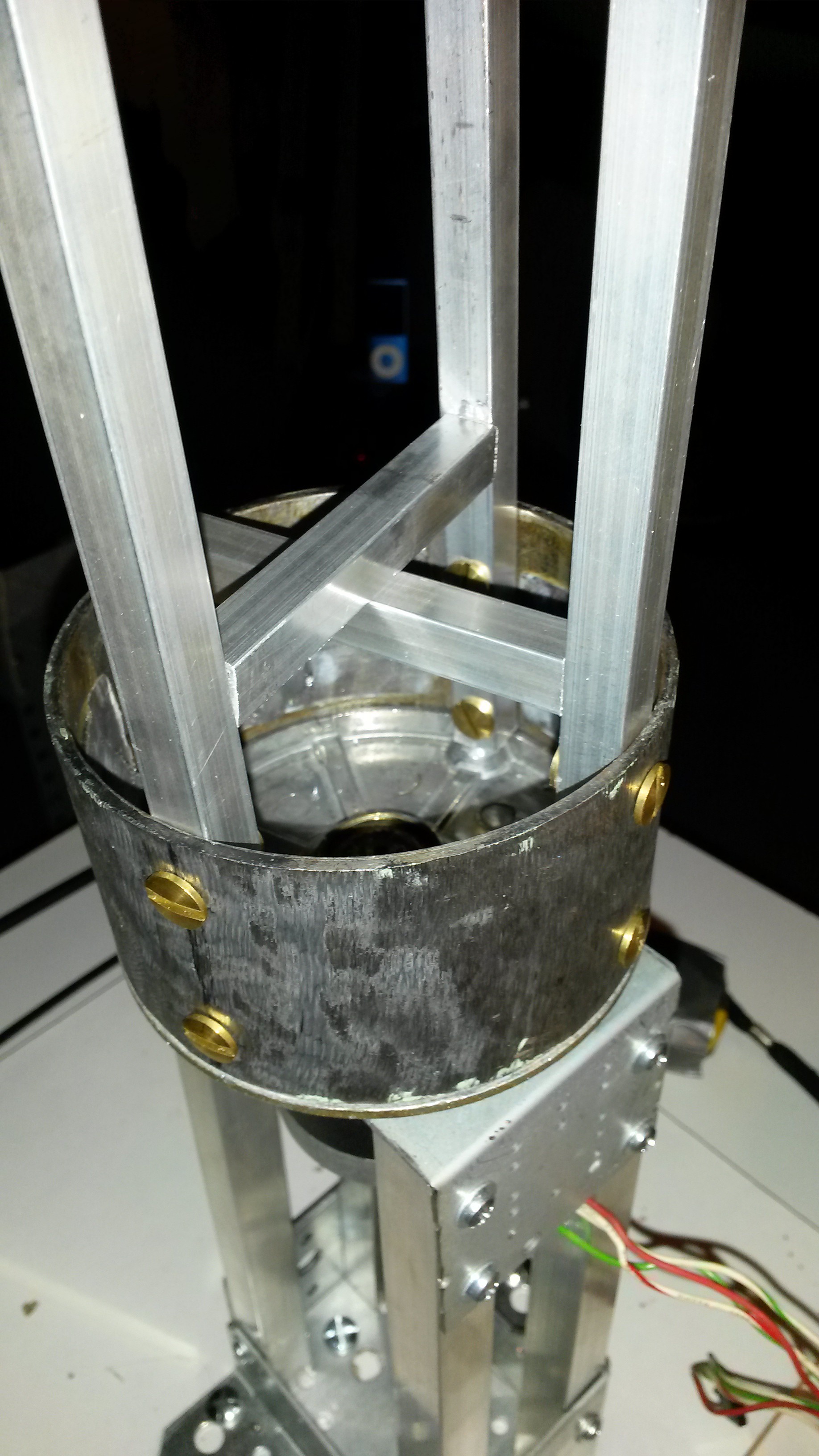

I used a base to anchor legs of a garden arbor and cut one aluminum profile 20 x 20 mm 1 meter long into 4 sections. I screwed these sections to the base and attach to a table, which in theory would be provisional.

I used a base to anchor legs of a garden arbor and cut one aluminum profile 20 x 20 mm 1 meter long into 4 sections. I screwed these sections to the base and attach to a table, which in theory would be provisional. I took a steel plate, gave U-shaped and placed on top of the 4 aluminum bars looking down, so the first part of the vertical axis was ready.

I took a steel plate, gave U-shaped and placed on top of the 4 aluminum bars looking down, so the first part of the vertical axis was ready.

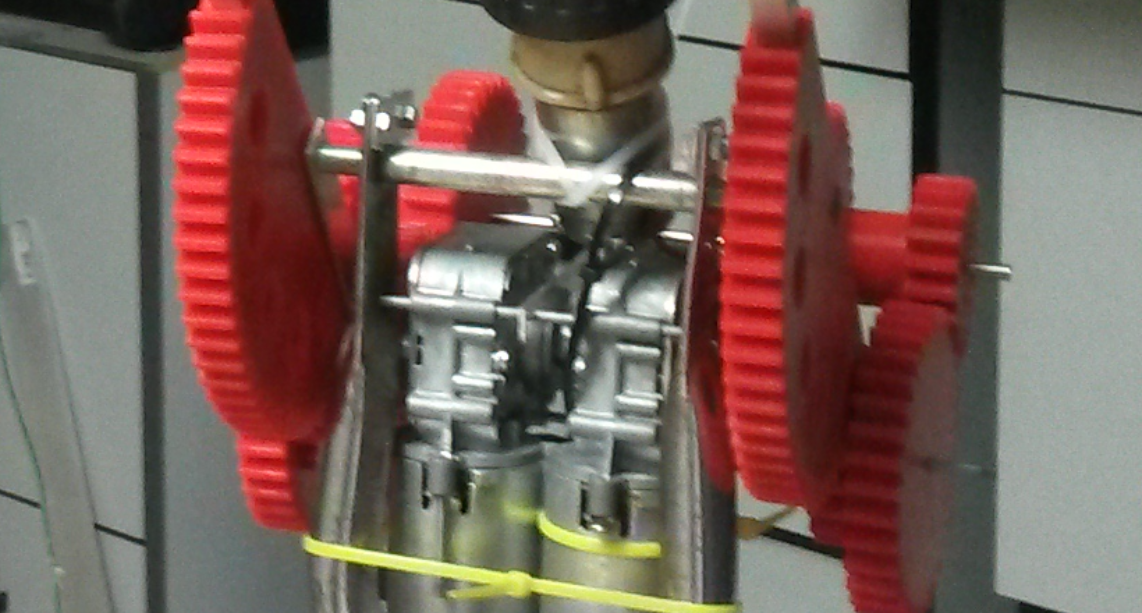

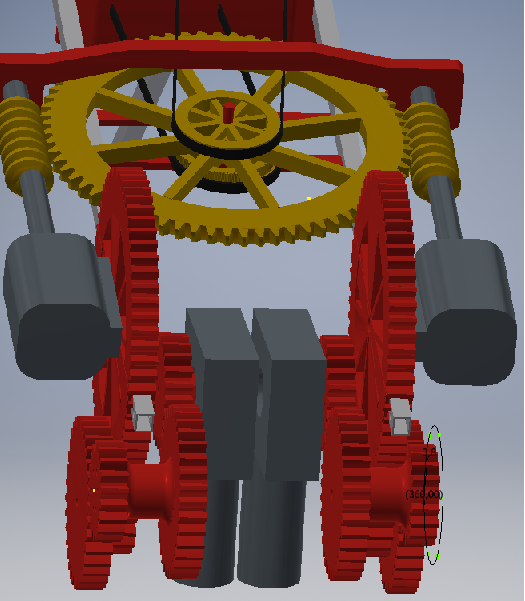

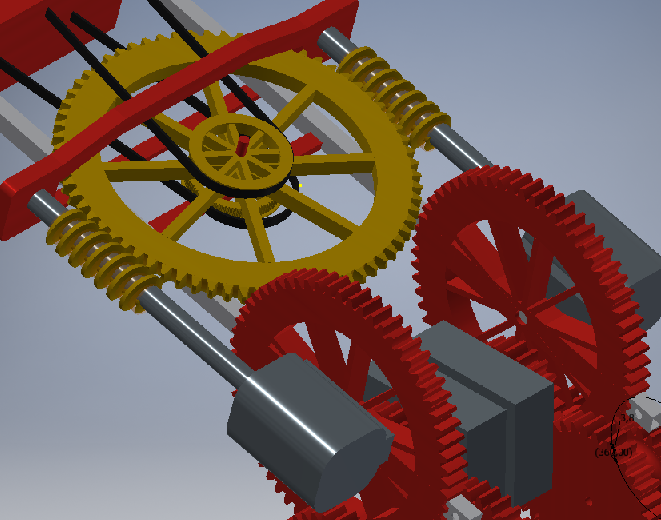

We have reached the last mechanical phase of dimmer, i will explain how I made the wrist.

We have reached the last mechanical phase of dimmer, i will explain how I made the wrist.

Deezmaker

Deezmaker

Robin Reiter

Robin Reiter

PixJuan

PixJuan

Giovanni Leal

Giovanni Leal