some of the adafruit projects this is inspired by and will be based upon:

the original piggrl: https://learn.adafruit.com/pigrrl-raspberry-pi-gameboy

(its ancestor: https://learn.adafruit.com/game-grrl )

the pocket variant: https://learn.adafruit.com/pocket-pigrrl

and its second iteration: https://learn.adafruit.com/pigrrl-2

Design Goals:

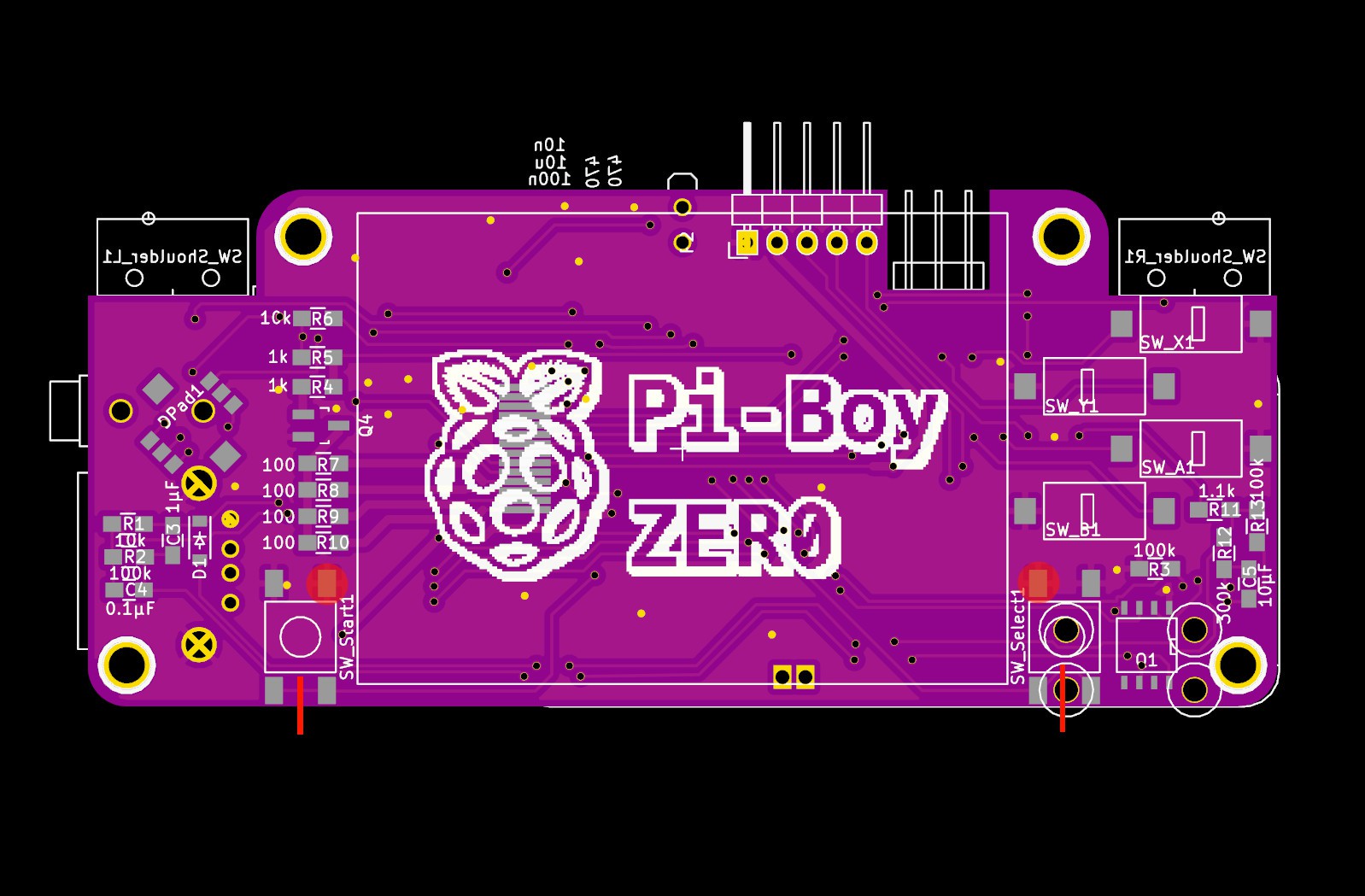

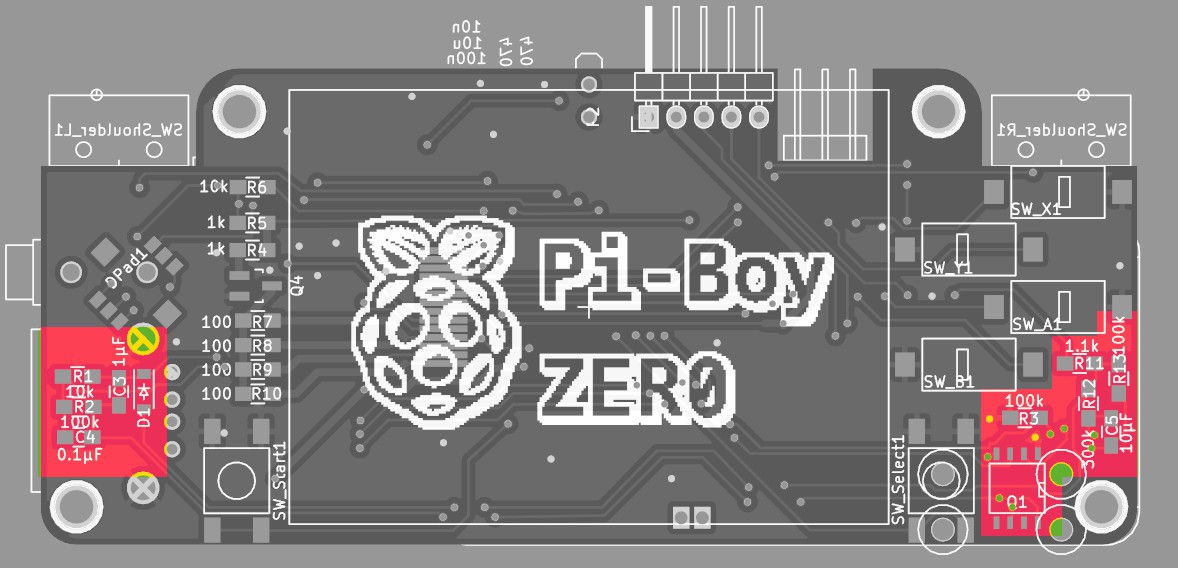

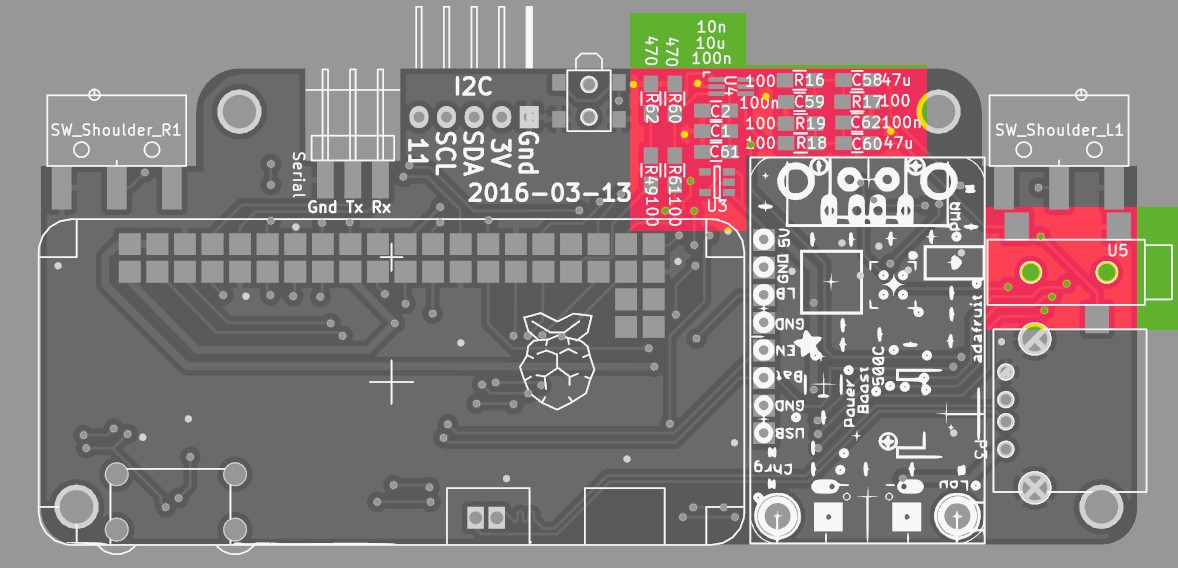

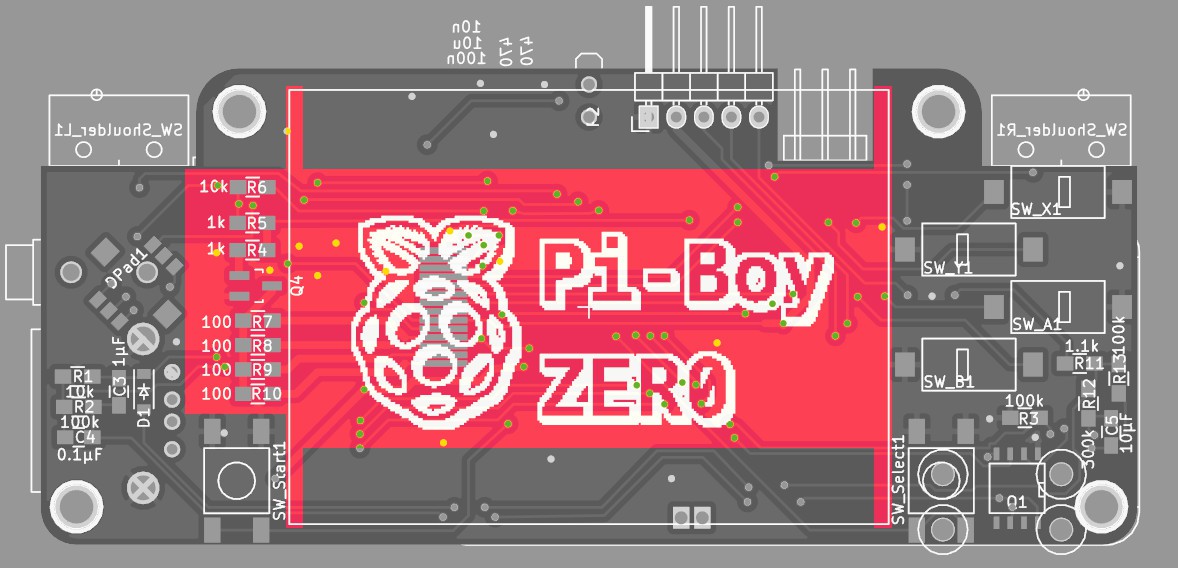

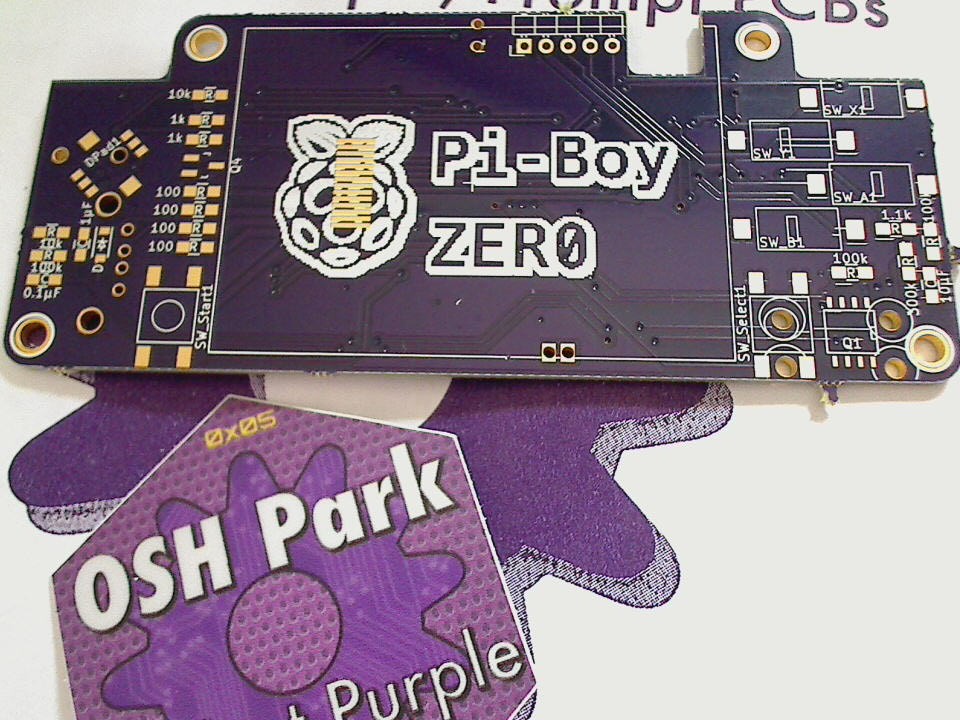

- reduce ratsnest of wires, done with a custom pcb

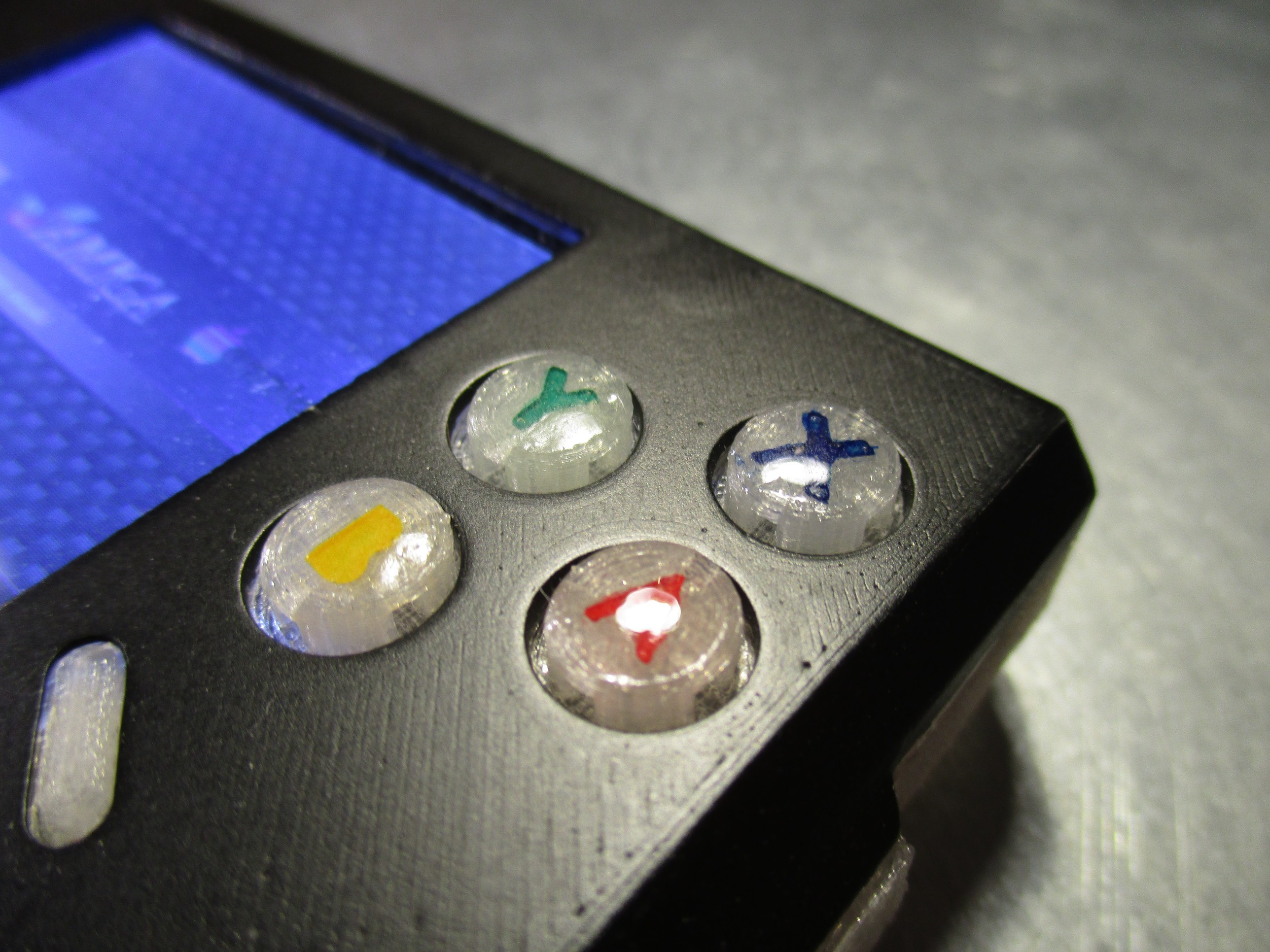

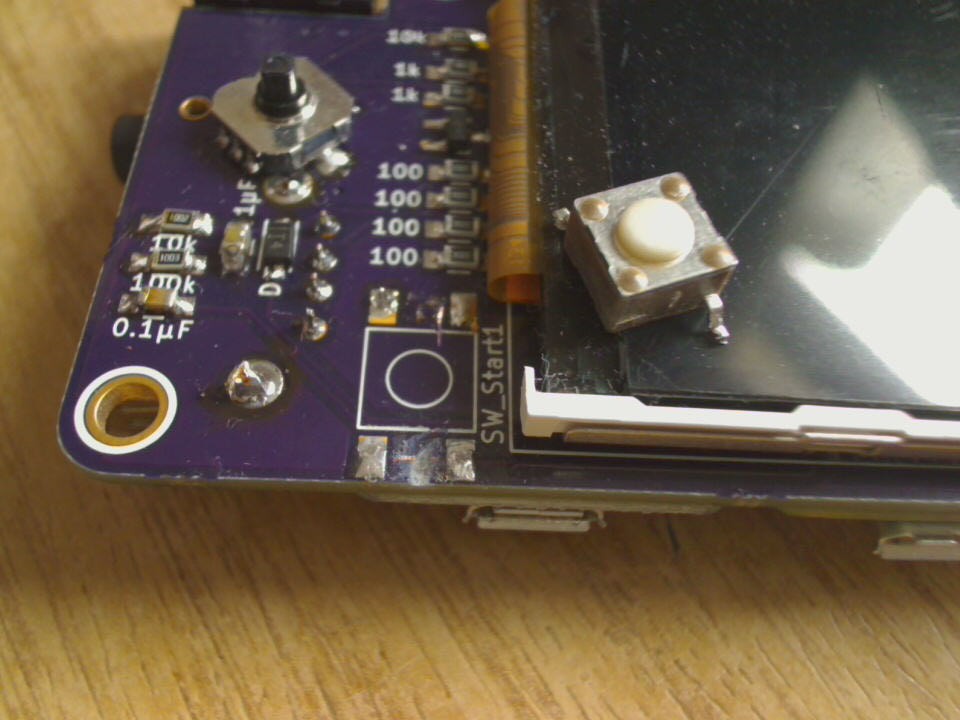

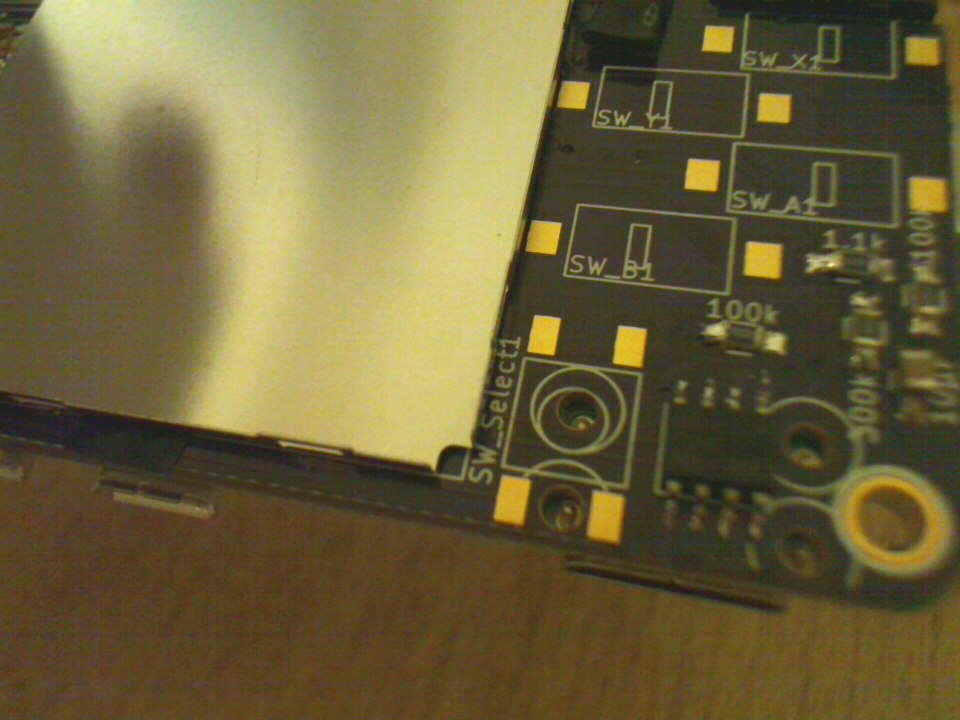

- use good-quality buttons with better "feel" instead of cheaper/harder 6mm tactile switches

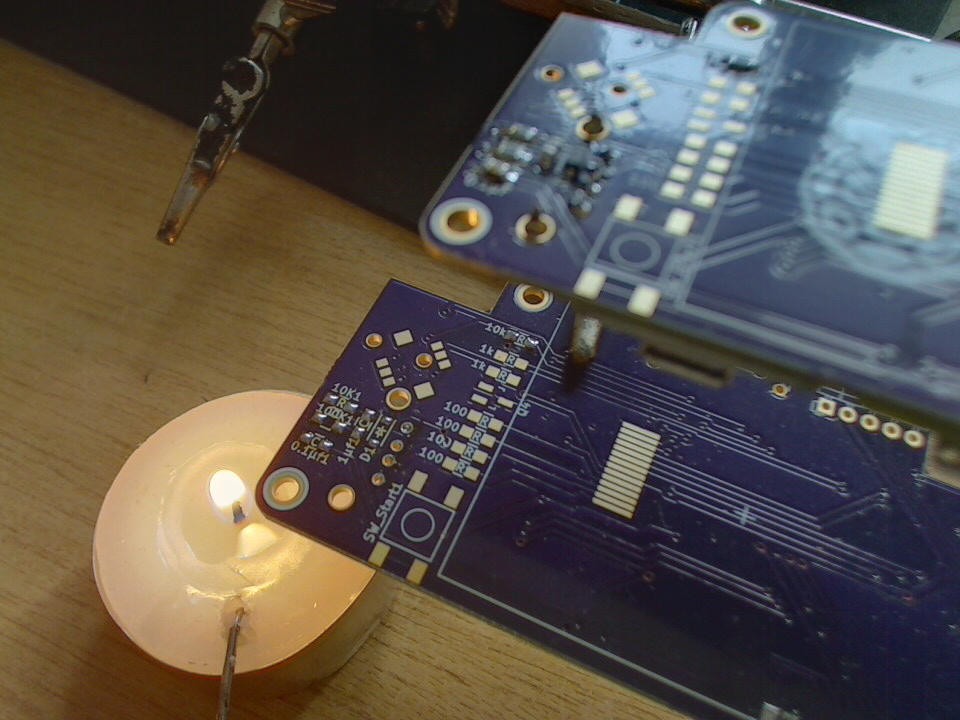

- hand-solderable, using 0805 sized smd components and slightly longer pads on the pcb

Features:

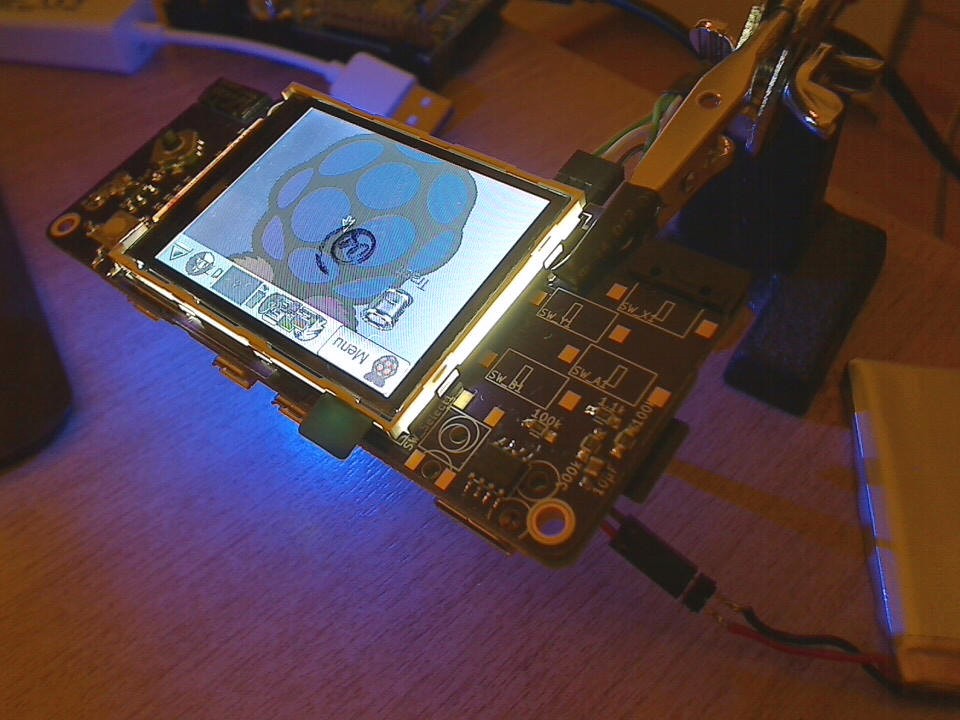

- 2.2" 320x240 display (for comparison, the gameboy-micro had a 2"240×160 display)

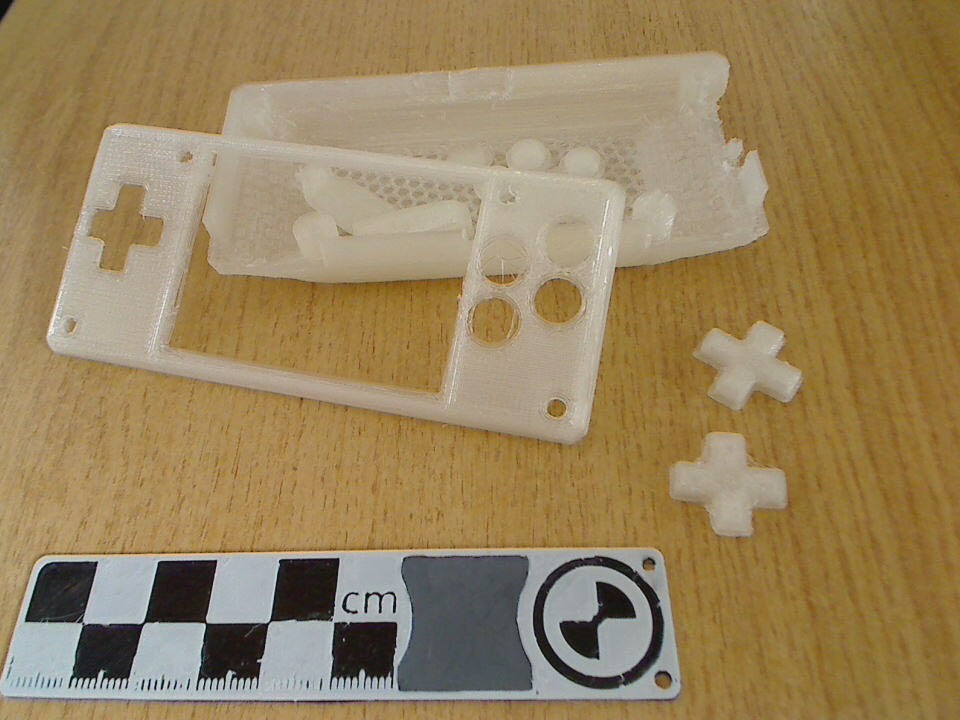

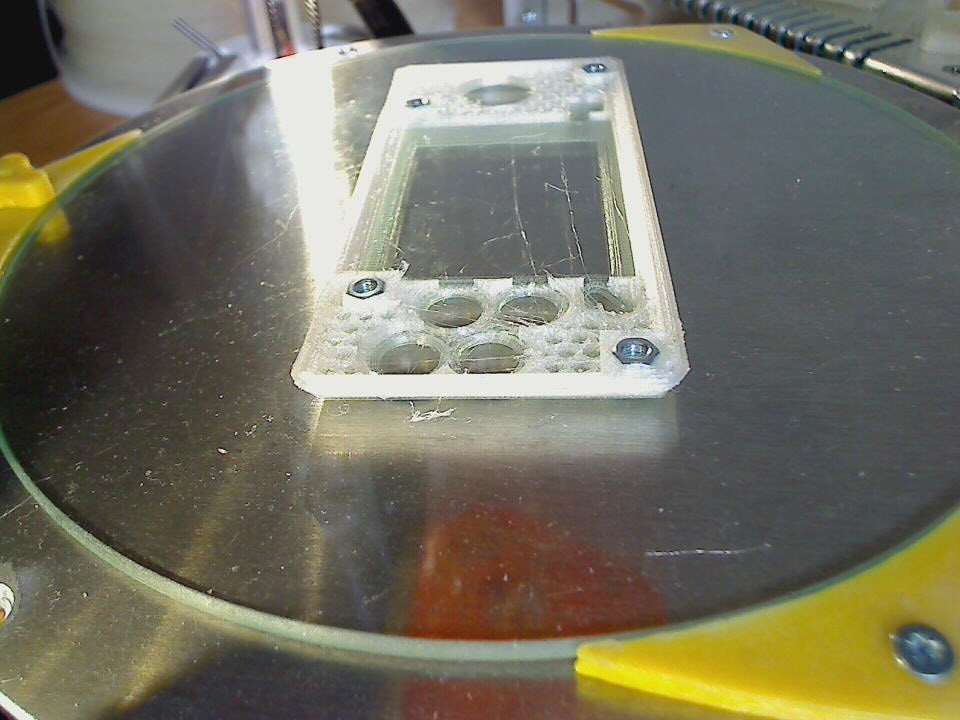

- 3d printable case, with overall size: 48x103x21mm (gameboy-micro: 50x101x17.2 mm)

- power button, for controlled shutdown of the pi (via a pushbutton - push for on/off, hold to force off)

- audio-out (via pwm, like the raspberry 2)

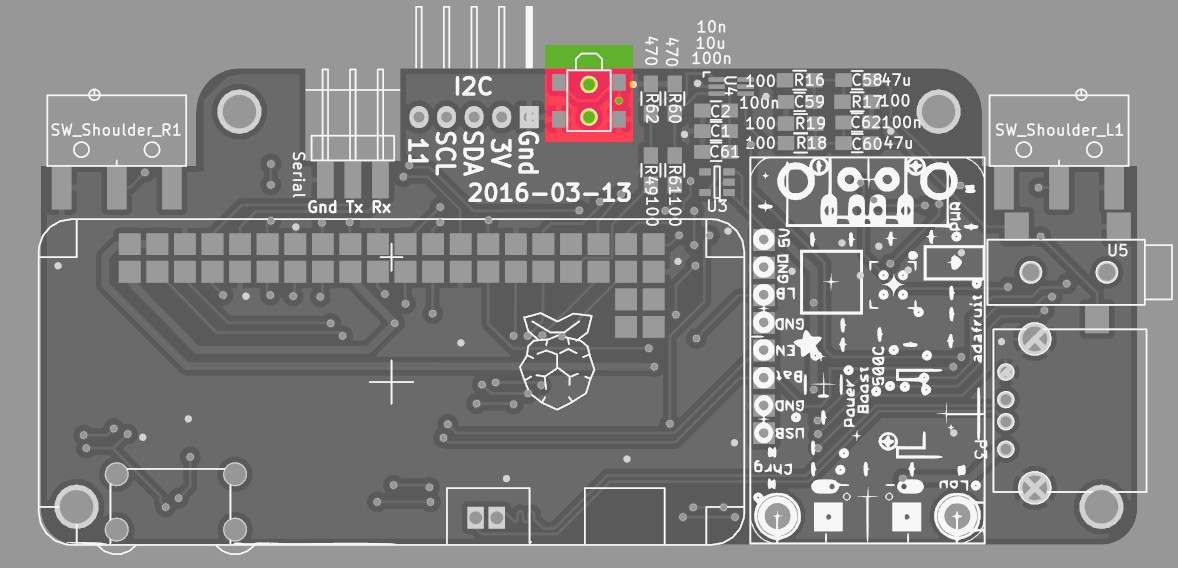

- 1200mAh LiPo battery connected to an adafruit powerboost 500c

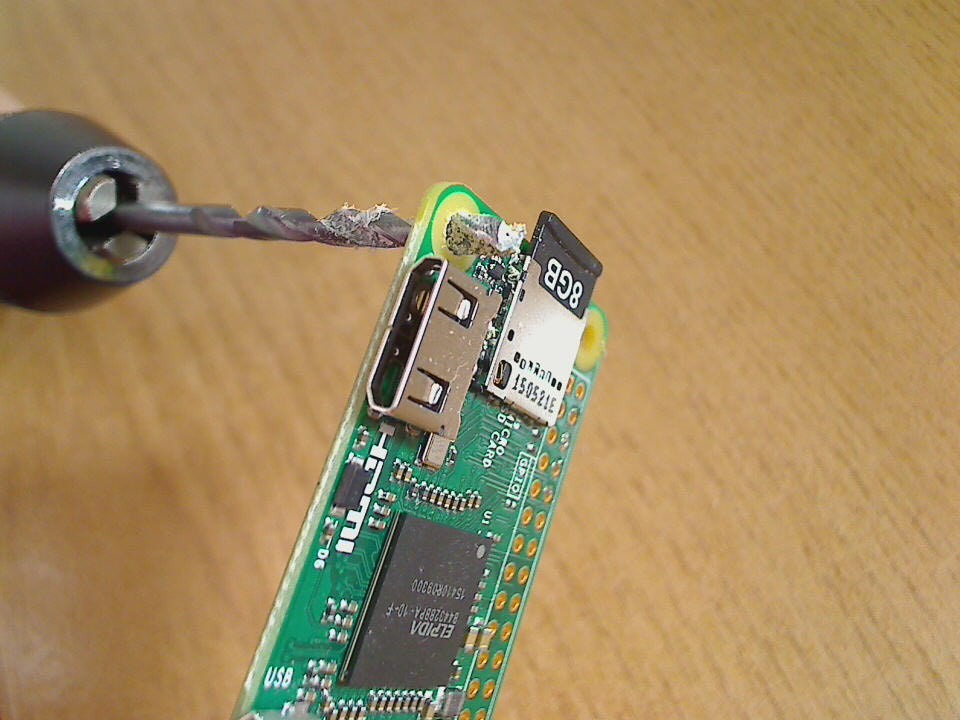

- USB-A socket (reusing the connector that comes with the powerboost pcb, connected to raspberry-zero testpads for USB)

- OS: raspbian running emulation-station (and some support daemons to tie in the hardware)

JohSchneider

JohSchneider

the way i build them was:

the way i build them was:

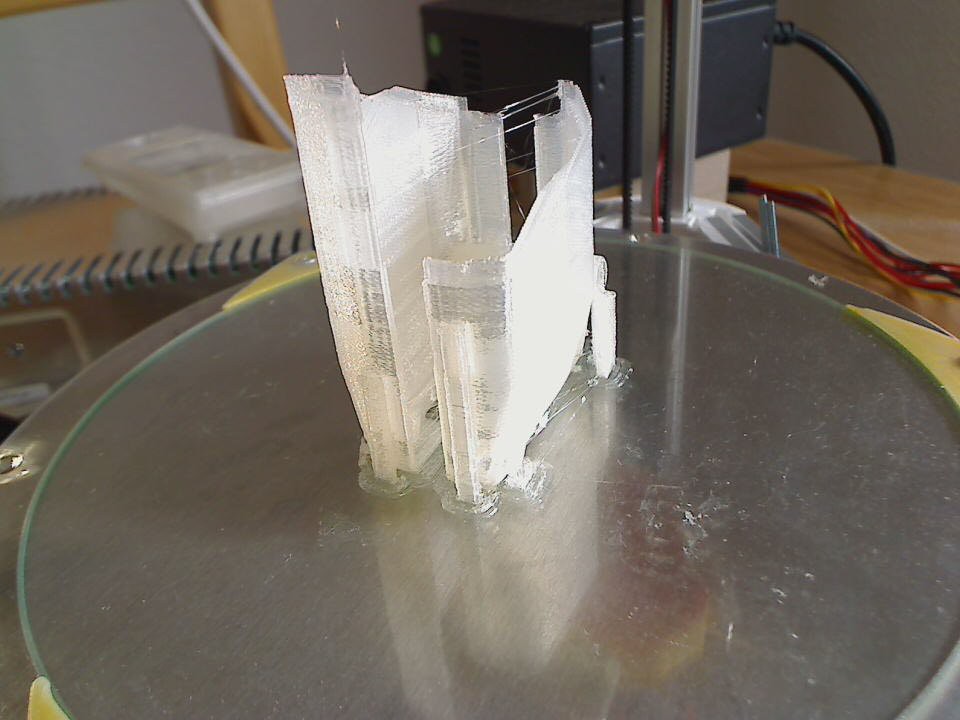

which would be printed standing up:

which would be printed standing up:

(upside down, but thats easily fixed in the config)

(upside down, but thats easily fixed in the config)

We have a similar project on Hackaday. Would you be interested in some collaboration? I think both our projects could benefit from it. [@Jean-André Santoni] and I hang out at https://discord.gg/0y3hRkVsItoaCAR1.