-

Pressing buttons remotely with laser

09/16/2018 at 12:26 • 0 commentsI have a humidity sensor. I would like to measure humidity in some boxes I store the filament in. However, it takes about 10 hours for the humidity to settle after resealing the box, and the battery drain of this particular instrument is pretty high. So I needed a way to switch it on and off inside the box.

A quick hack followed: I removed the button, and soldered a photodiode instead. No extra circuitry was added. It just happens to work.

-

Plastic cutter made of 3.5'' floppy disk

06/10/2016 at 21:05 • 9 comments![]()

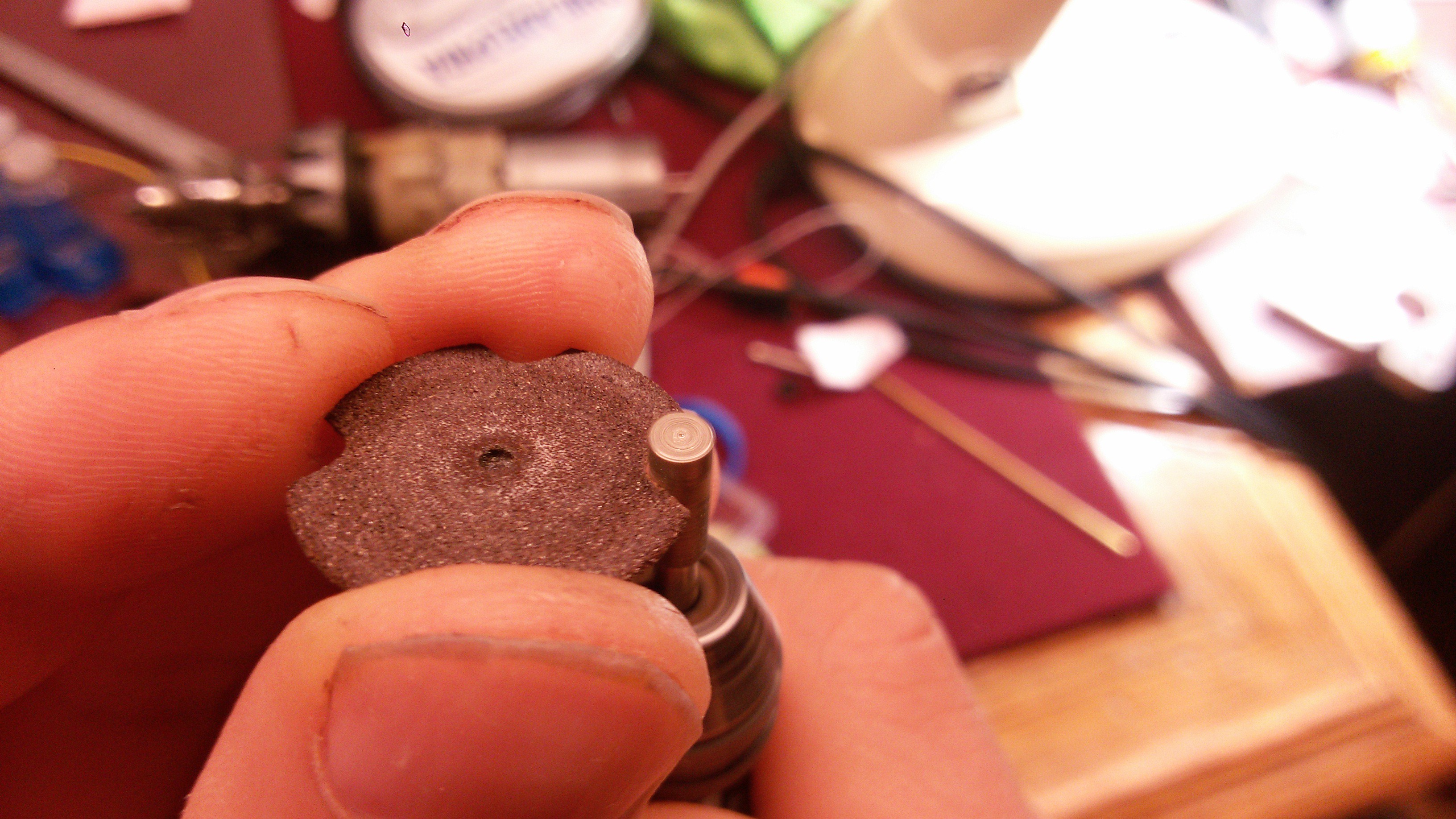

It's a tool I've been using for ages. A disk from a floppy diskette attached to a motor.

It can cut plastic quite well, yet is completely incapable of damaging metal. This combination of capabilities is super handy in some situations. Examples: stripping a wire; taking connectors apart for repair... and plain cutting plastic =)

In my recent project, I am making a motor with 3d printer. I use plastic to help me wind the coils, then wick the coils in superglue, and cut off the plastic with this tool.

What if you don't have floppy disks to tear apart? Well, actually, you can use other kind of plastic films for making the disk. Transparent sheets for printers work. Even paper will do, although it doesn't last long.

Why does it work?

I believe it cuts by melting the material through friction. It can cut anything that melts easily. PLA, ABS, PVC, POM, polystyrene, and other thermoplastics are all cuttable. Epoxies are not. Polyimide is not.

It can cut rosin. It can also cut solder, but not great (probably because of its high thermal conductivity.

-

high voltage: crude ammeter

03/31/2016 at 13:46 • 0 commentsTODO

-

high-voltage: terminals

03/31/2016 at 13:45 • 0 commentsWhen dealing with high voltages, corona discharges can easily form on sharp edges. For purpose of eliminating them, I made small guard rings by simply bending some papercilps.

Wires are to be soldered to center pins.

While this PCB is not particularly high-voltage (3kV), it's a piece of electron counter, so making it low noise was critical.

I use this technique on ion wind generators too, because corona discharges in undesired places make hissing noise, and may cause sparks.

-

terminals for wires

03/31/2016 at 13:44 • 0 commentsSoldering for quickly making connections between random things is often too messy. Yet, having connectors everywhere is not possible. So, I often put wire-wrap pins onto some electronic modules.

![]()

The trick here is to put a blob of solder at the end of the pin. Thanks to that blob, the wire wrapped around the pin will not slip off easily.

-

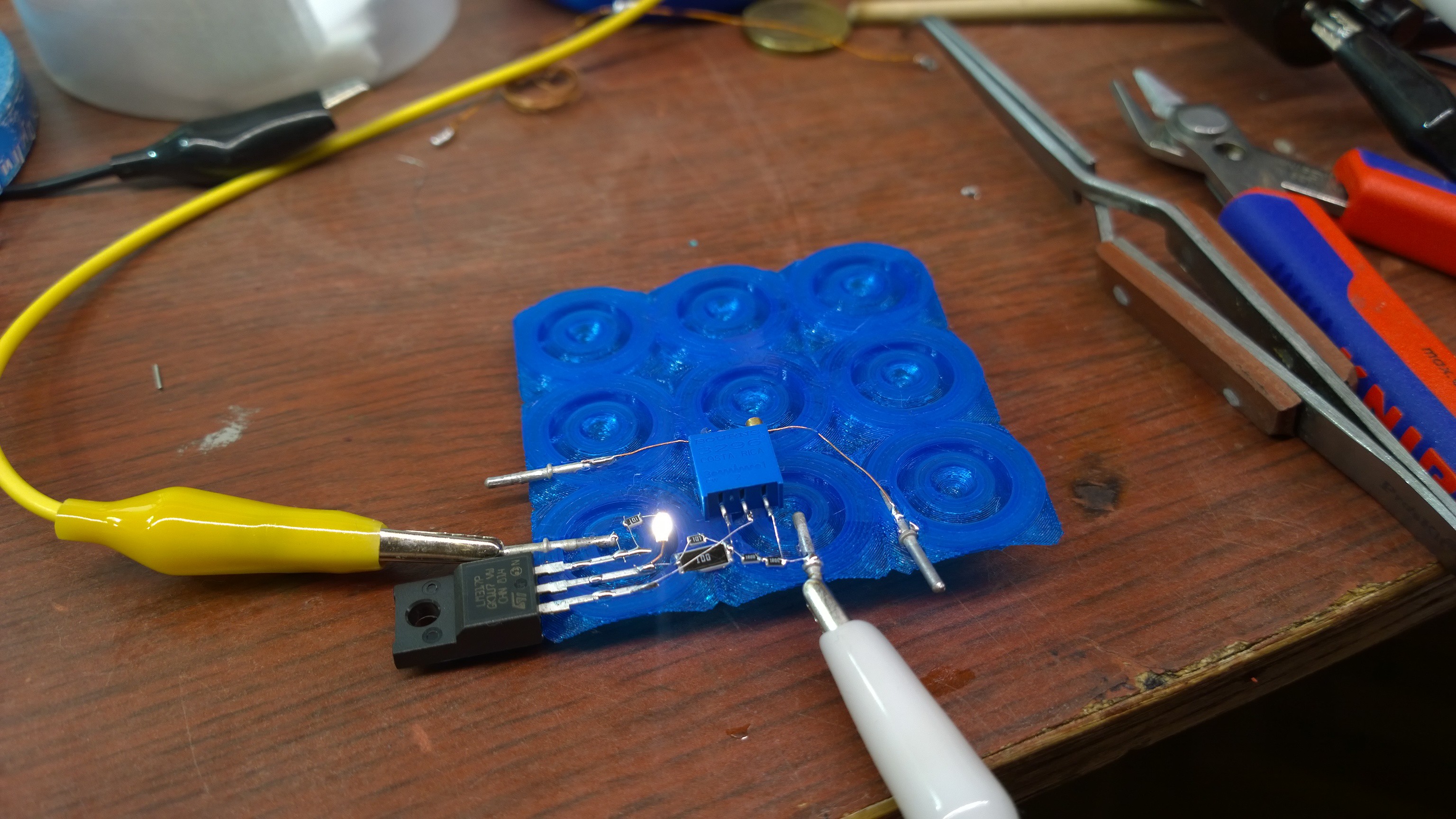

Breadboarding on scrap PLA

03/30/2016 at 23:44 • 0 commentsA gentle push on the component with soldering iron - and it sinks into PLA, sticking to it. Larger components can be fixed with superglue (multiturn trimpot, for example). Then I can wire them up with thin wire. And bingo, a small board made out of nothing!

![]() This is a current regulating circuit based on LM317, with fine current adjustment. LED lights up if dropout is above 2.5 V, which is enough for LM317 to regulate properly.

This is a current regulating circuit based on LM317, with fine current adjustment. LED lights up if dropout is above 2.5 V, which is enough for LM317 to regulate properly. -

Cleaning the outside of 3d printer nozzle

03/30/2016 at 22:05 • 0 commentsThere are lots of manuals of cleaning nozzle inside (my favorite is cold pull with nylon). Generally, the outside is easier to clean, and is not as important.

However, when leveling bed and calibrating gap, the residue of plastic can significantly affect the results. Also, for aesthetic purposes... Clean extruder can lower the amount of ooze, too.

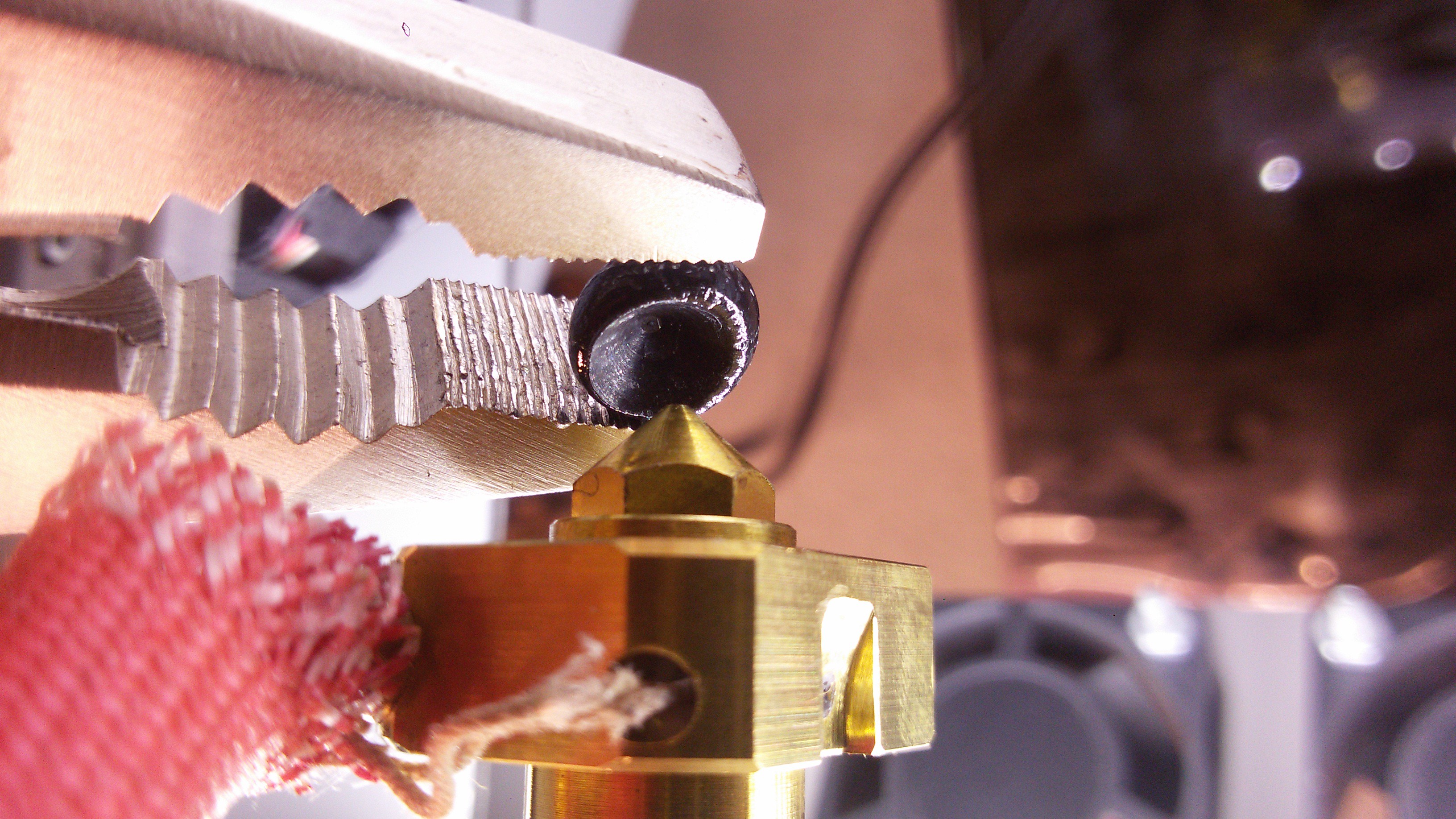

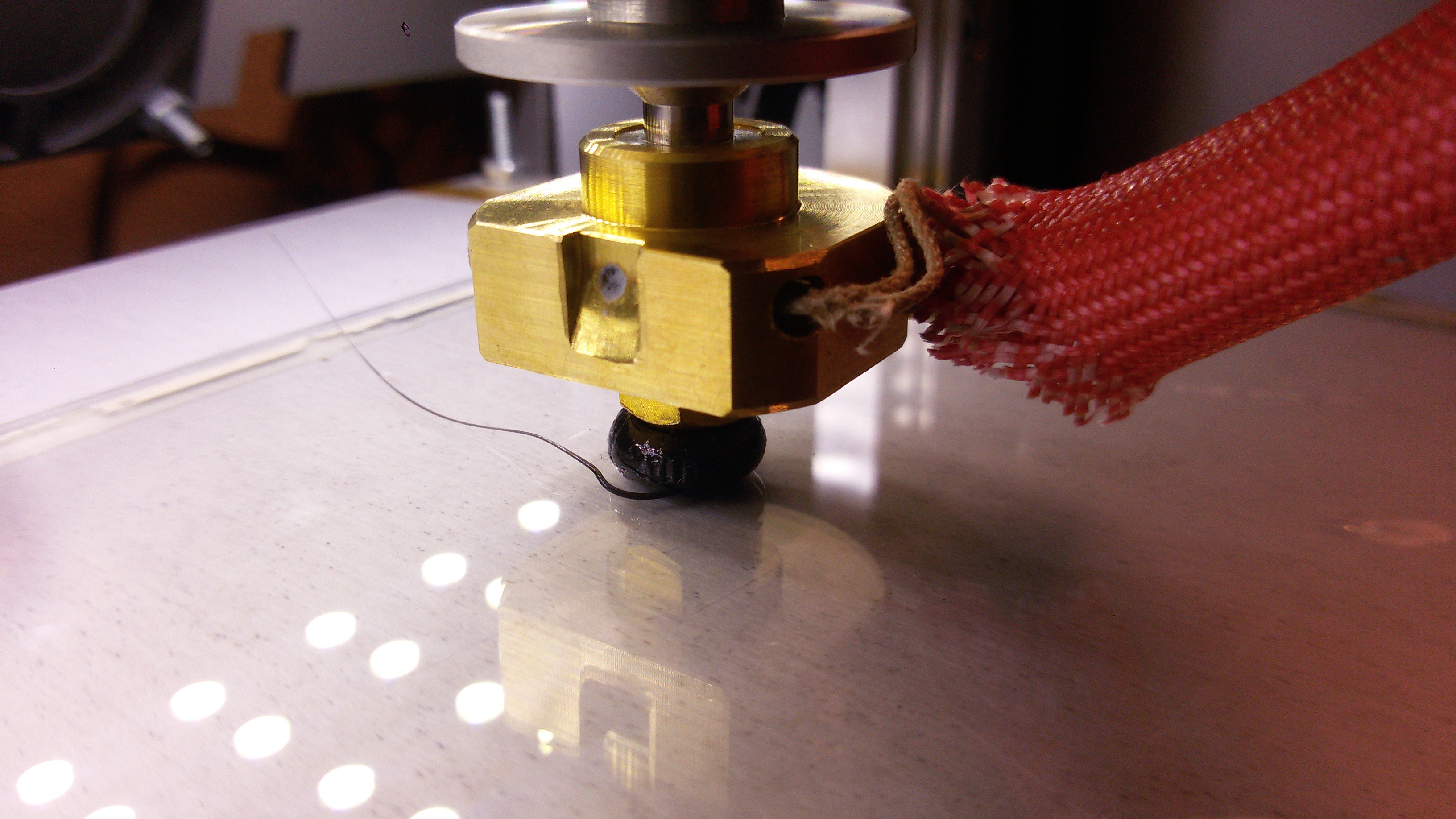

So, after each run, I lower the nozzle to be just above the bed, and let it extrude as much as it can while it cools down. This results in a nice blob that is stuck to the nozzle.

![]() And then, when nozzle is cool, I rip the blob off using pliers, and a plenty of force.

And then, when nozzle is cool, I rip the blob off using pliers, and a plenty of force.![]()

Note: the extruder on these photos looks good as new, because it is ... new! I have just replaced it, and did one test print to verify it's all working properly.

-

Transparent cut-off disks for Dremel

03/30/2016 at 21:40 • 1 commentWhen doing some fine sharpening, or cutting, it's very handy to be able to see, where are you cutting, and where exactly the material is being removed, and if you have cut through a layer

(say, to see exactly that you have just made it through the copper when quickly drafting a PCB for the ongoing hack project).

This can be achieved by cutting slots into the disk. Use diamonds.

![]()

Video demo:

DeepSOIC

DeepSOIC

This is a current regulating circuit based on LM317, with fine current adjustment. LED lights up if dropout is above 2.5 V, which is enough for LM317 to regulate properly.

This is a current regulating circuit based on LM317, with fine current adjustment. LED lights up if dropout is above 2.5 V, which is enough for LM317 to regulate properly.  And then, when nozzle is cool, I rip the blob off using pliers, and a plenty of force.

And then, when nozzle is cool, I rip the blob off using pliers, and a plenty of force.