You may wonder why you'd want to create a digital hydrometer rather than simply using a glass hydrometer.

A glass hydrometer is a device which has a number of markings on, indicating the specific gravity and also is specially weighted. It floats in your beer, you take a reading where the top marking is next to the beer line. The problem with such a device is that you can't take readings continuously with it - unless you fancy sitting monitoring your beer all day long ;).

My idea to have have a digital hydrometer was that it would then be easily possible to create a graph to show the progress of your fermentation. This would then allow you to modify the progress of the fermentation using additional hardware (by varying the temperature).

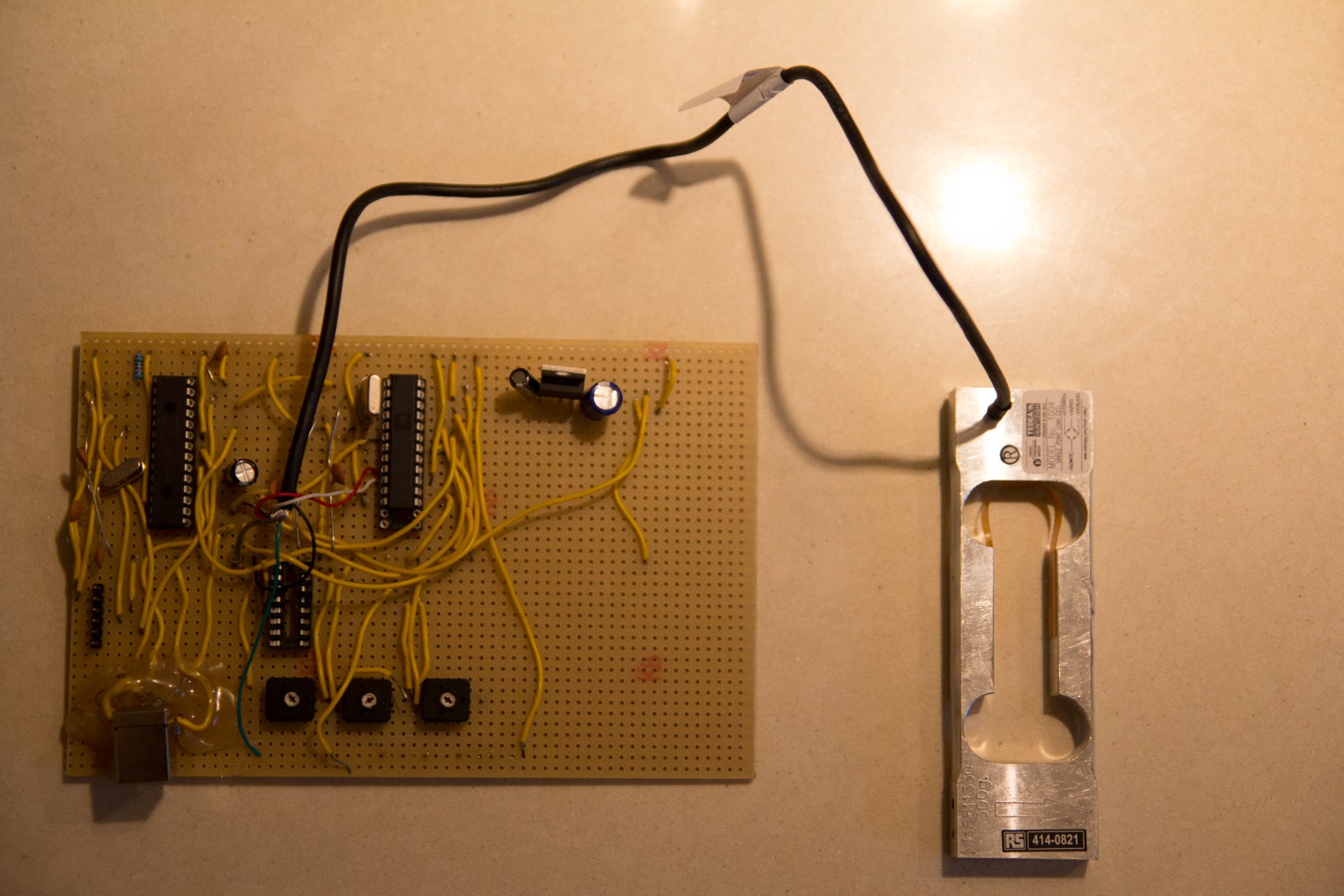

You can see in the photo (the one with the bucket and wooden frame) my original idea, using a load cell (which measures force). I had numerous issues with this approach due to 'creep' from the load cell over time.

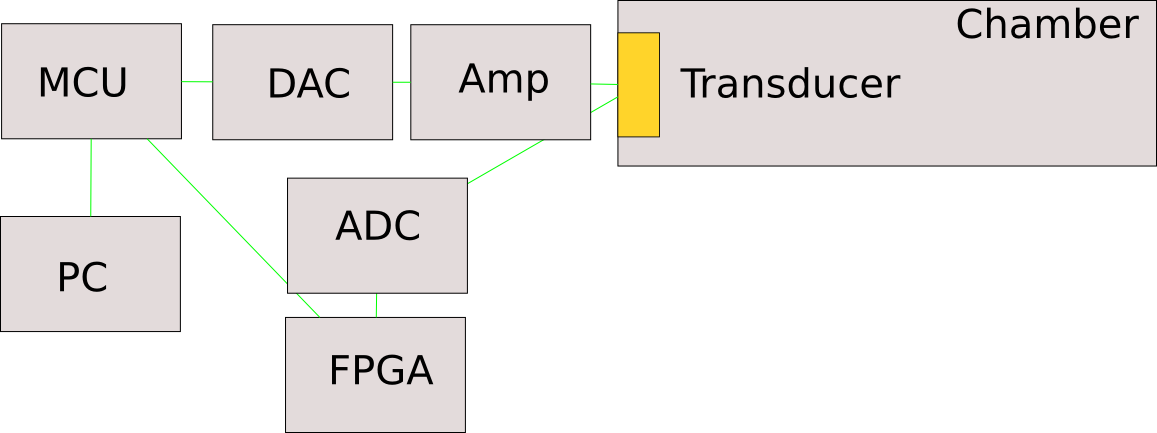

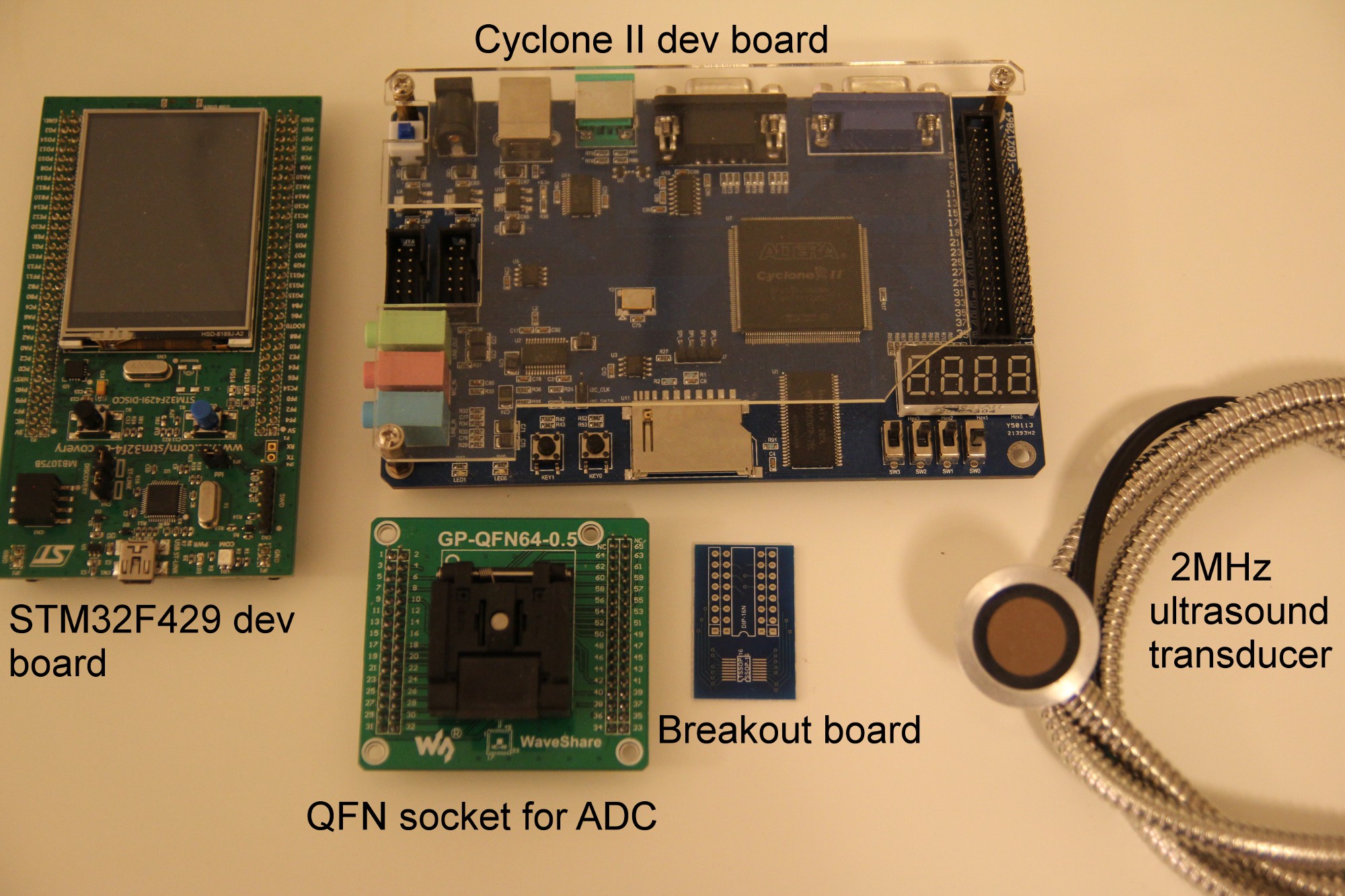

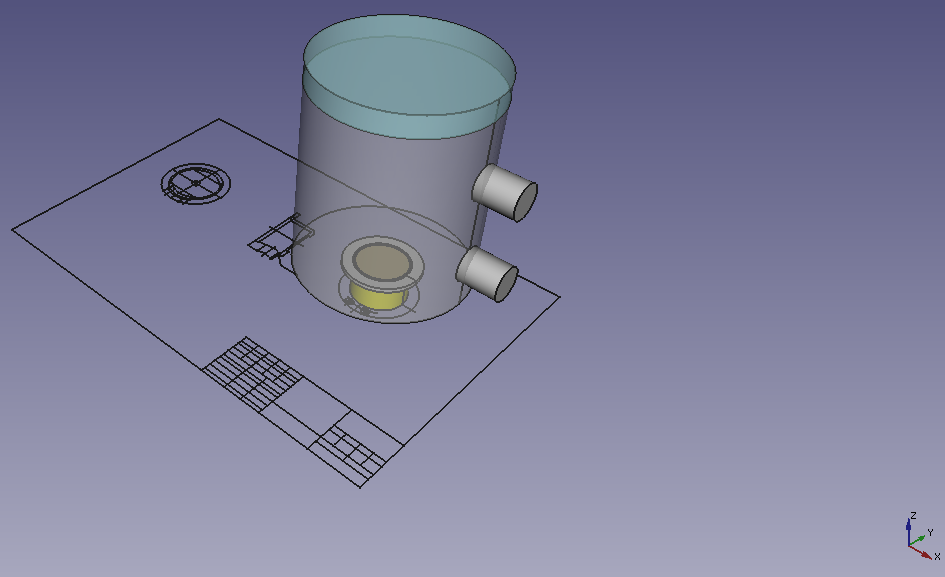

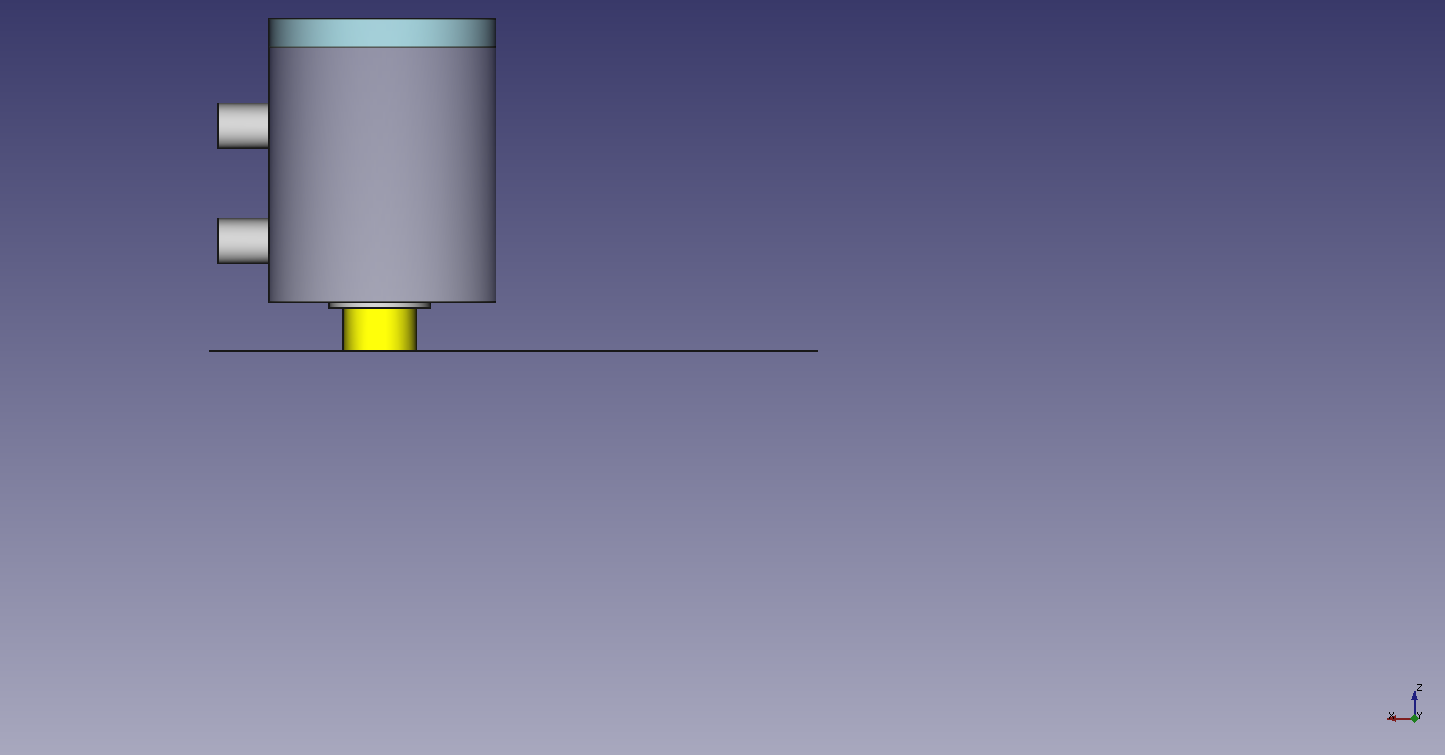

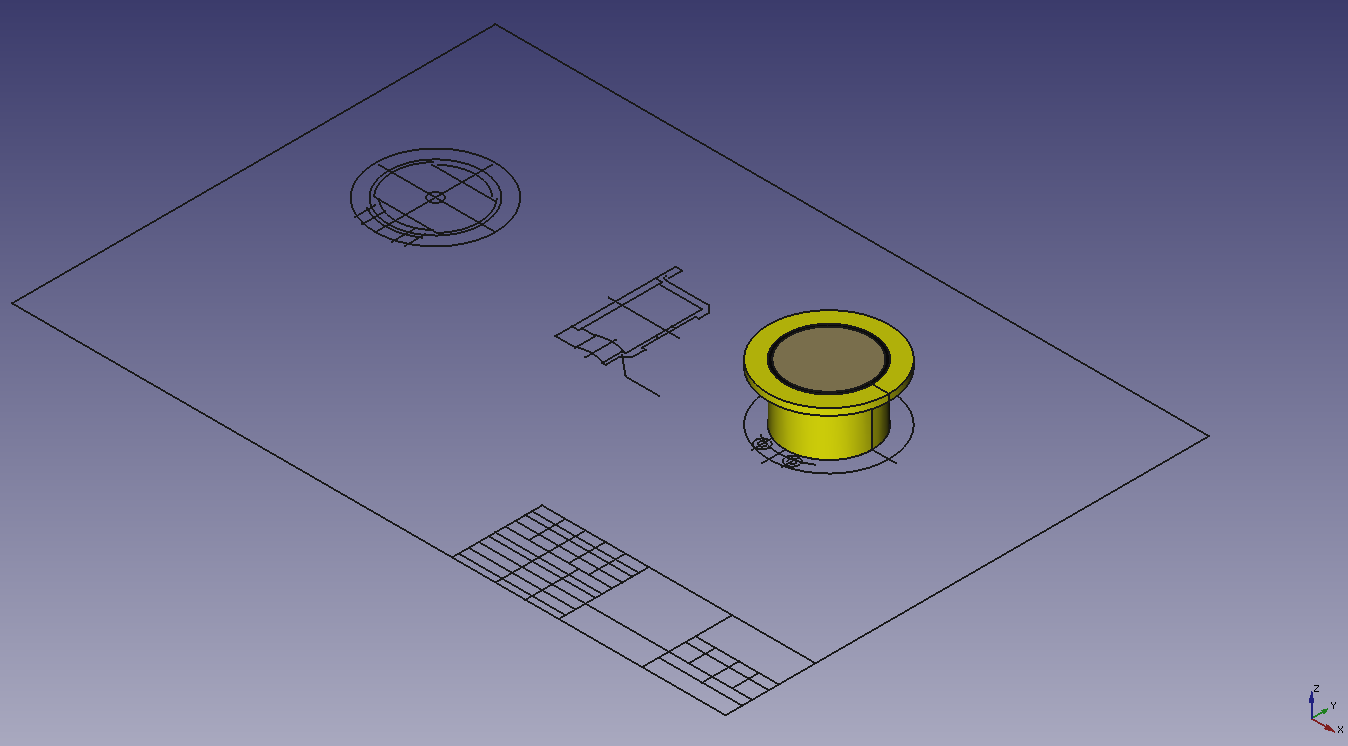

I'm now working on a vastly different approach using an ultrasonic transducer in order to measure the specific gravity - this is shown in the diagram below.

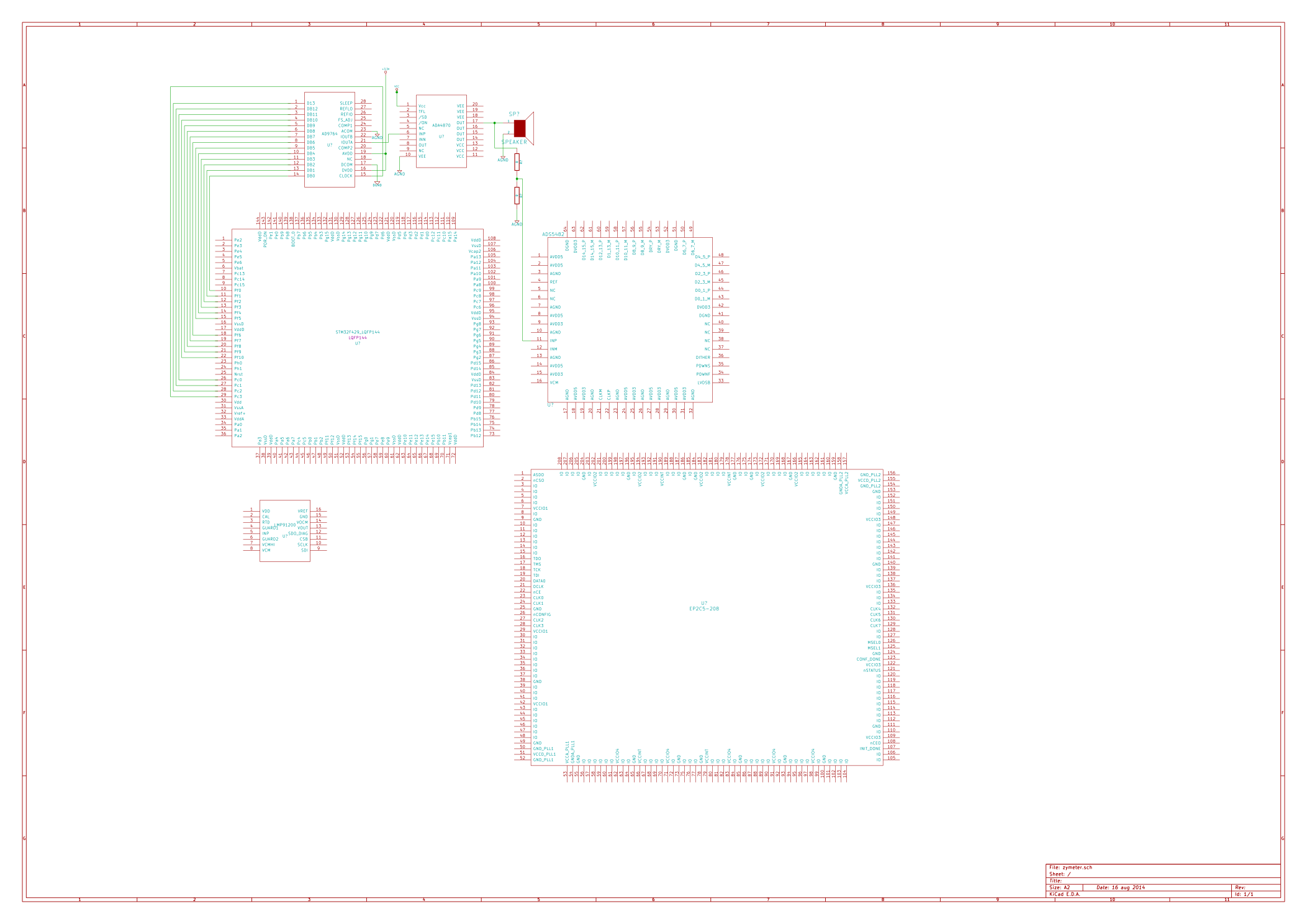

A single pulse of a sine wave will be generated and converted to analog. This will then be fed through an amplifier to an ultrasound transducer. The pulse will penetrate the beer and hit the opposite side of the chamber. The pulse will be reflected back towards the transducer, were it will be picked up by the ADC.

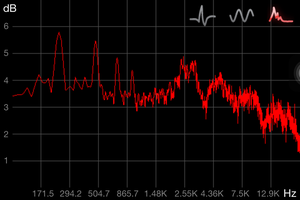

The ADC will be constantly running at 100MHz. The FPGA will decode the output of the ADC, to find the difference in time, between the pulse being emitted and retrieved. This will allow us to calculate the speed of sound in the beer along with the amplitude of the returned pulse.

By using a formula combining these values, it will be possible to determine the density and thus specific gravity of the beer (these formulae are listed in the science section below). From this alcohol can then be deduced using a simple formulae.

Alcohol = (Original specific gravity - current specific gravity)*131

Monitoring the temperature of the beer is important, as the hotter you ferment at, there will be more esters, the flavours the yeast produces.

I've been asked before why you'd want to monitor the pH during fermentation - there are a number of reasons for this. The pH of the wort changes during fermentation, especially with certain varieties of yeast/bacteria such as brett or lactobacillus. So by monitoring this you can keep a track of how acidic your beer will likely become (this is of particular importance for sour beers).

Ultimately we want to help people make their beers more consistent.

The Science:

We will use the following formulae obtained from [1] in order to calculate the density of the beer. R dennotes acoustic impedance, which is shown how to be calculated below.

Below is the formulae for acoustic impedance:

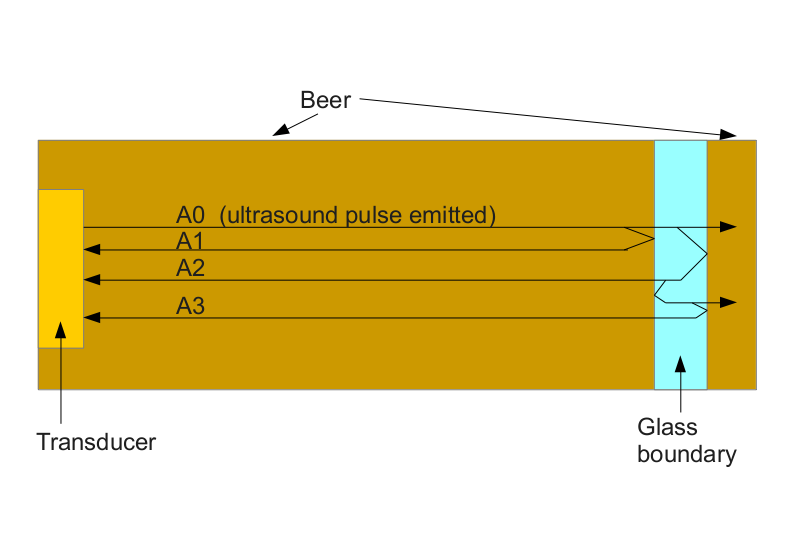

A1,A2,A3 denote the respective amplitudes of pulses.

The following diagram illustrates how pulses are recieved by the ultrasound transducer. The transducer emits one pulse (A0) and waits for 3 more to be recieved. The amplitudes of these three pulses is used by the above formulae to calculate acoustic impedance. And then density can be calculated.

This technique of using 3 pulses to calculate density is known as the ABC-method. Developed by Papadakis.

[1] Acoustic measurement of liquid density with applications for mass measurement of oil - Erlend Bjørndal

anfractuosity

anfractuosity

ThunderSqueak

ThunderSqueak

Varun Suresh

Varun Suresh

Anteneh Gashaw

Anteneh Gashaw

Adam

Adam

Why are you using such high frequency transmission requiring FPGA?