-

World Maker Faire 2018

10/08/2018 at 16:37 • 0 commentsHi!

it has been a long time o there is a lot to tell you about.

First, we made the ¨hall sensor 3d printed mini linear actuator¨ working. It works great and it much much easier to print and assemble that the previous one, less pieces, ligther and cheaper. So we will publish the files in due time or if anyone specifies a request.

Also, we were at the WMF at New York and it was awesome!

We met with:

Curt https://hackaday.io/project/159098-stomach-acid-powered-smart-pill

Kent https://hackaday.io/project/94611-gutters-to-gardens

Johannes https://hackaday.io/project/120377-3d-printed-strain-wave-gear

and Michael https://hackaday.io/project/20165-linear-delta-robot-3d-printed

All of them had great porject and most importantly willingness to contribute and share so check them out and drop a like.

We had the opportunity to be a part of a live tweet in hackaday so check that out also:

https://twitter.com/hackaday/status/1043532657437470720

![]()

Thank you everyone that took interest in this project, that got us to the semifinals and has made us learn a lot.

So as always feel fre to ask anything.

-

Fresh start

08/31/2018 at 17:26 • 0 commentsFirst of all, we are going to visit the WMF at NYC. Hackaday has a slot to speak about the Prize and they asked us if we would like to speak a little bit about the experience and we said yes! If you are going to be around the area come by and say hi.

So about the current actuator.... we had an idea.

We always tought that the design was pretty clunky, big, lots of mechanical components... and it comes for the thing that makes it "great", the potenciometer.

That thing its so hard to calibrate.

So the current desing we take the H bridge and the "position sensor"from the servo. So if we are going to replace the potenciometer.... no more H bridge. So thats an easy fix: https://www.adafruit.com/product/1438

We have use this board before in the OWI arms project and it works great, also the code its much much cleaner than having to simulate you have a servo attach.(also availabel for feathers)

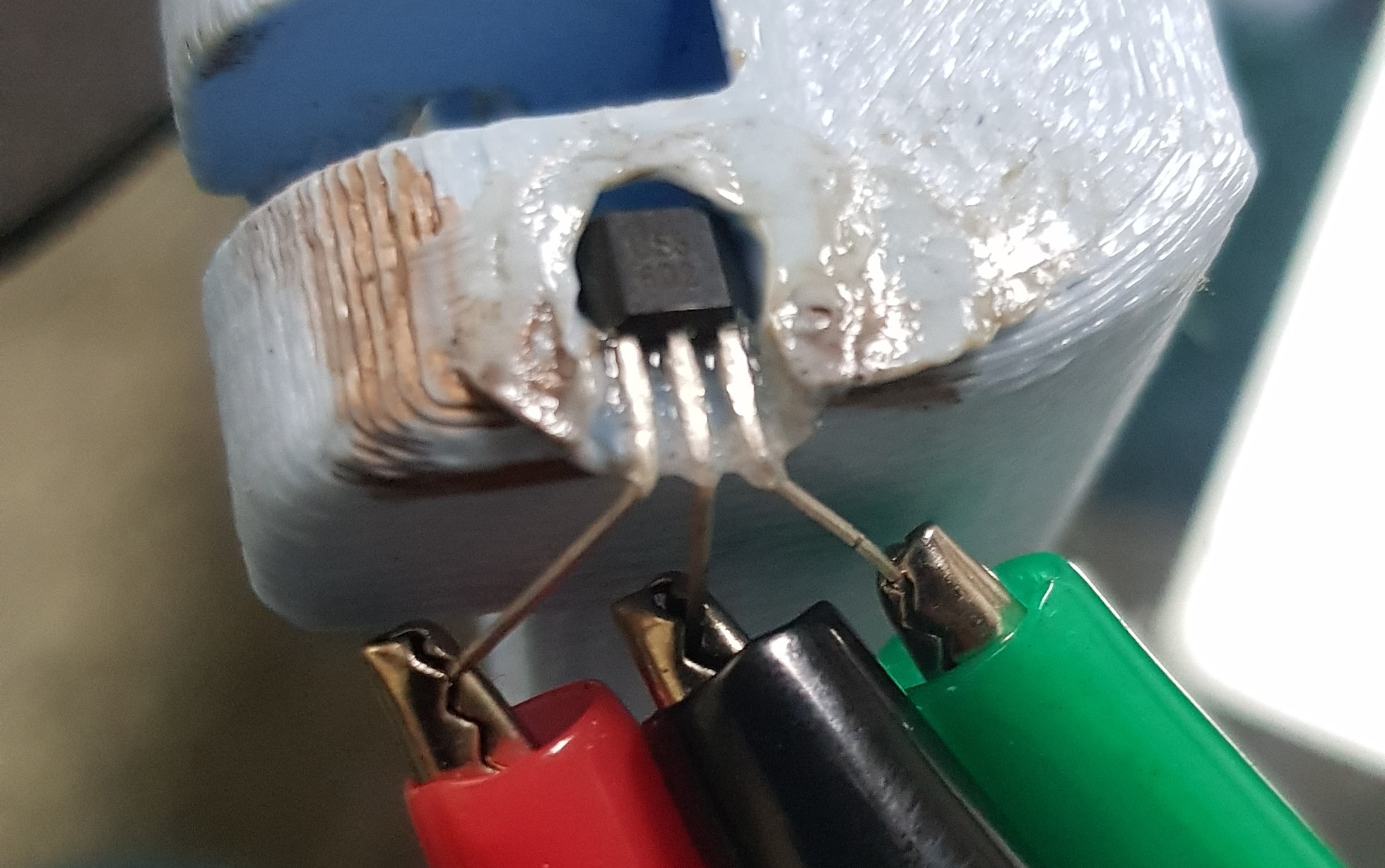

So the potenciometer? we need something thats not mechanical so, hall sensor.

![]()

We tried out hall sensors from Adafruit and they work great as a digital ( you need a resistor) or analog sensor. Keep in mind the polarity of your magnet because that matters.

So the lighter, thinner, simpler, less patrs...er linear actuator:

Please let us know any sugestions... we will print it try it out and if it work... share the files with you. -

How to print the actuator

08/23/2018 at 14:28 • 0 commentsHi!

So we have been asked how to print the actuator because theirs keeps breaking.

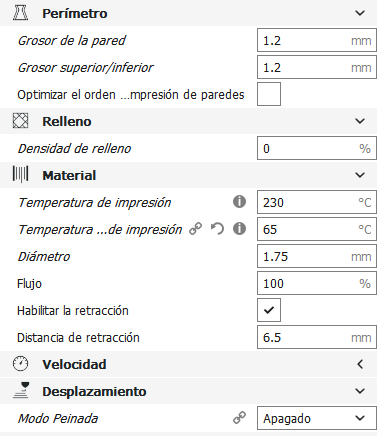

To address this concern we have uploaded the profile file from Cura in the file section(Perfilimrpresion.curaprofile) for you to implement it. Fare in mind that this configuration is with a 0.3 tip in a 30x30x30cms printer, you may want to adjust that.

![]()

It's in spanish but you'll get it.

Also two things, first we are thinking about redesigning the actuator in a way that yeah it will have like 5 cables BUT!!! it will be like so much slim so you can choose what works better for you.

Second thing, we have been invited to participate at the World Maker Faire. Like for 3 minutes in a panel but we tink its great! When we get more details we will share them with you.

-

Update on the silica gel

08/15/2018 at 22:43 • 0 commentsSo, remember when we said to all of you that you should put your filaments on a box with the biggest bag of silica gel that you could find?

About that... DON'T DO IT!

Really bad advise and sorry about that. The silica gel has a limit of water that can absorb and we are on a shared office space with full blown air conditioner, the silica disolved itself and became an oily liquid. This was all over our filaments and when it gets on the gear of the printer extruder, it grinds.... so a lot of unfinished prints.

The solution, we cleaned out all of it and replace it with rice.

![]()

Once every two weeks we take it out and let it rest on the sun. This happens because we dont have a lot of rotation on some filaments so....

However take this advise with a grain of salt( no pun intended), its working and we will keep you posted.

-

You want change the speed of the actuator?

08/13/2018 at 16:57 • 0 commentsWhat will happen if you want to change the speed of the actuator? Sometimes we need to control some factors of our design for some types of applications, simplifying it could be said: changing the engine is the correct way, but we have found another way.

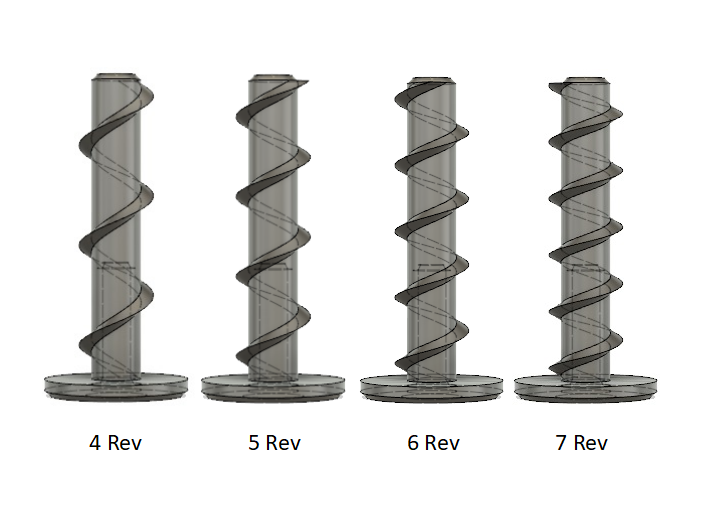

Whith modifying the steps of the screw can get good results, this can be done from the model. How? for many the answer is obvious but we will show how to do it with the designs we have made and are available for download.

In the Files section there is a file called Piston, this is available in various formats, We work in Autodesk Fusion 360, thus the instructions are made for this application but can also be used for help in other software. Changing the steps of the screw causes it turn faster or less quickly, in the post the screw have a five revolutions in the coil function so with other value the result would look like this

![]()

Also you have a change the piston in the same file,

![]()

If you want more details with how to do it, go to instructions section there are a step by step of the process.

-

Finals Entry

08/09/2018 at 19:39 • 0 commentsHi!

We wanted to share the video for the finals here also.

Have a great day!

-

Weight lifting sesion

06/21/2018 at 22:22 • 2 commentsHi everyone. So yesterday Alvaro Villoslada asked us how strong is the actuator and..... we didnt know. So the best way we found to measure it was to pull up weight until we broke it.

It worked great until 450 grs.

500grs broke it. Thats with our design and the wway we print the screw. Hope to see people pulling more!

-

Thank You!

06/15/2018 at 20:12 • 0 commentsHello everyone, Jonathan and i wanted to say thank you for all the support and attention that made this project get to the finals. This project has given us so many thing like joy, peer recognition and a challenge.

To the people that asked us about the finger, that is a part from an old version of this project:

So that is why the finger exists.

We will continue the project as long as any of you sees an aplication and we can chip in to make it better. So feel free to use it and to ask any question or suggestion.

We will see you again at August at the Human - Computer Interface Challenge!

-

Application

06/01/2018 at 21:57 • 0 commentsThis is a simple application of the mini linear actuator, in this case is a robotic finger used in a robotic hand

-

It's alive!

05/16/2018 at 16:32 • 0 commentsHi, we finally printed out and made it work as you can see on the next video.

The build instructions are pretty self explanatory, however in the video we skip the servo dismouting part and glueing the gear to the potenciometer, let us know if you need a video of that also.

About the humidity, this was the solution:

![]()

A big box with lots of silica in it.

3D printed mini linear actuator

Need a mini linear actuator that is easy to print and implement in your robotics DIY projects? We got you

Giovanni Leal

Giovanni Leal